Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Applications of Tungsten Carbide

● Comparison with Other Materials

>> Tungsten Carbide vs. Titanium

>> Tungsten Carbide vs. Steel

>> Tungsten Carbide vs. Diamond

● Environmental and Health Considerations

>> Recycling of Tungsten Carbide

● Economic Impact

● Future Developments

● Conclusion

● FAQ

>> 1. What is the hardness level of tungsten carbide?

>> 2. What are the primary applications of tungsten carbide?

>> 3. How is tungsten carbide manufactured?

>> 4. What is the difference between tungsten carbide and titanium?

>> 5. Is tungsten carbide recyclable?

● Citations:

Tungsten carbide is renowned for its exceptional hardness, making it one of the most sought-after materials in various industrial applications. Its hardness is often compared to that of diamond, which is the hardest substance known. In this article, we will delve into the specifics of tungsten carbide's hardness, its properties, applications, and how it compares to other materials.

Introduction to Tungsten Carbide

Tungsten carbide, with the chemical formula WC, is a compound made from equal parts of tungsten and carbon atoms. It is produced through a process known as powder metallurgy, where tungsten carbide powder is mixed with a metallic binder, typically cobalt, and then sintered at high temperatures to form a solid composite material.

Properties of Tungsten Carbide

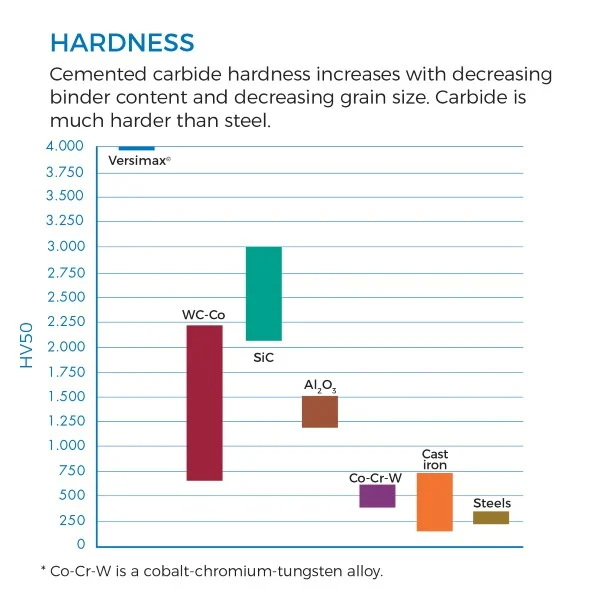

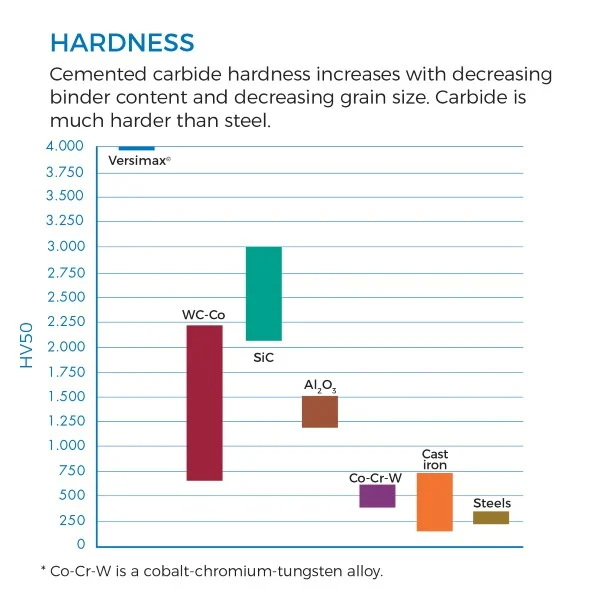

- Hardness: Tungsten carbide ranks between 8.5 and 9.5 on the Mohs hardness scale, which is second only to diamond. This high hardness makes it ideal for applications requiring wear resistance and durability.

