Content Menu

● Introduction to Carbide Lathe Tools

● Applications of Carbide Lathe Tools

>> Turning Operations

>> Facing Operations

>> Threading and Grooving

● Benefits of Carbide Lathe Tools

● Carbide Lathe Tooling in Production Shops

>> Customization and Versatility

>> Environmental Sustainability

>> Industry Applications

● Advanced Coatings and Technologies

>> DLC Coatings

>> Nanocomposite Coatings

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary materials used in carbide lathe tools?

>> 2. How do carbide lathe tools compare to high-speed steel (HSS) tools?

>> 3. What are the common applications of carbide lathe tools?

>> 4. Can carbide lathe tools be sharpened?

>> 5. What are the environmental benefits of using carbide lathe tools?

● Citations:

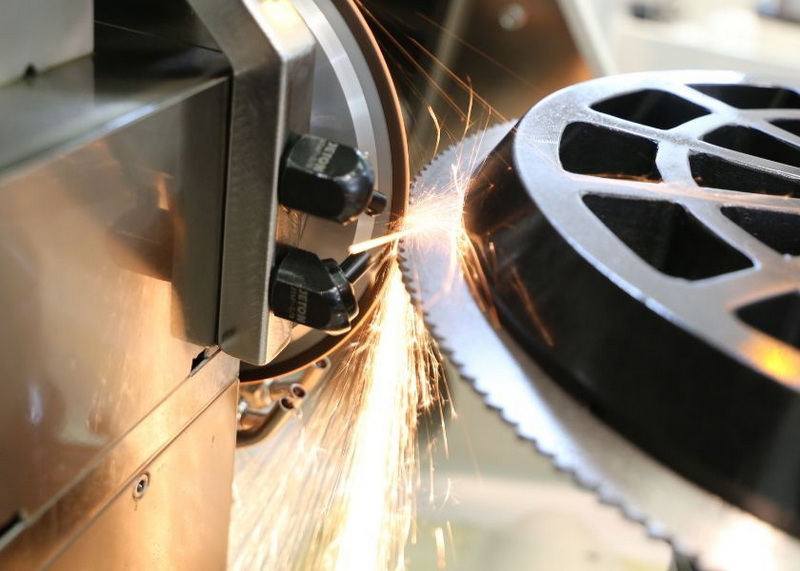

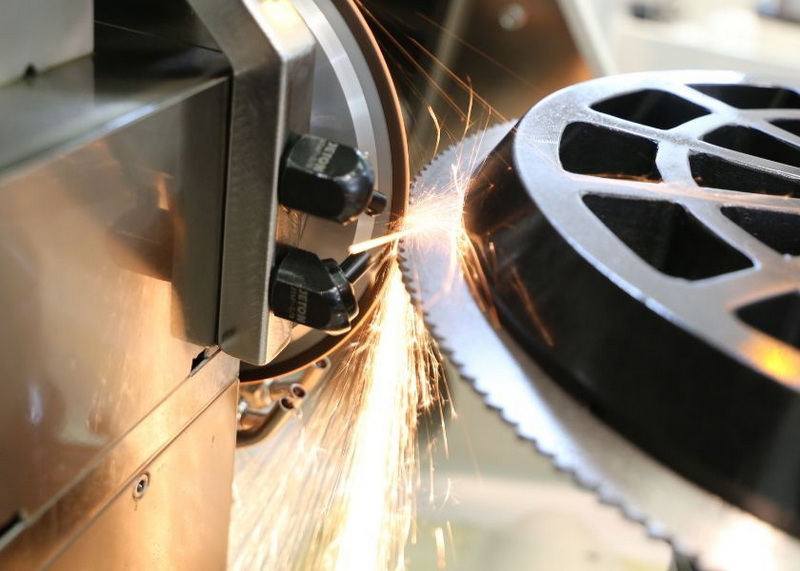

In the realm of industrial machining, precision and efficiency are paramount. Among the various tools available, carbide lathe tools have emerged as a preferred choice for manufacturers due to their exceptional durability, speed, and precision. This article delves into the reasons why carbide lathe tools are indispensable in modern machining processes, highlighting their applications, benefits, and how they enhance productivity in production environments.

Introduction to Carbide Lathe Tools

Carbide lathe tools are crafted from tungsten carbide, a compound renowned for its hardness, second only to diamond. This hardness allows carbide tools to withstand the demanding conditions of machining, including high-speed operations and the cutting of tough metals like stainless steel and titanium. The tools are often made with a carbide tip attached to a less brittle steel body, providing both hardness and structural integrity.

