Content Menu

● Understanding Carbide Plates

● Industries Benefiting from Carbide Plates

>> Manufacturing Industry

>> Mining and Mineral Processing

>> Construction Industry

>> Aerospace Industry

>> Oil and Gas Industry

>> Agriculture Industry

● Advantages of Using Carbide Plates

● Why Choose Shengyufeng?

● Conclusion

● Frequently Asked Questions

>> 1. What are carbide plates made of?

>> 2. What industries use carbide plates?

>> 3. How do carbide plates improve tool life?

>> 4. Can carbide plates be customized?

>> 5. What are the benefits of using carbide plates?

Understanding Carbide Plates

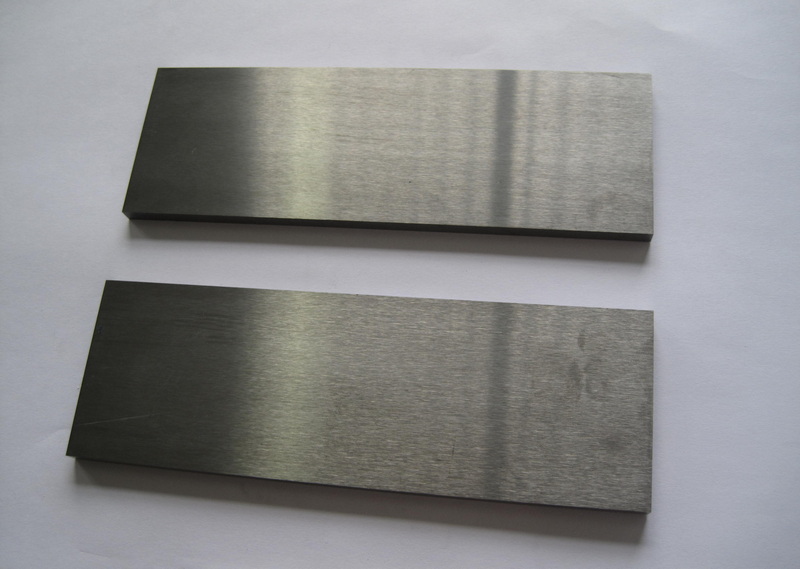

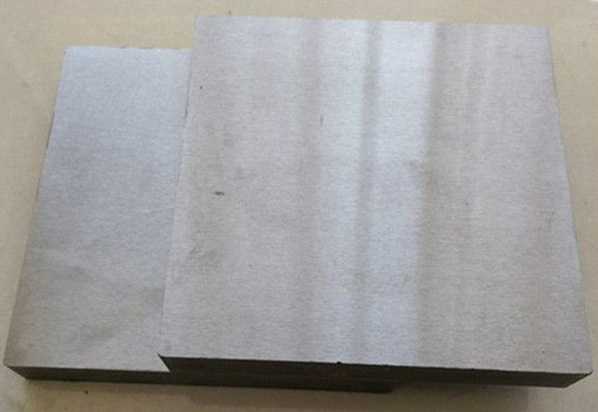

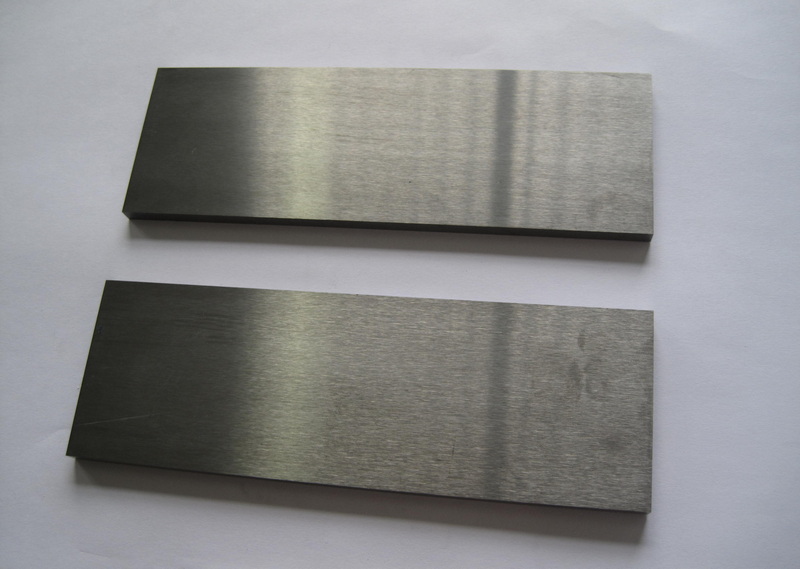

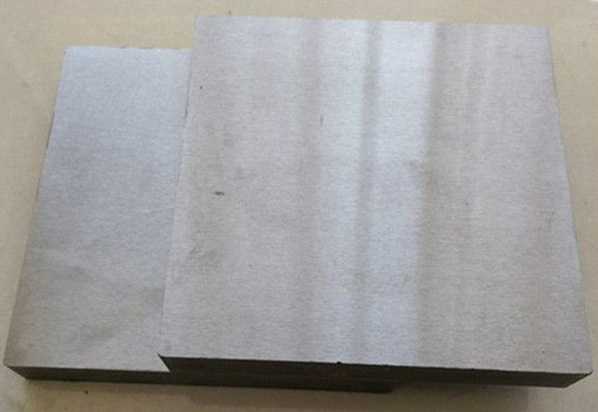

Carbide plates are essential components in various industries due to their exceptional hardness, wear resistance, and durability. Made from tungsten carbide, a compound of tungsten and carbon, these plates are known for their ability to withstand extreme conditions. The manufacturing process involves sintering tungsten carbide powder at high temperatures, resulting in a dense and durable product. The unique properties of carbide plates make them suitable for various industrial applications, including cutting, machining, and wear protection.

Industries Benefiting from Carbide Plates

Manufacturing Industry

The manufacturing industry is one of the primary sectors that benefit from carbide plates. These plates are used in various applications, including:

- Cutting Tools: Carbide plates are commonly used to manufacture cutting tools such as drills, end mills, and inserts. Their hardness allows for precise cutting and extended tool life, reducing the frequency of replacements. The ability to maintain sharp edges for longer periods translates to improved efficiency in production processes.

