Content Menu

● Introduction

● Russia's Industrial Edge in Carbide Round Mould Manufacturing

● The Science and Technology Behind Carbide Round Moulds

>> Material Composition and Structure

● Production Process: A Technical Overview

>> 1. Powder Selection and Mixing

>> 2. Shaping (Forming the Green Body)

>> 3. Sintering

>> 4. Machining and Finishing

>> 5. Inspection and Quality Control

● Modern Trends and Technological Innovations

● Key Applications Across Industries

● Best Practices in Sourcing Russian Carbide Round Mould Manufacturers and Suppliers

● Leading Russian Carbide Round Moulds Manufacturers and Suppliers

>> KMIZ (Kazan Medical Instruments)

>> Pumori Corporation

>> BETAR

>> Tomsky Instrument and KZTS

● Insights for Overseas OEM/ODM Buyers

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of tungsten carbide in round mould production?

>> 2. Are Russian manufacturers able to deliver fully customized carbide round moulds?

>> 3. How can I assess a Russian supplier's quality and reliability?

>> 4. Which industries benefit most from Russian carbide round moulds?

>> 5. What support do top suppliers offer after delivery?

Introduction

In today's globalized manufacturing landscape, the selection of reliable Carbide Round Moulds Manufacturers and Suppliers is pivotal for international brands, OEMs, and wholesalers. Carbide round moulds, composed primarily of tungsten carbide alloys, serve as essential tools for forming, shaping, and punching metals and composites under extreme conditions. Quality, precision, and consistent supply matter most in high-volume industries. Russia, as a rising center of metallurgical innovation and large-scale manufacturing, has become an increasingly attractive region for sourcing carbide round moulds, thanks to competitive pricing, advanced production technology, stringent quality standards, and comprehensive OEM services.

This article provides an exhaustive exploration of the leading Carbide Round Moulds Manufacturers and Suppliers in Russia. It explains their capabilities, the technical process behind high-end mould production, business advantages, relevant applications, recent industry trends, and detailed guidance for international buyers seeking to build sustainable, long-term supplier relationships.

Russia's Industrial Edge in Carbide Round Mould Manufacturing

Carbide round moulds are critical to sectors including automotive, aerospace, electronics, defense, and medical devices. The Russian manufacturing sector benefits from:

- Access to high-quality raw materials for producing robust, long-wearing moulds.

- Extensive investment in modern machinery, process automation, and quality inspection.

- A legacy of metallurgical research and training via specialist institutions.

- Active support for international business, including translation, export compliance, and global logistics.

Key Russian manufacturers have implemented lean production practices and robust R&D programs, resulting in both cost efficiency and technical innovation for international clients. Many maintain ISO 9001 compliance, ensuring all moulds are produced under systematically controlled conditions, which is especially important for foreign brands and OEM project managers.

The Science and Technology Behind Carbide Round Moulds

Material Composition and Structure

Carbide round moulds consist mainly of tungsten carbide (WC) particles, bonded by cobalt or nickel metals. The tungsten carbide grains provide extreme hardness and compressive strength, while the binder metal lends toughness and fracture resistance. Understanding the chemistry of these alloys is key: the WC grain size, binder ratio, and additional alloying elements are selected based on the mould's application—fine-grained alloys for precision dies and coarse-grained ones for heavy-duty wear.

Advanced manufacturers apply unique powder formulations and control the sintering process to optimize the mould's microstructure, improving thermal stability and resisting deformation or chipping under load. Customized blends address industry-specific requirements such as corrosion resistance, electrical conductivity, or high-impact performance.

Production Process: A Technical Overview

Creating reliable, long-lasting carbide round moulds involves meticulous steps from powder preparation to finishing. The main stages typically include:

1. Powder Selection and Mixing

Production starts with the selection of tungsten powder—derived from tungsten ore—and carbon sources. These are subjected to carburization at high temperatures (often 1400–2000°C), producing fine tungsten carbide. The resulting WC is blended with a metal binder such as cobalt in ball mills to achieve uniform particle size and distribution.

Additives like waxes or polymers are sometimes integrated to improve the powder's handling and “green strength”—the ability to retain shape before sintering.

