Content Menu

● Introduction to Acetylene and Calcium Carbide

>> What is Acetylene?

>> What is Calcium Carbide?

● Chemical Reaction Behind Acetylene Production

● Industrial Production Process

>> Overview

>> Wet vs. Dry Process

>> Step-by-Step Production Flow

● Equipment Used in Acetylene Production

>> 1. Acetylene Generator

>> 2. Condenser

>> 3. Ammonia Scrubber

>> 4. Dryer

>> 5. Compressor and Storage Cylinders

● Purification and Storage of Acetylene

● Safety Measures in Acetylene Production

● Applications of Acetylene Produced from Calcium Carbide

● Historical Development of Acetylene Production from Calcium Carbide

● Environmental Considerations in Acetylene Production

● Future Trends and Innovations

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. How is acetylene gas produced from calcium carbide?

>> 2. What equipment is essential for acetylene production from calcium carbide?

>> 3. What safety precautions are necessary during acetylene production?

>> 4. What impurities are found in acetylene produced from calcium carbide, and how are they removed?

>> 5. Why is calcium carbide preferred for acetylene production?

● Citations:

Acetylene (C₂H₂) is a vital industrial gas widely used in welding, metal cutting, chemical synthesis, and many other applications. One of the most common and historically significant methods for producing acetylene is through the reaction of calcium carbide (CaC₂) with water. This article provides a comprehensive overview of the production of acetylene from calcium carbide, detailing the chemical principles, industrial processes, equipment, safety considerations, and applications. Visual aids are included throughout to enhance understanding.

Introduction to Acetylene and Calcium Carbide

What is Acetylene?

Acetylene, also known as ethyne, is a colorless gas with the chemical formula C₂H₂. It is the simplest alkyne, characterized by a triple bond between two carbon atoms. Acetylene is highly combustible and burns with a very hot flame, making it ideal for welding and cutting metals. It is also a key raw material in the chemical industry for producing plastics, synthetic fibers, and other organic chemicals.

What is Calcium Carbide?

Calcium carbide (CaC₂) is a chemical compound produced industrially by heating lime (CaO) and coke (carbon) in an electric arc furnace at temperatures around 2200°C. The reaction is:

CaO+3C→CaC2+CO

Calcium carbide is typically a grayish solid containing about 80-85% CaC₂, with impurities such as calcium oxide, phosphides, and sulfides. It reacts vigorously with water to produce acetylene gas, which forms the basis of acetylene production from calcium carbide.

Chemical Reaction Behind Acetylene Production

The core chemical reaction for producing acetylene from calcium carbide is a hydrolysis reaction:

CaC2+2H2O→C2H2+Ca(OH)2+heat

- Calcium carbide reacts with water to form acetylene gas (C₂H₂) and calcium hydroxide (Ca(OH)₂), also known as slaked lime.

- This reaction is highly exothermic, releasing significant heat that must be controlled during production.

- The acetylene gas produced is then collected for further purification and use.

Industrial Production Process

Overview

The industrial production of acetylene from calcium carbide is typically conducted in specialized equipment called acetylene generators. The process can be summarized as follows:

1. Feeding Calcium Carbide: Calcium carbide granules are fed into the acetylene generator, where they come into contact with water.

2. Reaction: The hydrolysis reaction occurs, producing acetylene gas and calcium hydroxide slurry.

3. Cooling and Purification: The acetylene gas is cooled, purified to remove impurities like ammonia and phosphine, dried, and compressed.

4. Storage: The purified acetylene is dissolved in acetone and stored in cylinders for safe transportation and use.

Wet vs. Dry Process

- Wet Process: Calcium carbide is added directly to a large quantity of water. This is the most common method.

- Dry Process: Water is sprayed onto calcium carbide in a controlled manner to limit water quantity, reducing excess heat and improving safety.

