Content Menu

● What is Tungsten Carbide?

>> Properties of Tungsten Carbide

● Advantages of Tungsten Carbide Knife Blades

● Disadvantages of Tungsten Carbide Knife Blades

● Manufacturing Process of Tungsten Carbide Knives

>> Deeper Dive into the Sintering Process

>> Machining Challenges and Techniques

● Performance Comparison: Tungsten Carbide vs Steel

>> Edge Retention Explained

>> Brittleness and Toughness: A Balancing Act

● Applications of Tungsten Carbide Knives

>> Tungsten Carbide in the Medical Field

>> Customization and Emerging Trends

● Conclusion

● FAQ

>> 1. What is the main advantage of using tungsten carbide for knife blades?

>> 2. Are tungsten carbide knives easy to sharpen?

>> 3. How does the brittleness of tungsten carbide affect knife performance?

>> 4. Can tungsten carbide knives be customized easily?

>> 5. What industries commonly use tungsten carbide knives?

● Citations:

Tungsten carbide, a compound celebrated for its remarkable hardness and durability, has increasingly captured attention in the knife manufacturing sector. This article aims to thoroughly examine the characteristics of tungsten carbide, assessing both its strengths and weaknesses as a material for knife blades. We will compare its performance against more traditional materials like steel, investigate the intricacies of its manufacturing, and explore the diverse applications where tungsten carbide knives excel.

What is Tungsten Carbide?

Tungsten carbide is a composite material consisting of tungsten and carbon atoms. Its hallmark feature is its extreme hardness, second only to diamond. The structure is composed of tungsten carbide grains held together by a metallic binder, typically cobalt. This unique composition imparts remarkable properties, making it invaluable for applications requiring high wear resistance, such as cutting tools and industrial blades.

Properties of Tungsten Carbide

- Hardness: With a hardness rating of approximately 71 on the Rockwell C scale (Rc), tungsten carbide can maintain a sharp cutting edge far longer than many conventional knife materials.

- Wear Resistance: It exhibits exceptional resistance to wear, enduring significant abrasion without compromising its cutting ability.

- Corrosion Resistance: Tungsten carbide is highly resistant to corrosion, performing reliably even in harsh chemical environments.

- Brittleness: Despite its hardness, tungsten carbide is more brittle than steel, predisposing it to chipping or breakage upon impact.

Advantages of Tungsten Carbide Knife Blades

1. Longevity: Tungsten carbide blades retain their sharpness for extended periods, drastically reducing the frequency of required sharpening. This characteristic is particularly advantageous in professional settings where minimal downtime for maintenance is crucial.

2. Precision Cutting: Its inherent hardness facilitates remarkably precise cuts, making it ideal for applications demanding high accuracy, such as in surgical instruments or specialized industrial tasks.

3. Heat Resistance: Tungsten carbide maintains its structural integrity and properties even at elevated temperatures, rendering it suitable for cutting operations that generate substantial heat.

4. Reduced Re-sharpening Needs: Users benefit from the convenience of less frequent re-sharpening compared to steel blades, leading to time savings and reduced maintenance efforts.

5. Versatile Applications: Tungsten carbide knives are finding increased use in various industrial contexts due to their superior performance characteristics.

Disadvantages of Tungsten Carbide Knife Blades

1. Brittleness: The material's brittleness poses a significant drawback, as tungsten carbide blades are susceptible to chipping or fracturing when subjected to excessive force or impact. This limits their suitability for heavy-duty applications requiring flexibility.

2. Sharpening Difficulty: While they maintain their edge exceptionally well, sharpening tungsten carbide blades is a challenging endeavor. Specialized equipment, such as diamond sharpeners, is necessary due to the material's extreme hardness.

3. Cost: Tungsten carbide knives typically command a higher price point than steel knives, reflecting the complexity of their manufacturing process and the high cost of raw materials.

4. Limited Customization: In contrast to traditional knife materials like steel, customizing tungsten carbide knives presents considerable difficulties due to manufacturing constraints.

Manufacturing Process of Tungsten Carbide Knives

The fabrication of tungsten carbide knives involves a multi-stage process:

1. Powder Preparation: The process commences with the meticulous mixing of tungsten and carbon powders in precise proportions.

