Content Menu

● Introduction

● Understanding Tungsten Carbide

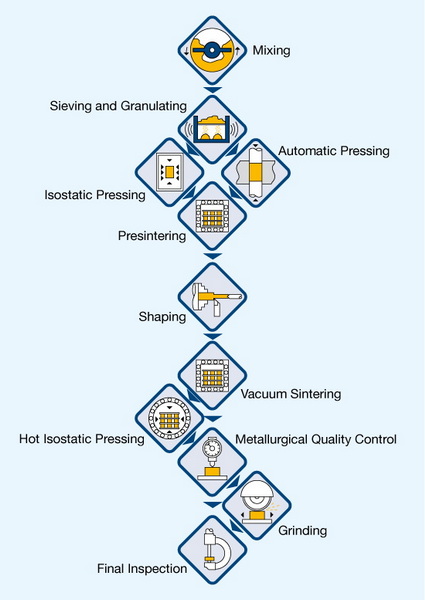

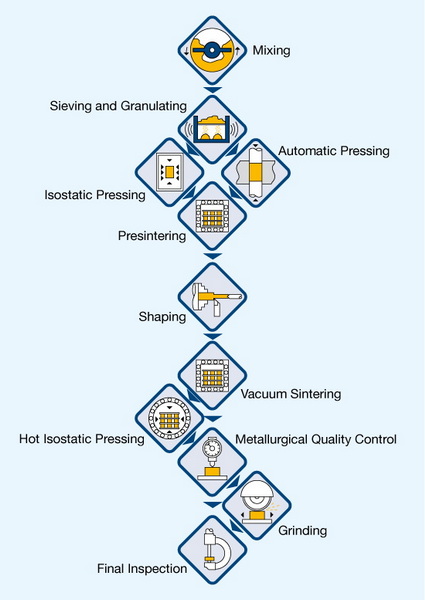

● Tungsten Carbide Machining Process Flow

>> 1. Smelting Process (If Applicable)

>> 2. Sintering and Inspection

>> 3. Molding and Machining

>> 4. Heat Treatment

>> 5. Surface Treatment

>> 6. Quality Testing

● Machining Techniques for Tungsten Carbide

>> 1. Electrical Discharge Machining (EDM)

>> 2. Grinding

>> 3. Ultrasonic Machining (USM)

>> 4. Cutting

● Best Practices for Machining Tungsten Carbide

● The Importance of Literature Review in Academic Writing

>> Key Aspects of a Literature Review:

>> Common Tenses Used in Literature Reviews:

● Conclusion

● FAQ

>> 1. What is the primary challenge in machining tungsten carbide?

>> 2. Which machining technique is most suitable for creating complex shapes in tungsten carbide?

>> 3. What role does coolant play in tungsten carbide machining?

>> 4. Why is heat treatment sometimes necessary after machining tungsten carbide?

>> 5. What surface treatments are commonly applied to tungsten carbide components?

● Citations:

Introduction

Tungsten carbide is a compound renowned for its exceptional hardness, wear resistance, and high-temperature strength[1][7]. These properties make it an ideal material for various industrial applications, including cutting tools, and molds[2][5]. However, its inherent hardness and brittleness pose significant challenges in machining[7]. This article explores the various techniques and processes involved in machining tungsten carbide, providing a comprehensive guide for achieving precision and quality in the final product[1].

Understanding Tungsten Carbide

Tungsten carbide (WC) is a composite material comprising tungsten and carbon atoms[1]. It is often combined with a binder metal, such as cobalt, to enhance its toughness[1][4]. The resulting material exhibits a unique combination of properties:

- High Hardness: Tungsten carbide is exceptionally hard, often ranging between 90 and 94 on the Rockwell A scale[1].

- Wear Resistance: It demonstrates superior resistance to abrasion and erosion[1][4].

- High-Temperature Strength: Tungsten carbide maintains its strength and hardness even at elevated temperatures[1].

- Brittleness: A notable drawback is its brittleness, which necessitates careful handling during machining to prevent cracking and chipping[7].

