Content Menu

● Composition and Structure of Tungsten Carbide

>> Crystal Structure

>> Variants of Tungsten Carbide

● Properties of Tungsten Carbide

>> Thermal Conductivity

>> Electrical Conductivity

● Manufacturing Process

>> Sintering Techniques

● Applications of Tungsten Carbide

>> Mining Industry

>> Oil and Gas Industry

>> Aerospace Applications

● Advantages of Tungsten Carbide

>> Environmental Considerations

● Challenges in Working with Tungsten Carbide

● Conclusion

● FAQ

>> 1. What is tungsten carbide used for?

>> 2. How is tungsten carbide manufactured?

>> 3. Is tungsten carbide more durable than steel?

>> 4. Can tungsten carbide be recycled?

>> 5. What are the benefits of using tungsten carbide tools?

● Citations:

Tungsten carbide, represented by the chemical formula WC, is a remarkable material formed by combining tungsten and carbon atoms in a precise ratio. This compound is renowned for its exceptional hardness and durability, making it a preferred choice in various industrial applications. In this article, we will explore the properties, manufacturing processes, applications, advantages of tungsten carbide, and its impact on various industries, providing a comprehensive understanding of this versatile material.

Composition and Structure of Tungsten Carbide

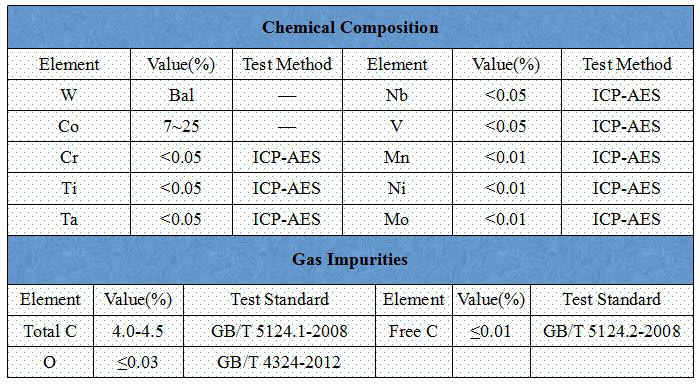

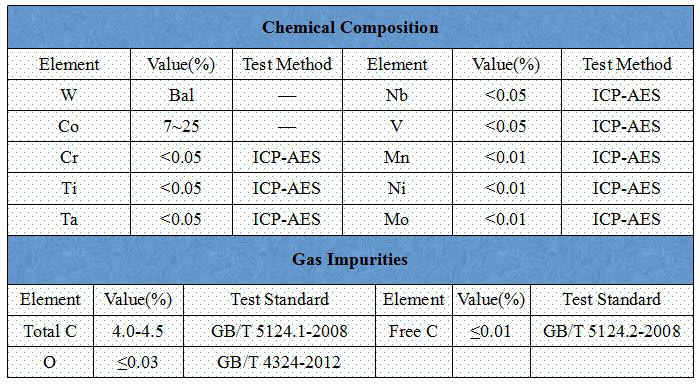

Tungsten carbide consists primarily of tungsten (approximately 94% by weight) and carbon (about 6%). The unique arrangement of these atoms forms a hexagonal crystal structure that contributes to its impressive physical properties. The material can be synthesized by heating tungsten powder with carbon at temperatures ranging from 1400°C to 2000°C. This process results in a fine gray powder that can be shaped through sintering.

Crystal Structure

The crystal structure of tungsten carbide is crucial to its performance characteristics. The hexagonal close-packed structure allows for efficient packing of atoms, which contributes to its hardness. Additionally, the strong covalent bonds between tungsten and carbon atoms provide stability under high stress and temperature conditions.

Variants of Tungsten Carbide

There are two primary forms of tungsten carbide: alpha (α) and beta (β) tungsten carbide. Alpha tungsten carbide is more stable at lower temperatures, while beta tungsten carbide is stable at higher temperatures. The properties of these variants differ slightly, making them suitable for specific applications.

Properties of Tungsten Carbide

Tungsten carbide possesses several key properties that make it stand out among other materials:

- Hardness: With a Mohs hardness rating between 9 and 9.5, tungsten carbide is one of the hardest materials available, surpassed only by diamond.

- Density: It has a high density (approximately 15.6 g/cm³), making it significantly heavier than steel.

- Strength: The compressive strength of tungsten carbide is two to three times greater than that of steel.

- Thermal Stability: It maintains its structural integrity even at high temperatures, with a melting point around 2,747°C.

- Corrosion Resistance: Tungsten carbide exhibits excellent resistance to wear and corrosion, making it suitable for harsh environments.

Thermal Conductivity

Another important property of tungsten carbide is its thermal conductivity. It has relatively high thermal conductivity compared to other hard materials, which helps dissipate heat during machining processes and reduces the risk of thermal damage to tools.

Electrical Conductivity

While not a conductor like metals such as copper or aluminum, tungsten carbide does have some electrical conductivity due to its metallic bonding characteristics. This property can be beneficial in certain applications where electrical conductivity is required.

