Content Menu

● Introduction to Lyman Carbide Dies

● The Advantages of Carbide Dies

● Lyman Pro Reloading Dies: A Cut Above the Rest

>> Key Features of Lyman Pro Reloading Dies

● Understanding the Die Set: From Sizing to Crimping

>> 1. Carbide Sizing Die

>> 2. Expanding Die

>> 3. Bullet Seating Die

>> 4. Taper Crimp Die (in 4-die sets)

● High-Volume Reloading: Maximizing Efficiency with Lyman Carbide Dies

>> Progressive Reloading Press Compatibility

>> Precision for Match-Grade Ammunition

● Rifle vs. Pistol Reloading Dies: Understanding the Differences

>> Pistol Reloading Dies

>> Rifle Reloading Dies

● The Role of Tungsten Carbide in Precision Reloading

● Maintaining Your Lyman Carbide Dies

>> Cleaning and Storage

>> Inspection

● Expanding Your Reloading Setup: Complementary Tools

● Safety Considerations in Reloading

● Conclusion: The Lyman Advantage in Precision Reloading

● Frequently Asked Questions

>> Q1: How long do Lyman carbide dies typically last?

>> Q2: Can Lyman carbide dies be used for both pistol and rifle cartridges?

>> Q3: Are Lyman Pro Reloading Dies worth the investment for a beginner reloader?

>> Q4: How do I know when it's time to replace my Lyman carbide dies?

>> Q5: Can I use Lyman carbide dies with reloading presses from other manufacturers?

Introduction to Lyman Carbide Dies

For serious shooters and reloaders, the quest for precision and efficiency never ends. At the forefront of this pursuit stands Lyman Products, a company renowned for its high-quality reloading equipment. Among their most coveted offerings are the Lyman carbide dies, which have revolutionized the world of ammunition reloading. These precision-engineered tools are designed to meet the demands of both casual reloaders and high-volume shooters who require consistent, match-grade ammunition.

The Advantages of Carbide Dies

Lyman carbide dies offer several advantages over traditional steel dies:

1. Durability: Carbide is extremely hard, ensuring that the dies maintain their dimensions even after processing thousands of rounds.

2. Reduced friction: The smooth surface of carbide reduces friction during the sizing process, which can extend the life of your brass cases.

3. No lubrication required: For straight-walled pistol cartridges, carbide dies eliminate the need for case lubrication, streamlining the reloading process.

4. Consistency: The precise tolerances of carbide dies contribute to more consistent ammunition, which is crucial for accuracy.

Lyman Pro Reloading Dies: A Cut Above the Rest

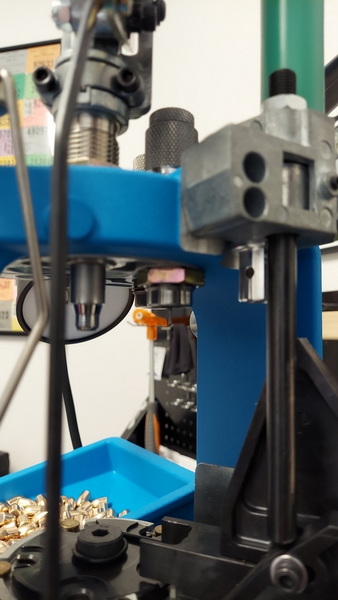

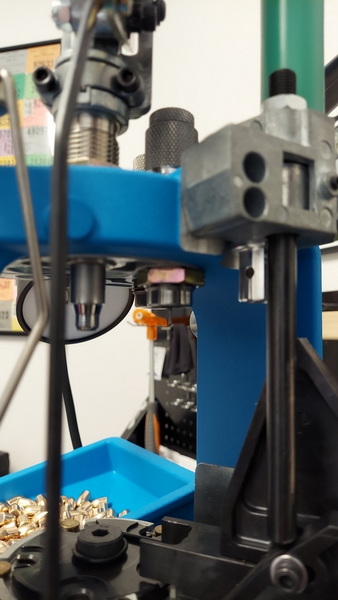

Lyman has recently introduced their Pro Reloading Dies series, which represents the pinnacle of reloading technology. These dies are specifically designed for high-volume reloading on progressive presses, though they're equally at home on single-stage and turret presses.

