Content Menu

● Introduction

● What is Boron Carbide?

● Advantages of Boron Carbide Armor Plates

>> A. Lightweight Design

>> B. High Penetration Resistance

>> C. Durability and Longevity

● Applications of Boron Carbide Armor Plates

>> A. Military Use

>> B. Law Enforcement

>> C. Civilian Applications

● Choosing the Right Boron Carbide Armor Plate

>> A. Understanding Armor Levels

>> B. Factors to Consider

● Conclusion

● Frequently Asked Questions

>> Q1. What are boron carbide armor plates made of?

>> Q2. How effective are boron carbide armor plates against bullets?

>> Q3. Can boron carbide armor plates be used in civilian applications?

>> Q4. How do I choose the right boron carbide armor plate?

>> Q5. Are boron carbide armor plates durable?

Introduction

In an era where personal safety and security are paramount, the choice of protective gear has never been more critical. Among the various materials available for armor, boron carbide stands out as a leading option for those seeking the ultimate protection. Known for its exceptional hardness and lightweight properties, boron carbide armor plates are increasingly being adopted in military, law enforcement, and civilian applications. This article delves into the significance of boron carbide armor plates, exploring their properties, advantages, applications, and considerations for selection.

What is Boron Carbide?

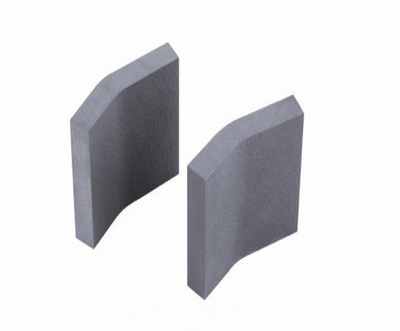

Boron carbide is a compound made from boron and carbon, recognized for its remarkable hardness, which ranks just below diamond on the Mohs scale. This unique material is not only lightweight but also exhibits excellent chemical resistance and thermal stability. These properties make boron carbide an ideal candidate for various applications, particularly in the field of armor.

When compared to traditional armor materials such as steel and aluminum, boron carbide offers a significant advantage in terms of weight. This lightweight nature allows for greater mobility and comfort, especially in high-stress situations where every ounce counts. Additionally, boron carbide's hardness provides superior protection against ballistic threats, making it a preferred choice for military and law enforcement personnel.

Advantages of Boron Carbide Armor Plates

A. Lightweight Design

One of the most significant advantages of boron carbide armor plates is their lightweight design. Traditional armor materials can be cumbersome, leading to fatigue and reduced mobility for the wearer. In contrast, boron carbide plates are significantly lighter, allowing for enhanced agility and comfort. This is particularly important for military personnel who may need to carry additional gear while remaining agile in the field.

The lightweight nature of boron carbide armor plates also means that they can be used in a variety of applications without compromising on protection. Whether in personal body armor or vehicle armor, the reduced weight allows for more efficient designs that do not sacrifice safety.

B. High Penetration Resistance

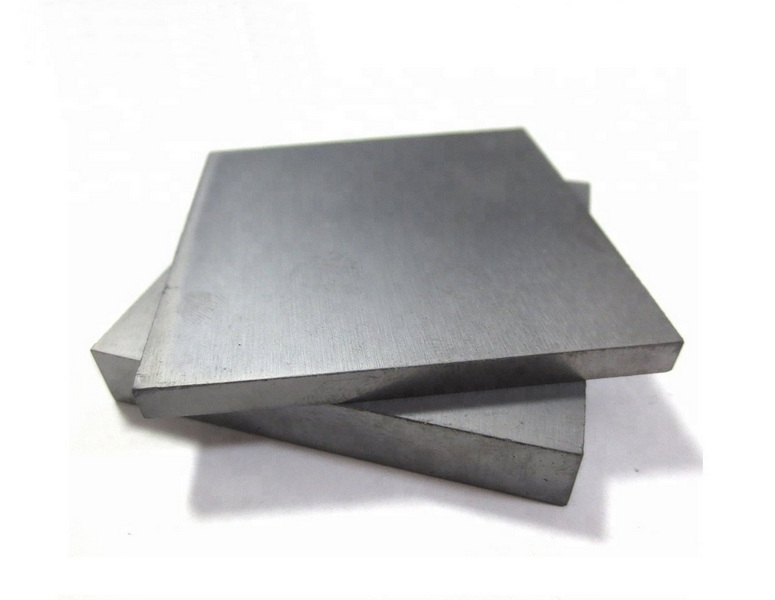

Boron carbide armor plates are renowned for their high penetration resistance. The material's hardness allows it to withstand impacts from various types of ammunition, including armor-piercing rounds. This makes boron carbide an excellent choice for Level IV body armor, which is designed to stop high-velocity projectiles.

The effectiveness of boron carbide against ballistic threats is further enhanced by its ability to dissipate energy upon impact. This means that not only does the plate stop the projectile, but it also reduces the force transmitted to the wearer, minimizing the risk of injury.

C. Durability and Longevity

Durability is a crucial factor when considering armor materials. Boron carbide armor plates are designed to withstand harsh conditions, including extreme temperatures and exposure to chemicals. This resilience ensures that the armor maintains its protective qualities over time, making it a cost-effective investment for both military and civilian users.

Moreover, boron carbide's resistance to wear and tear means that these plates can endure repeated use without significant degradation. This longevity is particularly beneficial for military applications, where equipment is subjected to rigorous conditions and must perform reliably.

