Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Applications of Tungsten Carbide

>> 1. Construction and Mining

>> 2. Cutting Tools

>> 3. Aerospace and Aviation

>> 4. Medical Instruments

>> 5. Jewelry

>> 6. Ammunition

>> 7. Electronics

>> 8. Sports Equipment

>> 9. Musical Instruments

>> 10. Ballpoint Pens

>> 11. Abrasive Materials

>> 12. Nuclear Applications

>> 13. Automotive Industry

>> 14. Oil and Gas

>> 15. Recycling and Waste Management

● Challenges and Future Developments

>> Advancements in Manufacturing Techniques

>> Environmental Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is Tungsten Carbide Used For?

>> 2. How is Tungsten Carbide Made?

>> 3. What are the Properties of Tungsten Carbide?

>> 4. Is Tungsten Carbide Used in Aerospace?

>> 5. Can Tungsten Carbide be Used in Jewelry?

● Citations:

Tungsten carbide is a highly versatile and durable material that has found its way into numerous applications across various industries. Its exceptional hardness, wear resistance, and thermal properties make it an ideal choice for manufacturing components that require high strength and longevity. In this article, we will explore the diverse uses of tungsten carbide and highlight some of the products that are sometimes made from this remarkable material.

Introduction to Tungsten Carbide

Tungsten carbide is a chemical compound formed by combining tungsten and carbon atoms. It is commonly used in the form of cemented carbide, where tungsten carbide particles are bound together with a metallic binder, typically cobalt or nickel. This composite material offers a unique combination of hardness and toughness, making it suitable for applications where both properties are crucial.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide is one of the hardest substances known, with a hardness that is second only to diamonds. This property makes it ideal for cutting tools and wear parts.

- Wear Resistance: Its high wear resistance ensures that components made from tungsten carbide have a long service life, even in harsh environments.

- Thermal Properties: Tungsten carbide has a high melting point and excellent thermal conductivity, which allows it to maintain its structural integrity under extreme temperatures.

Applications of Tungsten Carbide

Tungsten carbide is used in a wide range of industries due to its exceptional properties. Here are some of the key applications:

1. Construction and Mining

Tungsten carbide is commonly used in construction and mining for tools such as drill bits and saw blades. Its durability and ability to withstand high wear make it ideal for cutting through hard materials like cement and rock.

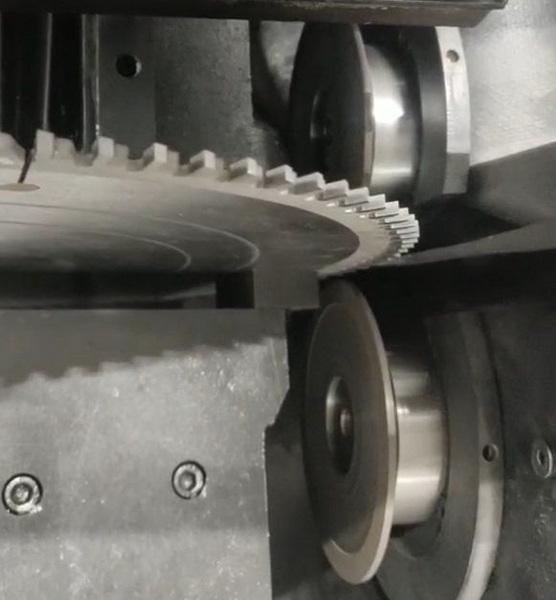

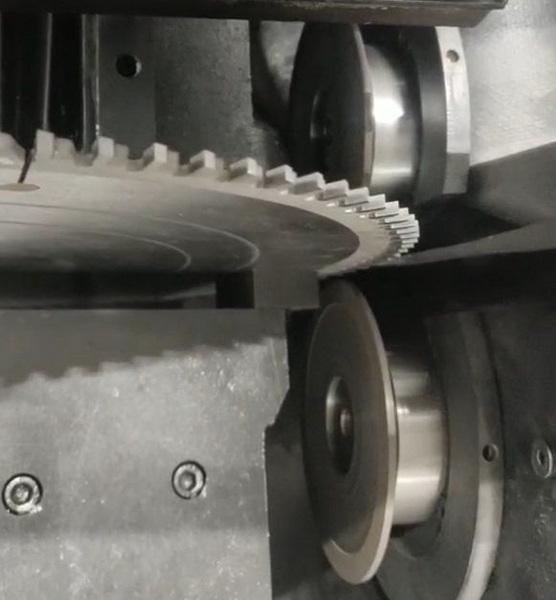

2. Cutting Tools

In the manufacturing sector, tungsten carbide is widely used for cutting tools such as milling cutters, drills, and saw blades. These tools are capable of machining tough materials like steel and titanium efficiently.

3. Aerospace and Aviation

The aerospace industry utilizes tungsten carbide coatings to protect critical engine components from wear and erosion. Its ability to maintain strength under extreme conditions makes it ideal for applications in turbines and landing gear.

4. Medical Instruments

Tungsten carbide is used in surgical instruments due to its high strength and durability. It is often used in dental drills and other precision medical tools.

5. Jewelry

In the jewelry industry, tungsten carbide is valued for its extreme hardness and resistance to scratching, making it a popular choice for wedding bands.

6. Ammunition

Tungsten carbide is used in armor-piercing ammunition due to its high density and hardness, which allow it to penetrate armor effectively.

7. Electronics

In the electronics industry, tungsten carbide is used for its thermal properties and durability in components such as electrodes and contacts.

8. Sports Equipment

Tungsten carbide is sometimes used in sports equipment, such as golf clubs, due to its strength and durability.

