Content Menu

● Introduction

● What is Tungsten Carbide?

>> Key Properties of Tungsten Carbide

● What is Boron Carbide?

>> Key Properties of Boron Carbide

● Comparative Hardness: Tungsten Carbide vs Boron Carbide

>> Hardness Scales

>> Direct Comparison

● Mechanical and Physical Properties

>> Density

>> Strength

>> Thermal Properties

● Applications and Use Cases

>> Tungsten Carbide

>> Boron Carbide

● Manufacturing and Cost Considerations

>> Production

>> Cost

>> Machinability and Processing

● Limitations and Challenges

>> Tungsten Carbide

>> Boron Carbide

● Environmental and Safety Considerations

>> Tungsten Carbide

>> Boron Carbide

● Future Trends in Superhard Materials

● Visual Comparisons

>> Table: Key Differences at a Glance

● FAQ: Top 5 Related Questions

>> 1. What is the main advantage of boron carbide over tungsten carbide?

>> 2. Why is tungsten carbide preferred for cutting tools?

>> 3. Is boron carbide more brittle than tungsten carbide?

>> 4. Can either material be used for jewelry?

>> 5. Which material is more expensive, and why?

● Citations:

When it comes to high-performance materials used in cutting tools, armor, and industrial applications, tungsten carbide and boron carbide are two of the most renowned names. Both are celebrated for their extreme hardness, but which one is truly harder? This comprehensive article explores the science, properties, applications, and key differences between these two super-materials, helping you understand which is harder and why that matters.

Introduction

In materials engineering, hardness is a critical property that determines how well a substance resists deformation, scratching, cutting, or abrasion. Tungsten carbide and boron carbide are both non-oxide ceramics that push the boundaries of what is possible in terms of hardness and durability. But which one stands out as the harder material, and how does this affect their real-world applications?

Understanding the differences between these materials is crucial for industries ranging from manufacturing to defense. This article will not only compare their hardness but also delve into their broader properties, uses, limitations, and the future of superhard materials.

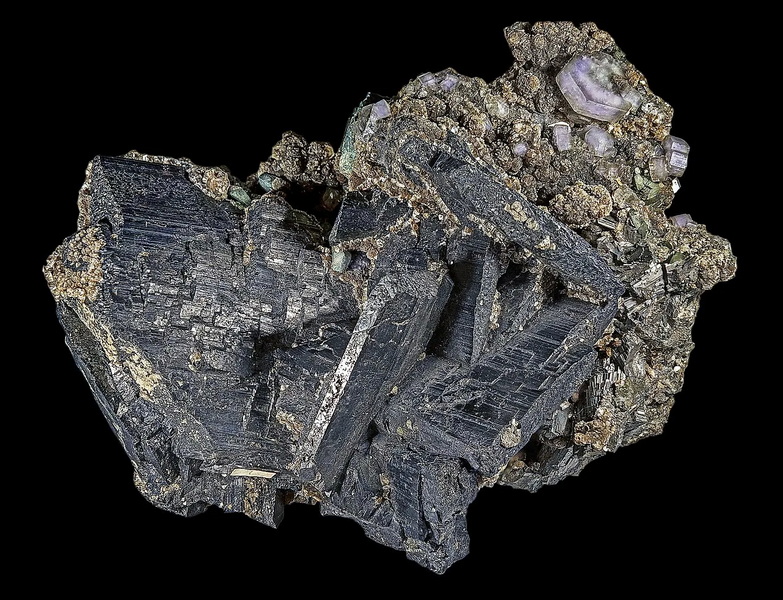

What is Tungsten Carbide?

