Content Menu

● Introduction

● Carbide Round Moulds: Core Concepts and Value Proposition

● Manufacturing Landscape in Spain

● Key Capabilities from Leading Spanish Suppliers

● Process Overview: From Raw Materials to Finished Moulds

>> 1. Material Selection and Blending

>> 2. Powder Preparation and Preforming

>> 3. Shaping and Forming

>> 4. Sintering and Bonding

>> 5. Grinding, Lapping, and Finishing

>> 6. Quality Assurance and Testing

>> 7. Packaging, Labeling, and Shipping

>> 8. After-Sales Support

● Market Trends and Competitive Positioning

● Selecting the Right Carbide Round Moulds Manufacturer or Supplier in Spain

● Case Studies: Real-World Applications and Outcomes

● Sourcing and Collaboration Options

● Quality Assurance: Ensuring Consistency Across Batches

● Sustainability and Corporate Social Responsibility

● Conclusion

● FAQ

>> 1. What differentiates Spanish carbide round moulds manufacturers and suppliers from others in Europe?

>> 2. Are there Spanish suppliers offering rapid prototyping for carbide round moulds?

>> 3. How can a buyer verify the quality of a carbide round mould before purchase?

>> 4. What factors influence the lead time for carbide round moulds?

>> 5. How should an international buyer initiate contact with Spanish carbide round moulds manufacturers and suppliers?

Introduction

Spain has emerged as a notable hub for carbide round moulds, drawing on deep metallurgical expertise, precision tooling culture, and a robust network of European suppliers. The landscape features specialized manufacturers who consistently deliver high-hardness, wear-resistant moulds suitable for demanding applications in automotive, aerospace, packaging, and heavy industry. This article provides an in-depth guide to the leading carbide round moulds manufacturers and suppliers in Spain, emphasizing capabilities, production processes, quality systems, and collaboration models that align with global OEM and contract manufacturing needs. For buyers seeking reliable partners for custom designs, volume production, or OEM/ODM services, Spain's carbide round moulds ecosystem offers a compelling mix of technical proficiency, scalable capacity, and strong export readiness. The focus remains on the keyword Carbine Round Moulds Manufacturers and Suppliers to ensure relevance for international buyers and industry professionals.

