Content Menu

● Understanding Chromium Carbide Overlay Plates

● Factors to Consider When Purchasing Chromium Carbide Overlay Plates

>> Material Quality

>> Supplier Reputation

>> Customization Options

>> Pricing and Discounts

>> Delivery and Lead Times

● Where to Find the Best Deals

>> Online Marketplaces

>> Manufacturer Websites

>> Industry Trade Shows

>> Local Distributors

>> Online Forums and Communities

● Tips for Maximizing Your Investment

>> Regular Maintenance

>> Educate Your Team

>> Keep an Eye on Market Trends

>> Consider Long-Term Costs

>> Build Relationships with Suppliers

● Conclusion

● Frequently Asked Questions

>> 1. What are chromium carbide overlay plates used for?

>> 2. How do I choose the right supplier for chromium carbide overlay plates?

>> 3. Can I get customized chromium carbide overlay plates?

>> 4. What factors affect the price of chromium carbide overlay plates?

>> 5. How can I extend the life of my chromium carbide overlay plates?

Understanding Chromium Carbide Overlay Plates

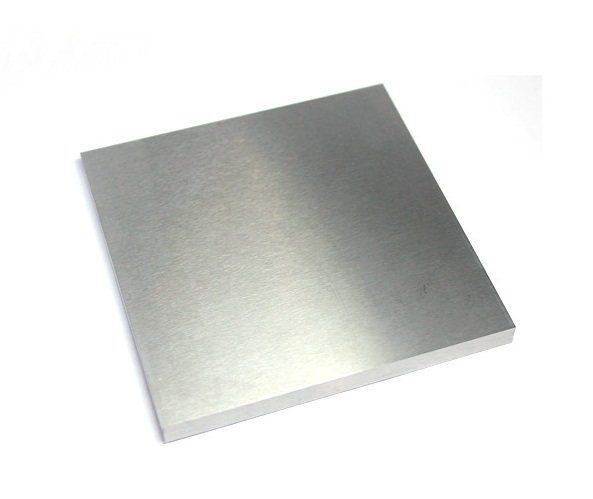

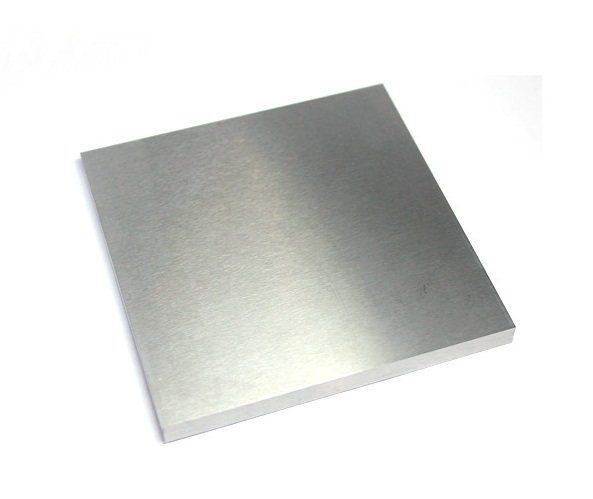

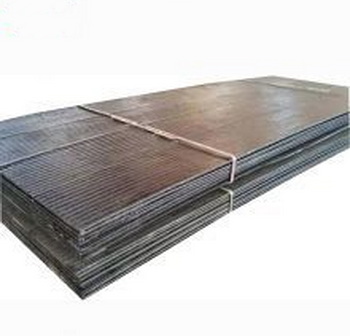

Chromium carbide overlay plates are essential components in various industries, particularly in applications that require high wear resistance. These plates are designed to withstand extreme conditions, making them ideal for use in mining, construction, and manufacturing. As the demand for these plates continues to grow, so does the need for finding the best deals. In this article, we will explore where to find the best deals on chromium carbide overlay plates, the factors to consider when purchasing, and tips for maximizing your investment.