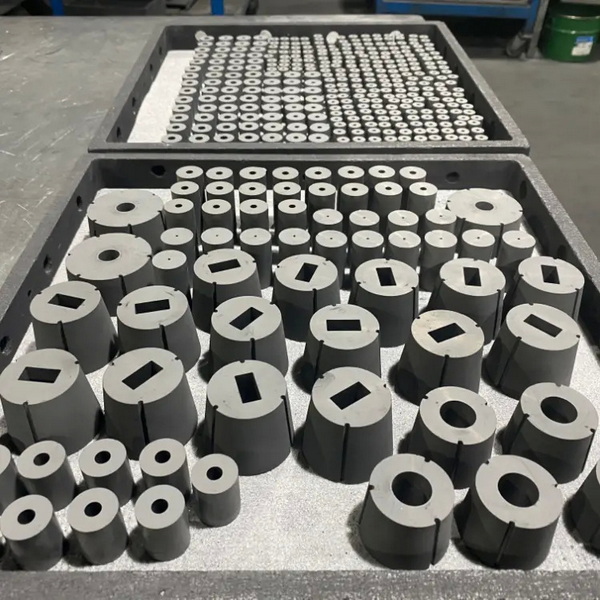

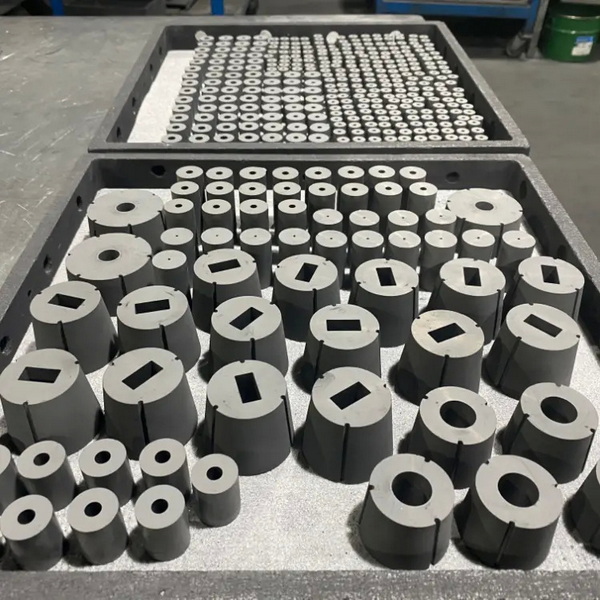

2. Shaping (Forming the Green Body)

The prepared blend is loaded into precision dies. Using hydraulic or isostatic press machines, enormous force is applied to shape the powder into a “green body”—an unsintered, preform part. Various forming methods are used:

- Isostatic Pressing: For complex or high-uniformity parts, applying hydraulic pressure from all angles yields consistent density.

- Extrusion: A viscous powder mass is pushed through a mold die, ideal for producing rods or tube-shaped round moulds.

- Injection Molding: For intricate designs and large quantities, the process mirrors plastic injection molding using carbide feedstock.

The green body is machined or drilled if special features or holes are required.

3. Sintering

The green preforms are loaded into furnaces with controlled vacuum or inert gas atmospheres, gradually heated to 1400–1600°C. During sintering, the binder metal melts and “wets” the WC grains, causing them to bond into a dense matrix. The part shrinks (by up to 25%) but attains high hardness and durability. Temperature cycling and exact atmosphere management are critical for minimizing pores and eliminating weaknesses.

Some manufacturers add a hot isostatic pressing (HIP) stage while still hot, applying gas overpressure to further compact the structure and achieve near-poreless, uniform density and mechanical strength.