- Density: It has a high density of approximately 15.6 to 15.8 g/cm³, which is significantly higher than most metals.

- Melting Point: Tungsten carbide has a very high melting point of about 2,870°C, making it suitable for high-temperature applications.

- Young's Modulus: Its Young's modulus ranges from 530 to 700 GPa, indicating high stiffness and rigidity.

Applications of Tungsten Carbide

Tungsten carbide is widely used in various industries due to its exceptional hardness and wear resistance. Some of its primary applications include:

- Cutting Tools: Tungsten carbide is used in cutting tools for machining and drilling due to its ability to maintain sharpness under high-stress conditions.

- Mining Equipment: Its high hardness makes it ideal for mining equipment that requires resistance to abrasion and wear.

- Aerospace: Tungsten carbide is used in aerospace for components that require high strength and resistance to extreme conditions.

- Jewelry: Due to its hardness and durability, tungsten carbide is also used in making jewelry, particularly wedding bands.

- Medical Applications: Tungsten carbide is used in medical implants due to its biocompatibility and resistance to corrosion.

- Military Applications: Its high density and hardness make it suitable for use in armor-piercing ammunition and other military components.

Comparison with Other Materials

Tungsten Carbide vs. Titanium

Tungsten carbide and titanium are both used in high-performance applications, but they serve different purposes based on their unique properties:

| Property | Tungsten Carbide | Titanium |

| Hardness | Very high (9 on Mohs scale) | Moderate (6 on Mohs scale) |

| Melting Point | 2,870°C | 1,668°C |

| Density | 15.6-15.8 g/cm³ | 4.5 g/cm³ |

| Typical Applications | Cutting tools, mining | Aircraft, medical implants |

| Cost | Higher | Moderate |

Tungsten Carbide vs. Steel

Tungsten carbide is significantly harder and more wear-resistant than regular steel. It maintains its sharpness longer and can withstand higher temperatures and abrasive conditions, making it suitable for demanding applications.

Tungsten Carbide vs. Diamond

While diamond is the hardest material known, tungsten carbide is more cost-effective and easier to work with for many industrial applications. Diamond is primarily used in cutting tools for very hard materials, while tungsten carbide is versatile across various industries.

Environmental and Health Considerations

Tungsten carbide, when used in industrial processes, can pose environmental and health risks if not handled properly. The production process involves the use of cobalt, which can be toxic if inhaled. Additionally, the disposal of tungsten carbide waste requires careful management to prevent environmental contamination.

Recycling of Tungsten Carbide

Recycling tungsten carbide is crucial for reducing waste and conserving resources. Worn-out tools and scrap material can be reclaimed and reused, reducing the need for new raw materials and minimizing environmental impact. The recycling process typically involves collecting scrap material, sorting it by type, and then re-melting it to produce new tungsten carbide products.

Economic Impact

The use of tungsten carbide has significant economic benefits due to its durability and long lifespan. By extending the life of tools and equipment, industries can reduce maintenance costs and improve productivity. Additionally, the recycling of tungsten carbide helps in conserving natural resources and reducing waste disposal costs.

Future Developments

Research is ongoing to improve the properties of tungsten carbide and expand its applications. New techniques in powder metallurgy and advanced materials science are being explored to enhance its performance and reduce production costs. Furthermore, efforts are being made to develop more sustainable and environmentally friendly methods for producing and recycling tungsten carbide.

Conclusion

Tungsten carbide is an extremely hard material with a hardness level of 8.5 to 9.5 on the Mohs scale, making it ideal for applications requiring high wear resistance and durability. Its high melting point, density, and Young's modulus further enhance its suitability for cutting tools, mining equipment, aerospace components, and other demanding applications.

FAQ

1. What is the hardness level of tungsten carbide?

Tungsten carbide has a hardness level of 8.5 to 9.5 on the Mohs scale, which is second only to diamond.

2. What are the primary applications of tungsten carbide?

Tungsten carbide is primarily used in cutting tools, mining equipment, aerospace components, jewelry, medical implants, and military applications due to its exceptional hardness and wear resistance.