The Lyman Pro Reloading Dies are crafted from stainless steel and feature tungsten carbide inserts in the sizing dies. This combination of materials ensures longevity and precision, even under the most demanding reloading schedules.

Key Features of Lyman Pro Reloading Dies

- Stainless steel construction for corrosion resistance

- Tungsten carbide sizing rings for pistol dies

- Optimized for use with progressive reloading presses

- Available in both pistol and rifle calibers

- Precision-machined for consistent performance

Understanding the Die Set: From Sizing to Crimping

A typical Lyman carbide die set for pistol cartridges includes three or four dies, each serving a specific purpose in the reloading process.

1. Carbide Sizing Die

The carbide sizing die is the workhorse of the set. It resizes the brass case to proper dimensions, ensuring it will chamber correctly in your firearm. For pistol cartridges, the carbide insert allows for sizing without lubrication, which speeds up the process and reduces the chance of contaminating your powder with lube.

2. Expanding Die

Also known as the "bell" die, this expands the case mouth slightly to allow for easy bullet seating. It's crucial for achieving consistent bullet seating depths.

3. Bullet Seating Die

This die seats the bullet to the proper depth in the case. Many Lyman seating dies feature a floating bullet seating stem for improved concentricity.

4. Taper Crimp Die (in 4-die sets)

For cartridges that headspace on the case mouth, like the 9mm Luger or .45 ACP, a separate taper crimp die is included. This die applies a slight crimp to secure the bullet without deforming it.

High-Volume Reloading: Maximizing Efficiency with Lyman Carbide Dies

For those engaged in high-volume reloading, whether for competition, training, or simply because of a passionate shooting hobby, Lyman carbide dies are indispensable tools. They're designed to withstand the rigors of continuous use on progressive reloading presses, where speed and consistency are paramount.

Progressive Reloading Press Compatibility

While Lyman carbide dies work excellently with single-stage presses, they truly shine when used with progressive reloading presses. These multi-station presses can produce a completed round with every pull of the handle, dramatically increasing output.

Precision for Match-Grade Ammunition

Despite the focus on high-volume production, Lyman hasn't sacrificed precision. The Pro Reloading Dies are capable of producing match-grade ammunition that meets the exacting standards of competitive shooters. The consistency achieved with these dies can lead to tighter groups and improved accuracy across a wide range of firearms.

Rifle vs. Pistol Reloading Dies: Understanding the Differences

Lyman offers carbide dies for both rifle and pistol cartridges, but there are some key differences in their design and use.

Pistol Reloading Dies

Pistol dies, particularly for straight-walled cartridges, often come in 3-die or 4-die sets. The carbide sizing die is a standout feature, eliminating the need for case lubrication. This is a significant time-saver for high-volume reloaders.

Rifle Reloading Dies

Rifle dies are typically sold in 2-die or 3-die sets. Unlike pistol dies, rifle sizing dies usually require case lubrication due to the bottleneck shape of most rifle cartridges. However, Lyman's rifle dies still benefit from precision engineering and durable construction.

The Role of Tungsten Carbide in Precision Reloading

Tungsten carbide is a compound of tungsten and carbon, known for its extreme hardness and wear resistance. In reloading dies, tungsten carbide inserts offer several benefits:

1. Longevity: Tungsten carbide maintains its dimensions far longer than steel, ensuring consistent sizing over thousands of reloads.

2. Smooth operation: The polished surface of carbide reduces friction, making the sizing process easier and potentially extending brass life.

3. No lubrication needed: For straight-walled pistol cases, carbide sizing dies eliminate the need for lubrication, speeding up the reloading process.

