Content Menu

● Understanding Tungsten Carbide Coating

>> Benefits of Tungsten Carbide Coating

● Can Tungsten Carbide Coated Ball Valves Be Repaired?

>> The Repair Process

● Advantages of Recoating Tungsten Carbide Ball Valves

● Considerations for Repairing Tungsten Carbide Coated Ball Valves

● Conclusion

● Frequently Asked Questions

>> 1. What types of damage can tungsten carbide coated ball valves experience?

>> 2. How often should tungsten carbide coated ball valves be inspected?

>> 3. What are the signs that a tungsten carbide coated ball valve needs recoating?

>> 4. Is it possible to recoat a valve multiple times?

>> 5. What are some common applications for tungsten carbide coated ball valves?

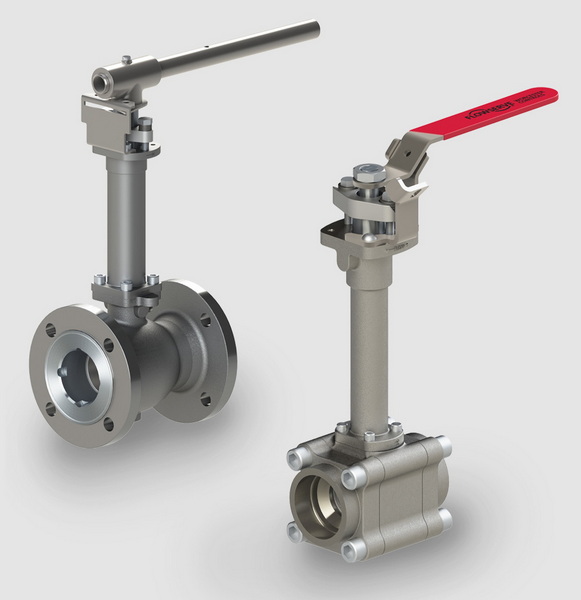

Tungsten carbide coated ball valves are essential components in various industrial applications due to their durability and resistance to wear and corrosion. However, like any mechanical component, they can experience wear over time, leading to questions about their repairability and recoating options. This article explores the process of repairing and recoating tungsten carbide coated ball valves, the benefits of such procedures, and the considerations that come into play.

Understanding Tungsten Carbide Coating

Tungsten carbide is a composite material made from tungsten and carbon, known for its exceptional hardness and strength. When applied as a coating to ball valves, it enhances their performance in harsh environments, making them ideal for applications in oil and gas, petrochemical, and mining industries. The coating significantly reduces wear from friction and erosion, extending the lifespan of the valve.

Benefits of Tungsten Carbide Coating

1. Wear Resistance: Tungsten carbide coatings provide a surface hardness that is nearly twice that of steel, making them highly resistant to wear.

2. Corrosion Resistance: The coating protects against corrosive substances, essential for valves operating in chemical processing environments.

3. Cost-Effectiveness: Instead of replacing entire valves, recoating can be a more economical solution that prolongs the life of existing equipment.

Can Tungsten Carbide Coated Ball Valves Be Repaired?

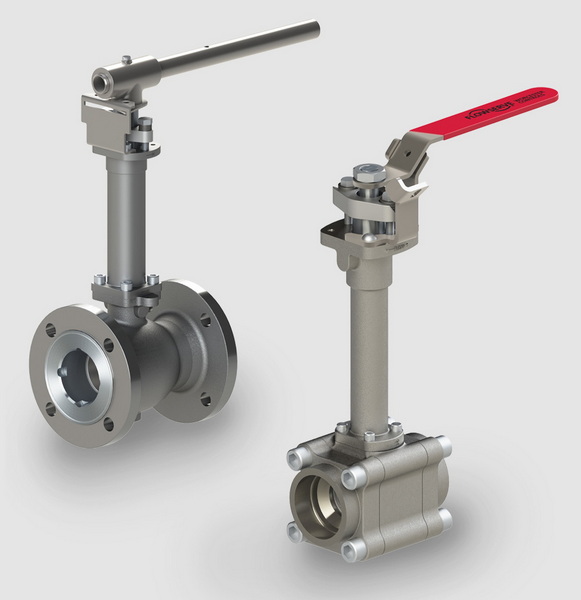

Yes, tungsten carbide coated ball valves can be repaired. The repair process typically involves evaluating the extent of wear or damage to the valve components. If the damage is superficial or limited to the coating, recoating may be sufficient.

