Content Menu

● Introduction to Dillon 9mm Carbide Dies

● Understanding Carbide Dies: The Dillon Advantage

● The Reloading Process with Dillon 9mm Carbide Dies

>> 1. Sizing and Decapping

>> 2. Priming and Powder Charging

>> 3. Bullet Seating

>> 4. Crimping

● Compatibility and Versatility

● Maintenance and Care

● Why Choose Dillon 9mm Carbide Dies?

● Comparing Dillon to Other Brands

● Tips for Using Dillon 9mm Carbide Dies

● The Future of Reloading: Innovations in Die Technology

● Conclusion: The Value of Quality Dies in Reloading

● Frequently Asked Questions

>> Q1: Are Dillon 9mm carbide dies compatible with all reloading presses?

>> Q2: How often should I replace my Dillon 9mm carbide dies?

>> Q3: Can I use Dillon 9mm carbide dies for other pistol calibers?

>> Q4: Do I need to lubricate cases when using Dillon 9mm carbide dies?

>> Q5: What's the difference between Dillon's standard and "New" style seating dies for 9mm?

Introduction to Dillon 9mm Carbide Dies

For firearm enthusiasts and reloaders, the quest for precision and reliability in ammunition production is never-ending. At the forefront of this pursuit stands the Dillon 9mm carbide die set, a cornerstone of quality reloading equipment. These dies have earned a reputation for excellence among both novice and experienced reloaders, offering unparalleled performance and longevity.

Dillon Precision, a name synonymous with top-tier reloading equipment, has crafted these carbide dies to meet the exacting standards of 9mm Luger ammunition reloading. The 9mm Luger, also known as 9x19mm Parabellum, is one of the most popular pistol cartridges worldwide, making reliable reloading tools for this caliber essential for many shooters.

Understanding Carbide Dies: The Dillon Advantage

Carbide dies represent the pinnacle of reloading technology. Unlike standard steel dies, carbide dies offer several significant advantages:

1. Durability: Carbide is exceptionally hard, ensuring that the dies maintain their dimensions over thousands of reloads.

2. No lubrication required: The smooth surface of carbide eliminates the need for case lubrication, streamlining the reloading process.

3. Consistency: The hardness and precision of carbide dies contribute to more consistent ammunition, a critical factor for accuracy.

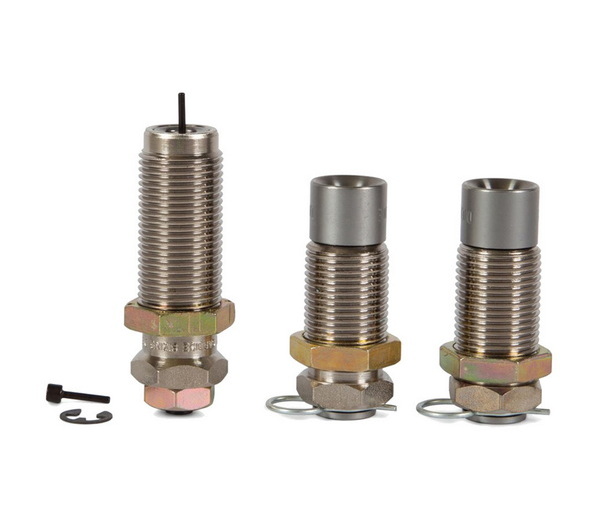

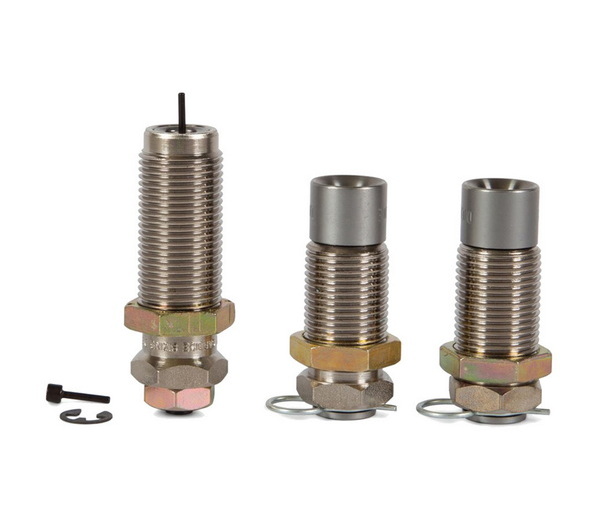

Dillon's 9mm carbide die set typically includes three essential components:

1. Sizing/decapping die

2. Bullet seating die

3. Crimp die (usually a taper crimp for auto pistol cartridges)

Each die in the set is meticulously crafted to perform its specific function with utmost precision, ensuring that your reloaded ammunition meets or exceeds factory specifications.

The Reloading Process with Dillon 9mm Carbide Dies

To fully appreciate the value of Dillon 9mm carbide dies, it's essential to understand how they function within the reloading process. Let's break down the steps:

1. Sizing and Decapping

The first die in the set, the sizing/decapping die, performs two crucial functions:

- It resizes the brass case to the correct dimensions for reliable chambering.

- It removes the spent primer from the case.

Dillon's carbide sizing die features a spring-loaded decapping pin, which efficiently kicks out the old primers, preparing the case for the next steps.

2. Priming and Powder Charging

While not directly related to the die set, these steps are integral to the reloading process. Dillon reloading presses often incorporate priming systems and powder measures to streamline these operations.

3. Bullet Seating

The seating die carefully places the new bullet into the case at the correct depth. Dillon's seating dies are known for their precision, ensuring consistent bullet seating depths for improved accuracy.

4. Crimping

The final die in the set, the crimp die, applies a taper crimp to the case mouth. This step is crucial for proper feeding in semi-automatic pistols and helps secure the bullet in place.