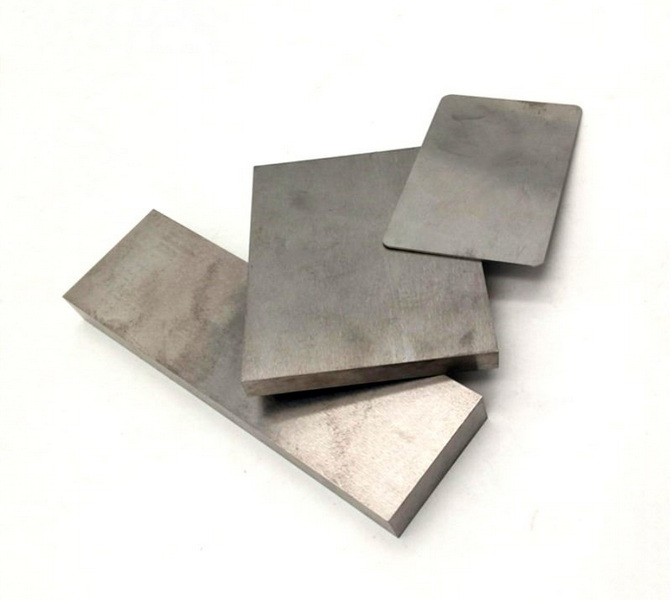

Chromium carbide overlay plates are made by welding a layer of chromium carbide onto a base metal, typically steel. This process creates a hard, wear-resistant surface that can significantly extend the life of equipment and components exposed to abrasive materials. The unique properties of chromium carbide make it an excellent choice for applications such as:

- Mining Equipment: Used in chutes, hoppers, and other components that experience high wear from rocks and minerals.

- Construction Machinery: Protects parts of machinery that come into contact with concrete, asphalt, and other abrasive materials.

- Manufacturing: Ideal for use in conveyor systems and other equipment that handle bulk materials.

Factors to Consider When Purchasing Chromium Carbide Overlay Plates

When searching for the best deals on chromium carbide overlay plates, it is essential to consider several factors that can impact both the price and the quality of the product:

Material Quality

The quality of the chromium carbide overlay is crucial. Look for suppliers that provide detailed specifications about the materials used in their plates. High-quality plates will have a uniform thickness and a consistent overlay that ensures maximum wear resistance. The hardness of the overlay is also an important factor; typically, chromium carbide plates have a hardness rating of 58-65 HRC (Rockwell Hardness Scale), which indicates their ability to withstand wear.

Supplier Reputation

Research potential suppliers to ensure they have a good reputation in the industry. Look for reviews and testimonials from previous customers to gauge their experiences. A reputable supplier will often provide better customer service and support. Additionally, consider suppliers that have been in the industry for a long time, as they are likely to have more experience and knowledge about the products they offer.

Customization Options

Some applications may require customized plates to fit specific machinery or equipment. Check if the supplier offers customization options, such as different sizes, thicknesses, or shapes, to meet your needs. Customization can also include specific overlay patterns or additional treatments to enhance the wear resistance of the plates.

Pricing and Discounts

Compare prices from multiple suppliers to find the best deals. Some suppliers may offer bulk discounts or seasonal promotions that can significantly reduce costs. Don't hesitate to negotiate prices, especially if you are purchasing in large quantities. It's also wise to inquire about warranty options, as some suppliers may offer warranties on their products, which can provide additional peace of mind.

Delivery and Lead Times

Consider the delivery times when purchasing chromium carbide overlay plates. Some suppliers may have longer lead times due to manufacturing processes or shipping logistics. Ensure that the supplier can meet your project deadlines. It's also beneficial to ask about shipping costs, as these can vary significantly between suppliers and impact the overall price.

Where to Find the Best Deals

Now that we understand the factors to consider, let's explore some of the best places to find deals on chromium carbide overlay plates:

Online Marketplaces

Websites like Alibaba, Amazon, and eBay often have a wide range of suppliers offering chromium carbide overlay plates. These platforms allow you to compare prices, read reviews, and find the best deals. Be sure to check the seller's ratings and feedback before making a purchase. Online marketplaces also provide the advantage of customer reviews, which can help you gauge the quality of the product before buying.