Applications of Carbide Lathe Tools

Carbide lathe tooling is generally used in production shops for various machining operations, including turning, facing, threading, and grooving. These tools are versatile and can be customized with coatings like titanium nitride (TiN) or titanium carbonitride (TiCN), which enhance their wear resistance and performance.

Turning Operations

Turning involves rotating the workpiece while the cutting tool removes material from its surface. Carbide inserts are ideal for this operation due to their ability to withstand high temperatures and speeds, making them suitable for high-volume production environments.

Facing Operations

Facing tools are used to smooth down the surface of a material at a right angle while it rotates. Although often made from HSS, carbide-tipped facing tools can provide superior hardness and longevity.

Threading and Grooving

Carbide tools are also used for threading and grooving operations, where precision and durability are crucial. These tools can be designed for specific tasks, ensuring optimal performance.

Benefits of Carbide Lathe Tools

The benefits of using carbide lathe tools are multifaceted:

1. Durability and Longevity: Carbide tools last significantly longer than HSS tools, reducing downtime and the need for frequent replacements. This longevity translates into cost savings and increased productivity.

2. High-Speed Machining: Carbide tools can operate at higher cutting speeds without losing hardness, even at elevated temperatures. This capability enhances productivity and surface finish quality.

3. Precision and Accuracy: The superior hardness and edge retention of carbide tools allow for finer finishes and dimensional accuracy, meeting the stringent requirements of advanced applications.

4. Cost-Effectiveness: Although initially more expensive, carbide tools offer a greater return on investment due to their extended lifespan and reduced maintenance needs.

5. Versatility: Carbide tools can be customized with different coatings and are available in various shapes and sizes, making them adaptable to different machining tasks. This versatility ensures that manufacturers can optimize their production processes.

Carbide Lathe Tooling in Production Shops

Carbide lathe tooling is generally used in production shops due to its ability to enhance efficiency and reduce costs. These tools are essential for maintaining high production standards and meeting tight deadlines.

Customization and Versatility

Carbide tools can be tailored to specific machining tasks by adjusting their geometry and applying different coatings. For instance, TiN coatings enhance wear resistance, while TiCN coatings improve performance in high-temperature applications.

Environmental Sustainability

The reduced need for frequent tool replacements makes carbide tools a more environmentally sustainable option. Fewer resources are consumed in their production and disposal, contributing to a greener manufacturing process.

Industry Applications

Carbide lathe tools are widely used in the automotive, aerospace, and tool and die making industries. Their precision and durability make them ideal for producing components that require tight tolerances and high-quality finishes.

Advanced Coatings and Technologies

Recent advancements in coating technologies have further enhanced the performance of carbide tools. Coatings like diamond-like carbon (DLC) and nanocomposite coatings offer improved wear resistance and reduced friction, allowing for even higher cutting speeds and longer tool life.

DLC Coatings

DLC coatings provide exceptional wear resistance and are particularly effective in machining operations involving high friction and wear. They are often used in applications where maintaining tool integrity is critical.

Nanocomposite Coatings

Nanocomposite coatings combine different materials at the nanoscale to achieve superior properties. These coatings can enhance tool life by reducing wear and improving thermal conductivity.

Conclusion

In conclusion, carbide lathe tools are indispensable in modern industrial machining due to their exceptional hardness, durability, and precision. Their ability to handle high-speed operations and deliver accurate results consistently makes them a preferred choice for production shops. As industries continue to demand higher performance and tighter tolerances, the role of carbide tools in achieving these goals is only expected to grow.

Frequently Asked Questions

1. What are the primary materials used in carbide lathe tools?

Carbide lathe tools are primarily made from tungsten carbide combined with a binding material like cobalt. This composition provides the tools with their remarkable hardness and durability.

2. How do carbide lathe tools compare to high-speed steel (HSS) tools?

Carbide lathe tools offer superior performance and longevity compared to HSS tools. They can operate at higher speeds, maintain their cutting edge longer, and are more resistant to wear and heat.

3. What are the common applications of carbide lathe tools?

Carbide lathe tools are commonly used in turning, facing, threading, and grooving operations. They are also used in the automotive, aerospace, and tool and die making industries due to their precision and durability.

4. Can carbide lathe tools be sharpened?

Carbide tools are generally not sharpened in the same way as HSS tools. Instead, carbide inserts are often replaced when they become dull, as they have multiple cutting edges that can be rotated.

5. What are the environmental benefits of using carbide lathe tools?

The use of carbide lathe tools reduces the need for frequent replacements, which in turn reduces the consumption of resources in tool production and disposal, making them a more environmentally sustainable option.

