Content Menu

● Understanding Carbide Plates

● Types of China Carbide Plates Available at Shengyufeng

>> Flat Carbide Plates

>> Carbide Wear Plates

>> Carbide Cutting Plates

>> Carbide Inserts

>> Custom Carbide Plates

● Applications of Carbide Plates

>> Manufacturing

>> Mining

>> Construction

>> Aerospace

>> Oil and Gas

● Benefits of Using Carbide Plates from Shengyufeng

>> Quality Assurance

>> Competitive Pricing

>> Customization Options

>> Expert Support

● How to Choose the Right Carbide Plate

>> Application

>> Size and Thickness

>> Material Composition

>> Supplier Reputation

● Conclusion

● Frequently Asked Questions

>> 1. What are carbide plates used for?

>> 2. How do I choose the right carbide plate?

>> 3. Can I order custom carbide plates from Shengyufeng?

>> 4. What are the benefits of using carbide plates?

>> 5. Is Shengyufeng a reliable supplier for carbide plates?

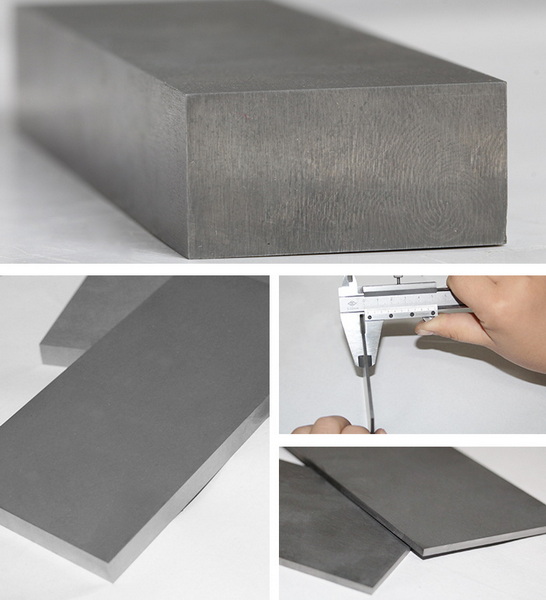

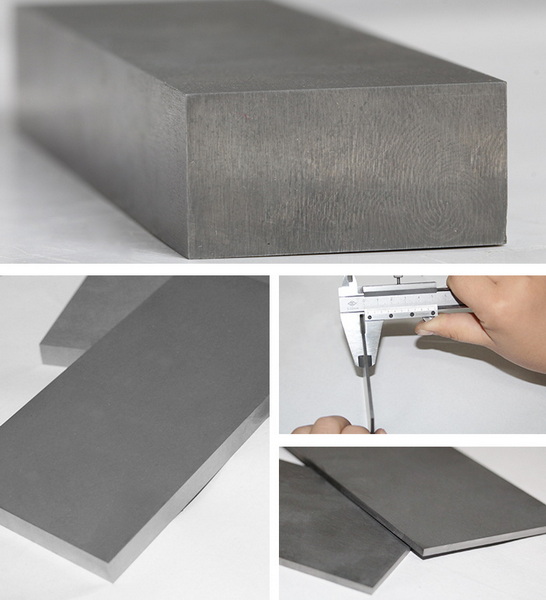

Understanding Carbide Plates

Carbide plates are made from tungsten carbide, a compound of tungsten and carbon. This material is known for its exceptional hardness and resistance to abrasion, making it ideal for various industrial applications. Carbide plates are used in manufacturing, mining, construction, and other sectors where durability is crucial. The unique properties of tungsten carbide allow it to withstand high temperatures and pressures, making it a preferred choice for many heavy-duty applications.