9. Musical Instruments

It is also used in musical instruments, like guitar slides, for its sustain and volume.

10. Ballpoint Pens

The tips of ballpoint pens often contain tungsten carbide for its durability and ability to maintain a precise point.

11. Abrasive Materials

Tungsten carbide is used in abrasive materials like grinding wheels and sandpaper due to its hardness, which allows it to effectively grind and polish hard surfaces.

12. Nuclear Applications

In nuclear reactors, tungsten carbide is considered for its potential use as a neutron absorber due to its high density and ability to absorb neutrons effectively.

13. Automotive Industry

Tungsten carbide is used in the automotive sector for wear parts and components that require high durability, such as engine components and brake pads.

14. Oil and Gas

In the oil and gas industry, tungsten carbide is used for drilling tools and wear components due to its ability to withstand high pressures and abrasive environments.

15. Recycling and Waste Management

Tungsten carbide is also used in recycling equipment for its durability in handling abrasive materials.

Challenges and Future Developments

Despite its many advantages, tungsten carbide faces challenges such as brittleness and the need for advanced manufacturing techniques to produce complex shapes. Research is ongoing to improve its toughness and develop new applications, such as in advanced composites and nanomaterials.

Advancements in Manufacturing Techniques

Advancements in 3D printing and sintering technologies are enabling the production of complex tungsten carbide components with improved properties. These techniques allow for the creation of customized parts with enhanced strength and durability.

Environmental Considerations

The extraction and processing of tungsten can have environmental impacts, such as pollution and habitat destruction. Efforts are being made to improve sustainability in tungsten mining and recycling tungsten carbide products.

Conclusion

Tungsten carbide is a versatile material that has found applications across multiple industries due to its exceptional hardness, wear resistance, and thermal properties. From cutting tools and construction equipment to medical instruments and jewelry, tungsten carbide plays a crucial role in enhancing the performance and longevity of various products.

Frequently Asked Questions

1. What is Tungsten Carbide Used For?

Tungsten carbide is used in a variety of applications, including cutting tools, construction equipment, medical instruments, jewelry, and ammunition. Its hardness and wear resistance make it ideal for high-impact environments.

2. How is Tungsten Carbide Made?

Tungsten carbide is typically made by sintering tungsten carbide particles with a metallic binder, such as cobalt or nickel. This process creates a composite material that combines the hardness of tungsten carbide with the toughness of the binder.

3. What are the Properties of Tungsten Carbide?

Tungsten carbide is known for its exceptional hardness, wear resistance, and thermal properties. It has a high melting point and excellent thermal conductivity, making it suitable for applications under extreme temperatures.

4. Is Tungsten Carbide Used in Aerospace?

Yes, tungsten carbide is used in the aerospace industry for coating critical engine components to protect them from wear and erosion. Its ability to maintain strength under extreme conditions makes it ideal for aerospace applications.

5. Can Tungsten Carbide be Used in Jewelry?

Yes, tungsten carbide is often used in jewelry, particularly in wedding bands, due to its extreme hardness and resistance to scratching. However, it can be brittle and may shatter under impact.

Citations:

[1] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[2] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[3] https://grafhartmetall.com/en/high-precision-parts-made-of-tungsten-carbide/

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[6] https://www.ipsceramics.com/tungsten-carbide-metals-and-ceramics-working-as-one/

[7] https://www.itia.info/applications-markets/

[8] https://www.durit.com/industries

[9] https://www.alamy.com/stock-photo/tungsten-carbide.html

[10] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[11] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[12] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/tungsten-carbide-grades-applications

[13] https://www.azom.com/article.aspx?ArticleID=1203

[14] https://shop.nanografi.com/blog/tungsten-discovery-types-products-applications/

[15] https://carbide-usa.com/spotting-tungsten-carbide-household-products/

[16] https://www.tungstenmetalsgroup.com/blog-blog/tungsten-metals-unique-history-modern-applications

[17] https://www.dymetalloys.co.uk/tungsten-carbide-products

[18] https://htscoatings.com/blogs/our-craft-our-culture/three-tungsten-carbide-thermal-spray-coatings-and-their-uses

[19] https://www.sciencing.com/info-8363311-things-made-out-tungsten/

[20] https://www.britannica.com/science/tungsten-carbide

[21] https://upload.wikimedia.org/wikipedia/commons/7/72/Tungsten_carbide_inserts.jpg?sa=X&ved=2ahUKEwjFz5ee18iMAxUFK7kGHWJ6I7EQ_B16BAgEEAI

[22] https://www.festool.com.au/150-mm-coarse-tungstencarbide-tool-head-778602.html

[23] https://stock.adobe.com/search?k=carbide

[24] https://www.gettyimages.com.au/photos/tungsten-carbide?page=3

[25] https://eshop.wurth.com.au/Product-categories/Tungsten-carbide-bur-with-MX-teeth/31027503020191.cyid/3102.cgid/en/GB/AUD/

[26] https://periodictable.com/Elements/074/pictures.html

[27] https://stock.adobe.com/search?k=tungsten+carbide

[28] https://rrcarbide.com/understanding-tungsten-carbide-composition-uses-and-expertise/

[29] https://www.istockphoto.com/photos/tungsten-carbide

[30] https://supraindustries.com/uses-of-tungsten-carbide-burrs/

[31] https://www.gettyimages.com.au/photos/tungsten-carbide

[32] https://www.shutterstock.com/search/tungsten-carbide

[33] https://www.bangerter.com/en/tungsten-carbide

[34] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[35] https://create.vista.com/photos/tungsten-carbide/