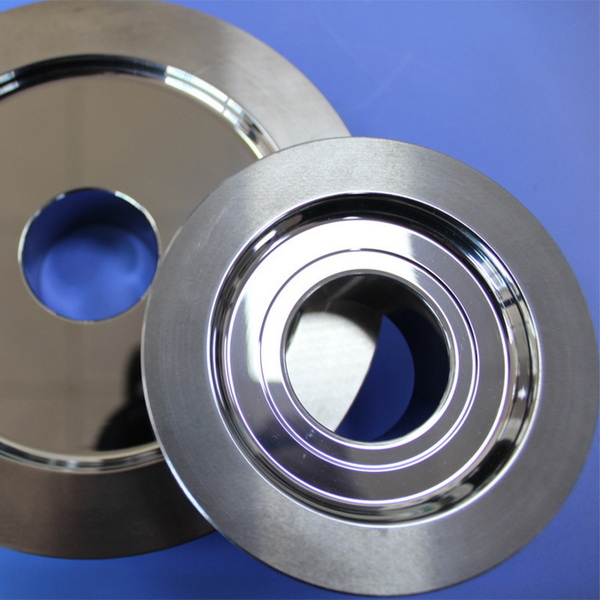

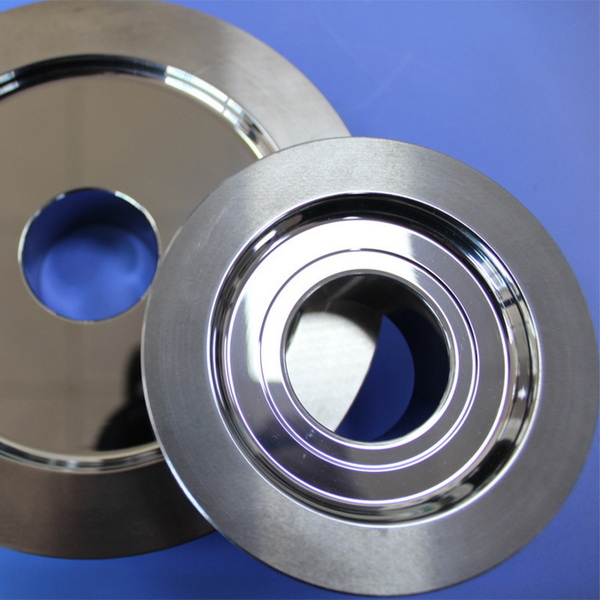

4. Machining and Finishing

After cooling, the now ultra-hard mould is finished through high-precision processes:

- Grinding and Honing: Diamond-grit grinding achieves the required dimensions and surface smoothness. Honing and lapping further tighten tolerances and refine finishes.

- EDM (Electrical Discharge Machining): Complex features, micro-profiles, and sharp edges are imparted with EDM, allowing for geometries impossible by physical grinding alone.

- Polishing and Coating: For specialty applications, polishing creates mirror surfaces or advanced boron, titanium, or DLC coatings boost surface hardness, minimize friction, or impart chemical resistance.

5. Inspection and Quality Control

Each finished mould undergoes rigorous inspection:

- Dimensional analysis using micrometers and CMMs to verify tolerances (often within ±0.004–0.010 mm or tighter).

- Ultrasonic and X-ray examination for detecting internal flaws.

- Microstructure analysis ensures homogeneity and optimal phase bonding.

Only after passing all tests are moulds cleaned, marked, and packed for shipment.

Modern Trends and Technological Innovations

The carbide round mould sector is experiencing rapid evolution:

- Additive Manufacturing: Select manufacturers now deploy 3D printing technologies, dramatically speeding sample creation, enabling bespoke, low-volume moulds for R&D, and cutting lead times.

- Automation and Robotics: Powder mixing, pressing, and inspection are increasingly handled by automated lines, reducing human error and boosting batch consistency.

- Digital Inspection: Laser scanning and computer-vision QC enable zero-defect shipments and automated dimensional control.

- Sustainability: Recycling of tungsten materials and improved energy management are now widespread, reflecting priorities of environmental responsibility among leading Russian and global suppliers.

- Custom Engineering: Digital simulation and rapid prototyping facilitate rapid fulfillment of complex, non-standard mould geometries, a major advantage for OEM buyers needing specialized tooling.

Key Applications Across Industries

Carbide round moulds produced in Russia serve a wide array of uses:

- Metal Forming: Used for stamping, punching, and shaping steel, aluminum, copper, and rare alloys.

- Automotive: Critical in forming body panels, drivetrain gears, bushings, and engine components.

- Aerospace: Applied in manufacturing high-stress and high-precision components.

- Electronics and Semiconductor: Micro-moulds are needed for tiny, precisely shaped metal pins and connectors.

- Medical and Dental: Used for surgical tool blanks and micro-punches for device implants.

- Food Processing: High-purity, wear-resistant moulds for precision forming and cutting systems.

The adoption of carbide round moulds enhances throughput, improves product consistency, and reduces downtime from tooling wear or failure.

Best Practices in Sourcing Russian Carbide Round Mould Manufacturers and Suppliers

For international buyers, establishing a robust supply relationship involves several key steps:

- Supplier Vetting: Check for internationally recognized certifications such as ISO 9001 and (for medical or dental) CE marking. This ensures the manufacturer adheres to consistent processes and material traceability.

