Content Menu

● Why Germany Is a World Leader in Carbide Round Moulds Manufacturing

● The Broad Industrial Applications of Carbide Round Moulds

>> Automotive and Aerospace

>> Electrotechnical and Medical

>> Packaging, Metalworking, and More

● Leading Companies: Carbide Round Moulds Manufacturers and Suppliers in Germany

>> BETEK GmbH & Co. KG

>> AFC Hartmetall GmbH & Co. KG

>> AKS Hartmetaltechnik GmbH

>> Precision Carbide Germany (PCG GmbH)

>> MILLER GmbH & Co. KG

>> HHT Hartmetall

>> Gühring KG

>> HASCO Hasenclever GmbH + Co KG

>> Braunform GmbH

>> Paul Horn GmbH

● Deep Dive: German Carbide Round Moulds Production Process

>> Powder Selection and Mixing

>> Pressing and Compaction

>> Dewaxing and Sintering

>> Grinding, Machining, and EDM

>> Inspection and Quality Assurance

● Innovations in German Carbide Round Moulds Manufacturing

● Choosing the Best Supplier: A Practical Guide

● Conclusion

● Frequently Asked Questions

>> 1. What makes German carbide round moulds unique?

>> 2. Which industries commonly use German carbide round moulds?

>> 3. What should I consider when choosing a German carbide round mould supplier?

>> 4. Are custom carbide round mould solutions available from German suppliers?

>> 5. How is quality maintained in German carbide round mould production?

Carbide round moulds are essential tools for the most demanding industrial production environments. Across sectors such as automotive, electronics, metalworking, medical, and packaging, these precision-engineered components shape, cut, stamp, and form parts with supreme accuracy and durability. Germany's reputation for advanced manufacturing and engineering makes it a global hub for carbide round moulds excellence.

Why Germany Is a World Leader in Carbide Round Moulds Manufacturing

German manufacturers are widely acknowledged for their impeccable quality standards, technical expertise, and innovative production methods. Advanced powder metallurgy, CNC automation, and rigorous inspection protocols combine to deliver carbide round moulds with outstanding hardness, dimensional precision, and operational longevity. German suppliers are often ISO-certified and offer full traceability across the supply chain, from raw powder selection through production and export.

Carbide round moulds from Germany stand apart for their consistency, reliable performance, and ability to operate in the most challenging environments. This is why German suppliers remain the first choice for international OEMs, global brands, and major industrial clients seeking tool reliability and process optimization.

The Broad Industrial Applications of Carbide Round Moulds

Automotive and Aerospace

In automotive and aerospace industries, carbide round moulds are vital for shaping and stamping high-strength alloy components that must withstand extreme loads, temperature fluctuations, and tight dimensional tolerances.

Electrotechnical and Medical

Electronics manufacturers depend on carbide round moulds for intricate part production, relying on their wear resistance for high-volume runs. Medical device companies trust these moulds to produce implantable components and precision assemblies that meet stringent quality, hygiene, and regulatory standards.

Packaging, Metalworking, and More

Carbide round moulds are extensively used in packaging, metal fabrication, tool manufacturing, and various stamping operations. Their resistance to deformation, high-temperature endurance, and cost-efficiency drive their popularity in mass production and custom fabrication.

Leading Companies: Carbide Round Moulds Manufacturers and Suppliers in Germany

BETEK GmbH & Co. KG

Founded over a century ago, BETEK delivers innovative carbide tool systems and round moulds for diverse industrial applications. Their mastery of pressing and sintering technology enables precise mould solutions for bulk production and custom projects.

AFC Hartmetall GmbH & Co. KG

AFC Hartmetall is renowned for high-precision tungsten carbide rods, round blanks, and mould inserts. Their responsive engineering support benefits OEM customers in automotive, aerospace, and metalworking segments.

AKS Hartmetaltechnik GmbH

AKS is recognized for its wide range of carbide rods, mould inserts, and semi-finished components. They provide flexible solutions for standard and custom requirements, supporting quick-turn and high-performance demands.

