Content Menu

● Understanding Carbide Chisel Tips

>> Benefits of Carbide Chisel Tips

● Ideal Projects for Carbide Chisel Tips

>> 1. Woodturning

>>> Tips for Woodturning with Carbide Chisels

>> 2. Detailed Carving

>>> Techniques for Detailed Carving

>> 3. Furniture Making

>>> Best Practices for Furniture Making

>> 4. Sign Making

>>> Sign Making Techniques

>> 5. Metalworking

>>> Tips for Metalworking with Carbide Chisels

>> 6. Jewelry Making

>>> Jewelry Making Techniques

>> 7. Model Making

>>> Best Practices for Model Making

● How to Use Carbide Chisel Tips Effectively

● Conclusion

● Related Questions

>> 1. What materials can I use with carbide chisel tips?

>> 2. How often should I replace my carbide chisel tips?

>> 3. Can I sharpen carbide chisel tips?

>> 4. Are there specific brands recommended for carbide chisel tips?

>> 5. What safety precautions should I take when using carbide chisels?

Carbide chisel tips are an essential tool for various woodworking and metalworking projects. Their durability and sharpness make them ideal for precision tasks, allowing craftsmen to achieve clean cuts and intricate designs. In this article, we will explore the types of projects that benefit most from carbide chisel tips, the advantages they offer, and practical tips for using them effectively.

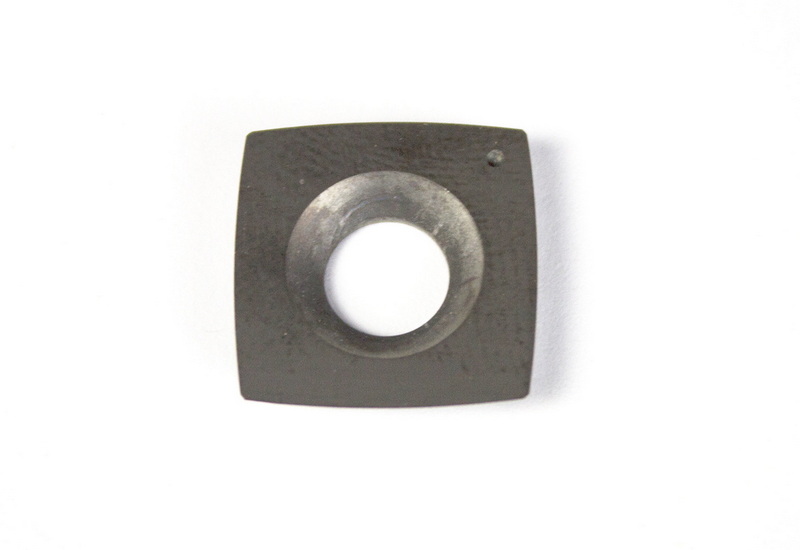

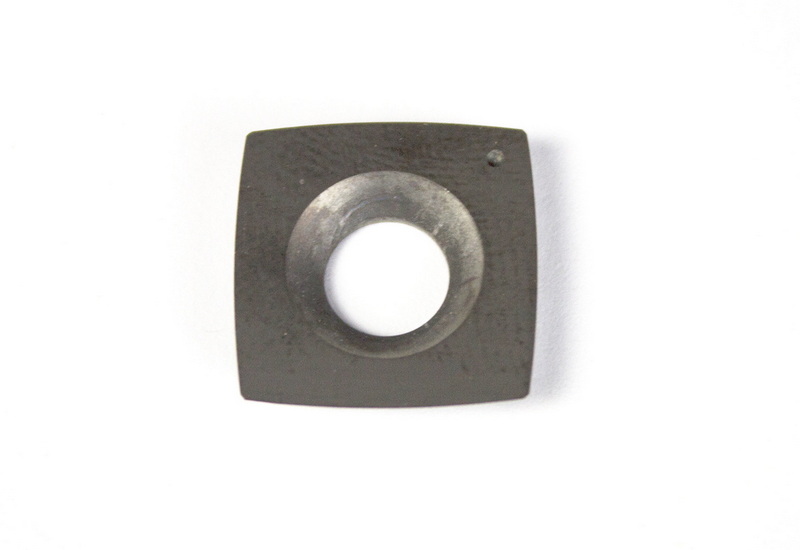

Understanding Carbide Chisel Tips

Carbide chisel tips are made from tungsten carbide, a material known for its hardness and wear resistance. Unlike traditional steel tips, carbide tips maintain their sharpness longer, reducing the need for frequent sharpening. This characteristic makes them particularly valuable in high-volume or detailed work where precision is paramount.

