Content Menu

● Introduction: Carbide Round Moulds in Portugal

● Why Portugal Stands Out

● Leading Carbide Round Moulds Manufacturers and Suppliers

>> TetraMOLD

>> Tecnifreza

>> Ricardo & Barbosa

>> Palbit

>> Costa & Martinez, LDA

>> A&M Moldes para Plásticos

● The Carbide Round Moulds Production Process

>> Raw Material Preparation

>> Pressing and Sintering

>> Precision Grinding and Finishing

>> Quality Control

>> OEM/ODM Customization

● Sustainability and Certifications

● Industry Applications

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. Which industries benefit most from sourcing carbide round moulds from Portugal?

>> 2. How do Portuguese manufacturers maintain product quality?

>> 3. Can Portuguese suppliers handle bespoke OEM/ODM requests?

>> 4. What sustainability practices do manufacturers follow?

>> 5. What should buyers consider when selecting a manufacturer or supplier?

Carbide round moulds are indispensable in various industries, from mining and construction to automotive, energy, and tooling. Portugal has risen as a premier destination for sourcing these high-performance components, boasting a sophisticated cluster of manufacturers and suppliers that combine technical expertise, innovative manufacturing, and global service orientation. This guide presents a comprehensive overview of the sector, profiles the top industry players, details the production process, and considers market trends and sustainability efforts, helping buyers and specifiers understand why Portuguese carbide round moulds manufacturers and suppliers are among the best in Europe and worldwide.

Introduction: Carbide Round Moulds in Portugal

Portugal's carbide round moulds sector leverages state-of-the-art technologies, skilled craftsmanship, and strategic regional clusters. With core strengths in CNC machining, high-precision sintering, rigorous quality assurance, and deep investment in R&D, Portuguese suppliers provide reliable solutions for demanding applications across global markets.

Why Portugal Stands Out

Portuguese manufacturers are distinguished by their commitment to excellence, advanced technology, and international certifications. They offer:

- Advanced manufacturing with 5-axis CNC systems, automated quality inspection, and rapid production cycles.

- Flexible OEM/ODM services spanning CAD design, prototyping, batch production, packaging, and logistics.

- Strict adherence to international standards such as ISO and CE, enhancing reputation and reliability.

- Industry-leading sustainability initiatives, including closed-loop cooling, recycled carbide utilization, and energy-efficient operations.

Marinha Grande and Oliveira de Azeméis are the primary moldmaking hubs, supporting hundreds of specialized companies that blend tradition with modern automation.

Leading Carbide Round Moulds Manufacturers and Suppliers

TetraMOLD

Founded in 2004 in Oliveira de Azeméis, TetraMOLD rapidly expanded to export to over 11 countries. Their modern facilities and skilled workforce provide comprehensive mould production, emphasizing carbide round moulds for various industrial sectors.

Tecnifreza

Based in Marinha Grande since 1989, Tecnifreza specializes in the design and manufacturing of complex, precision technical moulds, including 2K and 3K component solutions. Their full-cycle engineering—from CAD development to qualification trials—serves automotive, electric, pharmaceutical, and packaging clients.

Ricardo & Barbosa

Ricardo & Barbosa are innovators in precision machining of tungsten carbide and other exotic materials. Their digital, paperless workflows and lean production principles ensure top-tier quality, traceability, and efficiency in both standard and custom projects.

Palbit

With a global reach, Palbit is well known for carbide cutting tools, round moulds, and specialized inserts. Their products target mining, drilling, and automotive industries, adhering to strict quality controls and international export processes.

Costa & Martinez, LDA

Costa & Martinez combine technical skill with tailored customer solutions. They have a competitive edge in precision engineering, project management, and global supply chain coordination—ideal for demanding OEM clients.

A&M Moldes para Plásticos

Serving from Oliveira de Azeméis, A&M Moldes specializes in thermoplastic injection and high-precision carbide moulds. Their investment in CNC tech and R&D gives them a solid reputation in plastics and automotive manufacturing.

The Carbide Round Moulds Production Process

Raw Material Preparation

The process begins with the selection of high-purity tungsten and carbon powders. These materials are blended and milled to create a uniform mixture, ensuring consistent hardening and strength.

Pressing and Sintering

Automated presses compact the powder into preliminary mould shapes under high pressure. These shapes undergo sintering in a vacuum or hydrogen atmosphere at temperatures up to 1600°C. This step fuses the particles into a dense, solid mass with exceptional hardness.

