Content Menu

● Understanding Titanium Carbide

>> Properties of Titanium Carbide

● Benefits of Using Titanium Carbide Plates in Cutting Tools

>> 1. Enhanced Tool Life

>> 2. Improved Cutting Performance

>> 3. Versatility

>> 4. Cost-Effectiveness

>> 5. Reduced Tool Wear

● Applications of Titanium Carbide Plates

>> 1. Metal Machining

>> 2. Woodworking

>> 3. Aerospace Industry

>> 4. Oil and Gas Industry

>> 5. Medical Device Manufacturing

● The Future of Titanium Carbide in Cutting Tools

>> Innovations in Titanium Carbide Technology

>> Environmental Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is titanium carbide?

>> 2. Why are titanium carbide plates preferred for cutting tools?

>> 3. In which industries are titanium carbide plates commonly used?

>> 4. How do titanium carbide plates compare to traditional cutting materials?

>> 5. What advancements are being made in titanium carbide technology?

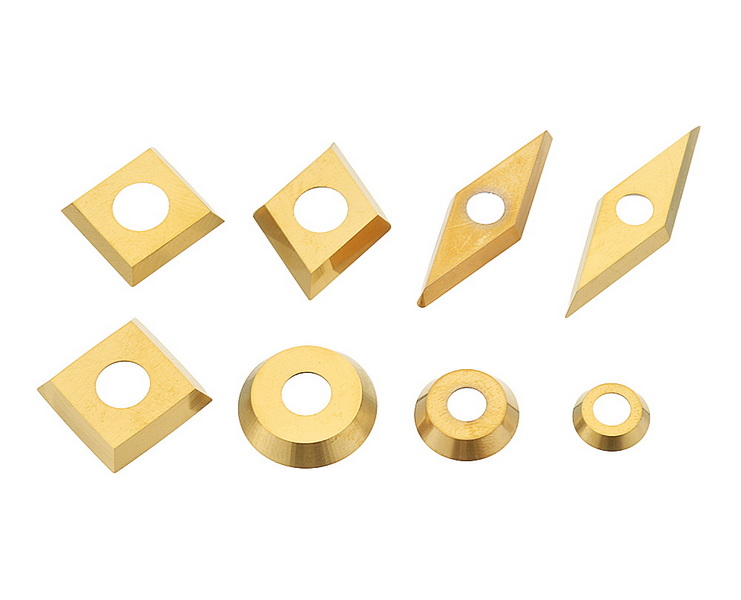

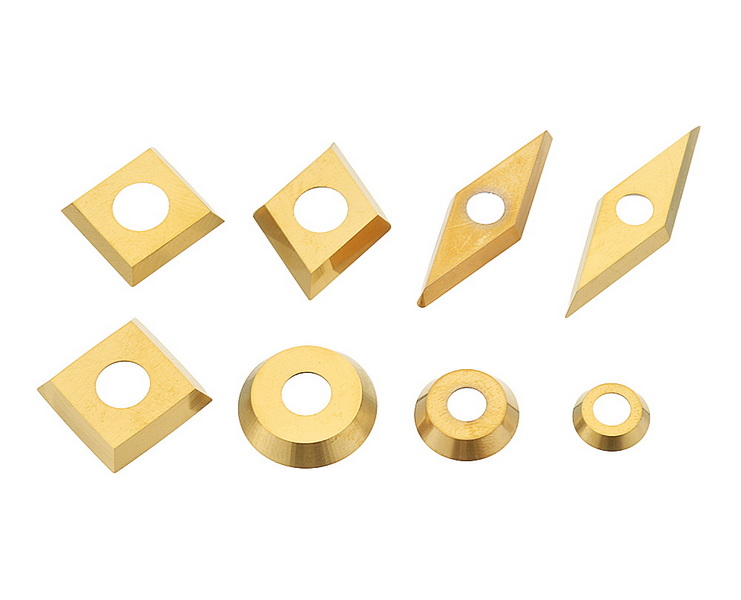

In the world of manufacturing and machining, the choice of materials for cutting tools is crucial. Among the various options available, titanium carbide plates have emerged as a preferred choice for many applications. This article explores the reasons behind this preference, delving into the properties, benefits, and applications of titanium carbide plates in cutting tools.

Understanding Titanium Carbide

Titanium carbide (TiC) is a ceramic compound that consists of titanium and carbon. It is known for its exceptional hardness, high melting point, and excellent wear resistance. These properties make titanium carbide an ideal material for cutting tools, where durability and performance are paramount.

Properties of Titanium Carbide

1. Hardness: Titanium carbide is one of the hardest materials available, ranking close to diamond on the Mohs scale. This hardness allows cutting tools made from titanium carbide to maintain their sharpness longer than those made from softer materials.

2. Wear Resistance: The wear resistance of titanium carbide is significantly higher than that of traditional steel tools. This means that tools made from titanium carbide can withstand the rigors of machining operations without degrading quickly.

3. Thermal Stability: Titanium carbide can withstand high temperatures without losing its structural integrity. This thermal stability is essential in cutting applications where friction generates heat.

4. Chemical Resistance: Titanium carbide exhibits excellent resistance to chemical corrosion, making it suitable for machining materials that may react with other tool materials.