3. How is tungsten carbide manufactured?

Tungsten carbide is manufactured through a powder metallurgy process involving the mixing of tungsten carbide powder with a metallic binder, followed by sintering at high temperatures.

4. What is the difference between tungsten carbide and titanium?

Tungsten carbide is much harder and denser than titanium, making it suitable for high-stress applications, while titanium is used in applications requiring moderate strength and low weight.

5. Is tungsten carbide recyclable?

Yes, tungsten carbide can be recycled. Worn-out tools and scrap material can be reclaimed and reused, reducing waste and conserving resources.

Citations:

[1] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[2] https://www.matweb.com/search/DataSheet.aspx?MatGUID=e68b647b86104478a32012cbbd5ad3ea

[3] https://www.aemmetal.com/news/tungsten-carbide-vs-titanium.html

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] http://hardmetal-engineering.blogspot.com/2011/

[6] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[7] https://www.tungstenman.com/tungsten-carbide-hardness.html

[8] https://outils.it/en/tungsten-carbide/

[9] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[10] https://www.imetra.com/tungsten-carbide-material-properties/

[11] https://www.basiccarbide.com/tungsten-carbide-grade-chart/

[12] https://www.azom.com/properties.aspx?ArticleID=1203

[13] https://www.mitsubishicarbide.net/contents/mmus/enus/html/product/technical_information/information/hardness.html

[14] https://upload.wikimedia.org/wikipedia/commons/7/72/Tungsten_carbide_inserts.jpg?sa=X&ved=2ahUKEwibr8KL6teMAxWwOrkGHYmfHOQQ_B16BAgFEAI

[15] https://www.bladeforums.com/threads/carbide-hardness-chart.1705186/

[16] https://www.dymetalloys.co.uk/what-is-tungsten-carbide

[17] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[18] https://westernmachine.com/machine-shop-services/tungsten-carbide-coatings/

[19] https://stock.adobe.com/search?k=tungsten+carbide

[20] https://www.innovativecarbide.com/grades/

[21] https://www.hyperionmt.com/en/Resources/materials/cemented-carbide/nano-ultrafine-and-submicron-grades/grade-comparative/

[22] https://www.azom.com/article.aspx?ArticleID=1203

[23] https://www.vistametalsinc.com/pdf/Tungsten-Carbide-Grade-Chart.pdf

[24] https://rrcarbide.com/understanding-tungsten-carbide-composition-uses-and-expertise/

[25] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/tungsten-carbide-grades-applications

[26] http://www.machiningtech.com/images/Grade%20Chart%20for%20web%20page.pdf

[27] https://www.reddit.com/r/askscience/comments/f02z1/materials_science_question_why_does_an_extremely/

[28] https://www.carbide-products.com/blog/hardness-testing-of-carbide/

[29] https://www.bladeforums.com/threads/carbide-hardness-data.1514372/

[30] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-selection.html

[31] https://www.bladeforums.com/threads/hardness-carbides-and-how-they-affect-durability-and-edge-retention.909226/

[32] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[33] https://www.practicalmachinist.com/forum/threads/carbide-hardness-of-drill-and-end-mills.294897/

[34] https://www.gordonengland.co.uk/sef/Thread-Tungsten-Carbide-Hardness-Range

[35] https://www.tungstenringsco.com/faq

[36] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[37] https://www.syalons.com/2024/07/08/silicon-carbide-vs-tungsten-carbide-wear-applications/

[38] https://www.tungstenringsco.com/blog/2023/06/tungsten-vs-diamond/

[39] https://outils.it/en/tungsten-carbide/

[40] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[41] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

[42] http://www.tungsten-carbide.com.cn

[43] https://www.vistametalsinc.com/tungsten-carbide-grade-chart/

[44] http://www.chinatungsten.com/cutting-tools/grades-and-performance/hardness-comparison-table.html

[45] https://www.bangerter.com/en/tungsten-carbide