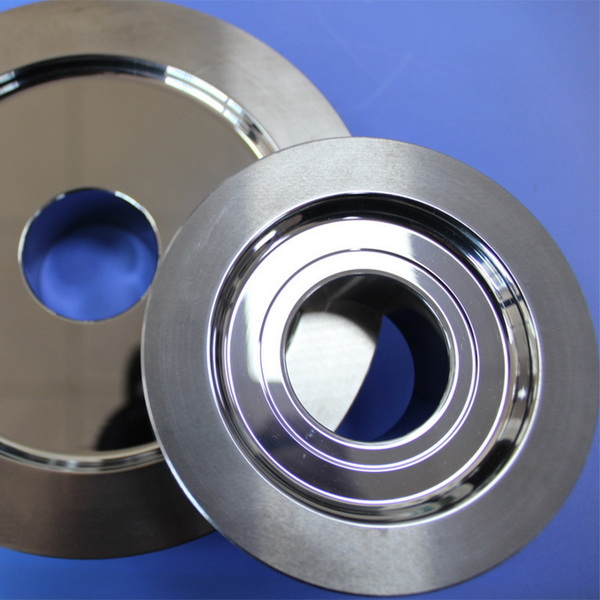

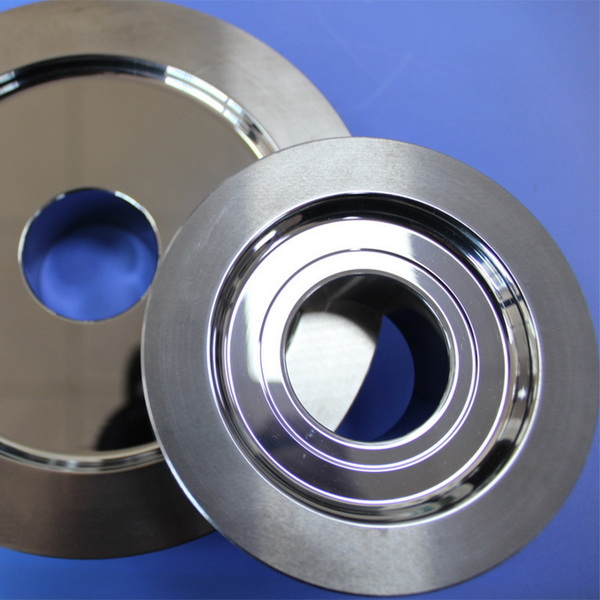

Carbide Round Moulds: Core Concepts and Value Proposition

Carbide round moulds are critical components in forming or shaping processes used across metalworking, plastics, and composite industries. Cemented carbide, typically tungsten carbide bound with cobalt, delivers superior hardness, wear resistance, and thermal stability compared with conventional steel or tool alloys. The result is longer tool life, tighter tolerances, and the ability to sustain high production speeds and energy efficiency. For manufacturers and suppliers, the value proposition centers on reproducible performance, predictable lifecycle costs, and compatibility with high-volume production lines. In Spain, reputable carbide round moulds manufacturers and suppliers combine this material science with advanced manufacturing techniques, including CAD/CAM-driven design, precision grinding, and rigorous QA testing, to meet exacting OEM requirements and international quality standards. The emphasis on precision, reliability, and scalability makes Spanish providers attractive to brands and contract manufacturers around the world.

Manufacturing Landscape in Spain

Spain's carbide round moulds sector is characterized by a blend of established traditional workshops and modern, automation-forward facilities. Companies often maintain ISO-based quality systems, enabling consistent part quality, traceability, and compliance with European environmental and safety standards. The supply ecosystem includes material suppliers, toolmakers, and mould shops that collaborate across the product lifecycle—from concept and prototyping to series production and after-sales service. The regional distribution network supports both local OEMs and global brands seeking European-based manufacturing partners with competitive lead times, short logistics routes, and strong after-sales technical support. This integrated approach helps carbide round moulds manufacturers and suppliers in Spain sustain a reputation for precision, reliability, and adaptability in diverse market segments.

Key Capabilities from Leading Spanish Suppliers

- Advanced material sourcing and metallurgy expertise for cemented carbide blends

- CAD/CAM-enabled design services and rapid prototyping

- Precision grinding, lapping, and finishing for tight tolerances

- High-volume production capabilities with robust process controls

- In-house heat treatment and sintering with controlled atmosphere technologies

- Rigorous quality assurance, hardness testing, and dimensional inspection

- Customization for bespoke shapes, bore patterns, and surface finishes

- Global logistics, multilingual support, and compliant export practices

- Sustainability initiatives, including waste reduction and energy-efficient operations

Process Overview: From Raw Materials to Finished Moulds

The typical lifecycle in Spanish carbide round moulds production follows a disciplined sequence designed to optimize performance and reliability:

1. Material Selection and Blending

- High-purity tungsten carbide powders are selected, often combined with cobalt binders to achieve the desired toughness and fracture resistance.

- Supplier selection emphasizes particle size distribution control and contaminant management to ensure consistent sinterability and mechanical properties.

2. Powder Preparation and Preforming

- Powder is mixed with binding agents and prepared for forming. Depending on the part geometry and size, forming can involve isostatic pressing, compact extrusion, or precision die pressing.

- Isostatic pressing is particularly effective for large or complex round mould profiles, delivering uniform density and dimensional stability.

3. Shaping and Forming

- Moulds are formed using methods such as die pressing, extrusion, or isostatic pressing, chosen to optimize material usage, cycle time, and part accuracy.

- Advanced forming technologies enable complex round geometries with tight tolerances and minimal post-forms.

4. Sintering and Bonding

- Sintering bonds carbide grains into a solid, dense structure. Controlled atmospheres, temperatures, and dwell times are essential to avoid porosity and crack formation.

- Post-sintering heat treatments may be employed to tailor hardness, fracture toughness, and residual stress.

5. Grinding, Lapping, and Finishing

- Precision grinding and lapping refine diameters, faces, and internal features. Surface finishing reduces micro-roughness and improves seating and sealing performance in assemblies.

- Tight tolerances (often in the micron range) demand robust metrology and process control.

6. Quality Assurance and Testing

- Dimensional verification, hardness testing, microstructural analysis, and non-destructive testing form the QA backbone.

- Traceability is maintained from raw material lots through to final inspection, ensuring compliance with customer specifications and international standards.

7. Packaging, Labeling, and Shipping

- Protective packaging and clear labeling ensure mould integrity during transit. Logistics planning emphasizes on-time delivery and secure handover to global carriers.

8. After-Sales Support

- Technical assistance, replacement parts, and on-site support for tool qualification and process optimization are common services offered by reputable suppliers.

Market Trends and Competitive Positioning

Spain's carbide round moulds sector benefits from strong engineering traditions, proximity to European markets, and a growing emphasis on sustainability. Key trends include:

- Increasing demand for custom moulds with rapid prototyping capabilities to support bespoke manufacturing needs.