Tungsten Carbide Machining Process Flow

The machining of tungsten carbide parts typically involves several key stages[1]. These include smelting, sintering and forming, machining and forming, heat treatment, and surface treatment, along with rigorous quality inspection at each step[1]. If the parts are manufactured using pre-made bars or plates, the smelting and sintering processes are not required[1].

1. Smelting Process (If Applicable)

- Batching and Mixing: The process begins with the selection and mixing of tungsten carbide and cobalt powders in precise ratios[1][4].

- Crushing and Drying: The mixture is then crushed and dried to achieve uniformity and optimal flowability[1][4].

- Binder Addition and Granulation: Binders are added, followed by additional drying and sieving to create a granulated mixture ready for pressing[1][4].

2. Sintering and Inspection

- Sintering: The pressed tungsten carbide is sintered in a vacuum low-pressure sintering furnace to form solid blanks[1][4].

- Quality Inspection: The blanks undergo thorough inspections, including ultrasonic testing and dimensional checks, to ensure they meet the required quality standards[1].

3. Molding and Machining

- Molding: The sintered blanks are molded into the desired shapes and sizes[1][4].

- Machining: This stage involves high-precision mechanical operations, including Wire EDM, CNC lathe machining, turning, milling, drilling, and grinding[1][4].

- Wire EDM (Electrical Discharge Machining): Utilizes electrical discharges to cut the material[1][4].

- CNC Lathe Machining: Employs computer-controlled lathes for precise material removal[1][4].

- Turning, Milling, and Drilling: Standard machining operations adapted for tungsten carbide[1][4].

- Grinding: Essential for achieving high accuracy and surface finish[1][7].

4. Heat Treatment

- Heat treatment is applied to eliminate internal stresses and achieve specific hardness tolerances, although it is not always required[1][4].

5. Surface Treatment

- Mirror Polishing: Achieves extremely fine surface roughness[1][4].

- PVD Coating: Enhances wear resistance and hardness[1][4].

6. Quality Testing

- After each processing step, stringent quality testing ensures that the product adheres to all specifications. This includes measuring dimensional accuracy, surface quality, hardness, and mechanical properties[1].

Machining Techniques for Tungsten Carbide

Several specialized techniques are employed to machine tungsten carbide effectively[7]. These methods mitigate the challenges posed by the material's hardness and brittleness[1][7].

1. Electrical Discharge Machining (EDM)

EDM is a widely used technique for machining tungsten carbide, particularly for creating complex shapes and intricate details[1][4]. It involves removing material through a series of rapid electrical discharges between an electrode and the workpiece, submerged in a dielectric fluid[1].

Advantages:

- Capable of machining complex geometries[1][4].

- Suitable for hard and brittle materials[1].

- High precision and good surface finish[1].

Disadvantages:

- Slower material removal rate[1].

- Potential for thermal damage to the workpiece[1].

2. Grinding

Grinding is a common precision machining method for tungsten carbide, especially when high accuracy and surface finish are required[1][7]. It involves using abrasive wheels to remove material[1][7].

Advantages:

- High precision and excellent surface finish[1][7].

- Suitable for creating smooth surfaces and tight tolerances[1][7].

Disadvantages:

- Can be time-consuming[1].

- Requires careful selection of abrasives and grinding parameters[7].

3. Ultrasonic Machining (USM)

USM is a process that utilizes high-frequency vibrations and abrasive particles to erode material[1]. It is particularly useful for machining hard and brittle materials like tungsten carbide[1].

Advantages:

- Minimal heat generation[1].

- Suitable for complex shapes and delicate features[1].

Disadvantages:

- Low material removal rate[1].

- Abrasive wear on the tool[1].

4. Cutting

Cutting methods such as turning, milling, and drilling are also employed for machining tungsten carbide[1][4]. However, these techniques require specialized carbide tools and carefully chosen cutting parameters to prevent material fracture[7].

Advantages:

- Relatively faster material removal compared to EDM and USM[1].

- Suitable for producing simple shapes and features[1][4].

Disadvantages:

- High risk of chipping and cracking due to the material's brittleness[7].

- Requires rigid setup and precise control of cutting parameters[7].

Best Practices for Machining Tungsten Carbide

Achieving optimal results in tungsten carbide machining requires adherence to best practices that address the material's unique properties[1][7].

