Content Menu

● Introduction to Super Fine Silicon Carbide Powder

● Industrial Applications of Super Fine Silicon Carbide Powder

>> Abrasives and Grinding Tools

>> High-Temperature Refractories and Kiln Materials

>> Electronics and Semiconductor Industry

>> Aerospace and Defense Applications

>> Mining and Industrial Machinery

>> Coatings and Composite Materials

● Manufacturing Process of Super Fine Silicon Carbide Powder

● Environmental Impact and Sustainability

● Future Trends and Innovations

● Additional Industrial Applications

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What industries benefit most from super fine silicon carbide powder?

>> 2. How does particle size affect the performance of silicon carbide powder?

>> 3. What is the difference between black and green silicon carbide powders?

>> 4. Can super fine silicon carbide powder be used in 3D printing?

>> 5. What makes super fine silicon carbide powder suitable for ballistic armor?

Silicon carbide (SiC) is a remarkable material known for its exceptional hardness, thermal stability, and chemical resistance. When processed into super fine powder form, silicon carbide unlocks even more advanced properties, making it indispensable in a wide array of industrial, military, and high-tech applications. This article explores the diverse uses of super fine silicon carbide powder products, highlighting their roles in abrasives, ceramics, electronics, metallurgy, defense, and more.

Introduction to Super Fine Silicon Carbide Powder

Super fine silicon carbide powder consists of ultra-small SiC particles, typically below 1 micron in size, with some grades reaching nanometer scales. This ultra-fine particle size increases surface area and reactivity, improving sintering behavior and enabling the production of high-performance ceramics and composites. The powder is manufactured using advanced methods such as carbothermal reduction, chemical vapor deposition, and plasma synthesis to ensure high purity and precise particle size distribution.

Industrial Applications of Super Fine Silicon Carbide Powder

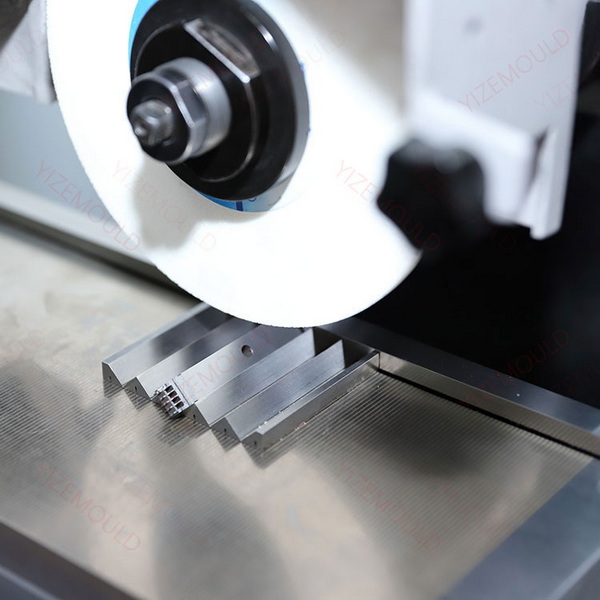

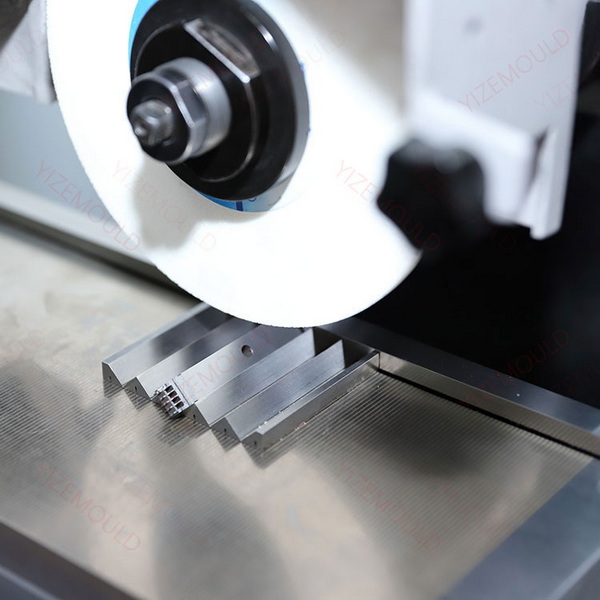

Abrasives and Grinding Tools

Due to its Mohs hardness of 9.5, second only to diamond, super fine silicon carbide powder is widely used in abrasive machining. It is a critical component in grinding wheels, sandpapers, lapping compounds, and polishing materials. The sharp-edged particles efficiently remove material from metals, ceramics, and composites, enabling precision finishing and surface smoothing.

