Content Menu

● Understanding Silicon Carbide Plates

● Factors Influencing the Price of Silicon Carbide Plates

● Where to Find the Best Deals

>> 1. Online Marketplaces

>> 2. Manufacturer Websites

>> 3. Trade Shows and Expos

>> 4. Local Suppliers and Distributors

>> 5. Online Forums and Communities

● Tips for Making Informed Purchases

>> 1. Research Suppliers

>> 2. Request Samples

>> 3. Compare Prices

>> 4. Negotiate

>> 5. Stay Informed

● Conclusion

● Frequently Asked Questions

>> 1. What are the main applications of silicon carbide plates?

>> 2. How can I determine the quality of silicon carbide plates?

>> 3. Are there discounts available for bulk purchases of silicon carbide plates?

>> 4. What factors influence the price of silicon carbide plates?

>> 5. Where can I find silicon carbide plates for sale?

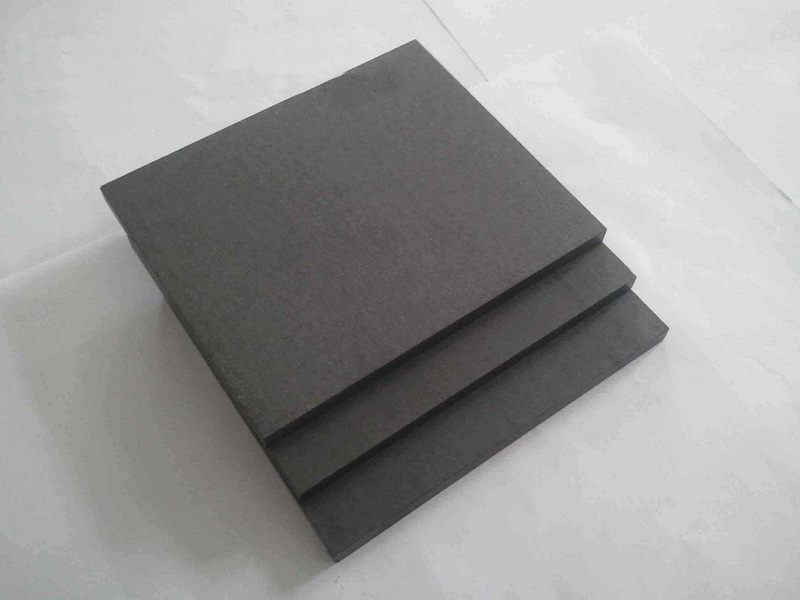

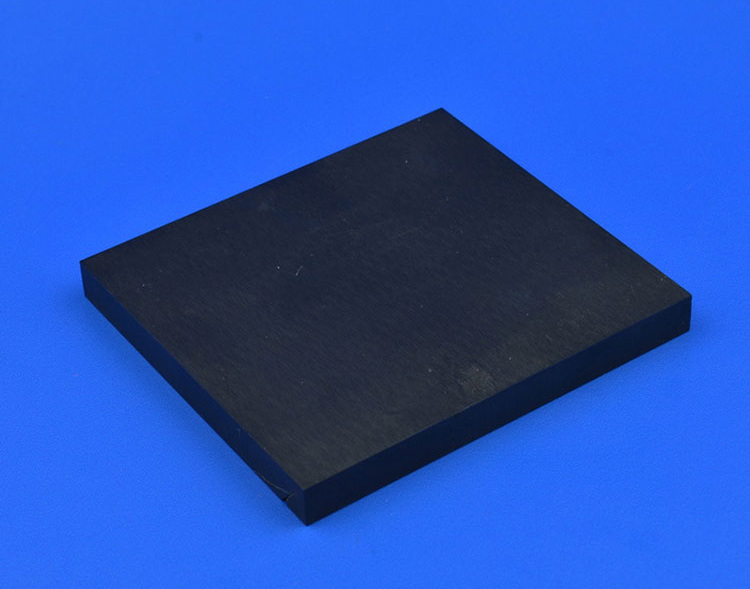

Understanding Silicon Carbide Plates

Silicon carbide (SiC) plates have become increasingly popular in various industries due to their exceptional properties, including high thermal conductivity, excellent wear resistance, and outstanding mechanical strength. As a result, many businesses and individuals are seeking the best deals on silicon carbide plates. This article will explore where to find these deals, the factors that influence pricing, and tips for making informed purchasing decisions.

Silicon carbide is a compound of silicon and carbon, known for its hardness and thermal stability. SiC plates are used in a variety of applications, including:

- Aerospace: SiC plates are used in high-temperature environments, such as rocket engines and turbine components. Their ability to withstand extreme conditions makes them ideal for aerospace applications.

- Electronics: They are essential in semiconductor devices due to their ability to withstand high voltages and temperatures. Silicon carbide is increasingly used in power electronics, such as inverters and converters, due to its efficiency.

- Defense: SiC plates are utilized in body armor and other protective gear due to their lightweight and strong properties. The military often employs silicon carbide in armor systems to provide enhanced protection without adding significant weight.

- Industrial Applications: They are used in grinding wheels, cutting tools, and other machinery that requires high durability. The hardness of silicon carbide makes it suitable for abrasive applications.

Factors Influencing the Price of Silicon Carbide Plates

When searching for the best deals on silicon carbide plates, it is essential to understand the factors that influence their pricing:

1. Material Quality: The purity and quality of the silicon carbide used in manufacturing the plates can significantly affect the price. Higher purity materials typically command higher prices due to their superior performance characteristics. For instance, high-purity SiC is often used in semiconductor applications, where even minor impurities can affect performance.