Tungsten carbide (WC) is a compound consisting of equal parts tungsten and carbon atoms. It is typically produced through powder metallurgy and is known for its exceptional hardness, high density, and excellent wear resistance. Tungsten carbide is widely used in:

- Cutting tools (drill bits, saw blades)

- Abrasives

- Industrial machinery parts

- Armor-piercing ammunition

- Jewelry

Key Properties of Tungsten Carbide

| Property | Value/Range |

| Chemical Formula | WC |

| Density | ~15 g/cm³ |

| Mohs Hardness | 9.0 – 9.5 |

| Vickers Hardness | ~2400 – 2600 Hv |

| Knoop Hardness | ~1670 |

| Elastic Modulus | 530 – 700 GPa |

| Compressive Strength | ~4780 MPa |

| Fracture Toughness | ~12 MPa·m1/2 |

| Melting Point | 2,870°C |

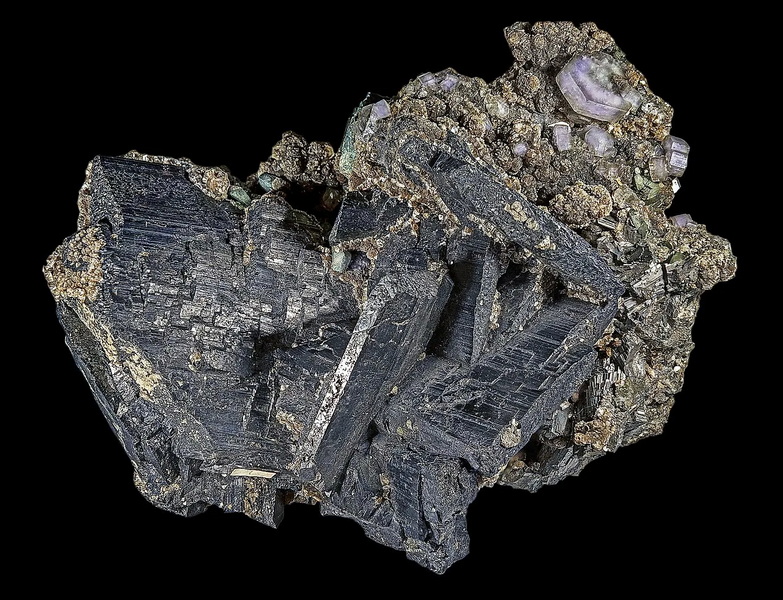

What is Boron Carbide?

Boron carbide (B₄C), often called "black diamond," is a ceramic material composed of boron and carbon. It is the third hardest material known, after diamond and cubic boron nitride. Boron carbide is famous for its:

- Extremely high hardness

- Low density

- High neutron absorption (nuclear shielding)

- Chemical stability

Common applications include:

- Lightweight body armor

- Abrasive powders and blasting nozzles

- Nuclear reactor shielding

- Wear-resistant components

Key Properties of Boron Carbide

| Property | Value/Range |

| Chemical Formula | B₄C |

| Density | 2.1 – 2.7 g/cm³ |

| Mohs Hardness | 9.5 – 9.75 |

| Vickers Hardness | ~30 – 38 GPa (3000–3800 Hv) |

| Knoop Hardness | 2600 – 3200 |

| Elastic Modulus | 240 – 460 GPa |

| Compressive Strength | 1710 – 2200 MPa |

| Fracture Toughness | 2.5 – 3.5 MPa·m1/2 |

| Melting Point | ~2,450°C |

Comparative Hardness: Tungsten Carbide vs Boron Carbide

Hardness Scales

- Mohs Hardness: Measures scratch resistance (scale of 1–10).

- Vickers/Knoop Hardness: Measures indentation hardness (higher numbers = harder).

Direct Comparison

| Property | Tungsten Carbide | Boron Carbide |

| Mohs Hardness | 9.0 – 9.5 | 9.5 – 9.75 |

| Vickers Hardness | ~2400 – 2600 Hv | ~30 – 38 GPa |

| Knoop Hardness | ~1670 | 2600 – 3200 |

Boron carbide is harder than tungsten carbide on every major hardness scale. This means boron carbide resists scratching and indentation better, making it more suitable for applications where maximum hardness is required.

Mechanical and Physical Properties

Density

- Tungsten carbide is much denser (~15 g/cm³) than boron carbide (2.1–2.7 g/cm³).

