Content Menu

● Composition and Construction

● Key Properties of Diamond Tungsten Carbide Saws

● Applications in Construction

● Applications in Fire and Rescue Operations

● Applications in Metalworking

● Applications in Stone and Ceramic Processing

● Advantages of Using Diamond Tungsten Carbide Saws

● Maintenance and Care

● Choosing the Right Diamond Tungsten Carbide Saw

● Conclusion

● FAQ

>> 1. What Materials Can a Diamond Tungsten Carbide Saw Cut?

>> 2. How Does a Diamond Tungsten Carbide Saw Differ from a Regular Saw?

>> 3. Can a Diamond Tungsten Carbide Saw Be Used for Both Wet and Dry Cutting?

>> 4. How Should I Maintain My Diamond Tungsten Carbide Saw?

>> 5. What Safety Precautions Should I Take When Using a Diamond Tungsten Carbide Saw?

● Citations:

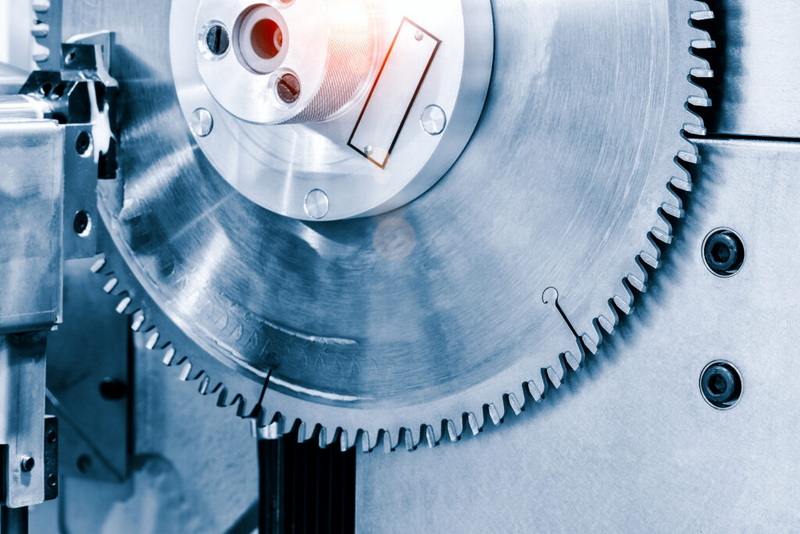

A diamond tungsten carbide saw is a versatile and robust cutting tool designed for a wide array of applications across various industries. Combining the exceptional hardness of diamonds with the durability of tungsten carbide, these saws offer superior performance when cutting through tough materials such as concrete, asphalt, stone, metal, and more[1][3]. This article delves into the multifaceted uses of a diamond tungsten carbide saw, its construction, benefits, and specific applications across different sectors.

Composition and Construction

The construction of a diamond tungsten carbide saw is a testament to its robust design and functionality. These saws typically consist of two primary components:

- Steel Core: The inner core is made from high-quality alloy steel, treated and hardened to provide a stable base[1][3]. This core is laser-cut to the required diameter and includes an arbor hole for precise mounting onto machinery[3]. The core may be slotted to create segmented blades or left unslotted for continuous rim blades[3].

- Cutting Edge: The cutting edge is composed of a blend of synthetic diamonds and metal powders, known as a bond matrix[3]. This matrix affixes the diamonds to the core, forming a durable and efficient cutting surface. The diamonds are synthetic, ensuring consistent quality and performance[3].

Key Properties of Diamond Tungsten Carbide Saws

Several key properties make a diamond tungsten carbide saw an indispensable tool in many industries:

- Hardness: Tungsten carbide is known for its extreme hardness, making it ideal for cutting tools[2][4]. The addition of diamonds, the hardest known material, further enhances the saw's ability to cut through tough substances[3].

- Heat Resistance: Tungsten carbide maintains its hardness and strength even at high temperatures, making it suitable for high-speed cutting applications[2].

- Versatility: These saws can cut through a variety of materials, including tar, fiberglass, gravel, hard concrete, roofing materials, wood, asphalt shingles, rubber, plastic, and metal sheets[1].

- Durability: The combination of a solid steel core and a diamond-impregnated cutting edge ensures that the saw can withstand heavy use and last longer than traditional saw blades[1].

- Efficiency: The rough tungsten segments on the blade provide high-length capabilities, increasing cutting efficiency and performance[1].

- Adaptability: Diamond tungsten carbide saws can be used in both wet and dry cutting conditions and are compatible with various power tools, including angle grinders and handheld saws[1].

