Content Menu

● Introduction

● Understanding Tungsten Carbide Bars

>> Types of Tungsten Carbide Bars

● Benefits of Tungsten Carbide Bars

● Applications of Tungsten Carbide Bars

● Choosing the Right Tungsten Carbide Bar Stock

>> Factors to Consider

● Conclusion

● Related Questions

>> 1. What are the main advantages of using tungsten carbide bars in manufacturing?

>> 2. How do I determine the right grade of tungsten carbide for my application?

>> 3. Can tungsten carbide bars be machined or modified?

>> 4. Where can I find reliable suppliers for tungsten carbide bars?

>> 5. What are the common applications of tungsten carbide bars in the aerospace industry?

Introduction

Tungsten carbide bars are essential components in various industrial applications due to their exceptional hardness, wear resistance, and thermal stability. As industries continue to evolve, the demand for high-quality tungsten carbide bars has surged, making it crucial for manufacturers and engineers to understand how to select the right bar stock for their specific projects. This article will explore the characteristics of tungsten carbide bars, the factors to consider when choosing the right bar stock, and the various applications of these versatile materials.

Understanding Tungsten Carbide Bars

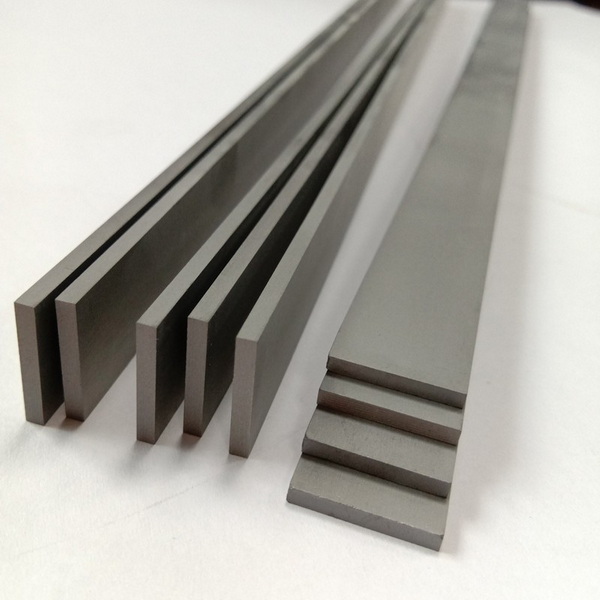

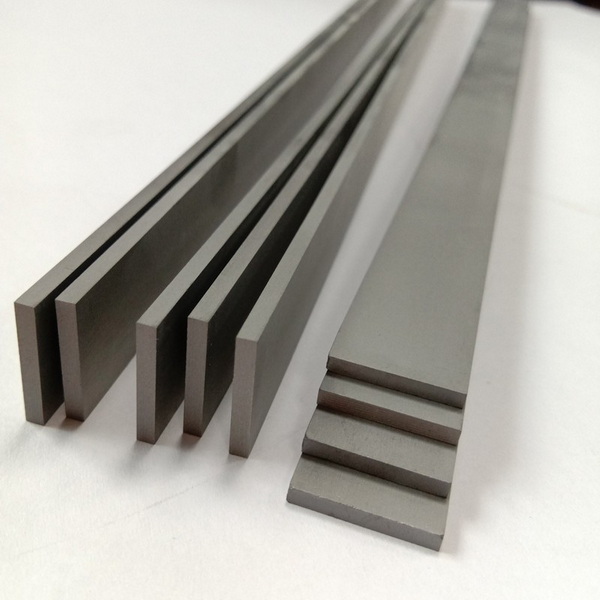

Tungsten carbide is a composite material made from tungsten and carbon atoms. It is known for its remarkable hardness, which is second only to diamond. Tungsten carbide bars come in various shapes, including round, flat, and rods, each designed for specific applications. The unique properties of tungsten carbide make it an ideal choice for cutting tools, wear-resistant parts, and other industrial applications.

Types of Tungsten Carbide Bars

1. Tungsten Carbide Round Bars: These bars are commonly used in machining and manufacturing processes. Their cylindrical shape allows for easy handling and versatility in various applications.

2. Tungsten Carbide Flat Bars: Flat bars are often used in applications requiring a flat surface, such as in the production of cutting tools and dies.