Applications of Boron Carbide Armor Plates

A. Military Use

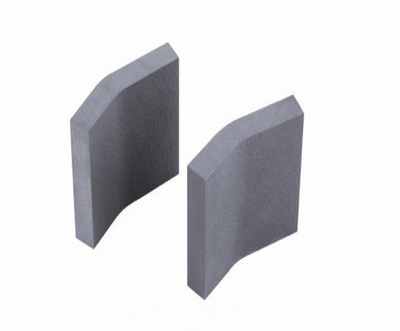

Boron carbide armor plates are widely used in military applications, providing essential protection for soldiers in combat situations. These plates are often integrated into body armor systems, ensuring that personnel are safeguarded against a range of ballistic threats. Additionally, boron carbide is utilized in armored vehicles, enhancing their defensive capabilities without adding excessive weight.

The military's adoption of boron carbide armor plates reflects a commitment to utilizing advanced materials that enhance soldier safety and operational effectiveness. As threats evolve, the need for innovative armor solutions becomes increasingly critical.

B. Law Enforcement

In law enforcement, the safety of officers is paramount. Boron carbide armor plates are commonly used in ballistic vests, providing officers with the protection they need while allowing for mobility and comfort. The lightweight nature of these plates ensures that officers can perform their duties effectively without being hindered by heavy armor.

Furthermore, the high penetration resistance of boron carbide makes it suitable for use in high-risk situations, where officers may face armed threats. The ability to stop high-velocity rounds is essential for ensuring the safety of law enforcement personnel.

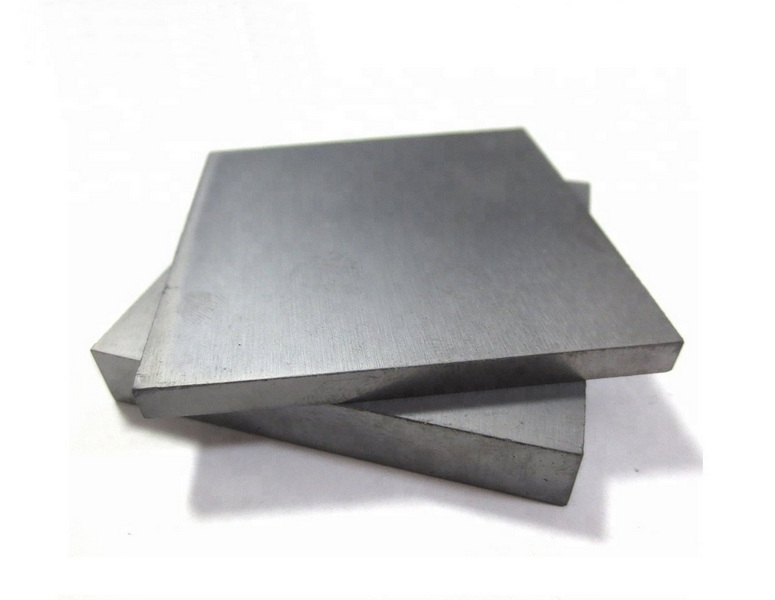

C. Civilian Applications

Beyond military and law enforcement, boron carbide armor plates are increasingly being considered for civilian applications. Personal protection gear, such as bulletproof vests and backpacks, can benefit from the lightweight and high-performance characteristics of boron carbide. As awareness of personal safety grows, more civilians are seeking effective protective solutions.

Additionally, boron carbide's versatility allows it to be used in various industries, including security and private protection services. The demand for reliable armor solutions in civilian contexts is on the rise, making boron carbide a valuable option.

Choosing the Right Boron Carbide Armor Plate

A. Understanding Armor Levels

When selecting boron carbide armor plates, it is essential to understand the different armor levels defined by the National Institute of Justice (NIJ). These levels indicate the type of threats the armor can withstand. For instance, Level IV armor is designed to stop armor-piercing rounds, making it suitable for high-risk environments.

B. Factors to Consider

Several factors should be considered when choosing boron carbide armor plates:

- Weight: Ensure that the armor is lightweight enough for your specific needs.

- Shape: The design of the armor plate should provide adequate coverage while allowing for mobility.

- Coverage Area: Consider the areas of the body that require protection and choose plates that offer sufficient coverage.

By carefully evaluating these factors, users can select the most appropriate boron carbide armor plates for their needs.

Conclusion

Boron carbide armor plates represent a significant advancement in protective technology, offering a combination of lightweight design, high penetration resistance, and exceptional durability. As the demand for effective armor solutions continues to grow, boron carbide stands out as a premier choice for military, law enforcement, and civilian applications. By understanding the properties and advantages of boron carbide armor plates, individuals and organizations can make informed decisions to enhance their safety and security.

Frequently Asked Questions

Q1. What are boron carbide armor plates made of?

Boron carbide armor plates are made from a compound of boron and carbon, known for its exceptional hardness and lightweight properties.

Q2. How effective are boron carbide armor plates against bullets?

Boron carbide armor plates are highly effective against bullets, particularly armor-piercing rounds, making them suitable for Level IV body armor.

Q3. Can boron carbide armor plates be used in civilian applications?

Yes, boron carbide armor plates can be used in civilian applications, including personal protection gear such as bulletproof vests and backpacks.

Q4. How do I choose the right boron carbide armor plate?

When choosing boron carbide armor plates, consider factors such as weight, shape, coverage area, and the specific armor level required for your needs.

Q5. Are boron carbide armor plates durable?

Yes, boron carbide armor plates are known for their durability and longevity, withstanding harsh conditions and repeated use without significant degradation.