- Adoption of automation and digitalization to improve consistency, throughput, and traceability.

- Growing emphasis on green manufacturing practices, including recycling of carbide scrap and energy-efficient heat-treatment processes.

- Expanding export activity to regions with high demand for precision tooling, leveraging Spain's reputation for reliability and quality control.

Selecting the Right Carbide Round Moulds Manufacturer or Supplier in Spain

A structured evaluation framework helps buyers identify the best partner for specific applications and programs:

- Technical competence: Confirm CAD/CAM capabilities, ability to produce complex round moulds, and proven performance data.

- Quality and compliance: Look for ISO certifications, documented QA procedures, and traceability systems.

- Capacity and lead times: Assess production capacity, tooling readiness, and historical on-time delivery performance.

- Support structure: Ensure accessible technical support, clear communication channels, and responsiveness for design changes.

- Global reach: Verify export experience, multilingual customer service, and logistics reliability.

- Sustainability: Preference for suppliers with waste minimization, energy efficiency, and recycling programs.

Case Studies: Real-World Applications and Outcomes

- Automotive stamping and forming: Car manufacturers rely on durable carbide round moulds to sustain high-volume cycles with tight tolerances in body panels, trim components, and precision inserts.

- Packaging and sealing components: Moulds designed for forming sealed packaging parts must maintain dimensional accuracy under repeated thermal cycling.

- Aerospace components: Precision moulds used in composite layup tooling or metallic form parts require high wear resistance and stable geometry under demanding manufacturing conditions.

Sourcing and Collaboration Options

Buyers can engage with Spanish carbide round moulds manufacturers and suppliers through several models:

- Direct OEM partnerships: Full customization, process development, and long-term supply arrangements with dedicated engineering support.

- ODM/OBM collaborations: Manufacturers provide design and manufacturing services under a customer's brand or specification.

- Silent production and contract manufacturing: Suppliers deliver finished moulds under third-party brands with defined quality criteria.

- Regional distribution and service centers: Local partners provide faster logistics, after-sales training, and maintenance support.

Quality Assurance: Ensuring Consistency Across Batches

Reputable Spanish suppliers implement rigorous QA regimes, including:

- Pre-production sampling and first-article inspection.

- Regular hardness testing and microstructure verification.

- Dimensional metrology with calibrated gauging and coordinate measuring equipment.

- Statistical process control (SPC) and continuous improvement frameworks.

Sustainability and Corporate Social Responsibility

Many carbide round moulds manufacturers in Spain are aligning with broader European sustainability initiatives. This includes reduced energy footprints in sintering furnaces, efficient waste management for carbide scrap, and investments in cleaner production technologies. Customers increasingly favor suppliers that demonstrate transparent environmental policies and measurable improvements over time.

Conclusion

The market for Carbide Round Moulds Manufacturers and Suppliers in Spain remains robust, underpinned by technical prowess, precision engineering, and a clear orientation toward meeting global OEM demands. By focusing on material quality, adaptable design, consistent process control, and strong after-sales support, Spanish suppliers offer compelling advantages for brands and contract manufacturers seeking reliable, high-performance moulds. The best partnerships emerge from a careful assessment of technical capability, quality assurance, production capacity, and international logistics readiness, ensuring that the selected supplier can deliver the right moulds on time and to specification.

FAQ

1. What differentiates Spanish carbide round moulds manufacturers and suppliers from others in Europe?

Spanish providers combine deep metallurgical knowledge with efficient, automation-driven processes, and strong export capabilities, delivering reliable lead times and consistent quality. These factors, alongside adherence to multinational quality standards, position Spain as a competitive source for carbide round moulds.

2. Are there Spanish suppliers offering rapid prototyping for carbide round moulds?

Yes, several Spanish firms provide rapid CAD/CAM design, quick tooling iterations, and pilot runs to accelerate development cycles before committing to full production.

3. How can a buyer verify the quality of a carbide round mould before purchase?

Request demonstrated QA data, first-article inspection results, hardness test reports, and, if possible, a recent production run sample to verify tolerances and surface finish.

4. What factors influence the lead time for carbide round moulds?

Lead time depends on design complexity, batch size, material availability, and current factory capacity. Efficient suppliers also have streamlined logistics and ready-to-ship stock for common diameters.

5. How should an international buyer initiate contact with Spanish carbide round moulds manufacturers and suppliers?

Reach out via official company websites or regional distributors, provide a detailed technical brief, required tolerances, material standards, and desired delivery timelines to receive a tailored quote.