Content Menu

● Understanding Tungsten Carbide

● Tungsten Carbide in Cutting Tools

● Cutting Porcelain with Tungsten Carbide

● Tools for Cutting Porcelain Tiles

● Best Practices for Cutting Porcelain Tiles

● Advantages of Using Tungsten Carbide for Cutting Porcelain

● Limitations and Considerations

● Other Applications of Tungsten Carbide

● Future of Tungsten Carbide in Cutting Technology

● Conclusion

● FAQ

>> 1. How long do tungsten carbide cutting tools typically last?

>> 2. Can tungsten carbide tools be resharpened?

>> 3. Are there any health risks associated with using tungsten carbide tools?

>> 4. How does the cost of tungsten carbide tools compare to other materials?

>> 5. Can tungsten carbide tools be used for cutting materials other than porcelain?

● Citations:

Tungsten carbide is a remarkable material known for its exceptional hardness and durability. When it comes to cutting tough materials like porcelain, many wonder if tungsten carbide is up to the task. In this comprehensive article, we'll explore the properties of tungsten carbide, its applications in cutting tools, and its effectiveness in cutting porcelain tiles.

Understanding Tungsten Carbide

Tungsten carbide is a compound made of tungsten and carbon atoms. It possesses unique properties that make it highly valuable in various industries:

1. Extreme hardness: Tungsten carbide has a hardness of 91-91.5 HRA, making it one of the hardest materials known, second only to diamond[1].

2. High density: This material is denser than steel, contributing to its strength and durability.

3. Heat resistance: Tungsten carbide can withstand extremely high temperatures, making it ideal for use in cutting tools[2].

4. Wear and corrosion resistance: Its ability to resist wear and corrosion makes it perfect for applications requiring long-lasting performance[2].

