Content Menu

● Introduction

● Composition of Carbide Overlay Plates

● Key Advantages

>> Wear Resistance

>> Impact Resistance

>> Corrosion Resistance

● Applications of Carbide Overlay Plates

>> Mining and Quarrying

>> Agricultural Machinery

>> Construction and Civil Engineering

>> Energy Sector

● Choosing the Right Carbide Overlay Plate

● Maintenance and Care

● Conclusion

● Frequently Asked Questions

>> Q1. What is a carbide overlay plate?

>> Q2. How does a chromium carbide overlay plate improve equipment lifespan?

>> Q3. In which industries are carbide overlay plates commonly used?

>> Q4. How do I choose the right carbide overlay plate for my application?

>> Q5. What maintenance practices should I follow for carbide overlay plates?

Introduction

In the realm of industrial applications, the durability and longevity of equipment are paramount. One of the most effective solutions for enhancing the wear resistance of machinery is the use of carbide overlay plates. These plates, particularly chromium carbide overlay plates, have gained significant attention due to their exceptional properties. This article delves into the key benefits of using chromium carbide overlay plates, exploring their composition, advantages, applications, and maintenance practices.

Composition of Carbide Overlay Plates

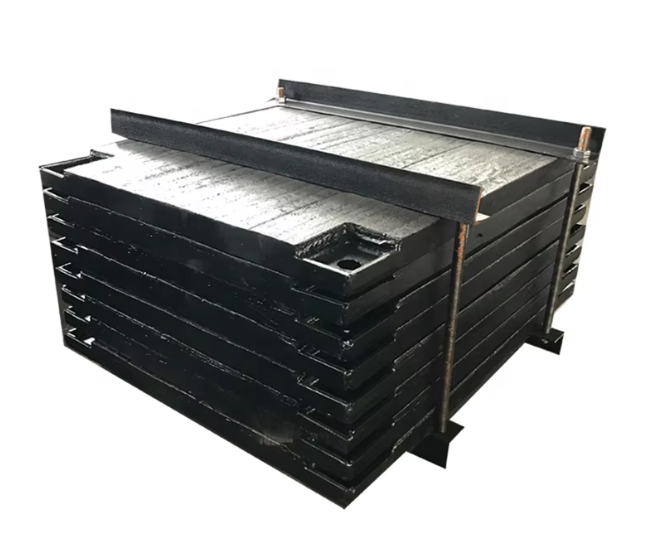

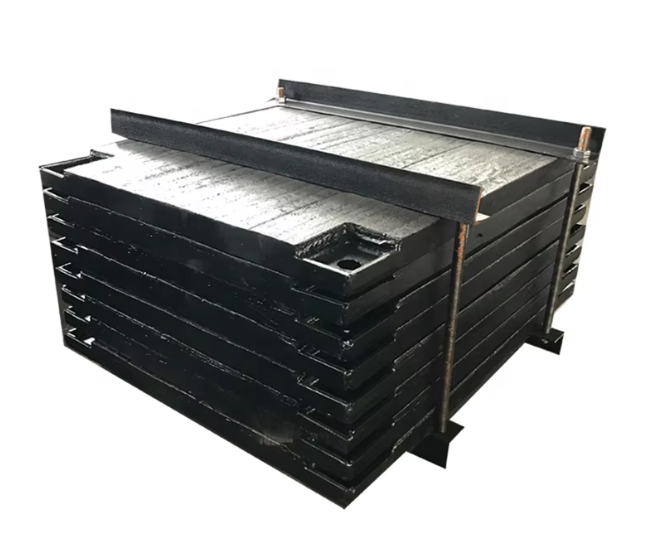

Carbide overlay plates are engineered products that consist of a base material, typically steel, with a layer of chromium carbide applied to its surface. The chromium carbide is created through a process known as hardfacing, where a mixture of chromium and carbon is melted and fused onto the base plate. This results in a hard, wear-resistant surface that can withstand extreme conditions.

Different types of carbide overlay plates exist, including:

- Chromium Carbide Overlay Plate: Known for its high hardness and wear resistance, making it ideal for abrasive environments.

- Complex Carbide Overlay: Offers enhanced toughness and is suitable for applications involving impact and abrasion.

- Ultra-Met Overlay Plate: Features a unique composition that provides superior wear resistance and is often used in heavy-duty applications.

