Content Menu

● Introduction to Sodium Carbide

● Overview of the Sodium Carbide Production Process

>> Key Raw Materials

● Detailed Industrial Process Description

>> 1. Preparation of Reactants

>> 2. Reaction Conditions

>> 3. Reactor Design and Operation

>> 4. Product Recovery and Handling

● Alternative Industrial Method: Steel Ball Condensation Process

● Chemical Reactions and Industrial Significance

● Enhanced Safety and Environmental Considerations

● Recent Technological Advancements

● Detailed Visualization Descriptions

● Industrial Applications of Sodium Carbide

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What temperature range is optimal for sodium carbide production?

>> 2. Why is excess carbon used in the sodium carbide production process?

>> 3. How is acetylene gas produced from sodium carbide?

>> 4. What forms of carbon can be used in sodium carbide production?

>> 5. How is the steel ball condensation process beneficial in sodium carbide production?

Sodium carbide is an important chemical compound used in various industrial applications, including the production of acetylene gas, which is essential in welding, chemical synthesis, and other manufacturing processes. As a high-tech enterprise specializing in carbide products for industrial, military, metallurgical, petroleum drilling, mining tools, and construction applications, understanding the sodium carbide production process is crucial for innovation and quality manufacturing.

This comprehensive article will explore the industrial process for producing sodium carbide, detailing the chemical reactions, equipment, and operational conditions involved. It will also include illustrative descriptions to help visualize the process, followed by a conclusion and a FAQ section addressing common questions related to sodium carbide production.

Introduction to Sodium Carbide

Sodium carbide (Na2C2) is a chemical compound formed by the combination of sodium and carbon. It serves as an intermediate in the production of acetylene gas (C2H2) when reacted with water. Sodium carbide is less common than calcium carbide but has unique industrial advantages, especially in controlled acetylene generation.

Overview of the Sodium Carbide Production Process

The industrial production of sodium carbide involves the direct reaction of sodium compounds with carbon at high temperatures under controlled conditions. The process requires precise temperature control, an inert or reducing atmosphere to prevent oxidation, and careful handling of reactants and products.

Key Raw Materials

- Sodium hydroxide (NaOH): Often used in molten form.

- Carbon: Various forms such as coal, coke, charcoal, or carbon black.

- Inert atmosphere: To exclude air and moisture.

Detailed Industrial Process Description

1. Preparation of Reactants

The process begins with preparing a mixture of sodium hydroxide and carbon. Sodium hydroxide is heated until it becomes molten, providing a reactive medium for carbon to interact chemically.

2. Reaction Conditions

The core reaction occurs at temperatures ranging from approximately 700°C to 900°C. This temperature range is critical; it is high enough to facilitate the reaction but kept below the boiling point of sodium (about 880°C at atmospheric pressure) to avoid sodium loss through volatilization.

The reaction can be summarized as follows:

2NaOH+3C→Na2C2+CO+H2O

In this reaction, molten sodium hydroxide reacts with carbon to form sodium carbide, carbon monoxide, and water vapor. The process must be carried out in the absence of air, water vapor, or other oxidizing gases to prevent unwanted side reactions.

3. Reactor Design and Operation

Industrial reactors for sodium carbide production are designed to maintain the required temperature and atmosphere. The reactants are mixed and heated in a closed vessel with controlled gas flow to remove hydrogen and other byproducts while retaining sodium vapor for reflux.

The carbon used is typically in excess (at least 50% more than stoichiometric requirements) to ensure complete reaction and maximize sodium carbide yield.

4. Product Recovery and Handling

After the reaction, the solid product mixture contains sodium carbide and sodium carbonate. Although separating these compounds is challenging, it is not necessary for many applications. The mixture can be used directly, especially for acetylene production by adding water.

Alternative Industrial Method: Steel Ball Condensation Process

Another industrial method involves reacting sodium vapor with carbon monoxide at higher temperatures (around 1050°C to 1100°C) using preheated steel balls as a condensation surface.

- Steel balls are heated to 400–600°C.

- The balls contact a gas mixture of sodium vapor and carbon monoxide.

- Sodium carbide condenses on the balls' surfaces as a hard, dense layer.

- The balls are cooled and treated with steam to generate acetylene.

- Carbon dioxide is used to convert byproducts into recyclable forms.

- The balls are mechanically agitated to remove carbonate layers and recycled.

This continuous process allows efficient carbide production and acetylene generation with effective recovery and reuse of materials.

Chemical Reactions and Industrial Significance

The sodium carbide production process is not only a matter of combining raw materials but also involves complex chemical reactions that are carefully controlled to optimize yield and purity. The reaction between molten sodium hydroxide and carbon produces sodium carbide, carbon monoxide, and water vapor. This reaction is endothermic, requiring continuous heat input to maintain the high temperatures necessary for the reaction to proceed efficiently.

The carbon monoxide generated as a byproduct can be captured and utilized as a fuel or chemical feedstock, contributing to the overall efficiency and sustainability of the process. Moreover, the water vapor produced must be carefully managed to prevent unwanted side reactions that could degrade the product quality.