Types of China Carbide Plates Available at Shengyufeng

Shengyufeng offers a wide range of carbide plates, each designed for specific applications. Here are some of the most common types:

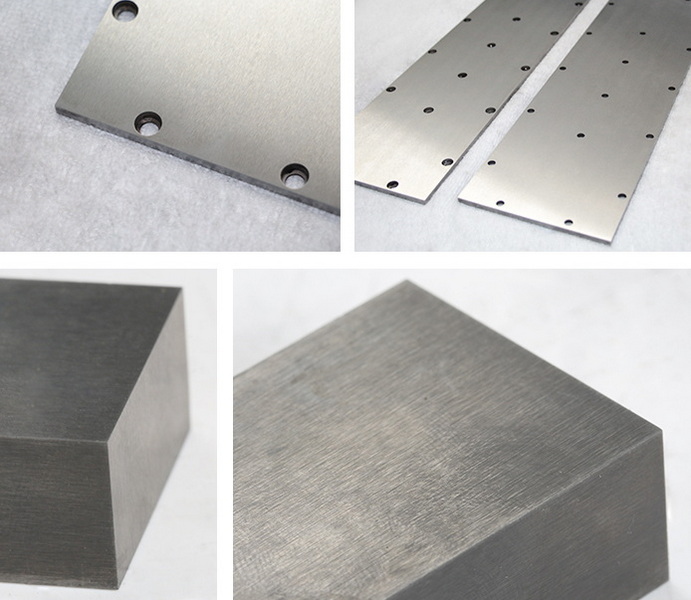

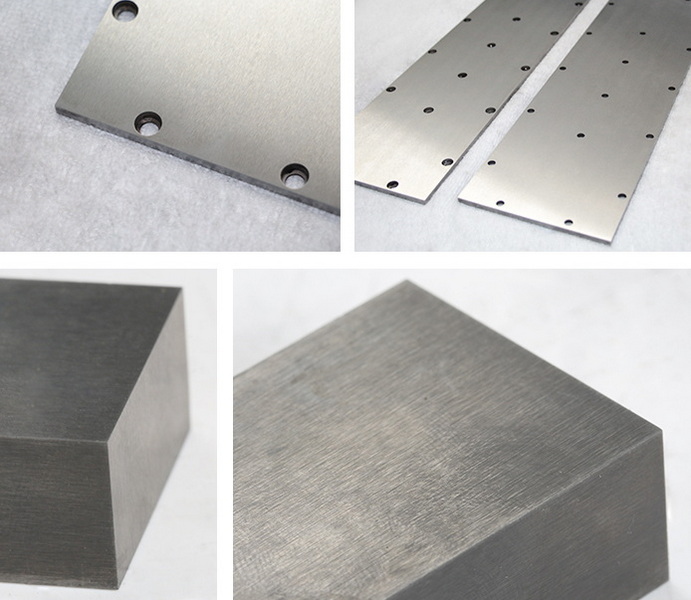

Flat Carbide Plates

Flat carbide plates are the most common type and are used in various applications, including machining and tooling. They provide a smooth surface for cutting and shaping materials. These plates are often used in industries that require precision and accuracy, such as aerospace and automotive manufacturing.

Carbide Wear Plates

These plates are designed to withstand extreme wear and tear. They are often used in mining and construction equipment to protect against abrasion and impact. The durability of carbide wear plates makes them ideal for use in harsh environments where other materials may fail.

Carbide Cutting Plates

Cutting plates are specifically designed for machining applications. They are used in tools that require high precision and durability, such as lathes and milling machines. The sharp edges of carbide cutting plates allow for clean cuts and efficient material removal, making them essential in manufacturing processes.

Carbide Inserts

Inserts are small, replaceable cutting tools made from carbide. They are used in various machining processes and are known for their ability to maintain sharp edges over time. Carbide inserts are often used in conjunction with other tools to enhance their performance and extend their lifespan.

Custom Carbide Plates

Shengyufeng also offers custom carbide plates tailored to specific requirements. This flexibility allows businesses to obtain plates that meet their unique operational needs. Customization can include specific dimensions, shapes, and material compositions, ensuring that customers receive exactly what they need for their applications.