Applications in Construction

In the construction industry, a diamond tungsten carbide saw is invaluable for its ability to cut through tough materials such as concrete, asphalt, and masonry[4]. Specific applications include:

- Cutting Concrete and Asphalt: These saws are used to cut expansion joints in concrete slabs, create openings for pipes and utilities, and repair damaged road surfaces[3][4].

- Masonry Work: They are ideal for cutting bricks, blocks, and pavers to the required sizes for walls, walkways, and other structures[3].

- Demolition: Diamond tungsten carbide saws are employed in demolition work to cut through reinforced concrete, metal structures, and other tough materials[1].

- Road Construction: These saws are crucial for cutting asphalt and concrete during road construction and repair projects[1].

Applications in Fire and Rescue Operations

Fire and rescue teams rely on diamond tungsten carbide saws for their ability to quickly cut through various materials during emergency situations. Key applications include:

- Breaching: These saws can cut through doors, windows, and walls to gain access to buildings and rescue trapped individuals[1].

- Roof Ventilation: Firefighters use these saws to cut ventilation holes in roofs, allowing heat and smoke to escape and improving visibility for rescue operations[1].

- Vehicle Extrication: Diamond tungsten carbide saws can cut through metal sheets and other materials to free victims trapped in vehicles[1].

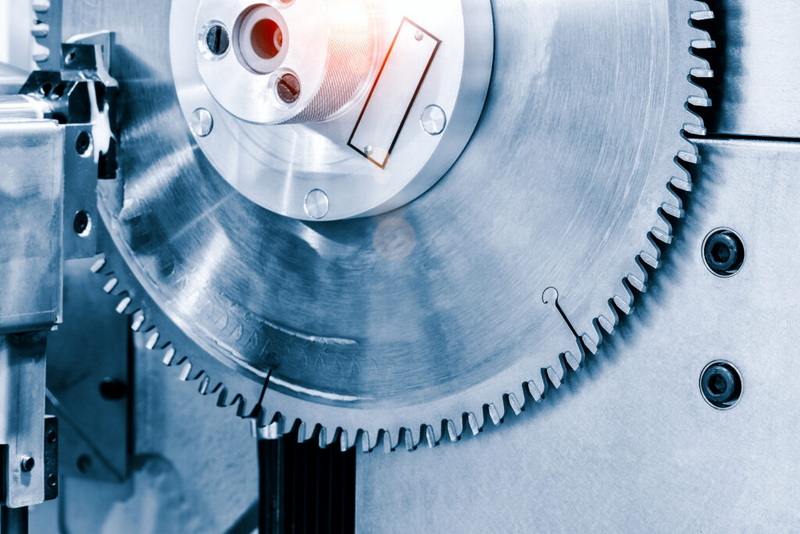

Applications in Metalworking

The metalworking industry benefits significantly from the precision and durability of diamond tungsten carbide saws. Common applications include:

- Cutting Metal Sheets: These saws can easily cut through various types of metal sheets, including steel, aluminum, and alloys[1].

- Fabrication: They are used to cut metal components to specific dimensions for fabrication purposes[1].

- Automotive Repair: Diamond tungsten carbide saws are essential for cutting through damaged vehicle frames and body panels during repair work[1].

Applications in Stone and Ceramic Processing

In the stone and ceramic industries, diamond tungsten carbide saws are used for cutting and shaping materials with precision. Specific applications include:

- Cutting Stone: These saws are used to cut marble, granite, and other types of stone for countertops, tiles, and decorative elements[3].

- Ceramic Tile Cutting: They provide clean and precise cuts in ceramic tiles for flooring, wall coverings, and decorative purposes[3].

- Sculpting: Artists and craftsmen use these saws to sculpt stone and create intricate designs[3].

Advantages of Using Diamond Tungsten Carbide Saws

There are numerous advantages to using a diamond tungsten carbide saw compared to traditional cutting tools:

- Extended Lifespan: The combination of tungsten carbide and diamonds ensures that the saw blade lasts significantly longer than conventional blades[8].

- Versatile Cutting: These saws can cut through a wide range of materials, reducing the need for multiple specialized blades[1].

- High Precision: The diamond cutting edge provides clean and precise cuts, minimizing material waste and ensuring accurate dimensions[8].

- Efficient Performance: The robust design and sharp cutting edge allow for faster cutting speeds and increased productivity[1].

- Cost-Effectiveness: While the initial investment may be higher, the extended lifespan and versatile cutting capabilities of diamond tungsten carbide saws make them a cost-effective choice in the long run[8].