5. Low Density: Compared to other hard materials, titanium carbide has a relatively low density, which can lead to lighter cutting tools that are easier to handle and operate.

Benefits of Using Titanium Carbide Plates in Cutting Tools

1. Enhanced Tool Life

One of the most significant advantages of titanium carbide plates is their ability to extend the life of cutting tools. The hardness and wear resistance of titanium carbide mean that tools can operate for longer periods without needing replacement or sharpening. This not only reduces downtime but also lowers overall production costs.

2. Improved Cutting Performance

Titanium carbide plates provide superior cutting performance compared to traditional materials. The sharpness and durability of these plates allow for cleaner cuts and better surface finishes. This is particularly important in industries where precision is critical, such as aerospace and automotive manufacturing.

3. Versatility

Titanium carbide plates can be used in a wide range of cutting applications, from machining metals to working with composites and plastics. This versatility makes them a valuable addition to any manufacturing operation, as they can be employed in various processes without the need for frequent tool changes.

4. Cost-Effectiveness

While titanium carbide plates may have a higher initial cost than some other materials, their long-term benefits often outweigh this expense. The extended tool life and reduced maintenance requirements lead to lower overall costs in the manufacturing process.

5. Reduced Tool Wear

The wear resistance of titanium carbide plates means that they experience less degradation during use. This results in less frequent tool changes and a more consistent quality of work, as tools maintain their cutting edges for longer periods.

Applications of Titanium Carbide Plates

1. Metal Machining

Titanium carbide plates are widely used in metal machining applications, including turning, milling, and drilling. Their hardness and wear resistance make them ideal for cutting through tough materials like steel and titanium. In metal machining, the ability to maintain sharp edges and resist wear is crucial for achieving high-quality finishes and precise dimensions.

2. Woodworking

In woodworking, titanium carbide-tipped tools are used for cutting, shaping, and finishing wood products. The durability of titanium carbide ensures that these tools can handle the demands of high-volume production. Woodworking tools equipped with titanium carbide tips can cut through hardwoods and softwoods alike, providing clean cuts and reducing the need for frequent tool changes.

3. Aerospace Industry

The aerospace industry requires precision and reliability in its manufacturing processes. Titanium carbide plates are used in cutting tools for machining aircraft components, where the quality of the cut can impact the overall performance and safety of the aircraft. The ability to withstand high temperatures and maintain sharpness is essential in this industry, where tolerances are tight and materials are often difficult to machine.

4. Oil and Gas Industry

In the oil and gas sector, titanium carbide plates are employed in drilling tools and equipment. The ability to withstand harsh conditions and resist wear makes them suitable for use in challenging environments. Drilling operations often involve abrasive materials and extreme pressures, making the durability of titanium carbide an invaluable asset.

5. Medical Device Manufacturing

The medical device industry often requires precision machining of materials that can be difficult to cut. Titanium carbide plates are used in cutting tools for manufacturing surgical instruments and implants, where accuracy is critical. The biocompatibility of titanium carbide also makes it suitable for applications in the medical field, ensuring that tools do not react adversely with biological tissues.

The Future of Titanium Carbide in Cutting Tools

As technology advances, the demand for more efficient and durable cutting tools continues to grow. Titanium carbide plates are likely to play an increasingly important role in this evolution. Ongoing research into improving the properties of titanium carbide and developing new applications will further enhance its position in the market.

Innovations in Titanium Carbide Technology

Recent advancements in manufacturing techniques, such as additive manufacturing and improved sintering processes, have led to the development of even more effective titanium carbide cutting tools. These innovations promise to enhance the performance and versatility of titanium carbide plates, making them an even more attractive option for manufacturers.

Environmental Considerations

As industries become more aware of their environmental impact, the demand for sustainable materials and processes is increasing. Titanium carbide, being a durable and long-lasting material, contributes to reducing waste in manufacturing. By extending tool life and reducing the frequency of replacements, titanium carbide plates can help minimize the environmental footprint of machining operations.

Conclusion

Titanium carbide plates have established themselves as a preferred choice for cutting tools due to their exceptional properties, benefits, and wide range of applications. Their hardness, wear resistance, and thermal stability make them ideal for various industries, from aerospace to woodworking. As technology continues to advance, the role of titanium carbide in cutting tools is expected to grow, offering manufacturers enhanced performance and cost-effectiveness.

Frequently Asked Questions

1. What is titanium carbide?

Titanium carbide is a ceramic compound made of titanium and carbon, known for its hardness and wear resistance.

2. Why are titanium carbide plates preferred for cutting tools?

They offer enhanced tool life, improved cutting performance, versatility, and cost-effectiveness.

3. In which industries are titanium carbide plates commonly used?

They are used in metal machining, woodworking, aerospace, oil and gas, and medical device manufacturing.

4. How do titanium carbide plates compare to traditional cutting materials?

Titanium carbide plates are harder and more wear-resistant than traditional materials, leading to longer tool life and better performance.

5. What advancements are being made in titanium carbide technology?

Innovations in manufacturing techniques and research into new applications are enhancing the performance and versatility of titanium carbide cutting tools.