- Machining Components: In machining processes, carbide plates are utilized for creating components that require high precision and durability. They can withstand high temperatures and pressures, making them ideal for machining metals and other hard materials. This capability is crucial in industries where precision is paramount, such as aerospace and automotive manufacturing.

Mining and Mineral Processing

In the mining industry, carbide plates play a crucial role in various applications:

- Drilling Equipment: Carbide plates are used in drill bits and other drilling equipment due to their ability to penetrate hard rock formations. This enhances drilling efficiency and reduces downtime. The longevity of carbide drill bits means fewer replacements and less time spent on maintenance.

- Wear Parts: Mining equipment is subject to extreme wear and tear. Carbide plates are used as wear parts in crushers, screens, and other machinery to extend their lifespan and reduce maintenance costs. This is particularly important in mining operations where equipment failure can lead to significant financial losses.

Construction Industry

The construction industry also benefits significantly from carbide plates:

- Cutting and Shaping Tools: Carbide plates are used in tools for cutting and shaping concrete, asphalt, and other construction materials. Their durability ensures that these tools maintain their effectiveness over time, which is essential for meeting project deadlines.

- Wear Protection: In construction machinery, carbide plates are used to protect critical components from wear. This is particularly important in equipment that operates in harsh environments, such as excavators and bulldozers, where exposure to abrasive materials is common.

Aerospace Industry

The aerospace industry requires materials that can withstand extreme conditions. Carbide plates are used in:

- Engine Components: Carbide plates are utilized in various engine components due to their ability to withstand high temperatures and pressures. This ensures the reliability and safety of aircraft. The aerospace sector demands materials that not only perform well but also meet stringent safety standards.