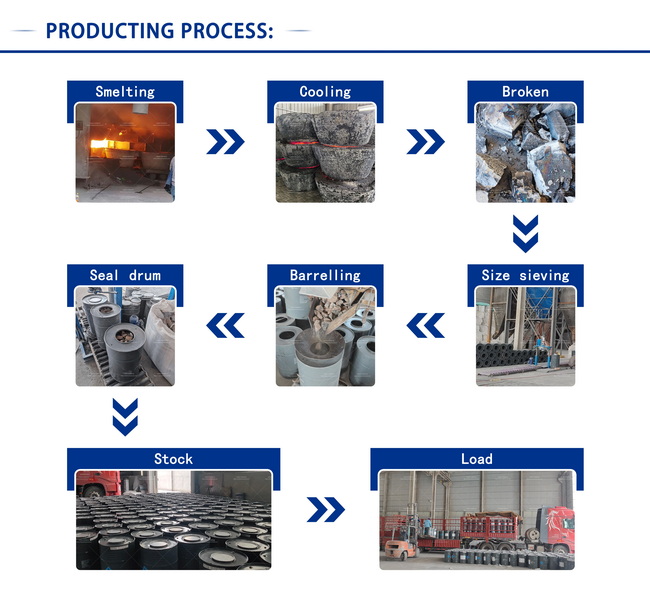

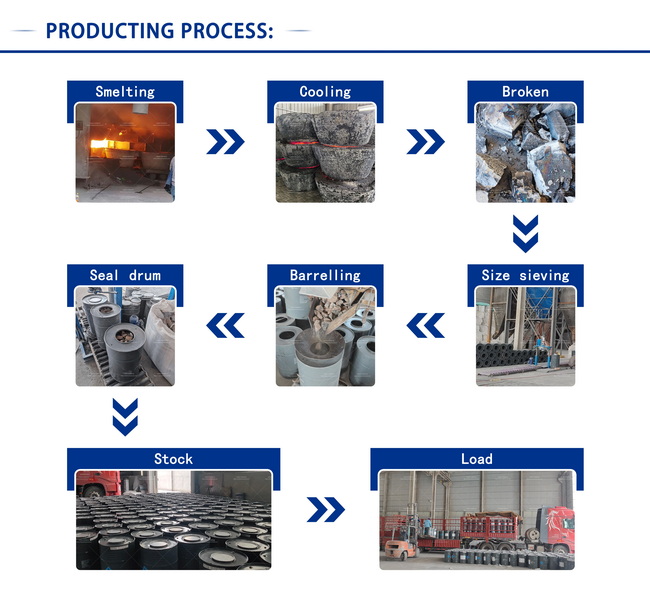

Step-by-Step Production Flow

1. Calcium Carbide Feeding: Calcium carbide of specific particle sizes (usually 7-25 mm) is fed into the generator hopper.

2. Hydrolysis Reaction: Calcium carbide reacts with water in the generator vessel.

3. Gas Collection: Acetylene gas rises and passes through a condenser to cool.

4. Scrubbing: Gas passes through ammonia scrubbers to remove ammonia impurities.

5. Drying: Acetylene gas is dried using calcium chloride or other drying agents.

6. Compression and Storage: Gas is compressed and dissolved in acetone-filled cylinders.

Equipment Used in Acetylene Production

1. Acetylene Generator

The heart of the process, where calcium carbide and water react. Key components include:

- Hopper: For feeding calcium carbide.

- Agitator: Ensures proper mixing and prevents floating of carbide lumps.

- Automatic Control Sensors: Monitor pressure, temperature, and water levels.

- Safety Valves and Arrestors: Prevent flashbacks and explosions.

2. Condenser

Cools the hot acetylene gas generated to prevent decomposition and improve safety.

3. Ammonia Scrubber

Removes ammonia and other gaseous impurities from acetylene.

4. Dryer

Removes moisture from acetylene gas to prevent corrosion and improve purity.

5. Compressor and Storage Cylinders

Compresses acetylene gas and stores it dissolved in acetone within specially designed cylinders to ensure safe handling.

Purification and Storage of Acetylene

Acetylene produced from calcium carbide contains impurities such as ammonia, phosphine, and water vapor. Purification steps include:

- Condensation: Cooling gas to remove water vapor.

- Scrubbing: Using scrubbers to remove ammonia and phosphine.

- Drying: Passing gas through drying agents like calcium chloride.

- Compression: Pressurizing acetylene and dissolving it in acetone for safe storage.

Storage cylinders are designed to keep acetylene dissolved in acetone under pressure, minimizing explosion risks.

Safety Measures in Acetylene Production

Acetylene is highly flammable and explosive under certain conditions. Safety considerations include:

- Temperature Control: The exothermic reaction generates heat; cooling systems prevent overheating.

- Pressure Monitoring: To avoid gas build-up and explosions.

- Use of Flash Arrestors: To prevent flame propagation back into the generator.

- Quality Control of Calcium Carbide: Impurities like phosphorus and iron can cause dangerous side reactions.

- Proper Storage: Cylinders stored in ventilated, cool areas away from ignition sources.

- Handling Protocols: Strict procedures for feeding calcium carbide and water to control reaction rate.

