Content Menu

● Understanding Tungsten Carbide Grades

>> Key Properties of Tungsten Carbide

● What Makes a Tungsten Carbide Grade "Light"?

● Examples of Light Tungsten Carbide Grades

>> 1. K30 Grade

>> 2. VM-L501 (Mixed Binder)

>> 3. Ultra-Fine Grain Grades

● Applications of Light Tungsten Carbide Grades

● Comparing Binder Materials in Tungsten Carbide

● Innovations in Lightweight Tungsten Carbide

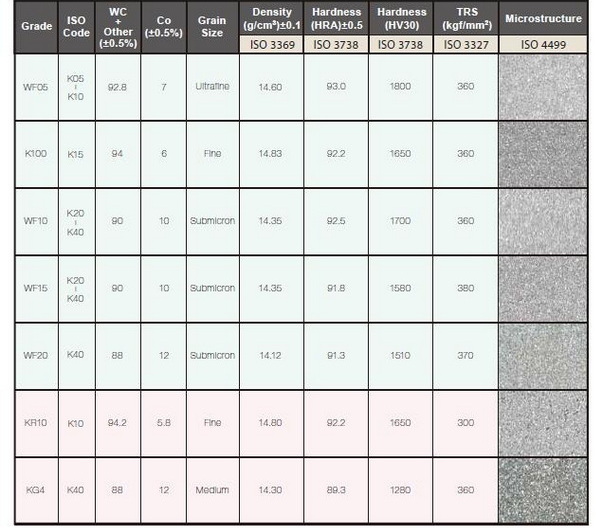

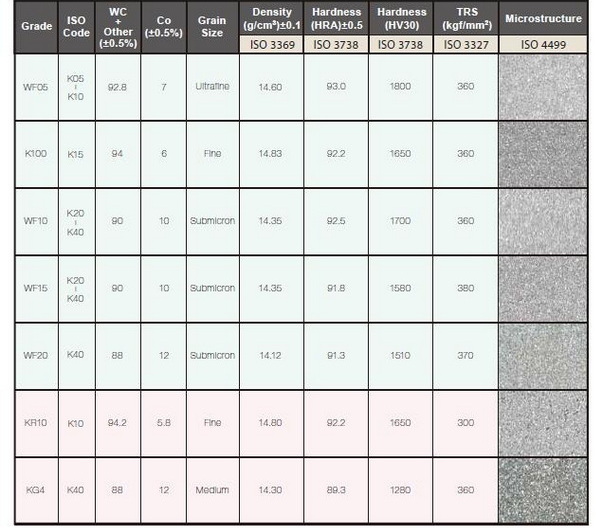

● Visual Guide: Tungsten Carbide Grades

● Conclusion

● FAQ: Frequently Asked Questions About Tungsten Carbide Grades

>> 1. What is the lightest tungsten carbide grade?

>> 2. How does grain size affect the weight of tungsten carbide?

>> 3. What are common applications for lightweight tungsten carbides?

>> 4. How does binder type impact the weight of tungsten carbide?

>> 5. Can lightweight tungsten carbides maintain high wear resistance?

● Citations:

Tungsten carbide is a composite material renowned for its exceptional hardness, wear resistance, and versatility. However, not all tungsten carbide grades are created equal. The composition of tungsten carbide, including the grain size and binder material, determines its properties, including weight. This article explores the lightest tungsten carbide grades, their characteristics, and applications while providing visual aids to enhance understanding.

Understanding Tungsten Carbide Grades

Tungsten carbide grades are classified based on their composition and properties. The two main components of tungsten carbide are:

1. Tungsten Carbide (WC): The hard phase that provides wear resistance.

2. Binder Material: Typically cobalt (Co) or nickel (Ni), which adds toughness.

The grade of tungsten carbide is determined by:

- The percentage of tungsten carbide and binder.

- Grain size (ultra-fine, fine, medium, or coarse).

- Hardness and density.

Key Properties of Tungsten Carbide

- Hardness: Resistance to deformation or scratching.

- Density: Determines the weight of the material.

- Toughness: Resistance to cracking or breaking under stress.

What Makes a Tungsten Carbide Grade "Light"?

The lightest tungsten carbide grades typically have:

1. A lower percentage of tungsten carbide (WC).

2. A higher proportion of lighter binders like nickel or titanium alloys.

3. Coarser grain sizes, which reduce density.

For example:

- Grades with 70%-75% WC and 25%-30% binder are lighter than those with 90%-94% WC.

- Nickel-bonded carbides tend to be lighter than cobalt-bonded carbides due to the lower density of nickel.

Examples of Light Tungsten Carbide Grades

1. K30 Grade

- Composition: 70% WC, 30% Cobalt Binder.

- Density: ~12.7 g/cm³.

- Characteristics: Lower hardness but higher toughness; suitable for light-impact applications.

2. VM-L501 (Mixed Binder)

- Composition: 78% WC with mixed binders (22% tantalum-niobium carbide).

- Density: ~11.85 g/cm³.

- Characteristics: High wear resistance and corrosion resistance; lightweight due to mixed binders.

3. Ultra-Fine Grain Grades

Ultra-fine grain sizes reduce weight while maintaining hardness. For example:

- TMK-326 (6% cobalt binder): A micrograin grade with a density of ~14.85 g/cm³ but optimized for light cutting applications.