2. Compaction: The mixed powders are then compacted into the desired blade shape using high-pressure techniques.

3. Sintering: The compacted forms are heated in a furnace at high temperatures (approximately 1400°C) under vacuum or in an inert atmosphere to fuse the particles together, achieving the necessary density and strength.

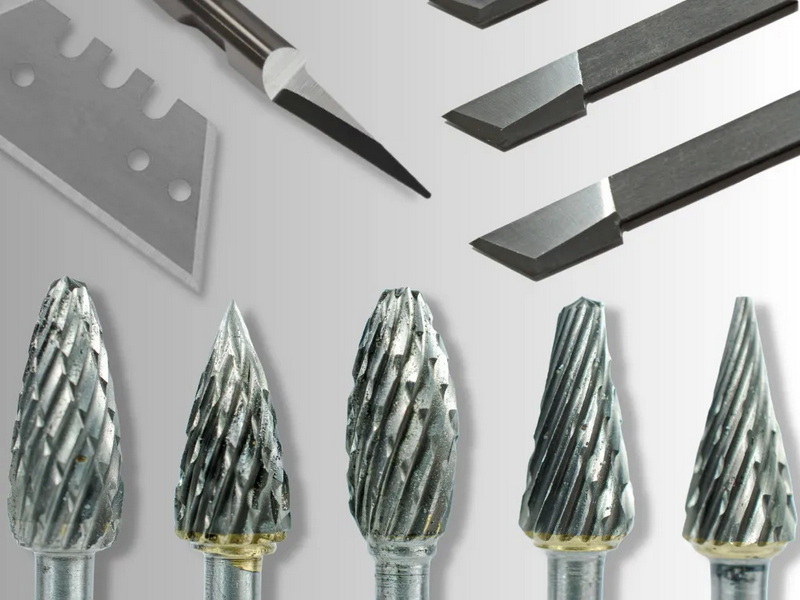

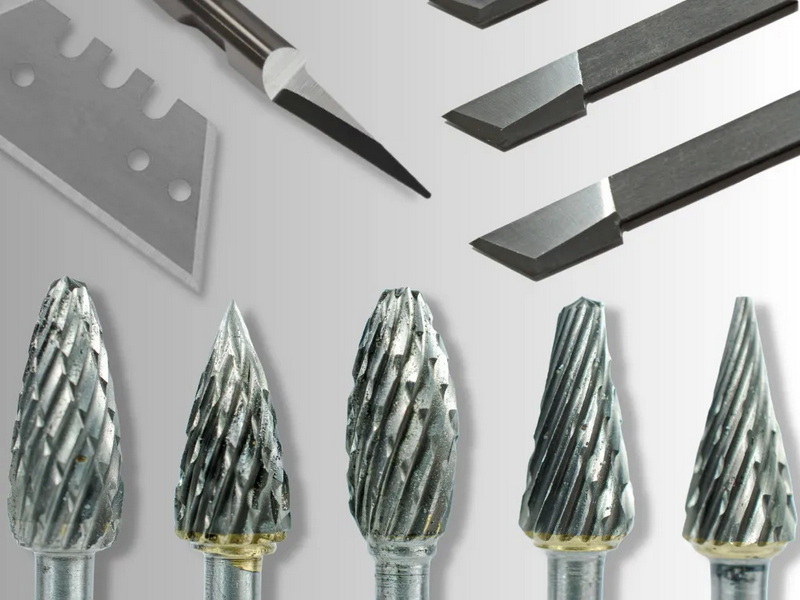

4. Machining: Following sintering, the blades undergo machining processes to achieve precise dimensions and surface finishes, often involving grinding and polishing.

5. Coating (Optional): Certain manufacturers apply surface coatings to enhance attributes such as corrosion resistance or aesthetic appeal. Common coatings include titanium nitride (TiN) or diamond-like carbon (DLC).

Deeper Dive into the Sintering Process

Sintering is arguably the most critical step in manufacturing tungsten carbide. This thermal treatment transforms the compacted powder into a solid, dense material. During sintering, the tungsten carbide grains form strong bonds, and the cobalt binder melts, filling the spaces between the grains and solidifying upon cooling. The sintering process parameters, such as temperature, pressure, and duration, are precisely controlled to achieve optimal mechanical properties in the final product.

