Content Menu

● Understanding Tungsten Carbide

● Industrial Applications of Tungsten Carbide

>> Cutting Tools

>> Mining and Drilling

>> Construction

>> Aerospace and Automotive Industries

● Medical Applications

>> Advantages in Medical Use

● Jewelry

>> Characteristics of Tungsten Carbide Jewelry

● Other Applications

● Environmental Considerations

>> Mining Impact

>> Recycling Initiatives

● Conclusion

● FAQ

>> 1. What makes tungsten carbide so hard?

>> 2. Is tungsten carbide suitable for high-temperature applications?

>> 3. Can tungsten carbide be recycled?

>> 4. How does tungsten carbide compare to other metals?

>> 5. What are the benefits of using tungsten carbide in jewelry?

● Citations:

Tungsten carbide is a remarkable compound composed of tungsten and carbon, known for its exceptional hardness and durability. Its unique properties make it a popular choice across various industries, from manufacturing to jewelry. This article explores the diverse applications of tungsten carbide, highlighting its significance in modern technology and industry.

Understanding Tungsten Carbide

Tungsten carbide (WC) is a chemical compound that combines tungsten, a dense metal with a high melting point, and carbon, which enhances its hardness. The resulting material exhibits properties that surpass many other metals, including steel.

- Hardness: Tungsten carbide ranks second in hardness after diamond, making it ideal for cutting and wear-resistant applications.

- Durability: It withstands extreme temperatures and pressures, ensuring longevity in demanding environments.

- Corrosion Resistance: Tungsten carbide is resistant to corrosion, which is crucial for tools and machinery exposed to harsh conditions.

The unique properties of tungsten carbide stem from its microstructure. The combination of tungsten and carbon forms a crystalline structure that contributes to its impressive mechanical properties. This structure allows tungsten carbide to maintain its hardness even at elevated temperatures, making it suitable for various applications.

Industrial Applications of Tungsten Carbide

Cutting Tools

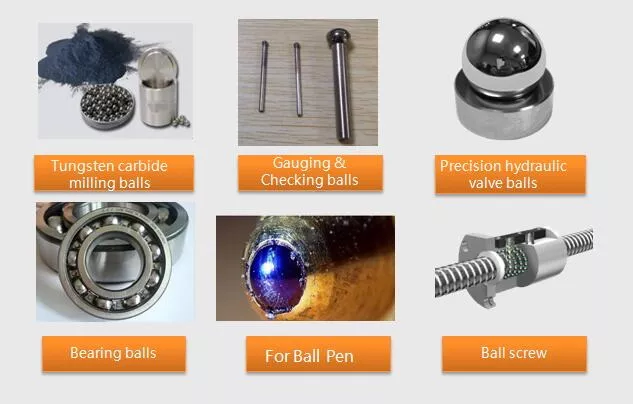

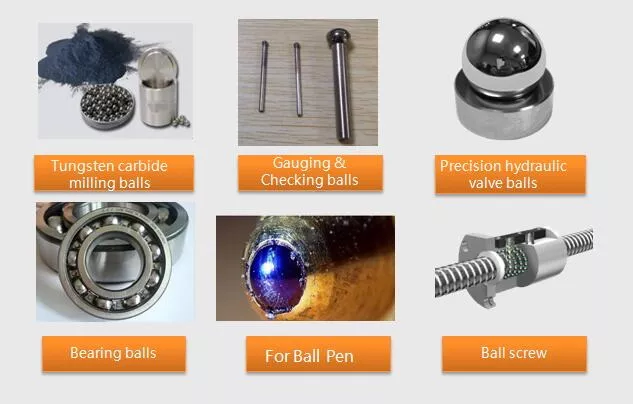

One of the primary uses of tungsten carbide is in the manufacture of cutting tools. Due to its hardness, it is commonly used for:

- Drills: Tungsten carbide drill bits are essential for penetrating tough materials such as metal and concrete. They provide superior cutting performance and longer tool life compared to traditional steel bits.

- Milling Cutters: These tools are used in milling machines to shape and cut materials with precision. Tungsten carbide milling cutters can maintain sharp edges longer, resulting in cleaner cuts and reduced downtime for tool changes.

- Saws: Tungsten carbide-tipped saw blades provide superior cutting performance and longevity. These blades are used in various applications, including woodworking and metalworking.

Mining and Drilling

Tungsten carbide plays a crucial role in the mining industry:

- Drilling Equipment: It is used in drill bits for oil drilling and mineral exploration due to its ability to withstand high wear. The toughness of tungsten carbide allows drill bits to penetrate hard rock formations effectively.

- Mining Tools: Tungsten carbide is employed in rock drills, chisels, and other excavation tools essential for mining operations. Its durability ensures that these tools can withstand the rigors of continuous use in harsh environments.

Construction

In construction, tungsten carbide is valued for its strength:

- Concrete Saws: These saws utilize tungsten carbide blades to cut through hard materials like concrete and asphalt. The blades' hardness allows them to maintain sharpness longer than conventional blades, resulting in smoother cuts.

- Pavement Maintenance: Tools made from tungsten carbide are used for road milling and resurfacing. The durability of these tools minimizes wear during operation, leading to cost savings on replacements.

