Content Menu

● Introduction to Calcium Carbide and Acetylene Gas

● The Chemical Basis for Using Calcium Carbide in Acetylene Production

>> High Reactivity and Efficiency

>> Energy Density and Flame Temperature

● Industrial Production Process of Acetylene Gas from Calcium Carbide

>> Step 1: Production of Calcium Carbide

>> Step 2: Generation of Acetylene Gas

>> Step 3: Gas Purification and Compression

● Applications of Acetylene Gas Produced from Calcium Carbide

>> Welding and Cutting

>> Chemical Synthesis

>> Metallurgy

>> Mining and Drilling

>> Agriculture

● Advantages of Using Calcium Carbide for Acetylene Production

● Safety Considerations in Acetylene Production Using Calcium Carbide

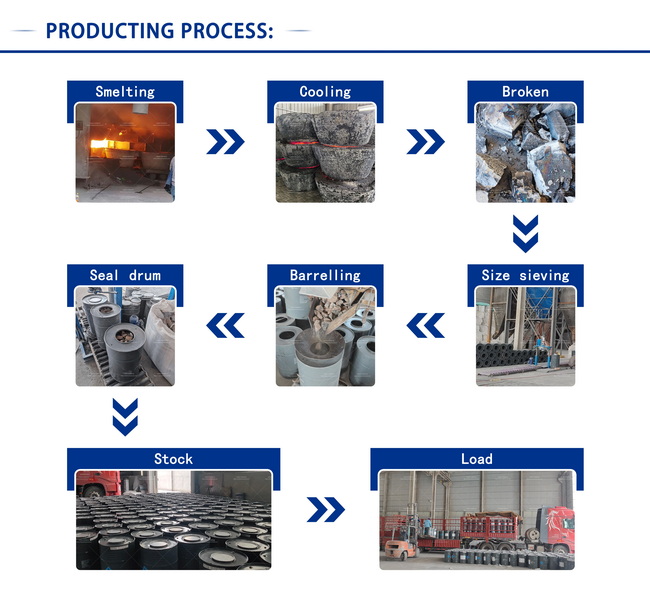

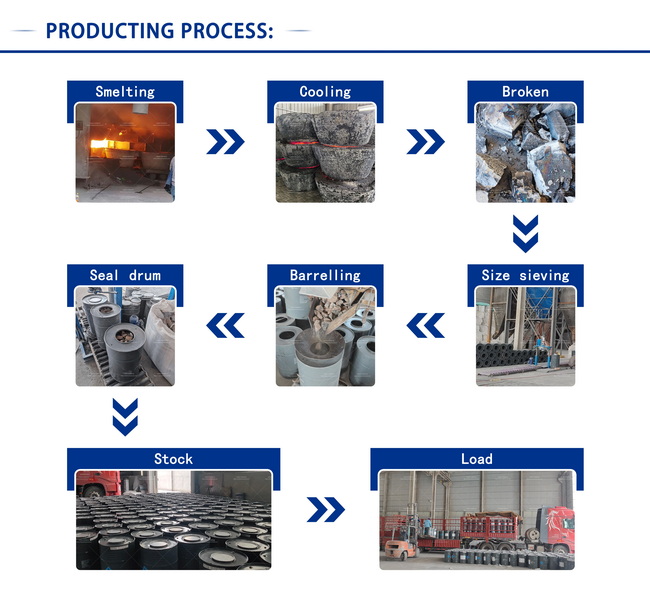

● Visual Aids: Illustrations and Diagrams

>> 1. Chemical Reaction Diagram

>> 2. Flowchart of Acetylene Production from Calcium Carbide

>> 3. Acetylene Generator Schematic

>> 4. Oxy-Acetylene Welding Setup

● Environmental Impact and Sustainability in Calcium Carbide and Acetylene Production

● Innovations and Future Trends in Acetylene Production

● Conclusion

● FAQ About Calcium Carbide and Acetylene Gas Production

>> 1. What is the chemical reaction involved in producing acetylene gas from calcium carbide?

>> 2. Why is calcium carbide preferred over other raw materials for acetylene production?

>> 3. What are the main industrial uses of acetylene gas produced from calcium carbide?

>> 4. How is safety ensured during acetylene production from calcium carbide?

>> 5. What factors affect the purity and yield of acetylene gas from calcium carbide?