- Grinding and Polishing: Super fine SiC powders are used in lapping and polishing semiconductor wafers, optical glass, and precision mechanical parts, delivering smooth, defect-free surfaces.

- Sandblasting: The powder is employed to remove rust, coatings, and contaminants from metal surfaces more effectively than alternatives like aluminum oxide.

- Cutting Tools: SiC's hardness makes it ideal for cutting tools that can withstand high wear rates and maintain sharpness over time.

High-Temperature Refractories and Kiln Materials

Super fine silicon carbide powder exhibits excellent thermal conductivity and resistance to thermal shock, making it suitable for refractory applications. It is used in kiln shelves, furnace linings, crucibles, and other components exposed to high temperatures up to 1600°C.

- Kiln Shelves and Furnace Linings: SiC kiln shelves are lighter and more durable than traditional alumina shelves, providing even heat distribution and resistance to cracking during thermal cycling.

- Metallurgical Applications: SiC powder acts as a deoxidizer in steel production, replacing ferrosilicon to improve steel purity and mechanical properties while lowering production costs.

Electronics and Semiconductor Industry

Super fine silicon carbide powder is a foundational material in the production of high-purity SiC substrates and epitaxial layers used in advanced electronic devices.

- Power Electronics: SiC-based semiconductors enable devices to operate at higher voltages and temperatures with reduced energy loss, critical for electric vehicles, renewable energy systems, and smart grids.

- LED Manufacturing: SiC substrates improve the performance and longevity of light-emitting diodes and other optoelectronic devices.

- High-Temperature and High-Power Devices: The powder's purity and particle size control are essential for fabricating components that perform reliably under extreme conditions.

Aerospace and Defense Applications

The lightweight nature, high hardness, and thermal shock resistance of super fine silicon carbide powder make it invaluable in aerospace and military sectors.

- Ballistic Armor: SiC ceramic plates made from super fine powder are used in body armor and vehicle armor systems, providing superior protection against bullets, shrapnel, and armor-piercing rounds while maintaining mobility due to their low weight.

- Aerospace Components: SiC composites are used in rocket nozzles, turbine blades, and radiation shielding materials, where durability under extreme thermal and mechanical stress is critical.

- Military Equipment: SiC's chemical resistance adds protection against chemical agents, enhancing the safety of personnel and equipment.

Mining and Industrial Machinery

Silicon carbide bushings and wear-resistant components made from super fine SiC powder extend the service life of mining equipment and industrial machinery.

- Mining Equipment: SiC bushings resist abrasion and corrosion in harsh mining environments, increasing durability by more than ten times compared to conventional steel parts.

- Pipeline Protection: SiC components protect pipelines transporting abrasive materials like ore concentrates, reducing maintenance costs and downtime.

Coatings and Composite Materials

Super fine silicon carbide powder is used to formulate protective coatings that enhance abrasion resistance, corrosion resistance, and thermal stability.

- Industrial Coatings: These coatings extend the service life of automotive, aerospace, and industrial equipment exposed to harsh environments.

- Nano-Composites: The ultra-fine particle size allows precise control over microstructure and mechanical properties, enabling the development of advanced composite materials with superior performance.

Manufacturing Process of Super Fine Silicon Carbide Powder

The production of super fine silicon carbide powder involves several advanced techniques to ensure high purity and precise particle size control. The most common methods include:

- Carbothermal Reduction: This traditional method heats silica and carbon at extremely high temperatures in an electric furnace, causing a chemical reaction that forms silicon carbide crystals. The process requires precise temperature control and atmosphere management to achieve the desired purity and particle size.

- Chemical Vapor Deposition (CVD): CVD produces SiC powders by depositing silicon and carbon atoms onto substrates in a controlled gaseous environment. This method yields powders with uniform particle size and very high purity, suitable for electronic and optical applications.

- Plasma Synthesis: Utilizing high-energy plasma torches, raw materials are vaporized and then rapidly cooled to form ultra-fine SiC particles. This technique allows for the creation of nano-sized powders with controlled morphology and minimal impurities.