Machining Challenges and Techniques

Machining tungsten carbide is no easy feat. Due to its extreme hardness, conventional machining methods are ineffective. Instead, specialized techniques like Electrical Discharge Machining (EDM) and abrasive grinding are employed. EDM uses electrical sparks to erode the material, while abrasive grinding utilizes diamond-impregnated wheels to slowly shape and refine the blade.

Performance Comparison: Tungsten Carbide vs Steel

To comprehensively evaluate whether tungsten carbide is a suitable material for knife blades, a detailed comparison against steel is essential:

| Property | Tungsten Carbide | Steel |

| Hardness | 71 Rc | Varies (55-65 Rc typical) |

| Edge Retention | Excellent | Good to Very Good |

| Sharpening Difficulty | Very Difficult (requires diamond tools) | Moderate |

| Brittleness | More brittle | More ductile |

| Cost | Higher | Generally lower |

| Corrosion Resistance | Excellent | Varies by alloy |

| Toughness | Lower | Higher |

Edge Retention Explained

Edge retention is a critical metric for knife performance. Tungsten carbide excels in this area because its hardness allows the blade to resist deformation and wear during cutting. This means it stays sharper for a longer time compared to steel. However, it's important to note that edge retention doesn't solely determine a knife's overall usefulness.

Brittleness and Toughness: A Balancing Act

While tungsten carbide boasts impressive hardness, its brittleness is a limitation. Brittleness refers to a material's tendency to fracture under stress, whereas toughness refers to its ability to absorb energy and deform without fracturing. Steel knives generally have higher toughness, making them more forgiving in demanding situations.

Applications of Tungsten Carbide Knives

Tungsten carbide knives are deployed in various industries requiring specific performance characteristics:

