Content Menu

● Understanding Silicon Carbide Ceramic Plates

● Properties of Silicon Carbide Ceramic Plates

● Applications of Silicon Carbide Ceramic Plates

>> Aerospace

>> Defense

>> Electronics

>> Manufacturing

>> Energy

● Where to Find the Best Quality Silicon Carbide Ceramic Plates

>> Specialized Manufacturers

>> Online Marketplaces

>> Industrial Supply Companies

>> Trade Shows and Expos

>> Research Institutions and Universities

● Factors to Consider When Choosing Silicon Carbide Ceramic Plates

>> Material Specifications

>> Size and Shape

>> Quality Assurance

>> Cost

>> Customer Support

● Benefits of Using Silicon Carbide Ceramic Plates

>> Enhanced Performance

>> Versatility

>> Environmental Resistance

>> Cost-Effectiveness

>> Innovation and Research

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of using silicon carbide ceramic plates?

>> 2. How do I choose the right silicon carbide ceramic plate for my project?

>> 3. Where can I purchase silicon carbide ceramic plates?

>> 4. Are silicon carbide ceramic plates suitable for high-temperature applications?

>> 5. What industries commonly use silicon carbide ceramic plates?

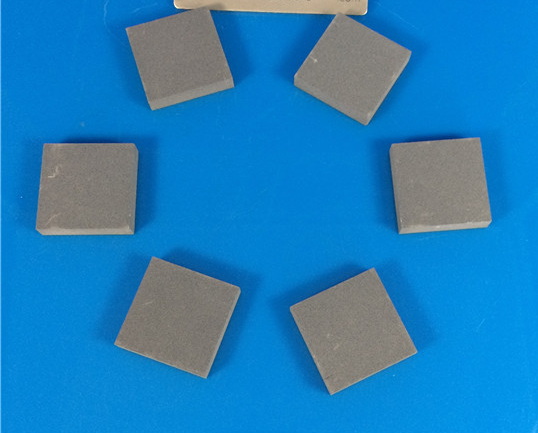

Understanding Silicon Carbide Ceramic Plates

Silicon carbide (SiC) ceramic plates have gained significant attention in various industries due to their exceptional properties, including high thermal conductivity, excellent wear resistance, and outstanding mechanical strength. These characteristics make them ideal for applications ranging from aerospace to electronics and even in the manufacturing of armor plates. As the demand for silicon carbide ceramic plates continues to rise, it becomes crucial to know where to find the best quality products for your specific projects. This article will explore the various sources, applications, and benefits of silicon carbide ceramic plates, providing you with a comprehensive guide to making informed purchasing decisions.

Properties of Silicon Carbide Ceramic Plates

Silicon carbide is a compound of silicon and carbon, known for its hardness and thermal stability. The ceramic plates made from silicon carbide are used in a variety of applications due to their unique properties:

- High Hardness: Silicon carbide is one of the hardest materials available, making it ideal for applications that require wear resistance. This property is particularly beneficial in industries where components are subject to abrasion and impact.

- Thermal Conductivity: SiC ceramic plates can withstand high temperatures, making them suitable for high-temperature applications. Their ability to dissipate heat efficiently is crucial in electronic devices and aerospace components.

- Chemical Resistance: These plates are resistant to many chemicals, which is beneficial in harsh environments. This property allows them to be used in chemical processing and manufacturing applications without degrading.

- Lightweight: Compared to metals, silicon carbide is much lighter, which is advantageous in applications where weight is a concern, such as in aerospace and automotive industries.

Applications of Silicon Carbide Ceramic Plates

Silicon carbide ceramic plates are utilized in various industries, including:

Aerospace

In the aerospace industry, SiC plates are used for thermal protection systems and as components in jet engines due to their ability to withstand extreme temperatures. Their lightweight nature also contributes to fuel efficiency in aircraft.

Defense

Silicon carbide is widely used in the production of body armor and vehicle armor due to its high hardness and lightweight properties. The use of SiC in armor systems enhances protection without adding significant weight, making it a preferred choice for military applications.

Electronics

In the electronics sector, SiC plates are used in semiconductor devices and high-power electronics, where thermal management is critical. Their ability to operate at high temperatures and voltages makes them ideal for power electronics in electric vehicles and renewable energy systems.

Manufacturing

These plates are also used in manufacturing processes, such as grinding and cutting, where durability and wear resistance are essential. Silicon carbide's hardness allows it to be used in abrasive applications, extending the life of tools and machinery.

Energy

Silicon carbide is increasingly being used in energy applications, including solar cells and fuel cells, due to its efficiency and performance. Its ability to withstand high temperatures and corrosive environments makes it suitable for advanced energy systems.

Where to Find the Best Quality Silicon Carbide Ceramic Plates

Finding high-quality silicon carbide ceramic plates involves considering several factors, including the supplier's reputation, product specifications, and customer reviews. Here are some reliable sources to consider:

Specialized Manufacturers

Many companies specialize in the production of silicon carbide ceramic plates. These manufacturers often have extensive experience and can provide customized solutions based on your project requirements. Look for manufacturers that offer detailed product specifications, including hardness ratings, thermal conductivity, and chemical resistance.

Online Marketplaces

E-commerce platforms like Amazon, Alibaba, and eBay can be excellent places to find silicon carbide ceramic plates. These platforms often feature a wide range of products from various suppliers, allowing you to compare prices and read customer reviews. However, ensure that you verify the seller's credibility and product quality before making a purchase.