Compatibility and Versatility

One of the strengths of Dillon 9mm carbide dies is their compatibility with various reloading presses. While they are optimized for Dillon's own lineup of progressive presses like the RL550, XL650, and XL750, these dies can often be used with other brands of reloading equipment as well.

It's worth noting that Dillon produces specific die sets for different press models. For instance, the Square Deal B press requires a unique die set not compatible with other Dillon presses. Always ensure you're selecting the correct die set for your specific reloading setup.

Maintenance and Care

To maintain the performance and longevity of your Dillon 9mm carbide dies, proper care is essential:

1. Regular cleaning: Wipe down the dies after each use to remove any residue.

2. Inspection: Periodically check the dies for signs of wear or damage.

3. Lubrication: While the carbide sizing die doesn't require case lubrication, a light application of die lubricant can help protect the other components.

4. Storage: Keep the dies in their original case or a dedicated die box to protect them from moisture and physical damage.

Why Choose Dillon 9mm Carbide Dies?

Investing in quality reloading equipment is crucial for anyone serious about producing their own ammunition. Dillon 9mm carbide dies offer several compelling reasons for their popularity:

1. Precision: The tight tolerances and superior materials ensure consistent, accurate ammunition.

2. Efficiency: Carbide dies speed up the reloading process by eliminating the need for case lubrication.

3. Durability: These dies are built to last, potentially outlasting multiple reloading presses.

4. Reputation: Dillon Precision's commitment to quality is well-known in the reloading community.

5. Support: Dillon offers excellent customer service and a robust warranty on their products.

Comparing Dillon to Other Brands

While Dillon is a leader in the reloading industry, other reputable brands also produce quality carbide dies for 9mm reloading. Brands like RCBS, Hornady,ZHONGBO CEMENTED CARBIDE, and Lee offer their own carbide die sets, each with unique features and price points.

However, Dillon's dies are often praised for their exceptional finish, precise machining, and user-friendly design. The separate crimp die, for instance, allows for more precise control over the crimping process compared to dies that combine seating and crimping.

Tips for Using Dillon 9mm Carbide Dies

To get the most out of your Dillon 9mm carbide dies, consider these tips:

1. Start with clean brass: Ensure your cases are clean and free from debris before reloading.

2. Check your work: Regularly measure your loaded rounds to ensure consistency.

3. Fine-tune your crimp: Experiment with different crimp settings to find the optimal crimp for your loads.

4. Keep detailed records: Document your load data, including die settings, for future reference.

5. Stay within recommended load data: Always follow published load data from reputable sources for safety.

The Future of Reloading: Innovations in Die Technology

As reloading technology continues to advance, we can expect to see further innovations in die design and materials. While carbide remains the gold standard for sizing dies, new coatings and manufacturing techniques may enhance the performance of seating and crimping dies in the future.

Dillon Precision continues to invest in research and development, ensuring that their 9mm carbide dies and other reloading equipment remain at the cutting edge of the industry.

Conclusion: The Value of Quality Dies in Reloading

For anyone serious about reloading 9mm ammunition, investing in a set of Dillon 9mm carbide dies is a decision that pays dividends in terms of efficiency, consistency, and overall satisfaction with the reloading process. These precision-engineered tools form the backbone of a reliable reloading setup, allowing enthusiasts to produce ammunition that meets or exceeds factory specifications.

Whether you're a competitive shooter demanding the utmost precision, a high-volume reloader seeking efficiency, or simply an enthusiast who appreciates quality tools, Dillon 9mm carbide dies offer a compelling solution to your reloading needs. By choosing Dillon, you're not just buying a set of dies; you're investing in a legacy of excellence in ammunition reloading.

As the world of firearms and ammunition continues to evolve, the principles of precision, reliability, and quality remain constant. Dillon 9mm carbide dies embody these principles, providing reloaders with the tools they need to pursue their passion with confidence and consistency.

Frequently Asked Questions

Q1: Are Dillon 9mm carbide dies compatible with all reloading presses?

Answer: While Dillon 9mm carbide dies are designed to work optimally with Dillon's own presses, they are generally compatible with most standard reloading presses that accept 7/8"-14 threaded dies. However, it's important to note that some Dillon presses, like the Square Deal B, require specific die sets that are not interchangeable with other models.

Q2: How often should I replace my Dillon 9mm carbide dies?

Answer: Dillon 9mm carbide dies are built for longevity and can last for tens of thousands of reloads with proper care. There's no set replacement schedule; instead, monitor your dies for signs of wear or damage. If you notice any inconsistencies in your reloaded ammunition or visible wear on the dies, it may be time to consider replacement.

Q3: Can I use Dillon 9mm carbide dies for other pistol calibers?

Answer: No, Dillon 9mm carbide dies are specifically designed for 9mm Luger (9x19mm) cartridges. Each caliber requires its own specific die set due to differences in case dimensions and overall cartridge specifications. Dillon offers carbide die sets for a wide range of pistol and rifle calibers, each tailored to the specific cartridge.

Q4: Do I need to lubricate cases when using Dillon 9mm carbide dies?

Answer: One of the primary advantages of carbide sizing dies is that they eliminate the need for case lubrication in most situations. The hard, smooth surface of the carbide allows cases to be sized without sticking. However, if you're working with exceptionally dirty or corroded brass, a light application of case lube may still be beneficial.

Q5: What's the difference between Dillon's standard and "New" style seating dies for 9mm?

Answer: Dillon offers two styles of seating dies for 9mm: the standard version and the "New" style. The primary difference is in the design of the seating stem. The "New" style features an improved design that some users find provides more consistent seating depths and is easier to adjust. Both styles perform well, and the choice often comes down to personal preference.