Tungsten Carbide in Cutting Tools

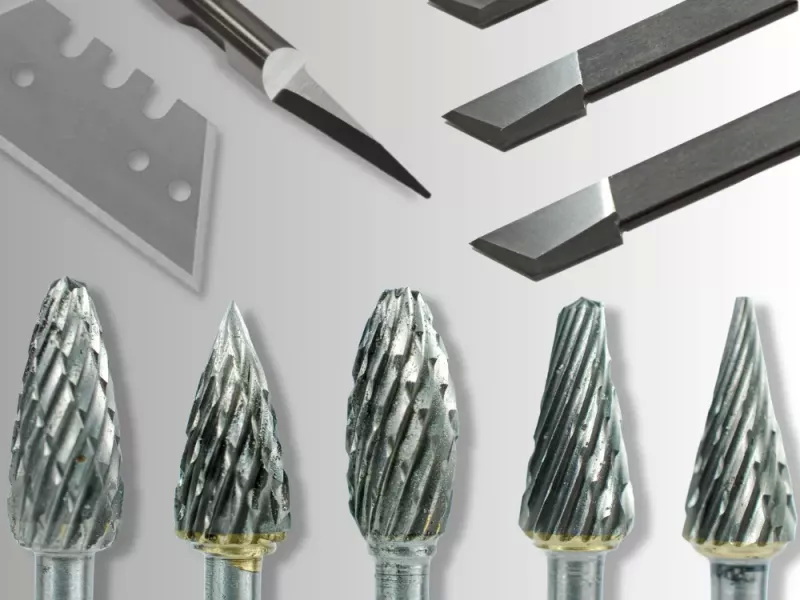

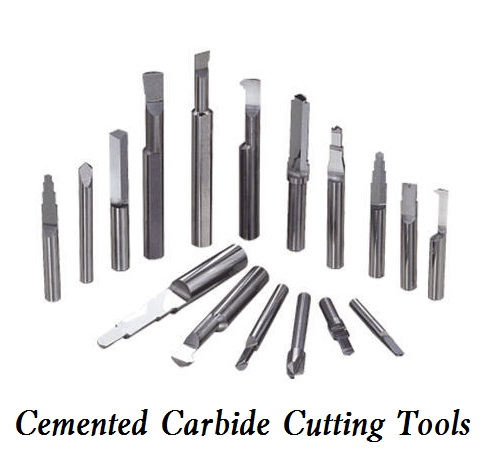

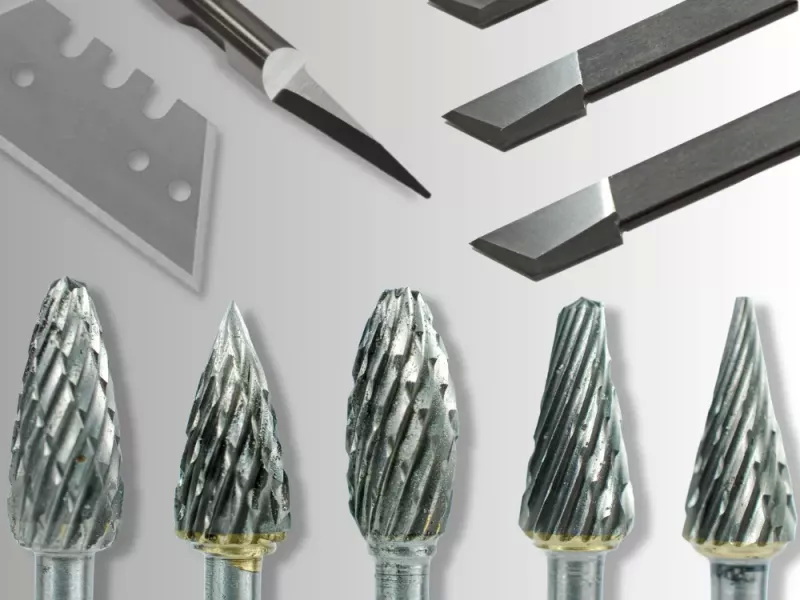

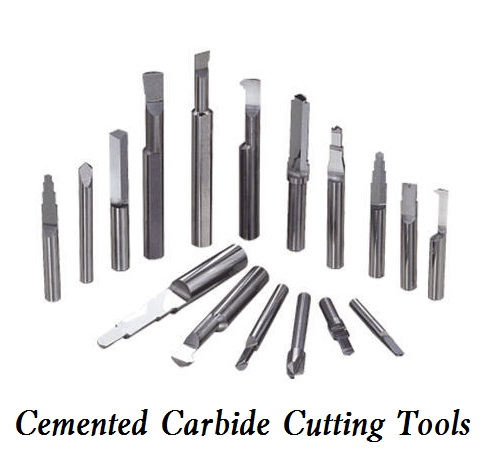

The exceptional properties of tungsten carbide make it an excellent choice for cutting tools. Here are some common applications:

1. Machining tools: Tungsten carbide is widely used in drill bits, milling cutters, and other machining tools for cutting hard materials like steel and titanium[9].

2. Construction tools: Saws and drill bits used in construction often feature tungsten carbide tips due to their ability to cut through tough materials like cement and asphalt[2].

3. Tile cutters: Manual tile cutters often use tungsten carbide scoring wheels for precise cuts on various types of tiles[4].

Cutting Porcelain with Tungsten Carbide

Now, let's address the main question: Can tungsten carbide cut porcelain? The answer is yes, tungsten carbide can effectively cut porcelain tiles. Here's why:

1. Hardness advantage: Porcelain is a very hard material, but tungsten carbide's superior hardness allows it to cut through porcelain effectively[3].

2. Precision cutting: Tungsten carbide tools can make clean, precise cuts on porcelain tiles without chipping or cracking the material[3].

3. Durability: The wear resistance of tungsten carbide ensures that cutting tools maintain their sharpness for longer periods, even when cutting hard materials like porcelain[2].

Tools for Cutting Porcelain Tiles

Several tools incorporating tungsten carbide are used for cutting porcelain tiles:

1. Manual tile cutters: These often feature tungsten carbide scoring wheels for making straight cuts on porcelain tiles[4].

2. Wet saws: Diamond-tipped blades, which contain tungsten carbide, are commonly used in wet saws for cutting porcelain tiles[3].

3. Nippers: Some tile nippers use tungsten carbide tips for making small, precise cuts or shaping porcelain tiles[3].

Best Practices for Cutting Porcelain Tiles

To achieve the best results when cutting porcelain tiles with tungsten carbide tools, follow these tips:

1. Use the right tool: Choose a tool appropriate for the type of cut you need to make. For straight cuts, a manual cutter or wet saw works well. For curved cuts, use nippers or a wet saw with a diamond blade[3].

2. Mark accurately: Use a grease pencil to mark your cutting line precisely. Measure twice to ensure accuracy[3].

3. Cut slowly: When using a wet saw, let the blade do the work. Don't force it through the tile too quickly[3].

4. Safety first: Always wear proper safety equipment, including goggles and gloves, when cutting tiles[3].

Advantages of Using Tungsten Carbide for Cutting Porcelain

1. Longevity: Tungsten carbide tools last longer than traditional steel tools, reducing the need for frequent replacements[2].

2. Precision: The hardness and sharpness of tungsten carbide allow for more precise cuts on porcelain tiles[3].

3. Versatility: Tungsten carbide tools can cut through various materials, not just porcelain, making them versatile for different projects[2].

