Content Menu

● What Is Tungsten Carbide?

● Natural Sources of Tungsten: Where Does Tungsten Come From?

>> Major Tungsten Mining Regions

● Geologic Context of Tungsten Deposits

● Tungsten Mining Locations Around the World

>> 1. China

>> 2. Canada

>> 3. United States

>> 4. Other Regions

● How Is Tungsten Carbide Produced?

>> Step 1: Extraction of Tungsten Ore

>> Step 2: Conversion to Tungsten Compounds

>> Step 3: Carburization

>> Step 4: Powder Metallurgy and Sintering

● Industrial Sources of Tungsten Carbide

● The Importance of Tungsten Carbide in Modern Industry

● Environmental and Economic Considerations

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. Where is tungsten carbide naturally found?

>> 2. What are the main minerals that contain tungsten?

>> 3. How is tungsten carbide produced from tungsten ore?

>> 4. Which countries are the largest producers of tungsten?

>> 5. In what industries is tungsten carbide commonly used?

Tungsten carbide is a remarkable material known for its exceptional hardness, durability, and resistance to wear and heat. It plays a critical role in numerous industrial applications, including cutting tools, mining equipment, jewelry, and military uses. Understanding where tungsten carbide is found involves exploring the natural sources of tungsten, the processes that convert tungsten into tungsten carbide, and the global distribution of tungsten resources. This article provides a comprehensive overview of the origins, mining locations, and industrial sources of tungsten carbide, along with its synthesis and applications.

What Is Tungsten Carbide?

Tungsten carbide (chemical formula WC) is a compound composed of equal parts tungsten and carbon atoms. It is a dense, grayish powder that can be pressed and sintered into extremely hard and wear-resistant shapes. With a density of about 15.6 g/cm³ and hardness comparable to diamond, tungsten carbide is much harder than most steels and other carbides such as silicon carbide or titanium carbide. It has a very high melting point of approximately 2780–2830°C, making it suitable for high-temperature and high-stress applications.

Tungsten carbide's unique combination of hardness, toughness, and resistance to corrosion and heat makes it a material of choice for cutting and drilling tools, abrasives, and protective coatings. Its ability to maintain sharpness and resist deformation under extreme conditions has revolutionized many manufacturing and mining industries.

Natural Sources of Tungsten: Where Does Tungsten Come From?

Tungsten does not occur naturally as a free metal but is found primarily in mineral ores. The two main tungsten minerals are:

- Wolframite: A solid solution of iron-manganese tungstate minerals, ferberite (FeWO₄) and hübnerite (MnWO₄).

- Scheelite: Calcium tungstate (CaWO₄).

These minerals are the primary sources of tungsten, which is then processed to produce tungsten carbide.

Major Tungsten Mining Regions

- China: The dominant producer, responsible for over 80% of the world's tungsten supply and containing nearly two-thirds of global reserves.

- North America: Notable tungsten deposits exist in western North America, especially in Canada (Cantung and Mactung deposits) and the United States (California and Colorado).

- Other Countries: Vietnam, Russia, Portugal, Bolivia, South Korea, Great Britain, and Australia also have significant tungsten resources.

Geologic Context of Tungsten Deposits

Tungsten deposits are often associated with specific geologic formations:

- Skarns: Hydrothermal mineral deposits in calc-silicate rocks, where scheelite is commonly found.

- Granite Intrusions: Tungsten mineralization is frequently linked to peraluminous granites and related intrusive rocks.

For example, the Canadian Tungsten Belt (CTB) is a major metallogenic province hosting large scheelite deposits. The CTB includes historic producers like the Cantung mine and large reserves like the Mactung deposit.

The formation of tungsten deposits typically involves hydrothermal fluids rich in tungsten interacting with host rocks, leading to the precipitation of tungsten minerals. These processes can occur over millions of years and are influenced by tectonic activity, magmatic intrusions, and regional metamorphism.

Tungsten Mining Locations Around the World

1. China

China leads global tungsten production and reserves, mining wolframite and scheelite extensively. Its dominance impacts the global tungsten carbide supply chain. Chinese mines are located primarily in the provinces of Jiangxi, Hunan, Guangdong, and Guangxi. The country's vast resources and well-developed mining infrastructure make it the world's largest supplier and exporter of tungsten products.

