Content Menu

● Introduction to Carbide Products

>> Carbide Inserts

>> Carbide Plates

>> Carbide Strips

>> Carbide Balls

● Benefits of Carbide Products in Industrial Applications

>> 1. Enhanced Productivity and Efficiency

>> 2. Cost Savings and Reduced Maintenance

>> 3. Improved Product Quality

>> 4. Versatility and Adaptability

>> 5. Environmental Considerations

● Advanced Applications of Carbide Products

>> Aerospace Industry

>> Automotive Industry

>> Construction and Mining

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary materials used to make carbide products?

>> 2. How do carbide inserts improve manufacturing processes?

>> 3. What are the advantages of using carbide plates in industrial applications?

>> 4. In which industries are carbide strips commonly used?

>> 5. What are the benefits of using carbide balls in industrial bearings?

● Citations:

Carbide products, including carbide inserts, plates, strips, and balls, have become indispensable in various industrial applications due to their exceptional properties such as hardness, wear resistance, and thermal stability. These materials are widely used in sectors like manufacturing, aerospace, automotive, energy, and construction, offering numerous benefits that enhance productivity, efficiency, and cost-effectiveness. In this article, we will explore the advantages of using carbide products in industrial settings and highlight their applications across different industries.

Introduction to Carbide Products

Carbide products are made from materials like tungsten carbide and silicon carbide, which are known for their high hardness and durability. These properties make them ideal for cutting tools, wear parts, and other applications where resistance to abrasion and high temperatures is crucial.

Carbide Inserts

Carbide inserts are widely used in metal cutting and shaping processes. They are employed in machining operations such as turning, milling, and boring, providing superior hardness, wear resistance, and high heat tolerance. This enables manufacturers to achieve high precision and repeatability in their production processes, resulting in improved surface finish, reduced cycle times, and extended tool life.

Carbide Plates

Carbide plates are used in applications where precision is critical. Their hardness allows for the creation of sharp edges and fine details, making them ideal for cutting tools and molds. These plates exhibit outstanding wear resistance, which is crucial in industries such as mining, construction, and manufacturing. They can withstand high temperatures without losing their structural integrity, making them a reliable choice for various industrial processes.

Carbide Strips

Carbide strips are a type of cutting tool used in metalworking, woodworking, mining, aerospace, and medical applications. They are made from a combination of tungsten carbide and cobalt, which makes them extremely hard and durable. Carbide strips are able to cut through a wide range of materials, including metals and wood, providing a high level of precision.

Carbide Balls

Carbide balls are popular in industrial applications due to their high hardness, wear resistance, and stability in harsh environments. They are commonly used in ball bearings for industrial machinery, where they can withstand high speeds and loads without deforming or wearing down quickly.

Benefits of Carbide Products in Industrial Applications

1. Enhanced Productivity and Efficiency

Carbide products, such as carbide inserts and plates, enable faster cutting speeds and reduce downtime due to their exceptional wear resistance. This leads to increased production rates without compromising on quality or precision, allowing companies to meet customer demand more efficiently.

CNC milling machine with metallic end mill carbide in industrial manufacture factory.

2. Cost Savings and Reduced Maintenance

While carbide products may have a higher initial cost, their extended lifespan often results in lower overall tooling expenses over time. The reduced need for tool changes and maintenance minimizes downtime, directly impacting productivity and profitability.

Industrial milling metal cutting tool with carbide cutter insert in workshop.

3. Improved Product Quality

The consistent tool wear of carbide products ensures greater dimensional accuracy and surface finish consistency throughout production runs, reducing scrap rates and improving overall part quality.

Quality testing of face milling cutter with carbide inserts.

4. Versatility and Adaptability

Carbide products can be customized for specific applications, allowing manufacturers to create tailored solutions that meet unique operational needs. This versatility makes them suitable for numerous industries, including aerospace, automotive, and manufacturing.

5. Environmental Considerations

The use of carbide products can also contribute to more sustainable manufacturing practices. By reducing the frequency of tool replacements and minimizing waste, companies can lower their environmental footprint. Additionally, the durability of carbide tools means less material is consumed over time, aligning with efforts to reduce resource usage and promote eco-friendly production methods.

Advanced Applications of Carbide Products

Aerospace Industry

In the aerospace sector, carbide products are used for machining complex components such as engine parts and structural elements. Their high strength-to-weight ratio and resistance to extreme temperatures make them ideal for these applications.