- Safety: The solid steel core and durable construction ensure safe operation, reducing the risk of blade breakage and accidents[1].

Maintenance and Care

To maximize the lifespan and performance of a diamond tungsten carbide saw, proper maintenance and care are essential:

- Regular Cleaning: Clean the blade after each use to remove debris and prevent buildup, which can reduce cutting efficiency.

- Proper Storage: Store the saw in a dry place to prevent corrosion and damage to the cutting edge.

- Sharpening: Although diamond blades are exceptionally durable, they may require occasional sharpening. Use a specialized diamond sharpening tool to maintain the cutting edge.

- Cooling: When cutting hard materials, use a coolant to reduce heat buildup and prevent damage to the blade. Wet cutting is often recommended for materials like concrete and stone[1].

- Inspection: Regularly inspect the blade for signs of wear or damage. Replace the blade if cracks, chips, or significant wear are present.

Choosing the Right Diamond Tungsten Carbide Saw

Selecting the right diamond tungsten carbide saw depends on the specific application and materials to be cut. Consider the following factors when making a purchase:

-Blade Diameter: Choose the appropriate blade diameter for the depth of cut required. Blades range from 4 inches to 16 inches[1].

- Arbor Size: Ensure that the arbor size matches the specifications of your power tool. Common arbor sizes include 1 inch with a 20mm bushing and pinhole[1].

- Segment Type: Select the appropriate segment type for the material being cut. Continuous rim blades are best for smooth, precise cuts, while segmented blades are suitable for faster, more aggressive cutting[3].

- Wet or Dry Cutting: Determine whether wet or dry cutting is required for your application. Some blades are designed for both wet and dry use[1].

- Machine Compatibility: Verify that the saw blade is compatible with your specific power tool, such as Stihl gas handsaws, Husqvarna K970, Makita, or Milwaukee Battery[1].

Conclusion

A diamond tungsten carbide saw is an essential tool for numerous industries due to its exceptional hardness, heat resistance, and versatility. From construction and fire rescue to metalworking and stone processing, these saws provide efficient and precise cutting performance on a wide range of materials. By understanding the construction, properties, applications, and maintenance of diamond tungsten carbide saws, professionals can maximize their benefits and ensure safe and effective operation.

FAQ

1. What Materials Can a Diamond Tungsten Carbide Saw Cut?

A diamond tungsten carbide saw can efficiently cut through a variety of tough materials, including tar, fiberglass, gravel, hard concrete, roofing materials, wood, asphalt shingles, rubber, plastic, metal sheets, stone, and ceramics[1][3].

2. How Does a Diamond Tungsten Carbide Saw Differ from a Regular Saw?

Unlike regular saws, a diamond tungsten carbide saw combines the hardness of diamonds with the durability of tungsten carbide, providing superior cutting performance and a longer lifespan. Regular saws typically use steel blades that wear down more quickly and are less effective on hard materials[8].

3. Can a Diamond Tungsten Carbide Saw Be Used for Both Wet and Dry Cutting?

Yes, many diamond tungsten carbide saws are designed for both wet and dry cutting. Wet cutting is often recommended for hard materials like concrete and stone to reduce heat buildup and prolong blade life[1].

4. How Should I Maintain My Diamond Tungsten Carbide Saw?

To maintain a diamond tungsten carbide saw, regularly clean the blade, store it in a dry place, and inspect it for signs of wear or damage. Use a specialized diamond sharpening tool to maintain the cutting edge when necessary[1].

5. What Safety Precautions Should I Take When Using a Diamond Tungsten Carbide Saw?

When using a diamond tungsten carbide saw, always wear appropriate safety gear, including eye protection, gloves, and hearing protection. Ensure that the blade is properly installed and compatible with your power tool. Use coolant when cutting hard materials to prevent overheating, and never force the blade[1].

Citations:

[1] https://globaldiamondpros.com/products/4-1-2

[2] https://www.hit-tw.com/newsdetails.aspx?nid=298

[3] https://www.usitc.gov/publications/701_731/pub5176.pdf

[4] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[5] https://ukam.com/product/tungsten-carbide-dicing-blades/

[6] https://www.topcutools.com/blog/

[7] https://www.leuco.ru/EN/US/media/DOK_MBR_Plattenaufteilsaegeblatt-Programm-HW-DP_DL.pdf

[8] https://karnasch.tools/en/newsletters/saw-blades_newsletter_2022-02/

[9] https://www.zhongzhi.biz/download.html

[10] https://www.brazing.com/applications/Tungsten_carbide.aspx