Content Menu

● Understanding the Carbide Tipped Tracer Chisel

>> Benefits of Using a Carbide Tipped Tracer Chisel

● 1. Stone Masonry Projects

>> 1.1 Building Walls

>>> Techniques for Wall Construction

>> 1.2 Creating Decorative Features

>>> Example Projects

>> 1.3 Landscaping Projects

>>> Landscaping Techniques

● 2. Sculpting and Artistic Projects

>> 2.1 Stone Sculptures

>>> Tips for Sculpting

>> 2.2 Memorials and Monuments

>>> Engraving Techniques

● 3. Restoration Projects

>> 3.1 Restoring Historical Buildings

>>> Restoration Techniques

>> 3.2 Repairing Damaged Stonework

>>> Repair Steps

● 4. Practical Techniques for Using a Carbide Tipped Tracer Chisel

>> 4.1 Scoring Technique

>> 4.2 Angle of Attack

>> 4.3 Regular Maintenance

>> 4.4 Safety Precautions

● 5. Choosing the Right Carbide Tipped Tracer Chisel

>> 5.1 Size Matters

>> 5.2 Weight Considerations

>> 5.3 Brand Quality

● Conclusion

● Questions & Answers

>> 1. What materials can I use a carbide tipped tracer chisel on?

>> 2. How do I maintain my carbide tipped tracer chisel?

>> 3. Can I use this chisel for woodwork?

>> 4. What size of carbide tipped tracer chisel should I choose?

>> 5. Is it necessary to wear safety gear when using a carbide tipped tracer chisel?

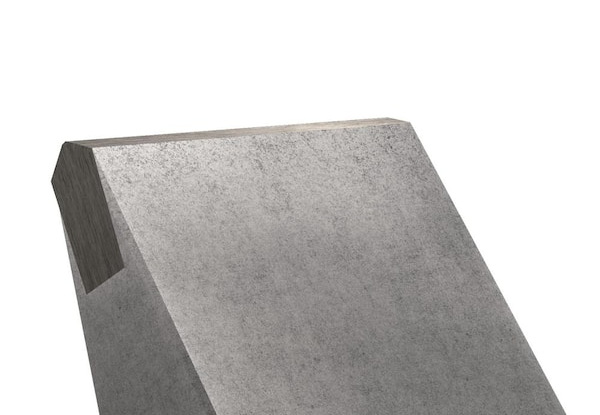

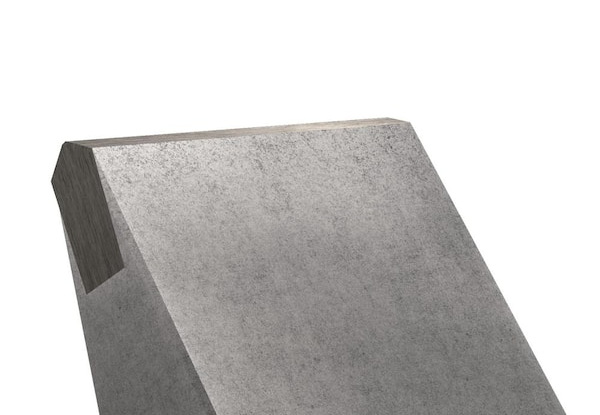

The carbide tipped tracer chisel is an essential tool for stone masons and craftsmen who work with hard materials like granite and marble. Its design allows for precision cutting, shaping, and splitting of stone, making it ideal for various projects. In this article, we will explore the best projects suited for a carbide tipped tracer chisel, detailing its applications, techniques, and tips to maximize its effectiveness.

Understanding the Carbide Tipped Tracer Chisel

A carbide tipped tracer chisel features a tungsten carbide tip that provides durability and sharpness, enabling it to handle tough materials. The two-sided angled design is particularly effective for scoring lines on stone surfaces, which is crucial for achieving clean splits. This tool is favored by professionals in the masonry field due to its efficiency and longevity.

Benefits of Using a Carbide Tipped Tracer Chisel

1. Durability: The carbide tip is significantly harder than steel, allowing it to maintain sharpness longer and withstand rigorous use.

2. Precision: The design of the tracer chisel enables precise cuts, making it easier to create intricate designs and achieve clean edges.

3. Versatility: It can be used on various types of stone, making it a versatile tool for different projects.

4. Efficiency: The ability to score and split stone accurately reduces the time spent on each project.

1. Stone Masonry Projects

1.1 Building Walls

When constructing stone walls, a carbide tipped tracer chisel is invaluable. It allows masons to create precise joints and fit stones snugly together. The ability to score lines accurately helps in determining where to split stones, ensuring that each piece fits perfectly.

Techniques for Wall Construction

- Lay Out Your Design: Before starting, sketch your wall design and mark where each stone will go.

- Score the Stones: Use the tracer chisel to score the stones along your marked lines.

- Split Carefully: After scoring, apply gentle pressure to break the stone along the scored line.

1.2 Creating Decorative Features

For projects that involve intricate designs or decorative stonework, the carbide tipped tracer chisel can be used to shape stones into specific patterns. This includes creating arches, columns, and other architectural elements that require detailed craftsmanship.