Precision Carbide Germany (PCG GmbH)

PCG specializes in fast-turn tungsten carbide rods and custom round blanks. Their high-speed CNC machining and robust inventory help international customers secure precision parts and rapid delivery.

MILLER GmbH & Co. KG

Miller offers rotary solid milling cutters, end mills, and carbide round mould solutions. Their modern facility, equipped with automation and rapid delivery logistics, serves the aerospace, automotive, and machinery sectors efficiently.

HHT Hartmetall

A respected force in carbide round rod production, HHT combines specialist machining teams and technical expertise, providing solutions for highly demanding industries.

Gühring KG

A global icon in carbide tooling, Gühring supplies a full spectrum of round shank carbide tools and customized moulds. Their integrated production—from powder processing to finished product—ensures premium consistency and material performance.

HASCO Hasenclever GmbH + Co KG

HASCO is celebrated for its standardized mould base manufacturing, supporting injection moulding operations and deploying carbide inserts for durability and longevity in demanding production environments.

Braunform GmbH

Braunform utilizes carbide round inserts for the medical and packaging sectors, delivering cleanroom-grade moulds for products requiring rigorous process control and extended lifespans.

Paul Horn GmbH

Horn's advanced carbide round moulds and microtools are essential to the electronics, metal-cutting, and micro-machining sectors, with an expansive portfolio supporting both standard and specialized production needs.

Deep Dive: German Carbide Round Moulds Production Process

The manufacturing of carbide round moulds in Germany is a disciplined blend of scientific rigour and engineering automation. The workflow ensures every mould delivers the desired balance of hardness, toughness, and dimensional accuracy.

Powder Selection and Mixing

Production begins with careful selection of tungsten carbide and cobalt powders. The mixture is fine-tuned for application, maximizing wear resistance, strength, and chemical stability. Modern plants utilize automated batching, mixing, and granulation techniques that yield homogeneous, flowable powder.

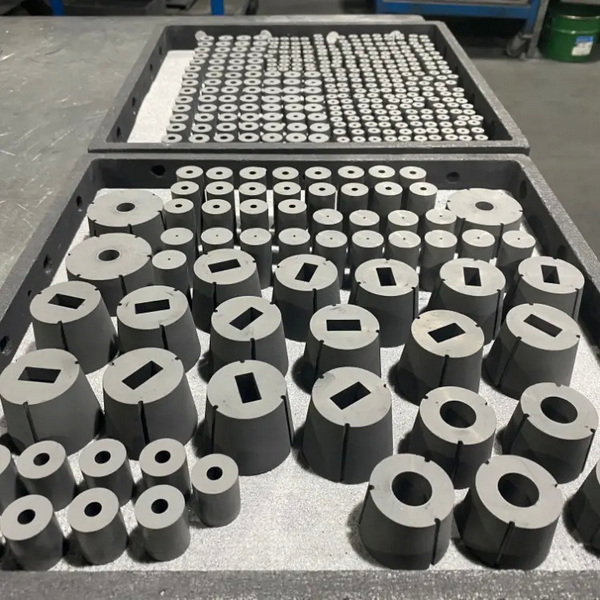

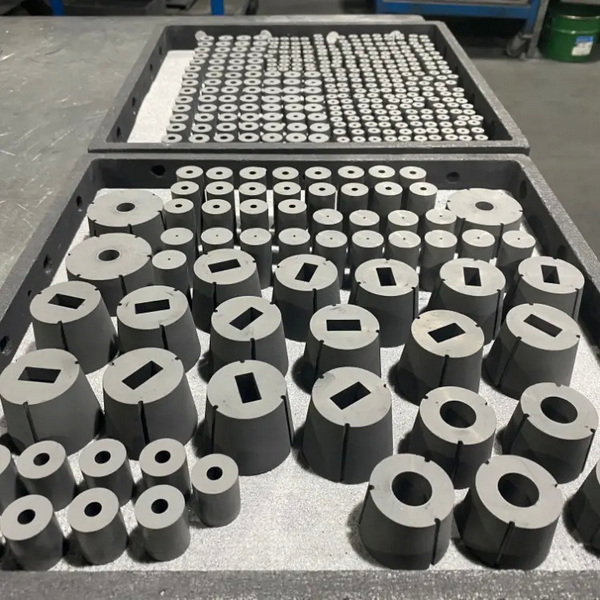

Pressing and Compaction

Using isostatic or uniaxial presses, the blended powder is shaped into “green” round blanks with high density but minimal mechanical strength. Some plants deploy extrusion or injection molding to produce complex forms or mass volumes, always controlling compaction for uniform microstructure.