- This makes tungsten carbide ideal for applications where mass and impact force are needed, while boron carbide is preferred for lightweight armor.

Strength

| Property | Tungsten Carbide | Boron Carbide |

| Compressive Strength | 4780 MPa | 1710–2200 MPa |

| Flexural Strength | 1830 MPa | 170–410 MPa |

| Fracture Toughness | 12 MPa·m1/2 | 2.5–3.5 MPa·m1/2 |

- Tungsten carbide is tougher and less brittle, with higher compressive and flexural strengths.

- Boron carbide is much more brittle, which can be a disadvantage in high-impact situations.

Thermal Properties

| Property | Tungsten Carbide | Boron Carbide |

| Melting Point (°C) | 2,870 | ~2,450 |

| Thermal Conductivity | 85 W/m·K | 31–90 W/m·K |

| Thermal Expansion | 5.4 µm/m·K | 4.5–5.6 µm/m·K |

Both materials are highly refractory and stable at high temperatures, but tungsten carbide is slightly more heat-resistant.

Applications and Use Cases

Tungsten Carbide

- Cutting tools: Drill bits, end mills, saw blades, mining tools

- Wear parts: Valve seats, nozzles, dies, punches

- Jewelry: Rings, bracelets, watches

- Ammunition: Armor-piercing rounds

Boron Carbide

- Body armor: Lightweight bulletproof vests, vehicle armor

- Abrasives: Lapping and polishing powders

- Nuclear industry: Neutron absorber in control rods

- Nozzles: Sandblasting and water jet cutting

Manufacturing and Cost Considerations

Production

- Tungsten carbide: Produced via powder metallurgy, combining tungsten and carbon powders, then sintering with a binder (often cobalt).

- Boron carbide: Produced by carbothermal reduction of boron oxide with carbon at high temperatures.

Cost

- Tungsten carbide is generally more affordable and widely available due to its broad industrial use.

- Boron carbide is more expensive, reflecting its specialized applications and more complex production.

Machinability and Processing

- Tungsten carbide can be ground and shaped with diamond tools, but its toughness allows for more complex shapes and larger components.

- Boron carbide is extremely hard to machine and is usually formed into simple shapes via hot pressing or sintering.

Limitations and Challenges

Tungsten Carbide

- Susceptible to corrosion in certain environments, especially in the presence of acids.

- Heavy weight can be a disadvantage in applications where mass is a concern.

- Cost can be significant for large-scale applications.

Boron Carbide

- High brittleness makes it prone to catastrophic failure under sharp impacts.

- Difficult to machine due to its extreme hardness.

- Expensive to produce, especially in large or complex shapes.

Environmental and Safety Considerations

Tungsten Carbide

- Mining and processing of tungsten can have environmental impacts, including habitat destruction and chemical runoff.

- Cobalt binders used in tungsten carbide can pose health risks if inhaled as dust during manufacturing or grinding.

- Recycling: Tungsten carbide is highly recyclable, and recycling programs are common in the tool industry.

Boron Carbide

- Production requires high temperatures and energy input, contributing to carbon emissions.

- Dust inhalation during processing or abrasion can be hazardous, requiring proper safety measures.

- Disposal: Boron carbide is chemically stable and non-toxic, but its production footprint is significant.

Future Trends in Superhard Materials

The quest for even harder, tougher, and more versatile materials continues. Both tungsten carbide and boron carbide are being improved through:

- Nanostructuring: Creating materials with nano-scale grains increases hardness and toughness.

- Composites: Combining boron carbide or tungsten carbide with metals or polymers to enhance toughness and reduce brittleness.

- Coatings: Applying thin layers of superhard materials (like diamond-like carbon) to tools and armor for improved performance.