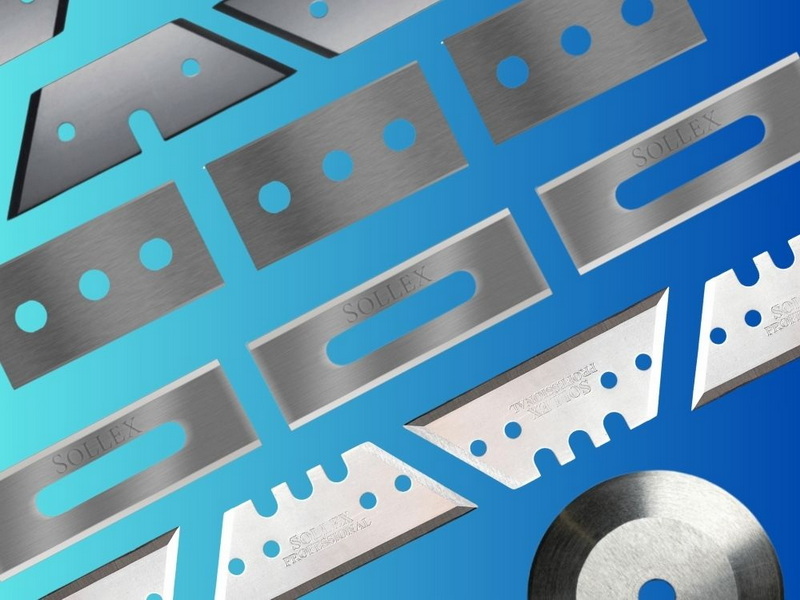

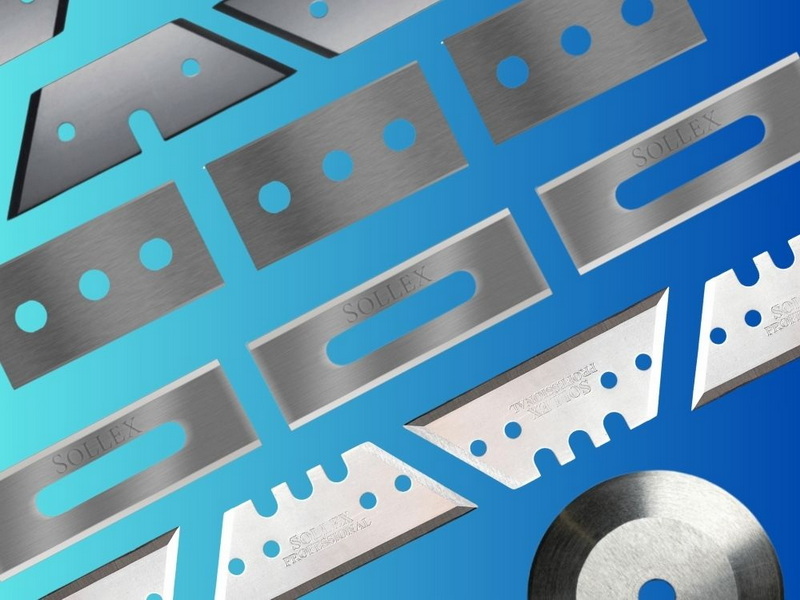

- Industrial Cutting Tools: Widely used in manufacturing for cutting materials like composites, plastics, and non-ferrous metals, where precision and durability are paramount.

- Medical Instruments: Employed in surgical tools where sharpness, sterility, and corrosion resistance are critical. Examples include scalpels and specialized biopsy instruments.

- Culinary Knives: Increasingly found in high-end kitchen knives, offering chefs extended sharpness and reduced maintenance.

- Mining and Quarrying: Utilized in specialized applications requiring cutting through abrasive materials in harsh environments.

- Textile Industry: Used in cutting fabrics and synthetic fibers where precision and clean cuts are necessary.

Tungsten Carbide in the Medical Field

In the medical field, tungsten carbide knives and blades are particularly valuable due to their ability to maintain a sharp edge even after repeated sterilization. This reduces the need for frequent blade changes during surgical procedures, improving efficiency and minimizing patient risk.

Customization and Emerging Trends

While customization of tungsten carbide knives is challenging, advancements in manufacturing techniques, such as additive manufacturing (3D printing), are opening new possibilities. 3D printing allows for the creation of complex shapes and geometries, potentially overcoming some of the traditional limitations of tungsten carbide processing.

Conclusion

In conclusion, tungsten carbide exhibits a compelling combination of advantages and disadvantages as a knife blade material. Its extraordinary hardness and wear resistance make it a desirable choice for applications where longevity and precision are essential. However, one must carefully consider its brittleness, sharpening complexities, and elevated cost when evaluating its suitability for specific tasks.

As materials science and manufacturing technologies continue to evolve, it is conceivable that future innovations may further enhance the practicality and versatility of tungsten carbide in knife-making, potentially mitigating some of its existing limitations. The key lies in finding the right balance between hardness, toughness, and cost to meet the diverse needs of knife users across different industries.

FAQ

1. What is the main advantage of using tungsten carbide for knife blades?

The primary advantage is its exceptional hardness and wear resistance, allowing blades to maintain sharpness longer than traditional materials like steel, reducing the frequency of sharpening.

2. Are tungsten carbide knives easy to sharpen?

No, sharpening tungsten carbide knives can be quite challenging, requiring specialized diamond sharpeners due to the material's extreme hardness.

3. How does the brittleness of tungsten carbide affect knife performance?

The brittleness can lead to chipping or breaking under impact or excessive force, making these knives less suitable for heavy-duty tasks that require flexibility.

4. Can tungsten carbide knives be customized easily?

Customization is more challenging compared to steel knives due to the manufacturing constraints associated with tungsten carbide, though advances in additive manufacturing may offer future possibilities.

5. What industries commonly use tungsten carbide knives?

Tungsten carbide knives are used in industrial cutting tools, medical instruments, culinary applications, mining operations, and the textile industry, among others, owing to their durability and precision cutting capabilities.

Citations:

[1] https://www.sollex.se/en/blog/post/overview-tungsten-carbide-slitter-blades

[2] https://knifenews.com/sandrin-tungsten-carbide-knives/

[3] https://cuchillascastillo.com/en/tungsten-carbide-blades-precision-and-durability-in-industrial-cutting/

[4] https://knifesteelnerds.com/2019/11/18/sandrin-carbide-what-is-it/

[5] https://www.passiontool.com/news/what-are-the-advantages-of-tungsten-carbide-blades/

[6] https://sheffieldgaugeplate.co.uk/blog/tungsten-blades/

[7] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[8] https://kapuga.pl/en/sandrin-knives-eng/