● Citations:

Calcium carbide (CaC₂) is a pivotal chemical compound in the industrial production of acetylene gas (C₂H₂), a highly versatile and energy-rich gas widely used across various sectors including welding, chemical synthesis, metallurgy, and construction. This article explores why calcium carbide is the preferred raw material for acetylene gas production, detailing the chemical processes involved, industrial applications, advantages, safety considerations, environmental impacts, innovations, and future prospects. Richly illustrated with diagrams and process flowcharts, this comprehensive guide also concludes with a FAQ section addressing common queries related to calcium carbide and acetylene production.

Introduction to Calcium Carbide and Acetylene Gas

Calcium carbide is a white to grayish crystalline solid produced industrially by heating lime (CaO) and coke (carbon) in an electric arc furnace at temperatures exceeding 2000°C. The reaction produces calcium carbide and carbon monoxide:

CaO+3C→CaC2+CO

When calcium carbide reacts with water, it generates acetylene gas and calcium hydroxide as a byproduct:

CaC2+2H2O→C2H2+Ca(OH)2

This reaction is highly exothermic and forms the basis of acetylene gas production from calcium carbide.

The Chemical Basis for Using Calcium Carbide in Acetylene Production

High Reactivity and Efficiency

Calcium carbide's unique chemical structure enables it to react readily with water, releasing acetylene gas efficiently. The reaction is simple, controllable, and yields a high volume of acetylene gas per unit of calcium carbide used. High-quality calcium carbide with low impurities ensures maximum gas yield and purity, which is critical for industrial applications.

Energy Density and Flame Temperature

Acetylene gas produced from calcium carbide burns with an extremely high flame temperature (up to 3200°C when combined with oxygen), making it ideal for welding, cutting, and metal fabrication. This high-temperature flame results from the energy stored in the calcium-carbon bonds in calcium carbide, released upon reaction with water.

Industrial Production Process of Acetylene Gas from Calcium Carbide

Step 1: Production of Calcium Carbide

- Raw materials: Limestone (CaCO₃) and coke (carbon).

- Process: Heating in an electric arc furnace at ~2000°C.

- Output: Calcium carbide and carbon monoxide gas.

Step 2: Generation of Acetylene Gas

- Calcium carbide is fed into a water-filled acetylene generator.

- The reaction with water produces acetylene gas and calcium hydroxide slurry.

- The acetylene gas is then cooled, dried, and purified to remove impurities like hydrogen sulfide and phosphine.

Step 3: Gas Purification and Compression

- The acetylene gas passes through condensers and driers (often using anhydrous calcium chloride).

- Purifiers remove impurities to ensure high gas quality.

- Finally, the gas is compressed and stored in cylinders containing acetone and porous materials to stabilize the acetylene.

Applications of Acetylene Gas Produced from Calcium Carbide

Welding and Cutting

Acetylene gas is widely used in oxy-acetylene welding and cutting due to its high flame temperature and clean combustion. It allows precise metal joining and cutting, essential in construction, automotive, and manufacturing industries.

Chemical Synthesis

Acetylene is a key precursor in producing various organic chemicals such as vinyl chloride (for PVC production), acrylonitrile, vinyl acetate, acetaldehyde, and acetic acid. These chemicals are foundational for plastics, synthetic fibers, adhesives, and coatings.

Metallurgy

Calcium carbide and acetylene gas are used in steelmaking for desulfurization and deoxidation, improving steel quality by removing impurities.

Mining and Drilling

Acetylene gas is used for metal cutting and welding in mining operations and for manufacturing mining tools, benefiting from its portability and high energy output.

Agriculture

Acetylene can be converted to ethylene, a plant hormone used to regulate fruit ripening, extending shelf life and improving agricultural productivity.

Advantages of Using Calcium Carbide for Acetylene Production

| Advantage | Explanation |

| High Gas Yield | High-quality calcium carbide produces more acetylene per unit, improving efficiency. |

| Purity Control | Low impurity calcium carbide ensures high acetylene purity, critical for sensitive applications. |

| Cost-Effectiveness | Calcium carbide is relatively inexpensive and easy to transport, reducing production costs. |

| Energy-Rich Reaction | The exothermic reaction releases significant heat, facilitating energy-efficient processes. |

| Versatility | Acetylene produced can be used in diverse industries from welding to chemical manufacturing. |

Safety Considerations in Acetylene Production Using Calcium Carbide

The reaction between calcium carbide and water is highly exothermic, releasing heat that can cause dangerous conditions if not properly controlled. Acetylene gas is highly flammable and explosive, requiring strict safety protocols in production, storage, and transportation.