2. Canada

The Cantung and Mactung mines in Canada are among the top tungsten producers in North America. These deposits are primarily scheelite hosted in skarn deposits. The Cantung mine, located in the Northwest Territories, has been a significant source of tungsten since the 1960s. The Mactung deposit, one of the largest undeveloped tungsten resources, is also located in the Northwest Territories and is expected to play a major role in future supply.

3. United States

- California: The Tungsten City mine in Inyo County is a notable historic tungsten mine located at an elevation of 5,200 feet. It operated as a surface and underground mine within the Sierra Nevada physiographic province. Although the U.S. tungsten production has declined in recent decades, there are ongoing exploration and development projects aimed at reviving domestic supply.

- Colorado: Other tungsten deposits exist in Colorado, associated with granitic intrusions and skarns. The high-grade deposits in the state have historically contributed to tungsten production.

4. Other Regions

- Portugal and Great Britain: Known for smaller tungsten deposits and mining operations. Portugal's Panasqueira mine is one of Europe's most significant tungsten producers.

- Russia and Vietnam: Important producers contributing to the global tungsten supply. Russia's tungsten production is mainly concentrated in the Far East region.

- Bolivia and South Korea: Also have tungsten resources mined for industrial use. Bolivia's tungsten deposits are often associated with tin and silver ores.

How Is Tungsten Carbide Produced?

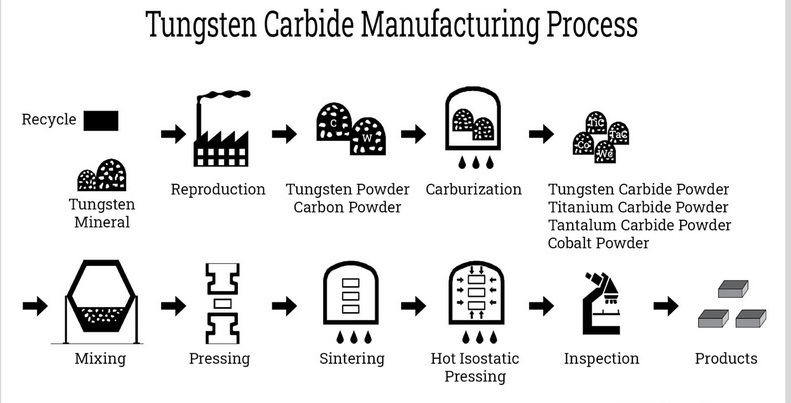

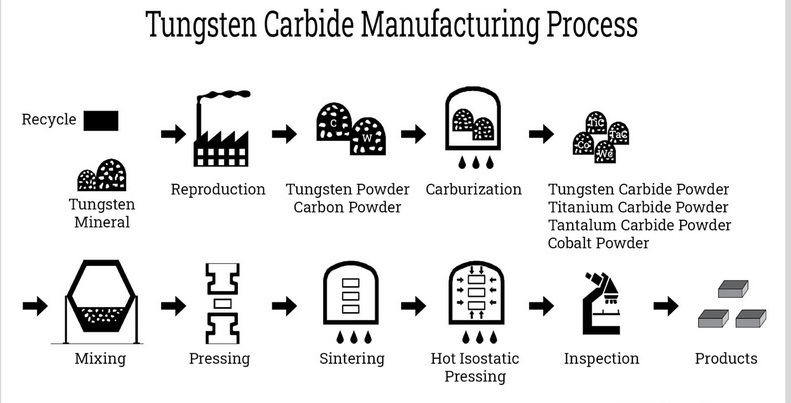

Tungsten carbide is not mined directly but synthesized from tungsten ores through several industrial processes:

Step 1: Extraction of Tungsten Ore

Tungsten ores like wolframite and scheelite are mined and concentrated by magnetic and mechanical methods. The ore is crushed and ground, and the tungsten minerals are separated from the gangue using gravity, flotation, and magnetic separation techniques.

Step 2: Conversion to Tungsten Compounds

The concentrate is processed to produce ammonium paratungstate (APT), which is then calcined to tungsten oxide and reduced to tungsten metal powder in a hydrogen atmosphere. This powder is extremely fine and forms the basis for tungsten carbide production.