Maintaining Your Lyman Carbide Dies

While Lyman carbide dies are built to last, proper maintenance will ensure they continue to perform at their best for years to come.

Cleaning and Storage

- After each use, wipe down the dies with a clean, lint-free cloth.

- Store dies in their original packaging or a die box to protect them from dust and moisture.

- Periodically check and clean the die threads to ensure smooth installation and removal.

Inspection

- Regularly inspect the carbide inserts for any signs of chipping or cracking.

- Check the decapping pins in sizing dies for straightness and wear.

- Ensure all adjusting screws and lock rings are tight before each reloading session.

Expanding Your Reloading Setup: Complementary Tools

To get the most out of your Lyman carbide dies, consider these additional tools:

1. Case prep tools: Trimmers, deburring tools, and primer pocket cleaners.

2. Powder measure: For accurate and consistent powder charges.

3. Digital calipers: To verify case lengths and overall cartridge lengths.

4. Reloading manual: Essential for load data and safety guidelines.

Safety Considerations in Reloading

Reloading ammunition is a rewarding hobby, but it comes with inherent risks. Always follow these safety guidelines:

- Wear safety glasses at all times when reloading.

- Follow load data precisely; never exceed maximum recommended charges.

- Keep your reloading area clean and free of distractions.

- Store primers and powder separately in approved containers.

- Never smoke or have open flames near your reloading setup.

Conclusion: The Lyman Advantage in Precision Reloading

Lyman carbide dies represent the cutting edge of reloading technology. Whether you're a competitive shooter demanding match-grade ammunition or a high-volume reloader looking for efficiency and consistency, these dies deliver outstanding performance. By investing in quality tools like Lyman Pro Reloading Dies, you're not just buying equipment – you're investing in the potential for better accuracy, more consistent loads, and a more enjoyable reloading experience.

As the shooting sports continue to evolve, Lyman remains at the forefront, continuously innovating to meet the needs of modern reloaders. With their carbide dies leading the way, precision and high-volume reloading have never been more accessible to enthusiasts at all levels.

Frequently Asked Questions

Q1: How long do Lyman carbide dies typically last?

A1: Lyman carbide dies are known for their exceptional durability. With proper care and maintenance, they can last for tens of thousands of reloads, often outlasting the reloading press itself. Many reloaders report using the same set of Lyman carbide dies for decades without any loss in performance.

Q2: Can Lyman carbide dies be used for both pistol and rifle cartridges?

A2: Yes, Lyman produces carbide dies for both pistol and rifle cartridges. However, it's important to note that while pistol carbide dies often eliminate the need for case lubrication, rifle dies typically still require it due to the bottleneck shape of most rifle cartridges.

Q3: Are Lyman Pro Reloading Dies worth the investment for a beginner reloader?

A3: While Lyman Pro Reloading Dies are designed with high-volume reloaders in mind, they can be an excellent investment for beginners as well. Their durability and precision mean you won't need to upgrade as your skills improve, and they can help you produce consistent, high-quality ammunition from the start. However, if budget is a concern, Lyman's standard carbide dies are also an excellent choice for beginners.

Q4: How do I know when it's time to replace my Lyman carbide dies?

A4: Carbide dies are extremely durable, but they're not indestructible. Signs that it might be time to replace your dies include:

- Visible damage to the carbide insert, such as chips or cracks

- Inconsistent dimensions in sized cases

- Difficulty in sizing or seating operations that can't be resolved through normal adjustments

- Visible wear on the decapping pin or seating stem

If you notice any of these issues, it's best to replace the affected die to maintain the quality and consistency of your reloads.

Q5: Can I use Lyman carbide dies with reloading presses from other manufacturers?

A5: Yes, Lyman carbide dies are designed to be compatible with standard 7/8"-14 thread presses, which is the industry standard. This means they can be used with most major brands of reloading presses, including RCBS, Hornady, Lee, and others. Always check the thread specifications of your press to ensure compatibility.