4. Cost-effective: While initially more expensive, the durability of tungsten carbide tools makes them cost-effective in the long run[2].

Limitations and Considerations

While tungsten carbide is excellent for cutting porcelain, there are some limitations to consider:

1. Cost: Tungsten carbide tools are generally more expensive than traditional steel tools[5].

2. Brittleness: Despite its hardness, tungsten carbide can be brittle and may chip if dropped or mishandled[5].

3. Sharpening: Tungsten carbide tools require special equipment for sharpening, which can be an additional cost[5].

4. Weight: Due to its high density, tungsten carbide tools can be heavier than their steel counterparts[2].

Other Applications of Tungsten Carbide

Beyond cutting porcelain, tungsten carbide finds use in various other applications:

1. Mining: Tungsten carbide is used in drill bits and other mining equipment due to its wear resistance[8].

2. Ammunition: Some armor-piercing rounds use tungsten carbide due to its high density and hardness[8].

3. Jewelry: Tungsten carbide's scratch resistance makes it popular for wedding bands and other jewelry[8].

4. Surgical instruments: The material's corrosion resistance and ability to hold a sharp edge make it ideal for surgical tools[2].

Future of Tungsten Carbide in Cutting Technology

As technology advances, we can expect to see further improvements in tungsten carbide cutting tools:

1. Enhanced coatings: New coatings may improve the heat resistance and durability of tungsten carbide tools even further[2].

2. Nano-grain carbides: Development of tungsten carbide with smaller grain sizes could lead to even harder and more wear-resistant tools.

3. Composite materials: Combining tungsten carbide with other materials may create cutting tools with enhanced properties.

4. Recycling advancements: Improved recycling techniques for tungsten carbide could make these tools more environmentally friendly and cost-effective[5].

Conclusion

Tungsten carbide is indeed an excellent material for cutting porcelain tiles. Its exceptional hardness, wear resistance, and ability to maintain a sharp edge make it ideal for this challenging task. While there are some limitations, such as higher initial costs and potential brittleness, the benefits of using tungsten carbide tools for cutting porcelain far outweigh these drawbacks. As technology continues to advance, we can expect even more innovative applications of tungsten carbide in cutting tools, further cementing its place as a crucial material in the world of precision cutting.

FAQ

1. How long do tungsten carbide cutting tools typically last?

Tungsten carbide cutting tools can last significantly longer than traditional steel tools, often up to 100 times longer depending on the application and usage. However, the exact lifespan depends on factors such as the specific tool, the material being cut, and how frequently the tool is used.

2. Can tungsten carbide tools be resharpened?

Yes, tungsten carbide tools can be resharpened, but it requires specialized equipment and expertise. The process often involves diamond grinding wheels due to the extreme hardness of tungsten carbide. It's important to note that not all tungsten carbide tools can be resharpened, particularly those with complex geometries or special coatings.

3. Are there any health risks associated with using tungsten carbide tools?

While tungsten carbide itself is not considered toxic, the dust produced when cutting or grinding tungsten carbide can be harmful if inhaled. It's crucial to use proper ventilation and wear appropriate personal protective equipment when working with these tools. Additionally, cobalt, which is often used as a binder in tungsten carbide tools, can pose health risks if exposed to high levels over long periods.

4. How does the cost of tungsten carbide tools compare to other materials?

Tungsten carbide tools are generally more expensive upfront compared to tools made from materials like high-speed steel. However, their longer lifespan and superior performance often make them more cost-effective in the long run, especially for professional use or high-volume production.

5. Can tungsten carbide tools be used for cutting materials other than porcelain?

Absolutely. Tungsten carbide tools are versatile and can be used to cut a wide range of materials, including various types of metal, stone, wood, and composites. Their hardness and wear resistance make them particularly suitable for cutting abrasive or hard materials that would quickly wear out tools made from softer materials.

Citations:

[1] https://zzzhongchengcarbide.en.made-in-china.com/product/njhmNOMdrzWG/China-Tungsten-Carbide-Cut-off-Wheel-for-Ceramic-Tile.html

[2] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[3] https://www.rubi.com/en/blog/how-to-cut-porcelain-tile/

[4] https://www.alibaba.com/showroom/tungsten-carbide-manual-tile-cutter.html

[5] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[6] https://www.mycarbides.com/will-tungsten-carbide-cut-porcelain-ceramic/

[7] https://www.aliexpress.com/item/1005007457870012.html

[8] https://en.wikipedia.org/wiki/Tungsten_carbide

[9] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[10] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html