Key safety measures include:

- Temperature control systems with cooling to prevent overheating.

- Use of spark-proof equipment and flash arrestors.

- Continuous monitoring of pressure and water levels.

- Proper storage of acetylene in acetone-filled cylinders with porous fillers to stabilize the gas.

Visual Aids: Illustrations and Diagrams

1. Chemical Reaction Diagram

CaC₂ + 2H₂O → C₂H₂ + Ca(OH)₂ + Heat

2. Flowchart of Acetylene Production from Calcium Carbide

- Raw Materials (Lime + Coke) → Electric Arc Furnace → Calcium Carbide

- Calcium Carbide + Water → Acetylene Gas + Calcium Hydroxide

- Gas Cooling → Drying → Purification → Compression → Storage

3. Acetylene Generator Schematic

- Calcium carbide hopper

- Water reservoir

- Reaction chamber with agitator

- Gas outlet with condenser and drier

- Safety valves and flash arrestors

4. Oxy-Acetylene Welding Setup

- Acetylene cylinder

- Oxygen cylinder

- Welding torch with flame control

Environmental Impact and Sustainability in Calcium Carbide and Acetylene Production

As industries worldwide move towards sustainable practices, the environmental impact of calcium carbide production and acetylene gas generation is gaining attention. The production process involves high energy consumption due to the electric arc furnace operation, which emits carbon monoxide and other greenhouse gases. However, advancements in energy efficiency and emission control technologies are helping to mitigate these effects.

Recycling calcium hydroxide byproducts and optimizing raw material usage contribute to reducing waste. Moreover, acetylene gas, when used efficiently in welding and cutting, can reduce energy consumption compared to other fuel gases, supporting greener industrial operations.

Innovations and Future Trends in Acetylene Production

Research continues to improve the production of calcium carbide and acetylene gas, focusing on reducing environmental footprint and enhancing safety. Innovations include the development of alternative raw materials, improved furnace designs for lower energy consumption, and advanced purification methods to increase acetylene quality.

The integration of digital monitoring and automation in acetylene generators enhances process control, minimizing risks and improving efficiency. These trends indicate a promising future for sustainable and safe acetylene production from calcium carbide.

Conclusion

Calcium carbide is indispensable in the industrial production of acetylene gas due to its unique chemical properties, high reactivity, and cost-effectiveness. The reaction of calcium carbide with water produces acetylene gas efficiently, which is essential for welding, cutting, chemical synthesis, metallurgy, and many other industrial applications. High-quality calcium carbide ensures superior gas yield and purity, enhancing production efficiency and product quality. Despite the inherent risks associated with acetylene's flammability and the exothermic reaction, stringent safety measures and advanced equipment designs have made acetylene production from calcium carbide a reliable and widespread industrial process. As demand for acetylene continues to grow, calcium carbide remains a cornerstone raw material, driving innovation and sustainability in acetylene gas production.

FAQ About Calcium Carbide and Acetylene Gas Production

1. What is the chemical reaction involved in producing acetylene gas from calcium carbide?

Calcium carbide reacts with water to produce acetylene gas and calcium hydroxide, as shown by the equation:

CaC2+2H2O→C2H2+Ca(OH)2

This reaction is exothermic and forms the basis of acetylene gas production.

2. Why is calcium carbide preferred over other raw materials for acetylene production?

Calcium carbide is preferred because it reacts readily and efficiently with water to produce a high yield of acetylene gas. It is cost-effective, easy to store and transport, and produces acetylene with fewer impurities compared to other methods like thermal cracking.

3. What are the main industrial uses of acetylene gas produced from calcium carbide?

Acetylene gas is primarily used in oxy-acetylene welding and cutting, chemical synthesis for plastics and synthetic fibers, metallurgy for steel desulfurization, mining operations, and agricultural applications for ethylene production.

4. How is safety ensured during acetylene production from calcium carbide?

Safety is ensured through strict temperature control to manage the exothermic reaction heat, use of spark-proof equipment, flash arrestors, continuous monitoring systems, and proper storage of acetylene in stabilized cylinders to prevent explosions.

5. What factors affect the purity and yield of acetylene gas from calcium carbide?

The quality and impurity content of calcium carbide directly affect acetylene gas purity and yield. High-purity calcium carbide with low sulfur, phosphorus, and iron impurities produces higher yields of purer acetylene gas, which is crucial for industrial applications.