- Technical Communication: Provide detailed technical drawings, including tolerances, material specifications, finish type, and application demands. Ensure the supplier can interpret and deliver upon these requirements.

- Batch and Sample Policy: Obtain initial samples and inspect for all critical dimensions and features. Ensure the supplier has batch traceability and can provide consistent quality for repeat orders.

- OEM Services: For custom or branded moulds, review the supplier's R&D and design support capabilities, as well as capacity for logo-marking, custom packaging, or differentiated coatings.

- After-Sales and Support: Confirm policies regarding warranty, technical troubleshooting, and replacement for defective goods. The best suppliers offer rapid communication and technical guidance throughout the lifecycle of the project.

- Export Compliance: Work with suppliers experienced in global logistics, customs documentation, and cross-border trade regulations to ensure smooth deliveries.

Leading Russian Carbide Round Moulds Manufacturers and Suppliers

KMIZ (Kazan Medical Instruments)

As one of Russia's oldest and largest carbide tooling manufacturers, KMIZ's portfolio covers both medical and industrial-grade tungsten carbide round moulds. Products are engineered using certified processes and subject to rigorous QC, gaining trust from clients in more than forty countries. Customization, fast turnaround, and on-demand OEM support are KMIZ hallmarks.

Pumori Corporation

Pumori is renowned for its solid carbide tooling, round mould dies, and metal-cutting inserts. Their advanced R&D, nano-coating line, and automation allow for high-volume, precise order fulfillment tailored to the machinery and automotive sectors.

BETAR

With expertise in both standard and bespoke carbide round moulds, BETAR offers in-house engineering and full-scale CNC and EDM capabilities, supporting flexible, medium-to-large batch production for manufacturers across Europe and Asia.

Tomsky Instrument and KZTS

Regional powerhouses like Tomsky Instrument and KZTS provide specialized round and custom-geometry carbide moulds for niche applications. Both brands focus on precision, tailored engineering, and rapid prototyping for diverse industries.

Insights for Overseas OEM/ODM Buyers

Sourcing carbide round moulds from Russia offers global buyers strategic advantages—in reliability, technical service, and adaptability. To maximize results when partnering with Russian suppliers, consider:

- Building trust via factory audits (onsite or virtual) and process transparency.

- Prioritizing suppliers that demonstrate fast prototyping, technical flexibility, and clear documentation of processes and quality assurance.

- Negotiating contracts that include well-defined after-sales support and warranty terms.

- Encouraging feedback and continuous improvement to foster a win-win, long-term partnership.

Conclusion

Russia has established itself among the global leaders in carbide round moulds manufacturing, leveraging deep technical expertise, advanced production technologies, and a strong commitment to international quality standards. Collaborating with top Russian manufacturers offers overseas brands, OEMs, and industrial buyers access to world-class tooling that delivers high value, performance, and dependability across demanding engineering applications.

Choosing a Russian Carbide Round Moulds Manufacturer or Supplier guarantees not only robust, precisely engineered products but also professional OEM/ODM support, competitive pricing, and responsive after-sales services. As the landscape continues to evolve with digitization, automation, and global integration, Russia remains a reliable source for high-precision carbide tooling.

Frequently Asked Questions

1. What is the main advantage of tungsten carbide in round mould production?

Tungsten carbide's exceptional hardness, resistance to wear, and thermal stability allow round moulds to maintain high precision and long service life in extremely demanding industrial processes.

2. Are Russian manufacturers able to deliver fully customized carbide round moulds?

Yes, most leading Russian suppliers offer full OEM/ODM customization, including unique geometries, coatings, marking, and packaging to suit specialized applications and global branding requirements.

3. How can I assess a Russian supplier's quality and reliability?

Review international certifications, require detailed QC records, assess customer testimonials, and request initial sample runs to evaluate technical communication and finished product consistency.

4. Which industries benefit most from Russian carbide round moulds?

Key sectors include automotive, aerospace, electronics, metal fabrication, medical devices, and food processing—all industries relying on sustained accuracy and durability under repetitive, high-stress conditions.

5. What support do top suppliers offer after delivery?

Reputable manufacturers provide technical assistance, quality tracking, spare parts, defect replacement, and regular performance reviews to ensure ongoing value and project success.