3. Tungsten Carbide Rods: These rods are typically used in drilling and milling applications, providing strength and durability in high-stress environments.

Benefits of Tungsten Carbide Bars

Tungsten carbide bars offer numerous advantages that make them a preferred choice in many industries:

- Exceptional Hardness and Wear Resistance: Tungsten carbide is renowned for its hardness, making it highly resistant to wear and tear. This property is particularly beneficial in applications where tools are subjected to high friction and abrasion.

- High Melting Point and Thermal Stability: Tungsten carbide has a high melting point, allowing it to maintain its structural integrity even in extreme temperatures. This makes it suitable for applications in high-heat environments.

- Versatility in Various Applications: Tungsten carbide bars can be used in a wide range of applications, from cutting tools to industrial machinery components. Their adaptability makes them a valuable asset in any manufacturing process.

Applications of Tungsten Carbide Bars

Tungsten carbide bars are utilized in various industries, including aerospace, automotive, and manufacturing. Here are some common applications:

- Cutting Tools and Machining: Tungsten carbide bars are often used to manufacture cutting tools, such as drills, end mills, and inserts. Their hardness allows for precise cutting and extended tool life.

- Aerospace Industry: In the aerospace sector, tungsten carbide bars are used in components that require high strength and durability, such as turbine blades and landing gear.

- Automotive Industry: Tungsten carbide is used in automotive applications, including engine components and wear parts, due to its ability to withstand high stress and wear.

- Manufacturing of Wear-Resistant Parts: Many industries rely on tungsten carbide bars to produce wear-resistant parts, such as bushings, bearings, and nozzles, which are essential for maintaining equipment efficiency.

Choosing the Right Tungsten Carbide Bar Stock

When selecting tungsten carbide bar stock for your project, several factors must be considered to ensure optimal performance and suitability for your specific application.

Factors to Consider

1. Size and Shape: The size and shape of the tungsten carbide bar are critical for its intended use. Consider the dimensions required for your project and choose a bar that fits those specifications.

2. Grade of Tungsten Carbide: Tungsten carbide bars come in various grades, each with different properties. For example, C2 grade tungsten carbide is commonly used for general-purpose applications, while higher grades may be necessary for more demanding environments.

3. Application Requirements: Assess the specific requirements of your application, such as temperature, pressure, and wear conditions. This will help you determine the most suitable tungsten carbide bar for your needs.

4. Supplier Reputation: Choose a reputable supplier with a track record of providing high-quality tungsten carbide products. Research customer reviews and industry reputation to ensure you are sourcing from a reliable source.

5. Cost Considerations: While tungsten carbide bars can be more expensive than other materials, their durability and performance can lead to cost savings in the long run. Consider the total cost of ownership, including maintenance and replacement costs, when making your decision.

Conclusion

Choosing the right tungsten carbide bar stock for your project is crucial for ensuring optimal performance and longevity. By understanding the characteristics of tungsten carbide, the various types of bars available, and the factors to consider when making your selection, you can make informed decisions that will benefit your manufacturing processes. Whether you are in the aerospace, automotive, or general manufacturing industry, tungsten carbide bars offer the durability and performance needed to meet the demands of modern applications.

Related Questions

1. What are the main advantages of using tungsten carbide bars in manufacturing?

Tungsten carbide bars offer exceptional hardness, wear resistance, and thermal stability, making them ideal for cutting tools and wear-resistant parts in various industries.

2. How do I determine the right grade of tungsten carbide for my application?

The right grade depends on the specific requirements of your application, including wear conditions, temperature, and pressure. Higher grades are suitable for more demanding environments.

3. Can tungsten carbide bars be machined or modified?

Yes, tungsten carbide bars can be machined, but specialized tools and techniques are required due to their hardness. It is advisable to consult with experts when modifying tungsten carbide.

4. Where can I find reliable suppliers for tungsten carbide bars?

You can find reliable suppliers by researching online, checking industry directories, and reading customer reviews. Look for suppliers with a strong reputation for quality and service.

5. What are the common applications of tungsten carbide bars in the aerospace industry?

In the aerospace industry, tungsten carbide bars are used in components such as turbine blades, landing gear, and other parts that require high strength and durability under extreme conditions.