Dewaxing and Sintering

To enhance mechanical properties, green blanks undergo dewaxing, eliminating binders and organic additives. Controlled sintering follows at over 1400°C—fusing carbide grains into a dense, ultra-hard solid. Low-pressure or vacuum sintering technologies further increase product integrity, reduce porosity, and improve compactness.

Grinding, Machining, and EDM

Post-sintered blanks are machined using high-precision CNC grinding, turning, and electrical discharge machining (EDM). These steps deliver final geometries, ultra-fine tolerances, and surface finishes needed for high-accuracy production. Mirror polishing and advanced coatings may be added to boost wear resistance and lower friction.

Inspection and Quality Assurance

German facilities maintain rigorous quality control with non-destructive ultrasonic testing, dimensional checks, and hardness verification. Each round mould undergoes multi-step inspection to guarantee compliance with client specifications and global quality standards.

Innovations in German Carbide Round Moulds Manufacturing

German manufacturers invest heavily in advanced CNC technology, high-speed automation, low-pressure sintering, and additive manufacturing. Some companies experiment with laser texturing and mixed-process machining to achieve surface finishes of Ra 0.2 μm or finer. Digital twins, process simulation, and automated QA are transforming the industry toward smarter, more flexible manufacturing.

Choosing the Best Supplier: A Practical Guide

When selecting a carbide round moulds manufacturer or supplier in Germany, evaluate these key criteria:

- Customization capacity: Ability to accommodate unique tolerances and geometries for specialized applications.

- Lead time and inventory: Robust supply chain and quick turnaround for standard or urgent orders.

- R&D support: Technical guidance on material choice, tooling designs, and process improvements.

- Certification: ISO, automotive, aerospace, or medical sector compliance.

- Export logistics: Experience in international shipping, documentation, and customer support.

- After-sales and engineering services: Tool design consulting, failure analysis, and material upgrading.

German suppliers excel by combining traditional engineering expertise with automation, global logistics, and a spirit of innovation.

Conclusion

Germany leads the global industry for carbide round moulds manufacturing with unmatched quality, advanced processes, and a broad portfolio of suppliers capable of serving every industrial segment. Companies such as BETEK, AFC Hartmetall, AKS, PCG, and Gühring have set benchmarks for precision, durability, and innovation. Their commitment to continuous improvement ensures manufacturers and brand owners worldwide receive tools that optimize production, reduce downtime, and meet exacting technical standards.

For any organization seeking consistent, high-performance carbide round moulds, Germany's network of manufacturers and suppliers offers a proven path to superior quality and efficiency. Buyers can be confident in both standardized and custom solutions delivered with reliability and technical backing that few other markets can match.

Frequently Asked Questions

1. What makes German carbide round moulds unique?

German carbide round moulds offer unmatched precision, superior wear resistance, and longer tool life due to advanced manufacturing processes and strict quality standards.

2. Which industries commonly use German carbide round moulds?

Automotive, aerospace, electronics, medical, packaging, and metalworking industries depend on German carbide round moulds for high-volume and high-precision applications.

3. What should I consider when choosing a German carbide round mould supplier?

Consider their experience, technical capabilities, customization options, certifications, inventory, delivery speed, and after-sales engineering support.

4. Are custom carbide round mould solutions available from German suppliers?

Yes, most German manufacturers and suppliers offer tailored mould solutions, meeting complex specifications for unique tooling requirements.

5. How is quality maintained in German carbide round mould production?

Manufacturers deploy rigorous powder selection, pressing, sintering, precision machining, and multi-stage inspections to ensure each mould meets global quality standards.