Manufacturer Websites

Many manufacturers have their own websites where they sell products directly to consumers. This can often lead to better prices since you are buying directly from the source. Look for manufacturers that specialize in wear-resistant materials and check their product catalogs for available options. Some manufacturers may also offer exclusive online discounts or promotions.

Industry Trade Shows

Attending industry trade shows can be an excellent way to find deals on chromium carbide overlay plates. These events often feature multiple suppliers showcasing their products, and you may be able to negotiate better prices in person. Additionally, trade shows provide an opportunity to network with industry professionals and learn about the latest advancements in wear-resistant technology. Engaging with suppliers face-to-face can also help you build relationships that may lead to better pricing in the future.

Local Distributors

Don't overlook local distributors who may carry chromium carbide overlay plates. Building a relationship with a local supplier can lead to better pricing and faster delivery times. Local distributors may also have insights into the specific needs of your region, allowing them to recommend the best products for your applications. Additionally, purchasing locally can reduce shipping costs and lead times.

Online Forums and Communities

Participating in online forums and communities related to your industry can provide valuable insights into where to find the best deals. Members often share their experiences with different suppliers and may recommend specific companies that offer competitive pricing. Engaging in these communities can also help you stay informed about industry trends and new products.

Tips for Maximizing Your Investment

To ensure you get the most value from your purchase of chromium carbide overlay plates, consider the following tips:

Regular Maintenance

Proper maintenance of your equipment can extend the life of chromium carbide overlay plates. Regularly inspect the plates for signs of wear and replace them as needed to prevent further damage to your machinery. Implementing a maintenance schedule can help you keep track of the condition of your plates and ensure they are functioning optimally.

Educate Your Team

Ensure that your team understands the importance of using chromium carbide overlay plates and how to handle them properly. Training your staff on best practices can help prevent damage and ensure optimal performance. Providing resources and training sessions can empower your team to make informed decisions regarding the use and maintenance of these plates.

Keep an Eye on Market Trends

Stay informed about market trends and pricing fluctuations for chromium carbide overlay plates. This knowledge can help you make informed purchasing decisions and take advantage of sales or promotions. Subscribing to industry newsletters or following relevant social media accounts can keep you updated on the latest news and offers.

Consider Long-Term Costs

While finding the best deal is essential, consider the long-term costs associated with the plates. Investing in higher-quality plates may result in lower replacement costs and less downtime for your equipment. Analyzing the total cost of ownership, including maintenance and replacement, can help you make better purchasing decisions.

Build Relationships with Suppliers

Establishing a good relationship with your suppliers can lead to better pricing and service in the long run. Regular communication and feedback can help you stay informed about new products and promotions. Building trust with your suppliers can also lead to priority service and support when you need it most.

Conclusion

Finding the best deals on chromium carbide overlay plates requires research, comparison, and an understanding of your specific needs. By considering factors such as material quality, supplier reputation, and customization options, you can make informed purchasing decisions. Utilize online marketplaces, manufacturer websites, and local distributors to find competitive pricing. Additionally, maintaining your equipment and building relationships with suppliers can maximize your investment in these essential components.

Frequently Asked Questions

1. What are chromium carbide overlay plates used for?

Chromium carbide overlay plates are used in various industries to provide wear resistance in applications such as mining, construction, and manufacturing. They are particularly effective in environments where equipment is exposed to abrasive materials.

2. How do I choose the right supplier for chromium carbide overlay plates?

Look for suppliers with a good reputation, quality materials, customization options, and competitive pricing. Researching reviews and testimonials can help you gauge the reliability of potential suppliers.

3. Can I get customized chromium carbide overlay plates?

Yes, many suppliers offer customization options to meet specific requirements for size, thickness, and shape. Customization can also include specific overlay patterns or additional treatments to enhance the wear resistance of the plates.

4. What factors affect the price of chromium carbide overlay plates?

Material quality, supplier reputation, customization options, and market demand can all influence the price. Comparing prices from multiple suppliers can help you find the best deal.

5. How can I extend the life of my chromium carbide overlay plates?

Regular maintenance, proper handling, and educating your team on best practices can help extend the life of the plates. Implementing a maintenance schedule and training sessions can ensure optimal performance and longevity.