- Cutting Tools: In aerospace manufacturing, carbide plates are used to create cutting tools that can machine tough materials like titanium and nickel alloys. These materials are commonly used in aircraft components, where strength and weight are critical factors.

Oil and Gas Industry

The oil and gas industry relies on carbide plates for several applications:

- Drilling Tools: Carbide plates are used in drilling tools for oil and gas extraction. Their hardness allows them to penetrate tough geological formations, improving drilling efficiency. The ability to drill deeper and faster can significantly impact the profitability of oil and gas operations.

- Wear Protection: In oil and gas extraction, equipment is exposed to harsh conditions. Carbide plates provide wear protection for critical components, extending their lifespan and reducing maintenance costs. This is vital in an industry where equipment downtime can lead to substantial financial losses.

Agriculture Industry

The agriculture industry also benefits from carbide plates:

- Tillage Tools: Carbide plates are used in tillage tools, such as plows and harrows, to improve soil preparation. Their durability ensures that these tools can withstand the rigors of agricultural work, leading to better crop yields.

- Harvesting Equipment: In harvesting machinery, carbide plates are used to enhance the performance and longevity of cutting components. This is particularly important during peak harvest seasons when efficiency is crucial.

Advantages of Using Carbide Plates

The use of carbide plates offers several advantages across various industries:

- Durability: Carbide plates are highly durable and can withstand extreme conditions, making them ideal for heavy-duty applications. Their resistance to deformation under stress ensures that they maintain their shape and functionality over time.

- Wear Resistance: Their exceptional wear resistance reduces the frequency of replacements, leading to cost savings in maintenance and downtime. This is particularly beneficial in industries where equipment failure can result in significant operational disruptions.

- Precision: Carbide plates provide high precision in machining and cutting applications, ensuring quality results. This precision is essential in industries where tolerances are tight, such as aerospace and automotive manufacturing.

- Versatility: Carbide plates can be used in a wide range of applications, making them a versatile choice for different industries. Their adaptability allows manufacturers to use them in various processes, from cutting to wear protection.

Why Choose Shengyufeng?

Shengyufeng stands out as a leading exporter of carbide plates for several reasons:

- Quality Assurance: Shengyufeng is committed to providing high-quality carbide plates that meet international standards. Their rigorous quality control processes ensure that customers receive reliable products. This commitment to quality has earned them a reputation as a trusted supplier in the industry.

- Customization: Shengyufeng offers customization options to meet specific customer requirements. This flexibility allows industries to obtain carbide plates tailored to their unique applications, enhancing operational efficiency.

- Expertise: With years of experience in the industry, Shengyufeng has the expertise to provide valuable insights and support to customers, helping them choose the right products for their needs. Their knowledgeable staff can assist in selecting the appropriate carbide plates for various applications.

- Competitive Pricing: Shengyufeng offers competitive pricing without compromising on quality, making their carbide plates an attractive option for businesses looking to optimize their operations. This affordability allows companies to invest in high-quality materials without exceeding their budgets.

Conclusion

Carbide plates are invaluable in various industries, providing durability, wear resistance, and precision. From manufacturing to aerospace, the applications of carbide plates are vast and varied. Shengyufeng, as a leading exporter, offers high-quality carbide plates that cater to the needs of different sectors. By choosing Shengyufeng, businesses can benefit from reliable products, customization options, and expert support.

Frequently Asked Questions

1. What are carbide plates made of?

Carbide plates are primarily made from tungsten carbide, a compound of tungsten and carbon known for its hardness and durability.

2. What industries use carbide plates?

Industries such as manufacturing, mining, construction, aerospace, oil and gas, and agriculture utilize carbide plates for various applications.

3. How do carbide plates improve tool life?

The hardness and wear resistance of carbide plates allow cutting tools to maintain their effectiveness over time, reducing the need for frequent replacements.

4. Can carbide plates be customized?

Yes, Shengyufeng offers customization options for carbide plates to meet specific customer requirements.

5. What are the benefits of using carbide plates?

The benefits include durability, wear resistance, precision, and versatility in various applications.