Applications of Acetylene Produced from Calcium Carbide

- Welding and Cutting: Oxy-acetylene welding uses acetylene's high flame temperature.

- Chemical Synthesis: Acetylene is a precursor for plastics (PVC), synthetic fibers, and organic chemicals.

- Metallurgy: Used in carburization and flame hardening of steel.

- Lighting: Historically used in carbide lamps.

- Other Industrial Uses: Flame heating, thermal spraying, and chemical manufacturing.

Historical Development of Acetylene Production from Calcium Carbide

The discovery of calcium carbide and its use in acetylene production dates back to the late 19th century. Thomas L. Willson is credited with the invention of calcium carbide in 1892, which revolutionized the production of acetylene gas. Initially, acetylene was produced by the reaction of calcium carbide with water in small-scale carbide lamps used for lighting. Over time, the process was industrialized, leading to the development of large acetylene generators and widespread use in welding and chemical industries.

This historical perspective highlights the importance of calcium carbide in the evolution of industrial gases and its continued relevance despite newer technologies.

Environmental Considerations in Acetylene Production

While the production of acetylene from calcium carbide is efficient, it is important to consider its environmental impact. The production of calcium carbide itself requires high energy consumption due to the electric arc furnace process, which emits carbon dioxide and other greenhouse gases.

Moreover, the by-product calcium hydroxide must be managed properly to avoid environmental contamination. Advances in recycling and waste management have improved the sustainability of this process. Research is ongoing to develop greener methods for calcium carbide production and acetylene generation.

Future Trends and Innovations

The acetylene industry is evolving with innovations aimed at improving safety, efficiency, and environmental footprint. New catalyst technologies and alternative raw materials are being explored to reduce reliance on traditional calcium carbide.

Additionally, digital monitoring and automation in acetylene generators enhance process control and safety. The integration of renewable energy sources in calcium carbide production is also a promising area for reducing carbon emissions.

Conclusion

The production of acetylene from calcium carbide remains a critical industrial process due to its efficiency, cost-effectiveness, and versatility. The hydrolysis reaction between calcium carbide and water produces acetylene gas, which is then purified and stored safely for various applications. Despite the emergence of alternative acetylene production methods, calcium carbide-based production is still widely used, especially in regions with abundant calcium carbide resources. Proper control of reaction conditions and safety measures ensures high-quality acetylene and minimizes risks associated with this highly combustible gas.

Frequently Asked Questions (FAQs)

1. How is acetylene gas produced from calcium carbide?

Acetylene gas is produced by reacting calcium carbide (CaC₂) with water (H₂O), resulting in acetylene (C₂H₂) and calcium hydroxide (Ca(OH)₂). The reaction is:

CaC2+2H2O→C2H2+Ca(OH)2

This reaction is exothermic and occurs in an acetylene generator under controlled conditions.

2. What equipment is essential for acetylene production from calcium carbide?

Key equipment includes an acetylene generator (with hopper, agitator, sensors), condenser, ammonia scrubber, dryer, compressor, and acetylene storage cylinders. These components ensure safe and efficient production, purification, and storage of acetylene gas.

3. What safety precautions are necessary during acetylene production?

Safety measures include controlling reaction temperature and pressure, using flash arrestors, ensuring the purity of calcium carbide to avoid impurities, proper storage of acetylene cylinders, and continuous monitoring of equipment to prevent explosions.

4. What impurities are found in acetylene produced from calcium carbide, and how are they removed?

Impurities such as ammonia, phosphine, and water vapor are common. They are removed through scrubbing (ammonia scrubbers), condensation (cooling), and drying (using calcium chloride or other drying agents) to ensure acetylene purity.

5. Why is calcium carbide preferred for acetylene production?

Calcium carbide offers high reaction efficiency, low production cost, and flexibility in production scale. It is easy to store and transport compared to other acetylene production methods, making it widely used globally, especially in chemical and welding industries.

