Content Menu

● Introduction

● Properties of Chromium Carbide Overlay Plates

● Applications of Chromium Carbide Overlay Plates

● Advantages of Using Chromium Carbide Overlay Plates

● Installation and Maintenance

● Case Studies

● Conclusion

● Frequently Asked Questions

>> Q1. What is a chromium carbide overlay plate?

>> Q2. How do chrome carbide plates compare to traditional wear materials?

>> Q3. In which industries are chromium carbide overlay plates commonly used?

>> Q4. What are the installation requirements for chrome carbide plates?

>> Q5. How can I maintain chromium carbide overlay plates?

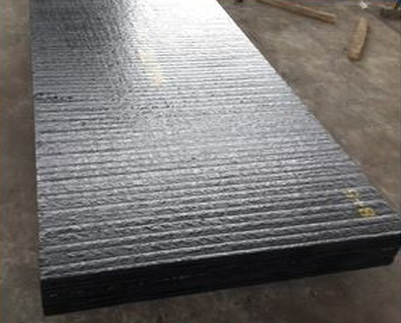

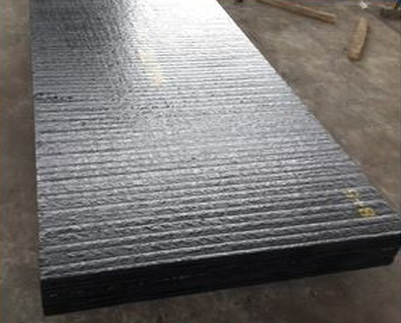

Introduction

Chromium carbide overlay plates, commonly referred to as chrome carbide plates, are engineered materials designed to provide exceptional wear resistance and durability in harsh industrial environments. These plates are created by welding a layer of chromium carbide onto a base metal, resulting in a composite material that can withstand extreme abrasion and impact. The importance of chrome carbide plates in various industrial applications cannot be overstated, as they play a crucial role in enhancing the performance and longevity of equipment used in sectors such as mining, construction, and oil and gas.

Properties of Chromium Carbide Overlay Plates

Chromium carbide overlay plates possess several key properties that make them ideal for industrial applications:

- Hardness and Wear Resistance: One of the most significant advantages of chrome carbide plates is their hardness. The chromium carbide layer provides a hardness rating that can exceed 60 HRC (Rockwell Hardness Scale), making them highly resistant to wear and tear. This property is particularly beneficial in environments where equipment is subjected to constant abrasion from materials like sand, gravel, and other particulates.

- Corrosion Resistance: In addition to their wear resistance, chrome carbide plates also exhibit excellent corrosion resistance. The chromium content in the overlay helps protect the base metal from oxidation and chemical degradation, which is essential in industries where exposure to corrosive substances is common.

- Temperature Tolerance: Chrome carbide plates can withstand high temperatures without losing their structural integrity. This makes them suitable for applications involving hot materials or environments, such as in steel mills or foundries.

Applications of Chromium Carbide Overlay Plates

Chromium carbide overlay plates are utilized across various industries due to their unique properties. Some of the most common applications include:

- Mining and Mineral Processing: In the mining industry, equipment is often exposed to abrasive materials that can cause significant wear. Chrome carbide plates are used to protect chutes, hoppers, and other components from wear, extending the life of the equipment and reducing downtime.

- Construction and Heavy Machinery: Construction sites often involve heavy machinery that operates in rugged conditions. Chrome carbide plates are used to reinforce buckets, blades, and other components, ensuring they can withstand the stresses of excavation and material handling.

- Oil and Gas Industries: In the oil and gas sector, equipment is frequently exposed to harsh conditions, including corrosive substances and high temperatures. Chrome carbide plates are used in pipelines, valves, and other critical components to enhance their durability and performance.

Advantages of Using Chromium Carbide Overlay Plates

The benefits of using chrome carbide overlay plates in industrial applications are numerous:

- Cost-Effectiveness Compared to Traditional Materials: While the initial investment in chrome carbide plates may be higher than traditional materials, the long-term savings are significant. The durability and wear resistance of these plates lead to reduced maintenance costs and less frequent replacements, ultimately saving money over time.

- Longevity and Reduced Maintenance Costs: The extended lifespan of chrome carbide plates means that equipment can operate longer without the need for repairs or replacements. This not only reduces maintenance costs but also minimizes downtime, allowing for more efficient operations.

- Enhanced Performance in High-Stress Environments: Chrome carbide plates are designed to perform exceptionally well in high-stress environments. Their ability to withstand abrasion, impact, and corrosion makes them ideal for use in industries where equipment is subjected to extreme conditions.

Installation and Maintenance

Proper installation and maintenance of chrome carbide overlay plates are essential to maximize their lifespan and performance:

- Best Practices for Installation: When installing chrome carbide plates, it is crucial to ensure that the surface is clean and free of contaminants. The plates should be welded or bolted securely to the base material, and any gaps should be filled to prevent wear at the joints. Following the manufacturer's guidelines for installation will help ensure optimal performance.

- Maintenance Tips to Maximize Lifespan: Regular inspections of chrome carbide plates are essential to identify any signs of wear or damage. Cleaning the plates to remove debris and contaminants can also help maintain their performance. In some cases, re-welding or adding additional layers of chrome carbide may be necessary to extend the life of the plates.

Case Studies

Several industries have successfully implemented chrome carbide overlay plates to enhance their operations:

- Mining Industry: A mining company faced significant wear issues with their conveyor systems due to the abrasive nature of the materials being transported. By installing chrome carbide overlay plates on the conveyor chutes, the company was able to reduce wear significantly, resulting in lower maintenance costs and increased uptime.

- Construction Sector: A construction firm used chrome carbide plates to reinforce the buckets of their excavators. The enhanced durability of the buckets allowed them to operate more efficiently, reducing the frequency of repairs and replacements.

- Oil and Gas Industry: An oil and gas company implemented chrome carbide plates in their pipeline systems to combat corrosion and wear. The result was a marked improvement in the lifespan of the pipelines, leading to significant cost savings and reduced environmental risks.

Conclusion

In conclusion, chromium carbide overlay plates offer numerous benefits for industrial applications, including exceptional wear resistance, corrosion protection, and temperature tolerance. Their ability to enhance the performance and longevity of equipment makes them a valuable investment for industries such as mining, construction, and oil and gas. By understanding the properties, applications, and advantages of chrome carbide plates, businesses can make informed decisions that lead to improved efficiency and cost savings.

Frequently Asked Questions

Q1. What is a chromium carbide overlay plate?

Chromium carbide overlay plates are composite materials created by welding a layer of chromium carbide onto a base metal, providing exceptional wear resistance and durability.

Q2. How do chrome carbide plates compare to traditional wear materials?

Chrome carbide plates offer superior hardness and wear resistance compared to traditional materials, leading to longer lifespans and reduced maintenance costs.

Q3. In which industries are chromium carbide overlay plates commonly used?

These plates are commonly used in mining, construction, and oil and gas industries, where equipment is subjected to harsh conditions and abrasive materials.

Q4. What are the installation requirements for chrome carbide plates?

Proper installation requires a clean surface, secure welding or bolting, and filling any gaps to prevent wear at the joints.

Q5. How can I maintain chromium carbide overlay plates?

Regular inspections, cleaning to remove debris, and re-welding or adding layers as needed can help maximize the lifespan and performance of chrome carbide plates.