Applications of Light Tungsten Carbide Grades

Light tungsten carbide grades are ideal for applications where weight reduction is critical without compromising performance:

1. Aerospace Components: Lightweight tools and parts for fuel efficiency.

2. Medical Instruments: Durable yet lightweight surgical tools.

3. Sports Equipment: High-performance golf clubs or bicycle components.

4. Wear Parts: Compacting dies and nozzles in industries requiring high wear resistance but reduced weight.

Comparing Binder Materials in Tungsten Carbide

Binders play a critical role in determining the weight, toughness, and corrosion resistance of tungsten carbide grades. Below is a comparison between cobalt and nickel binders:

| Property | Cobalt Binder | Nickel Binder |

| Density | Higher (~8.9 g/cm³) | Lower (~8.1 g/cm³) |

| Corrosion Resistance | Moderate | Excellent |

| Toughness | Higher | Moderate |

| Applications | General-purpose tools | Chemical-resistant tools |

Nickel-bonded tungsten carbides are often preferred for lightweight applications due to their lower density and superior corrosion resistance.

Innovations in Lightweight Tungsten Carbide

Recent advancements in tungsten carbide manufacturing have focused on creating lighter grades without sacrificing performance:

1. Nanostructured Tungsten Carbide: Incorporating nanotechnology reduces grain size further while optimizing hardness and toughness.

2. Hybrid Binders: Combining cobalt with titanium or tantalum improves weight reduction while maintaining durability.

3. Additive Manufacturing: 3D printing techniques allow precise control over material composition and density, enabling lightweight designs.

These innovations have expanded the use of tungsten carbide in industries like automotive manufacturing and renewable energy.

Tungsten Carbide Grades

different tungsten carbide applications:

1. Tungsten Carbide Inserts

Tungsten carbide inserts used in industrial machining.

2. Drill Bit with Tungsten Carbide Teeth

Spiral drill bit tipped with tungsten carbide.

3. Cemented Carbide Cutting Tools

Cutting tools made from cemented tungsten carbide.

4. Lightweight Aerospace Components

Aircraft parts made from lightweight tungsten carbide.

Conclusion

The lightest tungsten carbide grades balance wear resistance with reduced density by adjusting the composition of tungsten carbide and binder materials. These grades are essential in industries where weight reduction improves performance without sacrificing durability.

By carefully selecting the appropriate grade based on application requirements—such as hardness, toughness, and weight—manufacturers can achieve optimal results in various fields, from aerospace to medical tools.

FAQ: Frequently Asked Questions About Tungsten Carbide Grades

1. What is the lightest tungsten carbide grade?

The lightest grades typically have lower percentages of tungsten carbide (e.g., 70%-75%) combined with higher binder content like cobalt or nickel. Examples include K30 (70% WC) and VM-L501 (78% WC).

2. How does grain size affect the weight of tungsten carbide?

Grain size influences density; coarser grains tend to reduce overall density, making the material lighter but less hard compared to ultra-fine grains.

3. What are common applications for lightweight tungsten carbides?

Lightweight grades are used in aerospace components, medical instruments, sports equipment, and compacting dies where reduced weight is critical.

4. How does binder type impact the weight of tungsten carbide?

Nickel binders are lighter than cobalt binders, making nickel-bonded carbides less dense while maintaining good corrosion resistance.

5. Can lightweight tungsten carbides maintain high wear resistance?

Yes, by optimizing grain size and binder composition, lightweight grades can achieve excellent wear resistance while reducing density.

Citations:

[1] https://centennialcarbide.com/carbide-grades/

[2] https://www.hyperionmt.com/en/products/Carbide-Rolls/grade-data/

[3] https://craftstech.net/wp-content/uploads/2021/05/Crafts-Whitepaper-Proper-Grade-Selection-for-Cemented-Tungsten-Carbide-Tooling-and-Wear-Part-Applications.pdf

[4] https://www.alamy.com/stock-photo/tungsten-carbide.html

[5] https://carbide.ultra-met.com/viewitems/iso-grades/iso-grade-classifications-tungsten-carbide

[6] https://conicalendmills.com/resources/materials/

[7] https://en.wikipedia.org/wiki/Tungsten_carbide

[8] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-GradeSpecs.pdf

[9] https://www.vistametalsinc.com/tungsten-carbide-grade-chart/

[10] http://www.tungsten-carbide.com.cn/tungsten-carbide-grade.html

[11] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

[12] https://www.basiccarbide.com/tungsten-carbide-grade-chart/

[13] https://www.imetra.com/tungsten-carbide-material-properties/

[14] https://s7d2.scene7.com/is/content/Kennametal/KMT_metalforming_grades_and_application_guide_ENpdf

[15] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-grades.html

[16] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/grade-chart

[17] https://hbcarbide.com/wp-content/uploads/2021/12/HB-Carbide-Grade-Selection-and-Blank-Design-Guide.pdf

[18] https://www.vistametalsinc.com/pdf/Tungsten-Carbide-Grade-Chart.pdf

[19] https://www.innovativecarbide.com/grades/

[20] https://www.vistametalsinc.com/tungsten-carbide-grade-chart/

[21] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/tungsten-carbide-grades-applications

[22] https://blog.carbideprocessors.com/tungsten-carbide/carbide-grades/

[23] https://stock.adobe.com/search?k=tungsten+carbide

[24] https://www.istockphoto.com/photos/tungsten-carbide

[25] https://periodictable.com/Elements/074/pictures.html

[26] https://stock.adobe.com/search?k=carbide

[27] https://www.shutterstock.com/search/tungsten

[28] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[29] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[30] http://www.machiningtech.com/tungsten-carbide-grade-Chart.html

[31] https://www.ctemag.com/sites/www.ctemag.com/files/archive_pdf/0802-Tungsten.pdf

[32] https://hbcarbide.com/carbide-grade-selection/