Citations:

[1] https://rexarc.com/blog/calcium-carbide-for-acetylene-production/

[2] https://www.acetyleneplant.net/technology/about-acetylene-gas/

[3] https://www.tjtywh.com/a-the-importance-of-acetylene-calcium-carbide-in-industrial-applications.html

[4] https://www.tjtywh.com/a-understanding-the-reaction-of-calcium-carbide-in-water.html

[5] https://www.tjtywh.com/acetylene-generation.html

[6] https://www.acetyleneplant.net/technology/process-description-of-acetylene-plant/

[7] https://en.wikipedia.org/wiki/Calcium_carbide

[8] https://www.kviconline.gov.in/pmegp/pmegpweb/docs/commonprojectprofile/AcetyleneGas.pdf

[9] https://www.tjtywh.com/calcium-carbide-gas-volume-and-production-efficiency-how-to-increase-acetylene-gas-yield.html

[10] https://www.tjtywh.com/how-to-ensure-safety-in-acetylene-production-using-calcium-carbide.html

[11] https://www.alzchem.com/en/company/news/calcium-carbide-for-acetylene-production/

[12] https://ocw.mit.edu/courses/22-033-nuclear-systems-design-project-fall-2011/4a2d1059fade1cce993afc566d35e42d_MIT22_033F11_lec07_note.pdf

[13] https://www.vedantu.com/question-answer/prepare-acetylene-from-calcium-carbide-class-11-chemistry-cbse-5f853c444dddb9022398bb07

[14] http://enggyd.blogspot.com/2012/03/acetylene-production-process-using.html

[15] https://www.tjtywh.com/common-faqs-about-calcium-carbide-10-key-questions-customers-care-about.html

[16] https://www.eiga.eu/uploads/documents/DOC226.pdf

[17] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[18] https://cdn.intratec.us/docs/reports/previews/acetylene-e31a-b.pdf

[19] https://patents.google.com/patent/US2422623A/en

[20] https://www.youtube.com/watch?v=AiHksObCLuU

[21] https://tianyuanweihong.en.made-in-china.com/product/yXTJfBkvgIpt/China-High-Quality-Calcium-Carbide-for-Acetylene-Gas-Welding-Industrial-Applications.html

[22] https://www.alzchem.com/fileadmin/Marken/Technische_Gase/20220924_Technical_Gases_2-Seiter_WEB.pdf

[23] https://www.tjtywh.com/a-uncovering-the-process-from-calcium-carbide-to-acetylene-gas.html

[24] https://www.acetyleneplant.net/technology/production-process-of-acetylene/

[25] https://en.wikipedia.org/wiki/Calcium_carbide

[26] https://www.tjtywh.com/a-the-role-of-acetylene-calcium-carbide-in-industrial-applications.html

[27] https://melscience.com/US-en/articles/chemical-characteristics-calcium-carbide-and-its-r/

[28] https://www.ijsrd.com/articles/IJSRDV8I30699.pdf

[29] https://www.sciencedirect.com/science/article/abs/pii/S0306261924011504

[30] https://gaftp.epa.gov/ap42/ch11/s04/related/rel01_c11s04.pdf

[31] https://www.alamy.com/stock-photo/calcium-carbide.html

[32] https://www.acetylenegasplant.com/photo-gallery.php

[33] https://www.youtube.com/watch?v=JGB4-rDYPyM

[34] https://www.gettyimages.com/photos/calcium-carbide

[35] https://www.gettyimages.com/photos/acetylene-generators

[36] https://www.shutterstock.com/search/calcium-carbide?image_type=illustration

[37] https://www.shutterstock.com/search/calcium-carbide

[38] https://www.alamy.com/stock-photo/acetylene-generator.html?cutout=1

[39] https://tw.voicetube.com/videos/111127

[40] https://www.istockphoto.com/photos/calcium-carbide

[41] https://www.vaia.com/en-us/textbooks/chemistry/chemistry-class-9-3-edition/chapter-9/problem-25-how-is-acetylene-prepared-from-calcium-carbide-gi/

[42] https://www.vedantu.com/chemistry/calcium-carbide

[43] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[44] https://testbook.com/question-answer/which-gas-is-evolved-when-water-is-added-to-calciu--612cb8db1c0d7fc68e81669b

[45] https://rexarc.com/blog/common-acetylene-plant-problems-their-solutions-part-ii/

[46] https://camachem.com/pt/blog/post/frequently-asked-question-about-calcium-carbide

[47] https://guide.resumegemini.com/interviews/top-10-questions-for-acetylene-plant-technician-interview/

[48] https://www.airproducts.com.hk/gases/acetylene

[49] https://testbook.com/question-answer/the-chemical-used-in-generating-acetylene-is--5fbe96555a4da4a2283eadfa

[50] https://www.eiga.eu/uploads/documents/DOC226.pdf

[51] https://www.eiga.eu/uploads/documents/DOC023H.pdf

[52] https://rexarc.com/products/model-50ps/

[53] https://www.youtube.com/watch?v=ovcYzWvyKVo

[54] https://nj.gov/health/eoh/rtkweb/documents/fs/0312.pdf

[55] https://www.doubtnut.com/qna/644115968