Example Projects

- Garden Arches: Use the chisel to carve out curves and shapes for garden arches that enhance landscaping.

- Column Bases: Create decorative bases for columns by shaping stones with precision.

1.3 Landscaping Projects

In landscaping, this chisel can be used to create pathways or garden borders from stone. The precision of the carbide tipped tracer chisel allows for clean edges and well-defined shapes, enhancing the aesthetic appeal of outdoor spaces.

Landscaping Techniques

- Pathway Creation: Score stones into uniform shapes for pathways that are both functional and visually appealing.

- Border Edging: Use the chisel to create sharp edges around flower beds or gardens.

2. Sculpting and Artistic Projects

2.1 Stone Sculptures

Artists working with stone often use carbide tipped tracer chisels to carve sculptures. The tool's ability to make fine cuts allows artists to achieve detailed textures and shapes in their work.

Tips for Sculpting

- Start with a Rough Shape: Begin by removing large sections of stone before focusing on details.

- Use Different Angles: Vary your chiseling angles to create depth and texture in your sculpture.

2.2 Memorials and Monuments

Creating memorials or monuments involves meticulous detail work. The carbide tipped tracer chisel is perfect for engraving names or dates into stone surfaces due to its precision.

Engraving Techniques

- Plan Your Layout: Sketch out your design on paper before transferring it to the stone.

- Score Lightly First: Start with light scoring before deepening your cuts to ensure accuracy.

3. Restoration Projects

3.1 Restoring Historical Buildings

In restoration projects, it's crucial to match existing stonework accurately. The carbide tipped tracer chisel enables restorers to replicate original designs while ensuring that new pieces fit seamlessly with old ones.

Restoration Techniques

- Analyze Existing Structures: Study the original design closely before beginning work on restoration.

- Careful Matching: Use the chisel to replicate patterns found in historical masonry.

3.2 Repairing Damaged Stonework

For repairing chips or cracks in stone surfaces, the carbide tipped tracer chisel can be used to reshape damaged areas before applying fillers or patches.

Repair Steps

- Assess Damage: Determine how much material needs removal before starting repairs.

- Smooth Edges: Use the chisel to create smooth edges around the damaged area for better adhesion of fillers.

4. Practical Techniques for Using a Carbide Tipped Tracer Chisel

To get the most out of your carbide tipped tracer chisel, consider these techniques:

4.1 Scoring Technique

Hold the chisel vertically against the stone surface and move it back and forth to score a line where you want to split the stone. This technique helps create a weak point along which the stone can be easily broken.

4.2 Angle of Attack

Using the correct angle when applying force with the chisel is crucial. A steeper angle can provide more control when making precise cuts.

4.3 Regular Maintenance

Regularly sharpen the carbide tip to maintain its effectiveness. A dull chisel can lead to uneven cuts and increased effort during use.

4.4 Safety Precautions

Always prioritize safety when using chisels:

- Wear safety goggles to protect your eyes from flying debris.

- Use gloves to prevent cuts from sharp edges.

- Ensure your workspace is clear of unnecessary clutter.

5. Choosing the Right Carbide Tipped Tracer Chisel

When selecting a carbide tipped tracer chisel, consider factors such as size, weight, and brand reputation:

5.1 Size Matters

Choose a size that fits comfortably in your hand while allowing you enough leverage for effective chiseling.

5.2 Weight Considerations

A heavier chisel may provide better control but can also lead to fatigue during extended use; find a balance that works best for you.

5.3 Brand Quality

Invest in high-quality brands known for their durability and performance; read reviews or seek recommendations from experienced craftsmen.

Conclusion

The carbide tipped tracer chisel is an indispensable tool for anyone working with stone, whether in masonry, sculpture, or restoration projects. Its ability to make precise cuts and withstand heavy use makes it ideal for various applications—from building walls to creating intricate sculptures.

Investing time in mastering this tool will significantly enhance your craftsmanship and project outcomes. Remember to practice proper techniques and maintain your tools for optimal performance.

With its versatility and effectiveness, incorporating a carbide tipped tracer chisel into your toolkit will open up countless possibilities in your stoneworking endeavors.

Questions & Answers

1. What materials can I use a carbide tipped tracer chisel on?

You can use a carbide tipped tracer chisel on hard stones like granite, marble, and other dense materials.

2. How do I maintain my carbide tipped tracer chisel?

Regularly sharpen the tip and clean it after each use to prevent debris buildup that could affect performance.

3. Can I use this chisel for woodwork?

No, the carbide tipped tracer chisel is specifically designed for stonework; using it on wood may damage both the tool and the wood.

4. What size of carbide tipped tracer chisel should I choose?

The size depends on your specific project needs; larger chisels are better for heavy-duty work while smaller ones are ideal for detailed work.

5. Is it necessary to wear safety gear when using a carbide tipped tracer chisel?

Yes, always wear safety goggles and gloves when using chisels to protect yourself from flying debris and sharp edges.