Applications of Carbide Plates

Carbide plates are used in various industries due to their versatility and durability. Here are some common applications:

Manufacturing

In the manufacturing sector, carbide plates are used in the production of tools and machinery, providing a long-lasting solution for cutting and shaping materials. Their hardness allows them to maintain their shape and sharpness over extended periods, reducing the need for frequent replacements.

Mining

In the mining industry, carbide wear plates protect equipment from the harsh conditions of extracting minerals. These plates are essential for ensuring the longevity of machinery used in mining operations, where exposure to abrasive materials is common.

Construction

Carbide plates are used in construction tools, ensuring they can withstand heavy use and maintain performance. Tools such as drills, saws, and other equipment benefit from the durability of carbide plates, allowing for efficient and effective construction processes.

Aerospace

The aerospace industry utilizes carbide plates for components that require high strength and resistance to wear. The ability of carbide to withstand extreme conditions makes it suitable for applications in aircraft manufacturing and maintenance.

Oil and Gas

In the oil and gas industry, carbide plates are used in drilling equipment and tools. Their resistance to wear and ability to perform under high pressure make them ideal for applications in harsh environments, such as offshore drilling.

Benefits of Using Carbide Plates from Shengyufeng

Choosing carbide plates from Shengyufeng comes with several advantages:

Quality Assurance

Shengyufeng is known for its high-quality products, ensuring that customers receive durable and reliable carbide plates. The company adheres to strict quality control measures, guaranteeing that each plate meets industry standards.

Competitive Pricing

As a wholesale supplier, Shengyufeng offers competitive pricing, making it an economical choice for businesses looking to purchase in bulk. This affordability allows companies to invest in high-quality materials without exceeding their budgets.

Customization Options

The ability to order custom carbide plates allows businesses to get exactly what they need for their specific applications. This customization can include variations in size, shape, and material composition, ensuring that the plates fit seamlessly into existing processes.

Expert Support

Shengyufeng provides expert guidance and support, helping customers choose the right products for their needs. Their knowledgeable staff can assist with technical questions and provide recommendations based on specific applications.

How to Choose the Right Carbide Plate

When selecting carbide plates, consider the following factors:

Application

Determine the specific application for which the carbide plate will be used. Different applications may require different types of plates, so understanding the intended use is crucial.

Size and Thickness

Ensure that the size and thickness of the plate meet the requirements of your machinery or tools. Proper dimensions are essential for optimal performance and compatibility.

Material Composition

Look for plates made from high-quality tungsten carbide to ensure durability and performance. The composition of the carbide can affect its hardness and resistance to wear.

Supplier Reputation

Choose a reputable supplier like Shengyufeng to ensure you receive quality products and support. Researching customer reviews and testimonials can provide insight into the supplier's reliability.

Conclusion

In summary, carbide plates are essential components in various industries, and Shengyufeng offers a wide range of options to meet diverse needs. From flat plates to custom solutions, the quality and durability of these products make them a preferred choice for businesses looking to enhance their operational efficiency. By understanding the types of carbide plates available and their applications, you can make informed decisions that benefit your business.

Frequently Asked Questions

1. What are carbide plates used for?

Carbide plates are used in manufacturing, mining, construction, and aerospace industries for cutting, shaping, and protecting equipment.

2. How do I choose the right carbide plate?

Consider the application, size, thickness, material composition, and supplier reputation when selecting carbide plates.

3. Can I order custom carbide plates from Shengyufeng?

Yes, Shengyufeng offers custom carbide plates tailored to specific requirements.

4. What are the benefits of using carbide plates?

Carbide plates provide durability, resistance to wear, and high performance in various applications.

5. Is Shengyufeng a reliable supplier for carbide plates?

Yes, Shengyufeng is known for its high-quality products and competitive pricing, making it a trusted supplier in the industry.