Aerospace and Automotive Industries

The aerospace sector utilizes tungsten carbide for:

- Engine Components: Parts such as turbine blades benefit from the material's heat resistance and strength. Tungsten carbide's ability to withstand extreme temperatures makes it ideal for high-performance aerospace applications.

- Machining Tools: Used in precision machining processes where durability is paramount. Tungsten carbide inserts are commonly used in lathes and other machining equipment.

In automotive applications, tungsten carbide is found in:

- Cutting Inserts: Used in the production of engine components and other critical parts. The hardness of tungsten carbide ensures that these inserts can handle the stresses involved in machining tough materials.

Medical Applications

In the medical field, tungsten carbide is utilized for:

- Surgical Instruments: Tools like scalpels and scissors are made from tungsten carbide due to their sharpness and durability. The material's ability to maintain a sharp edge reduces the need for frequent sharpening.

- Dental Instruments: Its hardness allows for precise cutting in dental procedures. Tungsten carbide burs are commonly used in dental drills for effective tooth preparation.

Advantages in Medical Use

The use of tungsten carbide in medical instruments offers several advantages:

- Precision Cutting: Tungsten carbide instruments can achieve finer cuts than traditional stainless steel tools.

- Longevity: Due to their resistance to wear, tungsten carbide instruments have a longer lifespan, reducing replacement costs.

- Sterilization Compatibility: Tungsten carbide can withstand sterilization processes without degrading or losing performance.

Jewelry

Tungsten carbide has gained popularity in the jewelry industry:

- Wedding Bands: Known for their scratch resistance and weight, tungsten carbide rings are a popular choice among couples seeking durable wedding bands that maintain their appearance over time.

- Fashion Jewelry: Its ability to be polished to a high shine makes it desirable for various jewelry pieces. Designers appreciate the versatility of tungsten carbide as it can be combined with other materials like gold or gemstones.

Characteristics of Tungsten Carbide Jewelry

Tungsten carbide jewelry offers several unique characteristics:

- Scratch Resistance: Unlike softer metals, tungsten carbide does not scratch easily, maintaining its polished look over time.

- Weighty Feel: Many people appreciate the substantial feel of tungsten carbide rings compared to lighter metals like titanium or silver.

- Hypoallergenic Properties: Tungsten carbide is generally hypoallergenic, making it suitable for individuals with sensitive skin.

Other Applications

Beyond the primary uses mentioned, tungsten carbide finds applications in various other fields:

- Abrasives: Used in grinding wheels and sandpaper due to its hardness. The abrasive properties of tungsten carbide make it effective for shaping materials during manufacturing processes.

- Consumer Electronics: Employed in manufacturing high-performance electrical contacts that require durability under electrical load.

- Defense: Utilized in armor-piercing ammunition due to its density and hardness. The effectiveness of tungsten carbide projectiles has made them a preferred choice in military applications.

Environmental Considerations

As industries increasingly focus on sustainability, it's important to consider the environmental impact of tungsten carbide production:

Mining Impact

The extraction of raw materials needed for tungsten carbide can have significant environmental effects:

- Habitat Disruption: Mining activities can lead to habitat destruction and biodiversity loss.

- Pollution Risks: Chemical runoff from mining sites can contaminate local water sources.

Recycling Initiatives

Fortunately, there are initiatives aimed at recycling tungsten carbide:

- Many manufacturers have established programs to reclaim worn-out tools and recycle them into new products.

- Recycling reduces the demand for new raw materials while also minimizing waste.

Conclusion

Tungsten carbide's unique properties make it an invaluable material across multiple industries. From cutting tools to jewelry, its applications are vast and varied. As technology advances, the demand for tungsten carbide continues to grow, solidifying its place as a cornerstone material in modern manufacturing.

FAQ

1. What makes tungsten carbide so hard?

Tungsten carbide's hardness comes from its unique composition of tungsten and carbon, which forms a dense structure that resists wear.

2. Is tungsten carbide suitable for high-temperature applications?

Yes, tungsten carbide can withstand extreme temperatures without losing its structural integrity, making it ideal for high-temperature environments.

3. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled effectively, allowing manufacturers to reclaim valuable materials from worn-out tools.

4. How does tungsten carbide compare to other metals?

Tungsten carbide surpasses most metals in hardness and wear resistance but may be more brittle than some softer metals like steel.

5. What are the benefits of using tungsten carbide in jewelry?

Tungsten carbide jewelry is scratch-resistant, durable, and maintains a polished appearance over time, making it an excellent choice for wedding bands.

Citations:

[1] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[2] https://www.samaterials.com/content/application-of-tungsten-in-modern-industry.html

[3] https://metalstek.com/tungsten-carbide/

[4] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[5] https://www.itia.info/applications-markets/

[6] https://www.wolframcarbide.com/what-is-in-tungsten-carbide-and-its-uses/

[7] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[8] https://consolidatedresources.com/blog/what-industries-produce-tungsten-carbide/

[9] https://material-properties.org/tungsten-carbide/

[10] https://thestartupmag.com/tungsten-carbide-applications-people-must-know/

[11] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/