Citations:

[1] https://www.gdcbabralagunnaur.org/tools/en/carbide-metal-lathe-tools.html

[2] https://jaibros.com/blogs/from-our-blog/what-are-some-common-applications-for-carbide-inserts

[3] https://www.rockrivertool.com/why-use-carbide-tipped-tools/

[4] https://www.alamy.com/stock-photo/carbide-insert.html

[5] https://ctpcryogenics.com/carbide-lathe-tools/

[6] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[7] https://www.instructables.com/Setting-up-carbide-tooling-on-a-lathe/

[8] https://www.accusharp.co.in/why-use-carbide-cutting-tools-benefits-of-carbide-cutting-tool-future-of-carbide-cutting-tool

[9] https://epictool.ca/carbide-cutting-tools-the-most-common-uses-for-carbide/

[10] https://waykenrm.com/blogs/lathe-cutting-tools-types/

[11] https://www.exactaform.com/blog/five-key-considerations-in-solid-carbide-tool-design/

[12] https://www.simplewoodturningtools.com/pages/faqs

[13] https://fmcarbide.com/blogs/techtalks/carbide-tool-services-the-most-common-uses-for-carbide

[14] https://hmaking.com/lathe-cutting-tools/

[15] https://www.rennietool.co.uk/blogs/news/choosing-the-right-carbide-tool-for-your-machining-needs-a-comprehensive-guide

[16] https://huanatools.com/complete-application-of-carbide-inserts/

[17] https://www.kennametal.com/in/en/resources/blog/metal-cutting/selecting-carbide-inserts-for-metalworking.html

[18] https://www.rroij.com/open-access/the-benefits-of-using-carbide-tools-in-manufacturing.pdf

[19] https://www.sundicuttingtools.com/news/technology-articles/types-of-lathe-cutting-tools/

[20] https://sntrading.in/unleashing-the-power-of-carbide-cutters-inindustrial-machining

[21] https://www.mmc-carbide.com/in/technical_information/tec_guide/tec_guide_carbide

[22] https://carbideprovider.com/carbide-cutting-tools-20241209/

[23] https://www.motherathenaschool.in/tools/en/carbide-turning-inserts.html

[24] https://ctpcryogenics.com/carbide-turning-tools/

[25] https://www.shutterstock.com/search/lathe-carbide-tools

[26] https://www.shutterstock.com/search/carbide-tools

[27] https://www.istockphoto.com/photos/carbide-tools

[28] https://www.shutterstock.com/search/carbide-turning-tool

[29] https://stock.adobe.com/search/images?k=carbide+end+mill

[30] https://www.shutterstock.com/search/carbide-cutting-tools

[31] https://www.istockphoto.com/photos/carbide-insert

[32] https://www.istockphoto.com/photos/industrial-cutting-tools

[33] https://www.shutterstock.com/search/turning-tool

[34] https://stock.adobe.com/search?k=carbide

[35] https://www.vecteezy.com/free-photos/carbide

[36] https://stock.adobe.com/search/images?k=carbide+cutting

[37] https://www.istockphoto.com/photos/lathe-tool

[38] https://www.dreamstime.com/photos-images/lathe-tools.html

[39] https://www.hobby-machinist.com/threads/carbide-lathe-tool-insert-questions.99754/

[40] https://www.mmc-carbide.com/in/technical_information/tec_turning_tools/tec_turning_insert

[41] https://testbook.com/objective-questions/mcq-on-cutting-tools--5eea6a0c39140f30f369e113

[42] https://www.cutwel.co.uk/lathe-tools/iso-turning-inserts-tool-holders-boring-bars/carbide-turning-inserts

[43] https://huntertoolsystems.com/about/faqs/

[44] https://gdptooling.com/frequently-asked-questions-on-cutting-tools/

[45] https://carbidetools.nz/faqs/

[46] https://www.findbuytool.com/blogs/university/carbide-vs-traditional-woodturning-tools-a-comprehensive-guide

[47] https://primatooling.co.uk/cnc-cutting-tool-maintenance-troubleshooting/

[48] https://www.fwt-gmbh.de/en/solid-carbide-lathe-tools

[49] https://www.reddit.com/r/turning/comments/zmutaq/questions_about_carbide/

[50] https://quickgrind.com/the-benefits-of-investing-in-solid-carbide-tooling/

[51] https://huanatools.com/applications-of-carbide-end-mill-in-different-industries/

[52] https://toolholderexchange.com/main-benefits-carbide-tools/

[53] https://www.alamy.com/stock-photo/carbide-inserts.html

[54] https://www.alamy.com/stock-photo/carbide-end-mill.html

[55] https://www.instructables.com/Carbide-Lathe-Tools/