Key Advantages

Wear Resistance

One of the most significant benefits of chromium carbide overlay plates is their exceptional wear resistance. The hardness of the chromium carbide layer allows these plates to withstand abrasive materials, significantly extending the life of the underlying equipment. This is particularly beneficial in industries such as mining, where machinery is constantly exposed to harsh conditions.

Impact Resistance

In addition to wear resistance, carbide overlay plates also exhibit excellent impact resistance. The tough nature of the overlay allows it to absorb shocks and impacts without cracking or breaking. This makes it an ideal choice for applications where heavy materials are handled, such as in construction and demolition.

Corrosion Resistance

Chromium carbide overlay plates are also known for their corrosion resistance. The chromium content in the overlay provides a protective barrier against corrosive substances, making these plates suitable for use in environments where exposure to chemicals and moisture is a concern. This property is particularly valuable in industries such as oil and gas, where equipment is often subjected to harsh chemicals.

Applications of Carbide Overlay Plates

Carbide overlay plates find applications across various industries due to their versatile properties. Some of the key sectors include:

Mining and Quarrying

In the mining industry, equipment such as crushers, chutes, and hoppers are constantly exposed to abrasive materials. The use of chromium carbide overlay plates in these applications helps to reduce wear and tear, ensuring that machinery operates efficiently for longer periods.

Agricultural Machinery

Agricultural equipment, such as plows and harrows, often encounters abrasive soil and debris. By incorporating carbide overlay plates, farmers can enhance the durability of their machinery, leading to reduced maintenance costs and increased productivity.

Construction and Civil Engineering

In construction, machinery like excavators and bulldozers frequently face harsh conditions. The application of carbide overlay plates on critical components can significantly improve their lifespan, reducing downtime and repair costs.

Energy Sector

In the energy sector, particularly in wind and solar energy, equipment is exposed to various environmental factors. The corrosion resistance of chromium carbide overlay plates makes them an excellent choice for protecting components from the elements, ensuring reliable operation.

Choosing the Right Carbide Overlay Plate

When selecting a carbide overlay plate, several factors should be considered:

- Thickness: The thickness of the overlay can impact its performance. Thicker overlays generally provide better wear resistance but may be less flexible.

- Base Material: The type of steel used as the base material can affect the overall performance of the overlay plate. It's essential to choose a base material that complements the overlay.

- Application Conditions: Understanding the specific conditions in which the plate will be used is crucial. Factors such as temperature, exposure to chemicals, and the type of materials being handled should influence the selection process.

Maintenance and Care

To maximize the lifespan of carbide overlay plates, proper maintenance is essential. Here are some tips for maintaining these plates:

- Regular Inspections: Conduct routine inspections to identify any signs of wear or damage. Early detection can prevent more significant issues down the line.

- Cleaning: Keep the plates clean to prevent the buildup of debris, which can lead to accelerated wear.

- Proper Installation: Ensure that the overlay plates are installed correctly to avoid misalignment, which can cause premature failure.

Conclusion

Chromium carbide overlay plates offer a multitude of benefits for industrial applications, including exceptional wear and impact resistance, corrosion protection, and versatility across various sectors. By understanding the composition, advantages, and maintenance practices associated with these plates, industries can significantly enhance the durability and efficiency of their equipment. As technology continues to advance, the use of carbide overlay plates will likely become even more prevalent, providing solutions to the challenges faced in demanding environments.

Frequently Asked Questions

Q1. What is a carbide overlay plate?

A carbide overlay plate is a type of engineered plate that features a layer of chromium carbide applied to a base material, typically steel. This overlay provides enhanced wear and impact resistance, making it suitable for various industrial applications.

Q2. How does a chromium carbide overlay plate improve equipment lifespan?

The hardness and durability of the chromium carbide layer protect the underlying equipment from wear and tear, significantly extending its lifespan and reducing maintenance costs.

Q3. In which industries are carbide overlay plates commonly used?

Carbide overlay plates are commonly used in industries such as mining, agriculture, construction, and energy, where equipment is exposed to abrasive materials and harsh conditions.

Q4. How do I choose the right carbide overlay plate for my application?

When selecting a carbide overlay plate, consider factors such as thickness, base material, and the specific conditions in which the plate will be used. Consulting with a supplier can also provide valuable insights.

Q5. What maintenance practices should I follow for carbide overlay plates?

Regular inspections, cleaning, and ensuring proper installation are essential maintenance practices to maximize the lifespan of carbide overlay plates.