Visual Comparisons

Table: Key Differences at a Glance

| Feature | Tungsten Carbide | Boron Carbide |

| Hardness | High | Higher |

| Density | Very high | Low |

| Toughness | High | Lower (brittle) |

| Cost | Moderate | High |

| Main Use | Cutting/wear tools | Armor, abrasives |

| Thermal Stability | Excellent | Excellent |

Boron carbide is harder than tungsten carbide, as evidenced by its superior scores on the Mohs, Vickers, and Knoop hardness scales. However, tungsten carbide is tougher and denser, making it more suitable for applications requiring both hardness and resistance to impact or deformation.

- Choose boron carbide for maximum hardness and lightweight protection (e.g., body armor, abrasives).

- Choose tungsten carbide for cutting tools, industrial wear parts, and applications where toughness and density are critical.

Each material excels in different roles, and the choice depends on the specific requirements of your application. As technology advances, the boundaries between these materials may blur, with new composites and processing techniques offering even greater performance.

FAQ: Top 5 Related Questions

1. What is the main advantage of boron carbide over tungsten carbide?

Boron carbide is significantly harder and lighter than tungsten carbide, making it ideal for lightweight armor and high-wear applications where weight is a concern.

2. Why is tungsten carbide preferred for cutting tools?

Tungsten carbide offers a combination of high hardness, toughness, and density, which allows it to withstand the extreme forces and temperatures encountered in cutting and machining operations.

3. Is boron carbide more brittle than tungsten carbide?

Yes, boron carbide is much more brittle, meaning it is more likely to fracture under impact or shock loading compared to tungsten carbide, which is tougher and can absorb more energy before breaking.

4. Can either material be used for jewelry?

Tungsten carbide is commonly used in jewelry due to its attractive metallic luster, scratch resistance, and hypoallergenic properties. Boron carbide is not typically used for jewelry because of its ceramic nature and brittleness.

5. Which material is more expensive, and why?

Boron carbide is generally more expensive than tungsten carbide due to its specialized applications, higher production costs, and the complexity of its manufacturing process.

Citations:

[1] https://www.makeitfrom.com/compare/Boron-Carbide-B4C/Tungsten-Carbide-WC

[2] https://en.wikipedia.org/wiki/Tungsten_carbide

[3] https://en.wikipedia.org/wiki/Boron_carbide

[4] http://hardmetal-engineering.blogspot.com/2011/

[5] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[6] https://www.differencebetween.com/what-is-the-difference-between-tungsten-carbide-and-boron-carbide/

[7] https://precision-ceramics.com/materials/boron-carbide/

[8] https://www.difference.wiki/tungsten-carbide-vs-boron-carbide/

[9] https://anamma.com.br/en/tungsten-carbide-vs-boron-carbide/

[10] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[11] https://www.samaterials.com/carbides-used-in-hardfacing-applications.html

[12] https://www.sciencedirect.com/science/article/pii/0043164895068864

[13] https://sandblastingabrasives.com/surface-prep-media/blog/167/when-to-use-a-boron-carbide-nozzle/

[14] https://stock.adobe.com/search?k=tungsten+carbide

[15] https://www.bangerter.com/en/tungsten-carbide

[16] http://www.nicrotec.com/welding-consumables/tungsten-carbide-alloys-nicrotec/products.html?c=1&g=13

[17] https://www.azom.com/article.aspx?ArticleID=5809

[18] https://shop.nanografi.com/blog/carbides-from-atomic-structure-to-industrial-applications-nanografi-/

[19] https://insaco.mystagingwebsite.com/material/boron-carbide/

[20] https://www.linkedin.com/pulse/questions-composite-materials-tungsten-carbide-shijin-lei

[21] https://www.imim.pl/files/archiwum/Vol2_2020/05.pdf

[22] https://www.sciencedirect.com/science/article/abs/pii/S0043164899002306

[23] https://en.wikipedia.org/wiki/Tungsten_carbide

[24] http://www.tungsten-carbide.com.cn

[25] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[26] https://www.differencebetween.com/what-is-the-difference-between-tungsten-carbide-and-boron-carbide/

[27] https://www.nature.com/articles/ncomms2047

[28] https://www.thermalspray.com/questions-tungsten-carbide/