Citations:

[1] https://www.tjtywh.com/a-the-importance-of-acetylene-calcium-carbide-in-industrial-applications.html

[2] https://www.tjtywh.com/the-core-role-and-advantages-of-calcium-carbide-in-acetylene-production.html

[3] https://tianyuanweihong.en.made-in-china.com/product/yXTJfBkvgIpt/China-High-Quality-Calcium-Carbide-for-Acetylene-Gas-Welding-Industrial-Applications.html

[4] https://www.alzchem.com/fileadmin/Marken/Technische_Gase/20220924_Technical_Gases_2-Seiter_WEB.pdf

[5] http://enggyd.blogspot.com/2012/03/acetylene-production-process-using.html

[6] https://www.tjtywh.com/common-faqs-about-calcium-carbide-10-key-questions-customers-care-about.html

[7] https://www.doubtnut.com/qna/46932710

[8] https://www.hitechgas.com/acetylene/acetylene-plants/how-acetylene-plant-produce-acetylene/

[9] https://www.tjtywh.com/how-to-ensure-safety-in-acetylene-production-using-calcium-carbide.html

[10] https://www.tjtywh.com/a-the-uses-and-production-of-acetylene-calcium-carbide.html

[11] https://www.tjtywh.com/a-the-role-of-acetylene-calcium-carbide-in-industrial-applications.html

[12] https://ocw.mit.edu/courses/22-033-nuclear-systems-design-project-fall-2011/4a2d1059fade1cce993afc566d35e42d_MIT22_033F11_lec07_note.pdf

[13] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[14] https://www.alzchem.com/en/company/news/calcium-carbide-for-acetylene-production/

[15] https://www.acetyleneplant.net/technology/process-description-of-acetylene-plant/

[16] https://rexarc.com/blog/calcium-carbide-for-acetylene-production/

[17] https://en.wikipedia.org/wiki/Calcium_carbide

[18] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[19] https://www.acs.org/education/whatischemistry/landmarks/calciumcarbideacetylene.html

[20] https://www.sciencedirect.com/science/article/abs/pii/S0306261924011504

[21] https://www.sciencedirect.com/science/article/pii/S0959652621032443

[22] https://air-source.com/blog/industrial-and-commercial-acetylene-gas-applications/

[23] https://www.eiga.eu/uploads/documents/DOC226.pdf

[24] https://www.fortunebusinessinsights.com/blog/calcium-carbide-market-9577

[25] https://www.sciencedirect.com/science/article/abs/pii/S0306261922013964

[26] https://onlinelibrary.wiley.com/doi/abs/10.1002/0471238961.0103052013011425.a01

[27] https://cdn.intratec.us/docs/reports/previews/acetylene-e31a-b.pdf

[28] https://www.eiga.eu/uploads/documents/DOC241.pdf

[29] https://melscience.com/US-en/articles/chemical-characteristics-calcium-carbide-and-its-r/

[30] https://www.basf.com/global/en/who-we-are/organization/locations/europe/german-sites/ludwigshafen/production/the-production-verbund/new_acetylene_facility

[31] https://www.gettyimages.com/photos/calcium-carbide

[32] https://www.istockphoto.com/photos/oxygen-acetylene-welding-cutting

[33] https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s04.pdf

[34] https://www.alamy.com/stock-photo/calcium-carbide-and-water.html

[35] https://www.acetylenegasplant.com/acetylene-gas.php

[36] https://www.shutterstock.com/search/acetylene-welding

[37] https://www.shutterstock.com/search/calcium-carbide

[38] https://camachem.com/es/blog/post/frequently-asked-question-about-calcium-carbide

[39] https://www.vedantu.com/question-answer/prepare-acetylene-from-calcium-carbide-class-11-chemistry-cbse-5f853c444dddb9022398bb07

[40] https://www.airproducts.co.uk/gases/acetylene/acetylene-faqs

[41] https://sathee.prutor.ai/article/chemistry/chemistry-calcium-carbide/

[42] https://www.bocgases.co.uk/files/Facts_about_acetylene.pdf

[43] https://www.eiga.eu/uploads/documents/DOC023H.pdf

[44] https://www.acetylenegasplant.com/faq.php

[45] https://www.acetylenegasplant.com/safety.php

[46] https://www.vedantu.com/chemistry/calcium-carbide

[47] https://www.alamy.com/stock-photo/calcium-reaction-water.html

[48] https://zh.wikipedia.org/zh-cn/en:acetylene

[49] https://byjus.com/chemistry/calcium-carbide/

[50] https://www.alamy.com/stock-photo/oxy-fuel-cutting.htm