Benefits of Carbide Chisel Tips

- Longevity: Carbide tips last significantly longer than steel tips, making them cost-effective over time.

- Precision: They provide cleaner cuts with less effort, which is crucial for intricate designs.

- Versatility: Suitable for various materials, including wood, metal, and composites.

- Reduced Friction: The smooth surface of carbide reduces friction during cutting, resulting in less heat generation and extended tool life.

- Resistance to Wear: Carbide chisel tips can withstand heavy use without significant degradation in performance.

- Less Frequent Sharpening: The ability to maintain a sharp edge means less downtime for sharpening, allowing craftsmen to focus on their projects.

Ideal Projects for Carbide Chisel Tips

1. Woodturning

Woodturning is one of the most popular applications for carbide chisel tips. These tools excel in shaping and finishing wooden pieces on a lathe. The sharpness of carbide tips allows woodworkers to create smooth surfaces and detailed patterns with ease.

For example, when turning bowls or vases, the ability to achieve fine details without frequent sharpening is invaluable. The consistent performance of carbide chisel tips means that woodturners can focus on their creativity rather than tool maintenance.

Tips for Woodturning with Carbide Chisels

- Choose the Right Profile: Different profiles (such as square or round) serve different purposes. Select the one that best fits your project.

- Maintain a Steady Hand: A steady hand is essential for achieving smooth finishes; practice your technique on scrap wood before starting your final piece.

- Use Proper Lathe Speed: Adjust the lathe speed according to the type of wood you are using to prevent burning or tearing.

2. Detailed Carving

For projects that require intricate carving, such as sculptures or decorative items, carbide chisel tips provide the precision needed to achieve fine details. Their ability to hold an edge means fewer interruptions for sharpening during the carving process.

Carvers often use these chisels to create textures and patterns that would be difficult to achieve with traditional tools. The durability of carbide also allows artists to work with harder woods without fear of damaging their tools.

Techniques for Detailed Carving

- Start with a Plan: Sketch your design before beginning to ensure you have a clear vision of what you want to create.

- Use Different Chisel Sizes: Employ various sizes of chisels for different details; smaller chisels work well for fine lines while larger ones can remove bulk material quickly.

- Take Your Time: Intricate work requires patience; don't rush through details as this can lead to mistakes.

3. Furniture Making

In furniture making, carbide chisel tips are used to create joints and edges that fit perfectly. The durability of these tips allows woodworkers to work with harder woods without worrying about dulling their tools quickly.

For instance, when crafting dovetail joints or mortise-and-tenon joints, precision is key. Carbide chisels ensure that cuts are clean and accurate, resulting in stronger and more aesthetically pleasing furniture pieces.

Best Practices for Furniture Making

- Measure Twice, Cut Once: Always double-check measurements before cutting; accuracy is crucial in furniture making.

- Dry Fit Joints: Before gluing pieces together, dry fit them to ensure everything aligns correctly.

- Finishing Touches: Use finer grit sandpaper after chiseling to achieve a smooth finish before applying any stains or finishes.

4. Sign Making

Carbide chisel tips are ideal for sign making, where precision is crucial. Whether engraving letters or creating decorative elements, the sharpness of carbide allows for clean lines and professional finishes.

Many sign makers appreciate how carbide chisels can produce consistent results across various materials such as wood, acrylic, or even metal signs. The ability to work quickly without sacrificing quality is a significant advantage in this field.

Sign Making Techniques

- Select Appropriate Materials: Choose materials that suit your design; softer woods are easier to carve but may not be as durable as harder options.

- Use Templates: Create templates for lettering or designs to ensure uniformity across multiple signs.

- Practice Engraving Techniques: Experiment with different angles and pressures when engraving letters to achieve desired effects.