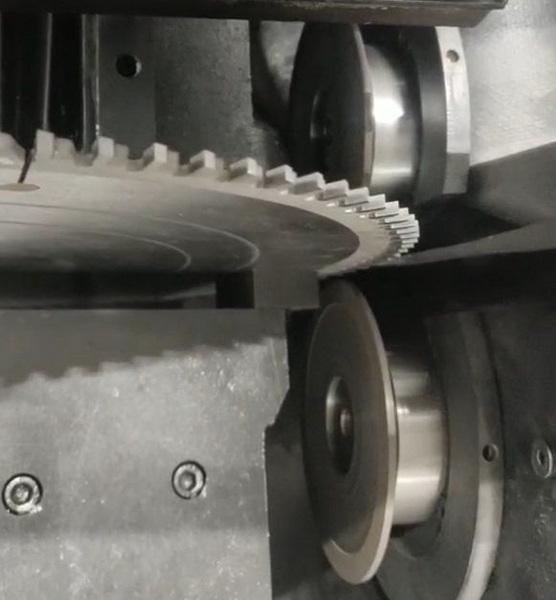

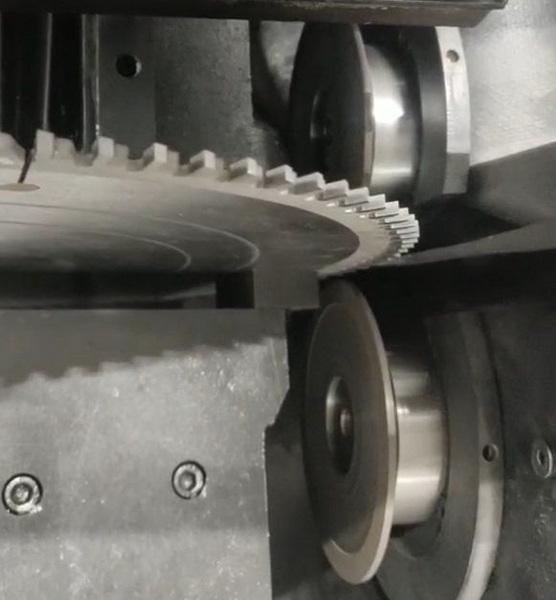

Automotive Industry

The automotive industry benefits from carbide products in the production of engine components, gearboxes, and other critical parts. Carbide tools enable precise machining, ensuring high-quality finishes and dimensional accuracy.

Construction and Mining

In construction and mining, carbide products are used in drilling and excavation tools. Their hardness allows for efficient cutting through hard materials like rock and concrete, improving project timelines and reducing equipment wear.

Conclusion

Carbide products offer a wide range of benefits in industrial applications, from enhanced productivity and efficiency to cost savings and improved product quality. Their versatility and adaptability make them a crucial component in various sectors, including manufacturing, aerospace, automotive, and construction. As technology continues to advance, the role of carbide products is likely to expand further, driving innovation and performance improvements in industrial processes.

Frequently Asked Questions

1. What are the primary materials used to make carbide products?

Carbide products are primarily made from materials like tungsten carbide and silicon carbide, which are known for their high hardness and durability.

2. How do carbide inserts improve manufacturing processes?

Carbide inserts improve manufacturing processes by providing superior hardness, wear resistance, and high heat tolerance, leading to improved surface finish, reduced cycle times, and extended tool life.

3. What are the advantages of using carbide plates in industrial applications?

Carbide plates offer outstanding wear resistance, high-temperature stability, and precision, making them ideal for cutting tools and molds. They reduce maintenance costs and enhance product quality.

4. In which industries are carbide strips commonly used?

Carbide strips are commonly used in metalworking, woodworking, mining, aerospace, and medical applications due to their hardness and precision.

5. What are the benefits of using carbide balls in industrial bearings?

Carbide balls provide high hardness, wear resistance, and thermal stability, making them ideal for use in industrial bearings where they can withstand high speeds and loads without deforming.

Citations:

[1] https://www.estoolcarbide.com/article/how-do-different-industries-benefit-from-the-use-of-carbide-inserts-in-their-applications--newsinfo-47.html

[2] https://quickgrind.com/the-benefits-of-investing-in-solid-carbide-tooling/

[3] https://nanografi.com/blog/carbides-from-atomic-structure-to-industrial-applications-nanografi-/

[4] https://www.alamy.com/stock-photo/carbide-end-mill.html

[5] https://www.alamy.com/stock-photo/carbide-insert.html

[6] https://www.alamy.com/stock-photo/carbide-inserts.html

[7] https://www.zhongbocarbide.com/what-are-the-key-benefits-of-using-carbide-plates-in-industrial-applications.html

[8] https://carbideprovider.com/7-advantages-of-carbide-inserts/

[9] https://www.scmtstool.com/blog/What-Are-the-Industrial-Applications-of_bid-316545588.html

[10] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[11] https://www.applecarbide.com/article/the-advantages-of-using-carbide-balls-in-industrial-applications.html

[12] https://toolholderexchange.com/main-benefits-carbide-tools/

[13] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[14] https://www.istockphoto.com/photos/carbide-tools

[15] https://www.shutterstock.com/search/carbide-insert

[16] https://www.shutterstock.com/search/carbide-tools

[17] https://www.shutterstock.com/search/carbide-cutting-tools

[18] https://www.shutterstock.com/search/tungsten-carbide

[19] https://stock.adobe.com/search?k=carbide

[20] https://www.hpmt-industries.com/maximizing-efficiency-and-precision-the-advantages-of-solid-carbide-tools-in-manufacturing