1. Tool Selection: Use high-quality carbide tools specifically designed for machining tungsten carbide[7]. Ensure that the tools are sharp and in good condition to minimize machining forces and prevent chipping[7].

2. Cutting Parameters: Carefully select cutting parameters such as speed, feed rate, and depth of cut[7]. Lower speeds and feed rates are generally recommended to reduce the risk of fracture[7].

3. Coolant Usage: Employ a suitable coolant to dissipate heat and lubricate the cutting interface[7]. Effective cooling helps to prevent thermal damage and extends tool life[7].

4. Machine Rigidity: Ensure that the machining setup is rigid and stable to minimize vibrations and chatter[7]. Vibration can lead to poor surface finish and premature tool wear[7].

5. Stress Relief: After machining, consider heat treatment to relieve internal stresses in the workpiece[1][4]. This can improve the material's overall strength and resistance to cracking[1][4].

6. Surface Finishing: Apply appropriate surface treatments such as polishing or coating to enhance wear resistance and achieve the desired surface finish[1][4].

The Importance of Literature Review in Academic Writing

In academic writing, a literature review is a critical component that provides a comprehensive overview of existing knowledge on a specific topic[3][9]. It involves a systematic analysis of published works, including research papers, books, and other scholarly articles, to identify relevant themes, debates, and gaps in the current understanding[3][9].

Key Aspects of a Literature Review:

- Establishing Context: A literature review sets the stage for your research by providing background information and context[3][9].

- Identifying Gaps: It helps to identify areas where further research is needed[3][9].

- Demonstrating Knowledge: It showcases your understanding of the topic and your ability to critically evaluate existing research[3][9].

- Supporting Arguments: It provides evidence and support for your own research questions and hypotheses[3][9].

Common Tenses Used in Literature Reviews:

- Present Tense: Used for stating general facts, current understandings, and established theories[9].

- Past Tense: Used for describing specific studies or findings that have been reported in the literature[9].

- Present Perfect Tense: Used for discussing ongoing research or developments that have implications for the present[9].

Conclusion

Machining tungsten carbide is a complex process that requires careful control and specialized techniques[1]. By understanding the material's properties and adhering to best practices, it is possible to achieve high-precision and high-quality results[1][7]. Continuous advancements in machining technologies are further enhancing the efficiency and capabilities of tungsten carbide machining, making it an increasingly viable option for a wide range of applications[1].

FAQ

1. What is the primary challenge in machining tungsten carbide?

The primary challenge in machining tungsten carbide is its high hardness and brittleness, which make it prone to chipping and cracking[7].

2. Which machining technique is most suitable for creating complex shapes in tungsten carbide?

Electrical Discharge Machining (EDM) is particularly suitable for creating complex shapes and intricate details in tungsten carbide due to its ability to machine hard and brittle materials with high precision[1][4].

3. What role does coolant play in tungsten carbide machining?

Coolant is essential in tungsten carbide machining as it dissipates heat and lubricates the cutting interface, preventing thermal damage and extending tool life[7].

4. Why is heat treatment sometimes necessary after machining tungsten carbide?

Heat treatment is sometimes necessary after machining tungsten carbide to relieve internal stresses in the workpiece, improving its overall strength and resistance to cracking[1][4].

5. What surface treatments are commonly applied to tungsten carbide components?

Common surface treatments applied to tungsten carbide components include mirror polishing to achieve extremely fine surface roughness and PVD coating to enhance wear resistance and hardness[1][4].

Citations:

[1] https://www.carbide-products.com/blog/tungsten-carbide-machining-process/

[2] https://www.alamy.com/stock-photo/tungsten-carbide.html

[3] https://blog.csdn.net/qq_34917728/article/details/125122327

[4] https://www.carbide-part.com/blog/tungsten-carbide-machining-process/

[5] https://www.istockphoto.com/photos/tungsten-carbide

[6] https://www.csulb.edu/sites/default/files/document/2019_mini_manuscript.pdf

[7] https://www.carbide-part.com/blog/how-to-machine-tungsten-carbide/

[8] https://stock.adobe.com/search?k=tungsten+carbide

[9] https://www.163.com/dy/article/EDIGQUV605370K28.html