2. Thickness and Size: The dimensions of the silicon carbide plates also play a crucial role in determining the price. Thicker and larger plates require more material and processing time, leading to higher costs. Custom sizes may also incur additional charges due to the need for specialized manufacturing processes.

3. Manufacturing Process: Different manufacturing techniques, such as sintering or chemical vapor deposition, can impact the final price. Advanced manufacturing processes may yield higher-quality plates but can also increase costs. Understanding the manufacturing process can help buyers assess whether the price reflects the quality of the product.

4. Supplier Reputation: Established suppliers with a proven track record of quality and reliability may charge more for their products. However, purchasing from reputable suppliers can ensure better quality and customer service. It is often worth paying a premium for products from suppliers known for their quality assurance and customer support.

5. Market Demand: The demand for silicon carbide plates can fluctuate based on industry trends and technological advancements. High demand can lead to increased prices, while lower demand may result in discounts and promotions. Keeping an eye on market trends can help buyers time their purchases for the best deals.

Where to Find the Best Deals

Finding the best deals on silicon carbide plates requires a combination of research, comparison, and strategic purchasing. Here are some effective strategies to consider:

1. Online Marketplaces

Online marketplaces such as Amazon, Alibaba, and eBay offer a wide range of silicon carbide plates from various suppliers. These platforms often feature customer reviews and ratings, allowing you to assess the quality of the products before making a purchase. Additionally, you can compare prices from different sellers to find the best deal. Many sellers also provide detailed product descriptions and specifications, which can help you make informed decisions.

2. Manufacturer Websites

Many manufacturers have their own websites where they sell silicon carbide plates directly to consumers. Purchasing directly from the manufacturer can sometimes result in lower prices, as it eliminates the middleman. Additionally, manufacturers may offer bulk discounts or special promotions. It's also beneficial to subscribe to newsletters from manufacturers, as they often announce sales and new product launches through these channels.

3. Trade Shows and Expos

Attending industry trade shows and expos can provide valuable opportunities to find deals on silicon carbide plates. These events often feature multiple suppliers showcasing their products, allowing you to compare prices and negotiate directly with manufacturers. Furthermore, many exhibitors offer exclusive discounts for attendees. Networking at these events can also lead to future purchasing opportunities and insights into upcoming trends in silicon carbide technology.

4. Local Suppliers and Distributors

Don't overlook local suppliers and distributors who may offer competitive pricing on silicon carbide plates. Building a relationship with local suppliers can lead to better deals and personalized service. Additionally, local suppliers may have lower shipping costs and faster delivery times. Visiting local suppliers can also provide the opportunity to inspect the products in person before making a purchase.

5. Online Forums and Communities

Participating in online forums and communities related to silicon carbide materials can provide insights into where to find the best deals. Members often share their experiences and recommendations for suppliers, as well as tips for negotiating prices. Engaging with these communities can also help you stay informed about industry trends and new product releases.

Tips for Making Informed Purchases

When searching for silicon carbide plates, consider the following tips to ensure you make informed purchasing decisions:

1. Research Suppliers

Before making a purchase, research potential suppliers to assess their reputation and reliability. Look for customer reviews, testimonials, and ratings to gauge the quality of their products and services. Websites like Trustpilot and Google Reviews can provide insights into customer experiences with specific suppliers.

2. Request Samples

If possible, request samples of silicon carbide plates before committing to a large order. This allows you to evaluate the quality and performance of the material firsthand. Many suppliers are willing to provide samples, especially for bulk orders, as it can lead to larger sales.

3. Compare Prices

Take the time to compare prices from multiple suppliers. Keep in mind that the lowest price may not always indicate the best value. Consider factors such as quality, shipping costs, and customer service when making your decision. Creating a spreadsheet to track prices and features can help you visualize your options.

4. Negotiate

Don't hesitate to negotiate prices with suppliers, especially if you are placing a bulk order. Many suppliers are willing to offer discounts or special deals to secure larger sales. Building a rapport with suppliers can also lead to better pricing and terms.

5. Stay Informed

Stay updated on industry trends and advancements in silicon carbide technology. This knowledge can help you make informed decisions about when to purchase and which products to consider. Following industry publications, blogs, and news sites can provide valuable insights into market trends.

Conclusion

Finding the best deals on silicon carbide plates requires a combination of research, comparison, and strategic purchasing. By understanding the factors that influence pricing and exploring various purchasing avenues, you can secure high-quality silicon carbide plates at competitive prices. Whether you are in aerospace, electronics, defense, or industrial applications, silicon carbide plates offer exceptional performance and durability.

Frequently Asked Questions

1. What are the main applications of silicon carbide plates?

Silicon carbide plates are used in aerospace, electronics, defense, and industrial applications due to their high thermal conductivity, wear resistance, and mechanical strength.

2. How can I determine the quality of silicon carbide plates?

Research suppliers, read customer reviews, and request samples to assess the quality of silicon carbide plates before making a purchase.

3. Are there discounts available for bulk purchases of silicon carbide plates?

Many suppliers offer discounts for bulk orders, so it is advisable to negotiate prices when placing large orders.

4. What factors influence the price of silicon carbide plates?

Factors include material quality, thickness and size, manufacturing process, supplier reputation, and market demand.

5. Where can I find silicon carbide plates for sale?

Silicon carbide plates can be found on online marketplaces, manufacturer websites, trade shows, local suppliers, and online forums.