The Repair Process

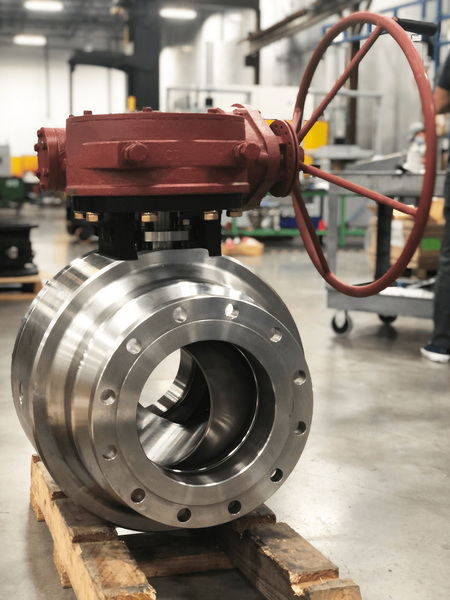

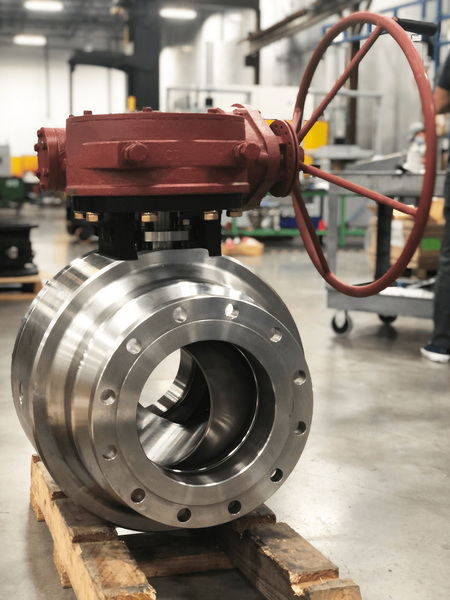

1. Inspection: The first step involves a thorough inspection of the valve to assess its condition. This includes checking for signs of wear on the ball, seat, and other critical components.

Inspection of Ball Valve

2. Stripping: If recoating is necessary, the existing tungsten carbide coating must be stripped away. This can be done using various methods such as grit blasting or chemical stripping.

3. Surface Preparation: After stripping, the surface is prepared for new coating application. This may involve grinding or polishing to ensure a smooth surface.

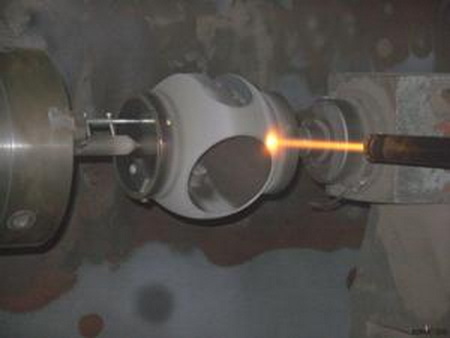

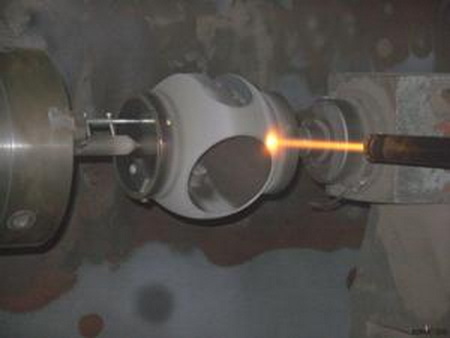

4. Recoating: The new tungsten carbide coating is applied using thermal spray techniques such as High-Velocity Oxygen Fuel (HVOF) or Plasma Spray. These methods ensure a strong bond between the coating and the substrate.

Thermal Spray Coating Process

5. Finishing: Once coated, the valve components are finished to meet specified tolerances through grinding or lapping processes.

6. Testing: Finally, the repaired valve undergoes testing to ensure it meets operational standards before being returned to service.

Advantages of Recoating Tungsten Carbide Ball Valves

- Restoration of Performance: Recoating can restore the valve's original performance characteristics, allowing it to function effectively in demanding applications.

- Extended Lifespan: Regular maintenance through recoating can significantly extend the lifespan of ball valves.

- Cost Savings: Repairing rather than replacing valves can lead to substantial cost savings for industries that rely on these components.

Considerations for Repairing Tungsten Carbide Coated Ball Valves

While repairing and recoating tungsten carbide coated ball valves is often feasible, several factors must be considered:

1. Extent of Damage: If a valve has sustained significant damage beyond just the coating, replacement may be more economical.

2. Application Requirements: Consider whether the repaired valve will meet the specific requirements of its application post-repair.

3. Downtime: The repair process can take time; planning for downtime is crucial in industrial settings where continuous operation is necessary.

Conclusion

Tungsten carbide coated ball valves play a vital role in many industrial applications due to their durability and resistance to harsh conditions. When these valves experience wear or damage, they can often be repaired through a thorough process involving inspection, stripping, recoating, and testing. This not only restores their functionality but also extends their lifespan while providing significant cost savings compared to complete replacement.

By understanding the repair process and its benefits, industries can make informed decisions about maintaining their equipment effectively.

Frequently Asked Questions

1. What types of damage can tungsten carbide coated ball valves experience?

Tungsten carbide coated ball valves may experience wear from friction, corrosion from chemicals, and mechanical damage due to improper handling or installation.

2. How often should tungsten carbide coated ball valves be inspected?

Regular inspections are recommended based on operational conditions; however, a general guideline is at least once every six months or after significant operational changes.

3. What are the signs that a tungsten carbide coated ball valve needs recoating?

Signs include visible wear on the coating surface, reduced sealing performance, and increased leakage during operation.

4. Is it possible to recoat a valve multiple times?

Yes, as long as the underlying material remains intact and there is sufficient thickness for additional coatings without compromising performance.

5. What are some common applications for tungsten carbide coated ball valves?

Common applications include oil and gas extraction, chemical processing plants, mining operations, and any environment where high wear resistance is required.