5. Metalworking

While primarily associated with woodworking, carbide chisel tips can also be used in metalworking projects. They are effective in shaping metals and can withstand the rigors of cutting through harder materials.

Metalworkers often use carbide chisels for tasks like deburring edges or creating precise cuts in sheet metal. The hardness of the carbide allows it to maintain its edge even when working with tough alloys.

Tips for Metalworking with Carbide Chisels

- Use Appropriate Safety Gear: Always wear gloves and eye protection when working with metal to prevent injuries from sharp edges or flying debris.

- Control Heat Generation: Use cutting fluids if necessary to keep temperatures down while working on metal surfaces.

- Check Tool Alignment Regularly: Ensure that your tools are aligned correctly during use to maintain precision.

6. Jewelry Making

Jewelry makers benefit from using carbide chisel tips when creating intricate designs in metals like silver or gold. The precision offered by these chisels allows artisans to craft detailed pieces that require fine workmanship.

Carbide chisels can be used for engraving patterns on metal surfaces or even for setting stones where accuracy is critical. This application highlights the versatility of carbide tools beyond traditional woodworking.

Jewelry Making Techniques

- Plan Your Design Carefully: Sketch designs on paper before transferring them onto metal; this helps visualize the final product.

- Use Light Pressure: When engraving delicate pieces, apply light pressure to avoid damaging the material.

- Finishing Touches Matter: After completing your piece, polish it carefully to enhance its shine and finish.

7. Model Making

In model making—whether for architectural models or miniature figures—carbide chisel tips provide the precision needed to create fine details and smooth finishes. Model makers often face the challenge of working with small parts; therefore, having reliable tools like carbide chisels is essential.

These chisels allow model makers to carve out intricate designs or make precise adjustments without damaging delicate components.

Best Practices for Model Making

- Work on a Stable Surface: Ensure your workspace is stable and well-lit; this helps maintain accuracy during detailed work.

- Practice Patience: Small-scale work requires meticulous attention; take your time with each component.

- Use Reference Models: Having reference models can guide you in achieving proportions and details accurately.

How to Use Carbide Chisel Tips Effectively

To maximize the benefits of carbide chisel tips, consider the following tips:

1. Proper Tool Setup: Ensure that your chisels are securely attached to your tool rest or lathe.

2. Maintain Correct Speed: Use appropriate speeds for different materials; too fast can cause burning or damage.

3. Use Light Pressure: Let the tool do the work; excessive force can lead to tool breakage or poor results.

4. Regular Cleaning: Keep your chisels clean from resin buildup to maintain performance.

5. Storage: Store chisels in a protective case to prevent damage when not in use.

6. Experiment with Angles: Different cutting angles can yield various results; experiment to find what works best for your project.

7. Practice Safety: Always wear safety glasses and use proper techniques to avoid accidents while working.

8. Sharpening Techniques: Although carbide chisels require less frequent sharpening, knowing how to sharpen them properly will extend their lifespan even further.

Conclusion

Carbide chisel tips are invaluable tools across various projects, from woodworking to metalworking and beyond. Their durability and precision make them suitable for both hobbyists and professionals alike. By understanding their applications and following best practices for use, craftsmen can enhance their work quality and efficiency.

Investing in high-quality carbide chisel tips will pay off in terms of time saved on maintenance and improved project outcomes. Whether you are turning wood on a lathe or engraving a sign, these tools will help you achieve professional results every time.

Related Questions

1. What materials can I use with carbide chisel tips?

Carbide chisel tips are versatile and can be used on wood, metal, plastic, and composite materials.

2. How often should I replace my carbide chisel tips?

The lifespan of carbide chisel tips varies based on usage but generally lasts much longer than steel tips before needing replacement.

3. Can I sharpen carbide chisel tips?

While carbide is much harder than steel and does not require frequent sharpening, specialized equipment is needed if sharpening is necessary.

4. Are there specific brands recommended for carbide chisel tips?

Brands like Easy Wood Tools and David Lloyd Tools are well-regarded for their high-quality carbide chisel tips.

5. What safety precautions should I take when using carbide chisels?

Always wear safety glasses, ensure your workspace is clear of debris, and maintain a firm grip on your tools while working.