Step 3: Carburization

Tungsten metal powder is mixed with carbon sources such as graphite or soot and heated at high temperatures (900–1600°C) in a controlled environment to form tungsten carbide powder. This process ensures the carbon atoms bond with tungsten atoms, creating the carbide compound.

Step 4: Powder Metallurgy and Sintering

The tungsten carbide powder is blended with a metallic binder, typically cobalt, pressed into shape, and sintered at temperatures around 1400–1600°C. This process produces dense, hard tungsten carbide parts used in industry. The cobalt binder provides toughness and resistance to fracture, balancing the extreme hardness of the carbide grains.

Industrial Sources of Tungsten Carbide

Apart from mining, tungsten carbide is found in many industrial tools and products, which can become sources of recycled material:

- Cutting tools: Drill bits, saw blades, end mills, and lathe tools used in manufacturing and machining.

- Mining and drilling equipment: Tungsten carbide is used in rock crushing, tunneling, and drilling tools due to its wear resistance.

- Jewelry: Tungsten carbide is popular in wedding bands and rings for its scratch resistance and strength.

- Military applications: Dense tungsten carbide is used in armor-piercing ammunition and missiles.

- Other industrial parts: Bushings, punches, dies, and wear plates in machinery.

Recycling tungsten carbide from used tools and scrap is an important aspect of the tungsten supply chain. Due to the high value of tungsten, recycling helps reduce dependence on mining and minimizes environmental impact.

The Importance of Tungsten Carbide in Modern Industry

Tungsten carbide's combination of hardness, toughness, and heat resistance makes it indispensable in many sectors:

- Manufacturing: CNC machining, metal cutting, and precision tooling rely heavily on tungsten carbide tools to maintain efficiency and accuracy.

- Mining and Construction: Tungsten carbide drill bits and cutting heads are essential for breaking hard rock and extracting minerals.

- Aerospace and Automotive: Components made from tungsten carbide withstand extreme wear and temperature conditions.

- Medical Devices: Surgical instruments and dental tools often use tungsten carbide for durability and precision.

- Jewelry: Tungsten carbide rings have become popular for their scratch resistance and modern aesthetic.

Environmental and Economic Considerations

Mining and processing tungsten have environmental impacts, including habitat disruption, water usage, and waste generation. Responsible mining practices and recycling efforts are critical to minimizing these effects. Economically, tungsten carbide is a high-value material that supports many industries, making secure and sustainable supply chains vital.

Conclusion

Tungsten carbide is a vital material derived from tungsten ores primarily found in minerals like wolframite and scheelite. The majority of the world's tungsten supply comes from China, with significant deposits in North America, Russia, Portugal, and other countries. Tungsten carbide is produced industrially through complex processes involving ore extraction, chemical conversion, carburization, and sintering with metallic binders. Its exceptional hardness and durability make it indispensable in industries ranging from manufacturing and mining to jewelry and defense. Understanding where tungsten carbide is found and how it is made provides insight into its critical role in modern technology and industry. Additionally, the importance of sustainable mining and recycling practices cannot be overstated in securing tungsten carbide's future availability.

Frequently Asked Questions (FAQs)

1. Where is tungsten carbide naturally found?

Tungsten carbide itself is not found naturally but is synthesized from tungsten ores, primarily wolframite and scheelite, which are mined in China, Canada, the United States, and other countries.

2. What are the main minerals that contain tungsten?

The two primary tungsten-containing minerals are wolframite (iron-manganese tungstate) and scheelite (calcium tungstate).

3. How is tungsten carbide produced from tungsten ore?

Tungsten ore is processed to produce tungsten metal powder, which is then carburized with carbon at high temperatures to form tungsten carbide powder. This powder is mixed with a metal binder and sintered to form solid tungsten carbide parts.

4. Which countries are the largest producers of tungsten?

China is the largest producer, supplying over 80% of the world's tungsten. Other producers include Canada, the United States, Russia, Vietnam, Portugal, and Bolivia.

5. In what industries is tungsten carbide commonly used?

Tungsten carbide is widely used in manufacturing cutting tools, mining and drilling equipment, jewelry, military ammunition, and wear-resistant machine parts.