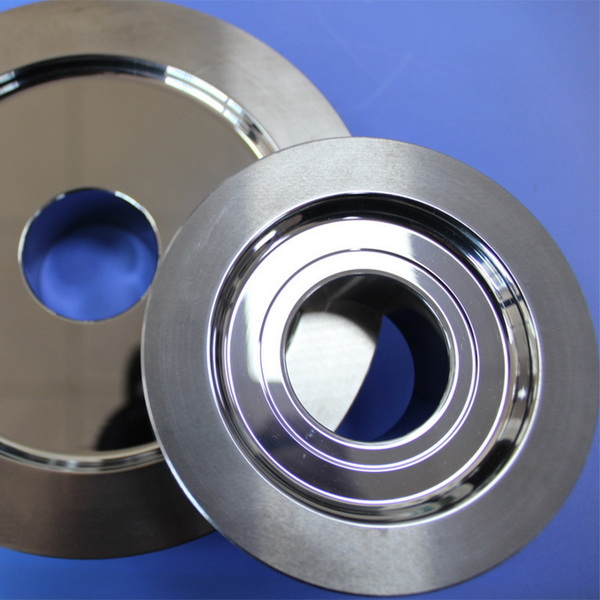

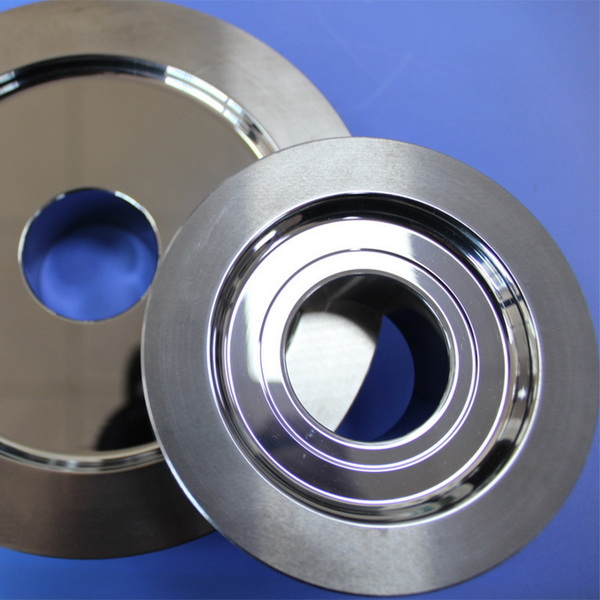

Precision Grinding and Finishing

After sintering, moulds are subjected to advanced grinding and polishing to achieve exacting tolerances, smooth finishes, and optimal performance. Inspection at this stage confirms dimensional accuracy and surface integrity.

Quality Control

Stringent testing—including hardness, wear, and impact resistance—occurs throughout production. Only components meeting benchmark criteria proceed to packaging and export.

OEM/ODM Customization

Portuguese suppliers offer extensive customization, supporting ERP-integrated order tracking, rapid prototyping, technical consultations, and flexible batch sizes. These services make them attractive to overseas buyers seeking tailored solutions.

Sustainability and Certifications

Portuguese carbide round moulds manufacturers are recognized for proactive sustainability:

- Recycling of carbide and scrap byproducts.

- Closed-loop water recovery and cooling systems.

- Energy-saving machinery and clean packaging practices.

They consistently meet or exceed international environmental, safety, and quality standards, underlining their reliability for global clients.

Industry Applications

Carbide round moulds produced in Portugal are vital in many sectors:

- Mining: Used in cutting and drilling equipment, increasing operational lifespan.

- Oil & Gas: Designed for high-pressure, corrosion-resistant drilling.

- Construction: Essential in road milling, tunnel boring, and concrete demolition tools.

- Automotive/Aerospace: Used in precision machining for advanced components.

- Renewable Energy: Integral to harsh-condition wear parts.

Market Trends and Future Outlook

The Portuguese carbide mould industry is evolving rapidly:

- Digitization and integration of CAD-CAM systems streamline design and production.

- AI-driven inspection and smart tracking heighten quality management.

- Clean manufacturing and sustainability practices set new benchmarks.

- Strong export growth, increased joint ventures, and technological innovation position Portuguese manufacturers for global leadership.

Conclusion

Portugal has firmly established itself as a global leader in carbide round moulds manufacturing and supply. With technologically advanced capabilities, flexible customer service, strict quality standards, and robust sustainability practices, Portuguese manufacturers represent the gold standard for global partners seeking innovative, reliable, and eco-friendly carbide round moulds solutions.

Frequently Asked Questions (FAQ)

1. Which industries benefit most from sourcing carbide round moulds from Portugal?

Industries such as mining, oil and gas, construction, automotive, aerospace, and renewables rely on Portugal's carbide round moulds for their durability and precision.

2. How do Portuguese manufacturers maintain product quality?

They implement advanced processes—high-purity material selection, precision pressing and sintering, automated inspection, and multi-stage quality checks—to ensure every mould meets strict international standards.

3. Can Portuguese suppliers handle bespoke OEM/ODM requests?

Yes, their expertise covers full-spectrum OEM/ODM offerings, including design collaboration, prototyping, process consultation, and flexible batch production.

4. What sustainability practices do manufacturers follow?

Key initiatives include carbide and scrap recycling, energy-efficient production systems, closed-loop water management, and eco-friendly packaging.

5. What should buyers consider when selecting a manufacturer or supplier?

Key considerations include certification verification, technical capability, sample evaluation, logistics arrangements, and the supplier's ability to provide clear communication and customization support.