Industrial Supply Companies

Many industrial supply companies offer silicon carbide ceramic plates as part of their product range. These companies often cater to specific industries, such as aerospace or defense, and can provide expert advice on selecting the right materials for your projects.

Trade Shows and Expos

Attending industry trade shows and expos can be a great way to connect with manufacturers and suppliers of silicon carbide ceramic plates. These events often showcase the latest products and technologies, allowing you to see the materials firsthand and discuss your needs with experts.

Research Institutions and Universities

Some research institutions and universities conduct studies on advanced materials, including silicon carbide ceramics. Collaborating with these institutions can provide access to cutting-edge research and potentially high-quality materials developed through academic programs.

Factors to Consider When Choosing Silicon Carbide Ceramic Plates

When selecting silicon carbide ceramic plates for your projects, consider the following factors:

Material Specifications

Ensure that the plates meet the specific requirements of your application. This includes checking the hardness, thermal conductivity, and chemical resistance. Different applications may require different specifications, so it's essential to match the material properties to your needs.

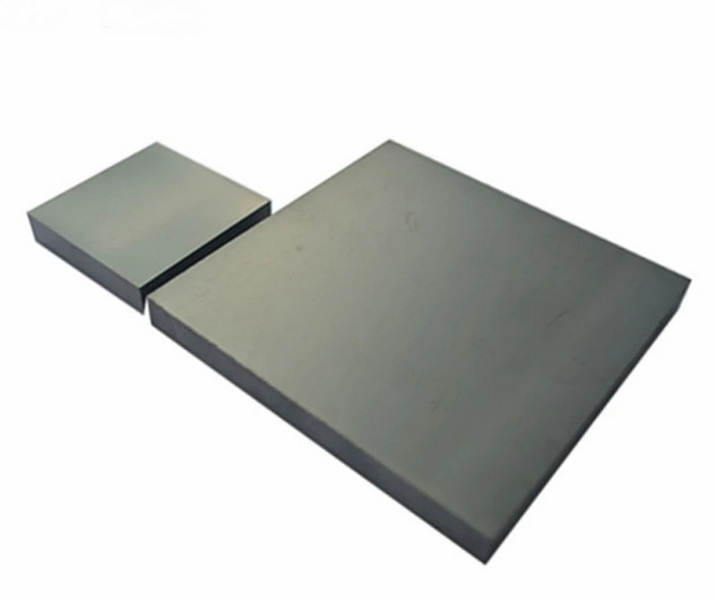

Size and Shape

Silicon carbide ceramic plates come in various sizes and shapes. Determine the dimensions you need for your project and ensure that the supplier can provide them. Custom sizes may be available, but they could come at a higher cost.

Quality Assurance

Look for suppliers that offer quality assurance and testing for their products. Certifications and compliance with industry standards can provide peace of mind regarding the quality of the materials. It's advisable to ask for test reports or certifications from recognized organizations.

Cost

While price should not be the only factor in your decision, it is essential to consider your budget. Compare prices from different suppliers and weigh them against the quality and specifications of the products. Sometimes, investing in higher-quality materials can lead to long-term savings due to reduced wear and tear.

Customer Support

Choose suppliers that offer excellent customer support. This can be crucial if you have questions or need assistance with your order. A responsive supplier can help you navigate any issues that arise during the purchasing process.

Benefits of Using Silicon Carbide Ceramic Plates

The advantages of using silicon carbide ceramic plates extend beyond their physical properties. Here are some key benefits:

Enhanced Performance

Silicon carbide plates can significantly enhance the performance of components in various applications. Their ability to withstand high temperatures and resist wear can lead to longer service life and reduced maintenance costs.

Versatility

The versatility of silicon carbide ceramic plates allows them to be used in a wide range of applications across different industries. This adaptability makes them a valuable material for engineers and designers.

Environmental Resistance

Silicon carbide is resistant to oxidation and corrosion, making it suitable for use in harsh environments. This property is particularly important in chemical processing and high-temperature applications.

Cost-Effectiveness

While the initial cost of silicon carbide ceramic plates may be higher than other materials, their durability and performance can lead to cost savings over time. Reduced downtime and maintenance can offset the initial investment.

Innovation and Research

The ongoing research and development in silicon carbide technology continue to improve the material's properties and applications. Staying informed about the latest advancements can help you leverage new opportunities in your projects.

Conclusion

Silicon carbide ceramic plates are invaluable in various industries due to their unique properties and versatility. By understanding where to find the best quality plates and what factors to consider when making a purchase, you can ensure that you select the right materials for your projects. Whether you are in aerospace, defense, electronics, or manufacturing, silicon carbide ceramic plates can provide the performance and durability you need.

Frequently Asked Questions

1. What are the main benefits of using silicon carbide ceramic plates?

Silicon carbide ceramic plates offer high hardness, excellent thermal conductivity, chemical resistance, and lightweight properties, making them suitable for various applications.

2. How do I choose the right silicon carbide ceramic plate for my project?

Consider factors such as material specifications, size and shape, quality assurance, cost, and customer support when selecting a silicon carbide ceramic plate.

3. Where can I purchase silicon carbide ceramic plates?

You can find silicon carbide ceramic plates from specialized manufacturers, online marketplaces, industrial supply companies, trade shows, and research institutions.

4. Are silicon carbide ceramic plates suitable for high-temperature applications?

Yes, silicon carbide ceramic plates are known for their ability to withstand high temperatures, making them ideal for applications in aerospace and other high-temperature environments.

5. What industries commonly use silicon carbide ceramic plates?

Silicon carbide ceramic plates are used in aerospace, defense, electronics, manufacturing, and energy industries due to their unique properties and performance.