Understanding these chemical dynamics is essential for engineers and chemists working to improve the process, reduce energy consumption, and minimize environmental impact.

Enhanced Safety and Environmental Considerations

Safety in sodium carbide production is paramount due to the high temperatures and reactive chemicals involved. The process requires strict exclusion of moisture and oxygen to prevent hazardous reactions such as explosions or fires. Industrial plants employ advanced monitoring systems to detect leaks and maintain inert atmospheres.

Environmental considerations include the management of byproducts like sodium carbonate and carbon monoxide. Modern facilities implement recycling systems to convert sodium carbonate back into useful chemicals, reducing waste. Carbon monoxide emissions are controlled through catalytic converters or used as fuel in onsite power generation, minimizing air pollution.

These measures not only protect workers and the environment but also improve the economic viability of sodium carbide production.

Recent Technological Advancements

Recent innovations in sodium carbide production focus on improving energy efficiency and process automation. Advanced reactor designs incorporate better insulation and heat recovery systems to reduce energy consumption. Automation and real-time monitoring allow precise control of reaction conditions, enhancing product consistency and safety.

Research into alternative raw materials and catalysts aims to lower production costs and environmental footprint. For example, using biomass-derived carbon sources or developing catalysts that enable lower temperature reactions are promising areas of development.

These technological advancements ensure that sodium carbide production remains competitive and sustainable in the evolving industrial landscape.

Detailed Visualization Descriptions

To better understand the sodium carbide production process, detailed visualizations can be created:

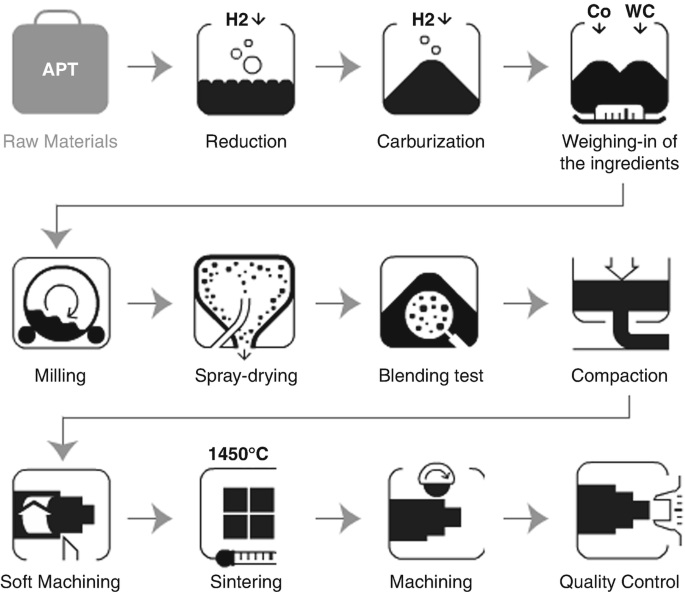

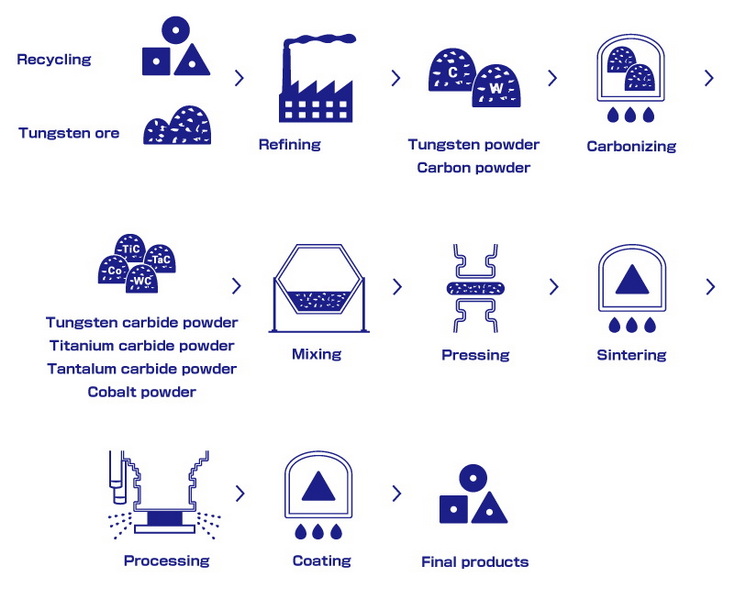

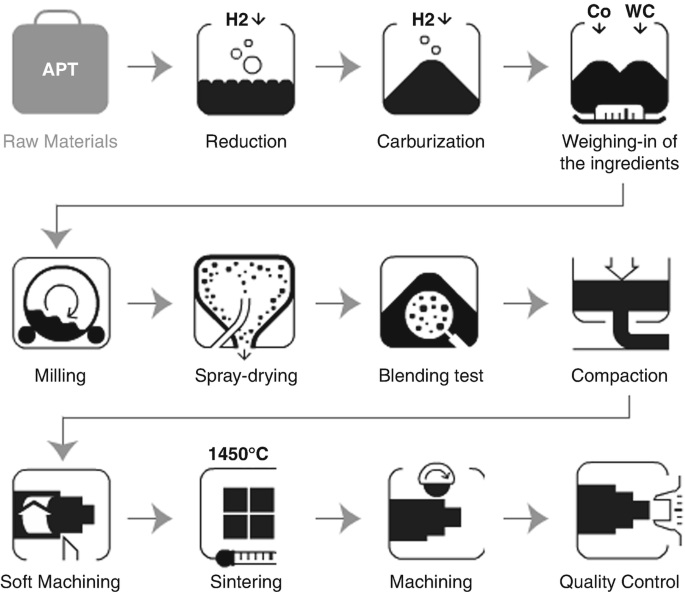

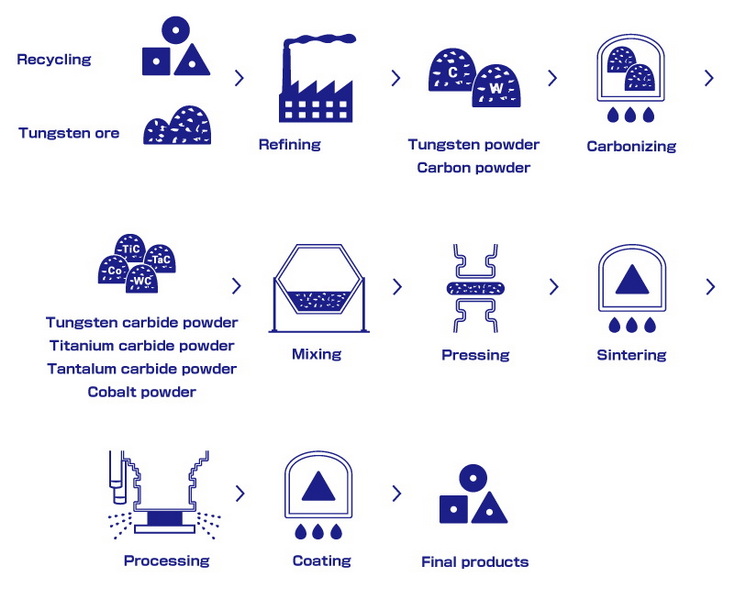

- Flow Diagram: This diagram illustrates the entire process flow, starting from raw material input (sodium hydroxide and carbon), moving through the heating and reaction zones, and ending with product collection and byproduct management. Arrows indicate the direction of material and gas flows, and key temperature zones are marked.

- Reactor Cross-Section: A cross-sectional view of the reactor shows the molten sodium hydroxide bath with suspended carbon particles. Heat sources such as electric heaters or gas burners are depicted around the vessel. Gas outlets for removing hydrogen and carbon monoxide are shown, along with temperature sensors and safety valves.

- Steel Ball Condensation Tower: This visualization depicts the movement of preheated steel balls through a vertical reaction chamber. Sodium vapor and carbon monoxide gases flow upward, reacting on the ball surfaces to form sodium carbide layers. Subsequent sections show steam treatment for acetylene generation and mechanical systems for carbonate removal and ball recycling.

These visual aids help engineers, operators, and students grasp the complex interactions and equipment involved in sodium carbide production.

Industrial Applications of Sodium Carbide

Sodium carbide produced through these processes is primarily used for:

- Acetylene generation: Reacting with water to produce acetylene gas for welding and chemical synthesis.

- Chemical intermediates: In organic synthesis and industrial chemical manufacturing.

- Specialty carbide products: For military, metallurgical, and mining tool applications.

Conclusion

The industrial process for producing sodium carbide is a sophisticated chemical operation involving the high-temperature reaction of molten sodium hydroxide with carbon under controlled atmospheres. Maintaining precise temperature control, an inert environment, and proper reactant ratios are essential for maximizing yield and product quality. Alternative methods, such as the steel ball condensation process, provide continuous production options with efficient material recovery.

Sodium carbide remains a vital compound in industrial chemistry, particularly for acetylene production and specialized carbide applications in various sectors, including industrial manufacturing, military, metallurgy, petroleum drilling, and construction.

Frequently Asked Questions (FAQ)

1. What temperature range is optimal for sodium carbide production?

The optimal temperature range for sodium carbide production is between 700°C and 900°C, with a preference to stay below the boiling point of sodium (~880°C) to prevent sodium volatilization and maximize yield.

2. Why is excess carbon used in the sodium carbide production process?

Excess carbon (at least 50% more than stoichiometric requirements) ensures the complete reaction of sodium hydroxide with carbon, preventing depletion of carbon which would reduce sodium carbide yield.

3. How is acetylene gas produced from sodium carbide?

Acetylene gas is produced by adding water to sodium carbide. The reaction releases acetylene gas and sodium hydroxide, which can be recycled in the process.

4. What forms of carbon can be used in sodium carbide production?

Various forms of carbon such as coal, coke, carbon black, and charcoal can be used effectively in the sodium carbide production process without significant differences in outcome.

5. How is the steel ball condensation process beneficial in sodium carbide production?

The steel ball condensation process allows continuous production by condensing sodium carbide on heated steel balls, facilitating efficient acetylene generation, easy recovery of byproducts, and recycling of materials, improving process sustainability.