Each method offers distinct advantages depending on the intended application, balancing factors such as cost, purity, and particle size distribution.

Environmental Impact and Sustainability

While the production of super fine silicon carbide powder is energy-intensive, primarily due to the high temperatures required in electric furnaces, efforts are underway to minimize environmental impacts:

- Energy Efficiency: Advances in furnace design and process optimization have significantly reduced energy consumption per unit of SiC produced.

- Recycling: Silicon carbide materials, especially from spent abrasives and ceramic components, can be recycled and reprocessed, reducing raw material demand and waste.

- Longevity of Products: The durability of SiC-based products means longer service life and fewer replacements, which contributes to sustainability by lowering resource consumption and waste generation.

Moreover, the use of SiC in energy-efficient electronics, such as power devices for electric vehicles and renewable energy systems, indirectly supports global carbon reduction goals by improving energy efficiency.

Future Trends and Innovations

The field of super fine silicon carbide powder products is rapidly evolving, driven by technological advancements and emerging market demands:

- Nano-Sized Powders: Research focuses on producing SiC powders at the nanoscale to further enhance mechanical strength, thermal conductivity, and chemical reactivity, enabling breakthroughs in composite materials and coatings.

- Hybrid Nanocomposites: Combining SiC powders with other nanomaterials like graphene and carbon nanotubes is opening new possibilities for multifunctional materials with superior electrical, thermal, and mechanical properties.

- Quantum Computing and Advanced Electronics: SiC's unique electronic properties are being explored for quantum bits (qubits) and other cutting-edge electronic devices that require stable, high-performance materials.

- Energy Storage: SiC powders are being integrated into battery and supercapacitor electrodes to improve charge rates, capacity, and thermal stability.

- Expansion in Electric Vehicles (EVs): The growing EV market is driving demand for SiC-based power electronics that enable faster charging, higher efficiency, and better thermal management.

These innovations promise to expand the applications and performance of super fine silicon carbide powder products well into the future.

Additional Industrial Applications

Beyond traditional sectors, super fine silicon carbide powder is increasingly used in innovative fields:

- Water Treatment: SiC's chemical inertness and hardness make it ideal for filtration membranes that resist fouling and corrosion in harsh chemical environments.

- Biomedical Devices: Due to its biocompatibility and mechanical strength, SiC powder is being researched for use in implants, prosthetics, and dental materials, offering durable and safe alternatives to conventional biomaterials.

- Environmental Protection: SiC coatings protect equipment exposed to aggressive chemicals and extreme conditions, reducing maintenance and extending operational life in industries such as chemical processing and waste management.

Conclusion

Super fine silicon carbide powder products are a cornerstone of modern industrial technology. Their unique combination of extreme hardness, thermal resistance, chemical stability, and lightweight properties enables their use across a vast range of applications—from precision abrasives and high-performance ceramics to advanced electronics and military-grade armor. As manufacturing techniques continue to evolve, and industries demand materials that can perform under increasingly harsh conditions, super fine silicon carbide powder will remain a vital material driving innovation and efficiency worldwide.

Frequently Asked Questions (FAQs)

1. What industries benefit most from super fine silicon carbide powder?

Super fine silicon carbide powder is extensively used in industries such as abrasives manufacturing, electronics and semiconductors, aerospace, defense, metallurgy, and mining due to its hardness, purity, and thermal stability.

2. How does particle size affect the performance of silicon carbide powder?

Smaller particle sizes increase surface area and reactivity, improving sintering behavior and enabling the production of denser, more uniform ceramics and coatings. This results in better mechanical and thermal properties in the final products.

3. What is the difference between black and green silicon carbide powders?

Green silicon carbide is purer (around 99%) and is preferred for high-precision applications like semiconductor wafer polishing and electronics. Black silicon carbide (97–98% purity) is commonly used for general abrasive applications such as grinding cast iron and non-ferrous metals.

4. Can super fine silicon carbide powder be used in 3D printing?

Yes, super fine SiC powders are increasingly used in advanced 3D printing and additive manufacturing processes to create ceramic and composite components with complex geometries and superior properties.

5. What makes super fine silicon carbide powder suitable for ballistic armor?

Its extreme hardness, high strength, and lightweight nature allow SiC ceramic plates to effectively absorb and dissipate kinetic energy from bullets and shrapnel, providing superior protection while maintaining wearer mobility.