Manufacturing Process

The production of tungsten carbide typically involves the following steps:

1. Powder Preparation: Tungsten and carbon powders are mixed in the correct proportions.

2. Sintering: The mixture is heated under controlled conditions to form solid tungsten carbide.

3. Binding Agents: To enhance toughness, metallic binders such as cobalt or nickel are often added during the manufacturing process.

4. Shaping: The resulting material can be pressed into various shapes for different applications.

Sintering Techniques

Various sintering techniques are employed in the manufacturing process:

- Conventional Sintering: This method involves heating the powder mixture in a furnace under vacuum or inert gas atmospheres.

- Hot Isostatic Pressing (HIP): In this advanced technique, pressure is applied uniformly while heating the material, resulting in improved density and mechanical properties.

- Spark Plasma Sintering (SPS): This technique uses pulsed electric current to rapidly heat the powder mixture, allowing for shorter processing times and finer microstructures.

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it suitable for a wide range of applications across various industries:

- Cutting Tools: Used extensively in manufacturing tools such as drills, milling cutters, and saw blades due to its hardness and wear resistance.

- Jewelry: Popular in the creation of wedding bands and other jewelry items because of its scratch resistance and aesthetic appeal.

- Industrial Machinery: Employed in components that require high durability and resistance to wear and tear.

- Ammunition: Utilized in armor-piercing projectiles due to its density and hardness.

- Medical Instruments: Incorporated into surgical tools for enhanced performance and longevity.

Mining Industry

In the mining industry, tungsten carbide is used for drill bits and other tools that must withstand extreme conditions while maintaining sharpness over extended periods. Its ability to resist wear makes it ideal for drilling through hard rock formations.

Oil and Gas Industry

The oil and gas industry employs tungsten carbide in drilling equipment due to its resistance to abrasion and high temperatures encountered during drilling operations. Components such as drill bits made from tungsten carbide can significantly enhance operational efficiency.

Aerospace Applications

In aerospace applications, tungsten carbide is utilized in components that require high strength-to-weight ratios and exceptional wear resistance. Parts such as turbine blades benefit from the material's thermal stability and mechanical strength.

Advantages of Tungsten Carbide

The advantages of using tungsten carbide include:

- Longevity: Tools made from tungsten carbide last significantly longer than those made from steel.

- Cost-effectiveness: Although initial costs may be higher, the durability leads to lower long-term costs due to reduced replacement frequency.

- Versatility: Its ability to be molded into various shapes allows for customization in different applications.

Environmental Considerations

Tungsten carbide's longevity also contributes positively to environmental sustainability by reducing waste generated from frequent tool replacements. Additionally, many manufacturers are adopting recycling practices for scrap materials generated during production.

Challenges in Working with Tungsten Carbide

Despite its many advantages, working with tungsten carbide does present some challenges:

- Brittleness: While extremely hard, tungsten carbide can be brittle under certain conditions, making it susceptible to chipping or cracking if not handled properly.

- Machining Difficulty: Machining tungsten carbide requires specialized equipment due to its hardness; traditional cutting tools may not be effective.

- Cost Factors: The initial cost of tungsten carbide products can be higher than alternatives like high-speed steel or ceramic materials.

Conclusion

In conclusion, tungsten carbide is an extraordinary material characterized by its hardness, strength, versatility, and wide-ranging applications across multiple industries. Its unique properties make it indispensable in manufacturing cutting tools, industrial machinery components, jewelry production, aerospace engineering, mining operations, and more. Understanding the composition, properties, manufacturing processes, applications, advantages, and challenges associated with tungsten carbide highlights its significance in modern technology.

As industries continue to advance toward more durable materials that can withstand extreme conditions while providing cost-effective solutions over time, tungsten carbide will undoubtedly remain at the forefront of innovation.

FAQ

1. What is tungsten carbide used for?

Tungsten carbide is widely used for cutting tools, industrial machinery components, jewelry, ammunition, and medical instruments due to its hardness and durability.

2. How is tungsten carbide manufactured?

Tungsten carbide is manufactured by mixing tungsten powder with carbon at high temperatures (1400°C to 2000°C) and then sintering it into solid forms.

3. Is tungsten carbide more durable than steel?

Yes, tungsten carbide is significantly more durable than steel; it has a hardness rating that ranks it among the hardest materials available.

4. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled effectively due to its valuable properties and materials.

5. What are the benefits of using tungsten carbide tools?

The benefits include longer tool life, reduced replacement costs over time, high resistance to wear and corrosion, and superior performance in demanding applications.

Citations:

[1] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[2] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[3] https://metalstek.com/tungsten-carbide/

[4] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[5] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[6] https://material-properties.org/tungsten-carbide/

[7] https://www.carbideprobes.com/wp-content/uploads/2019/07/TungstenCarbideDataSheet.pdf

[8] https://en.wikipedia.org/wiki/Tungsten_carbide

[9] https://www.vedantu.com/chemistry/tungsten-carbide

[10] https://www.hitechseals.com/includes/pdf/tungsten_carbide.pdf

[11] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[12] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html