Content Menu

● Introduction

● The Role of Carbide Round Moulds in Modern Industry

● Top Carbide Round Moulds Manufacturers and Suppliers in Canada

>> Canada Carbide

>> Flair Precision Inc.

>> Hard Metals Canada Inc.

>> De Boer Tool Ltd.

>> General Carbide Canada

>> Castelar Tool & Grinding Inc.

>> Sharpex Inc.

● The Manufacturing Process of Carbide Round Moulds

● Key Technologies Driving Canadian Carbide Round Moulds Excellence

● OEM Services and Custom Solutions

● Application Scenarios for Carbide Round Moulds

● Sustainability and Ethical Manufacturing

● Market Trends and Global Positioning

● How to Select a Carbide Round Mould Manufacturer in Canada

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What makes Canadian carbide round moulds superior to steel alternatives?

>> 2. Can Canadian suppliers deliver private-label and OEM solutions?

>> 3. What industries most benefit from Canadian carbide moulds?

>> 4. How do sustainability practices influence the Canadian carbide tooling sector?

>> 5. What should buyers consider when choosing a Canadian carbide round mould supplier?

Introduction

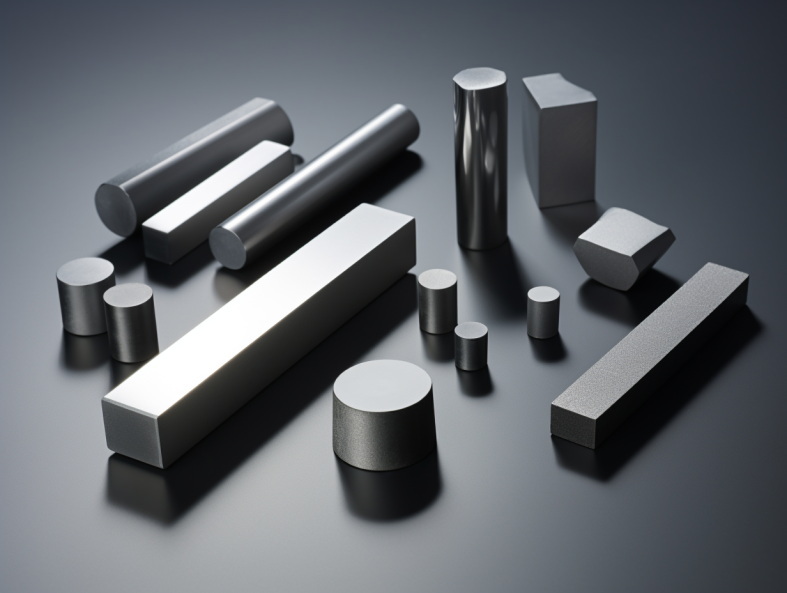

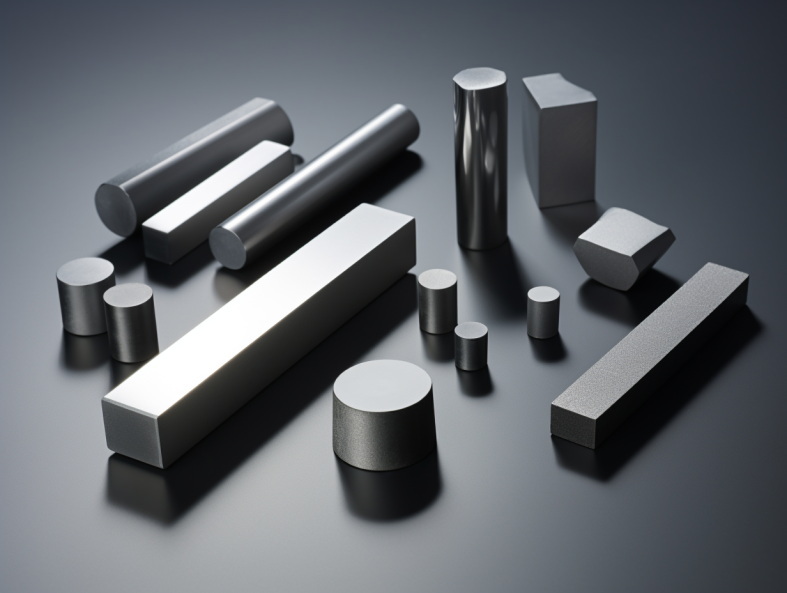

Carbide round moulds represent a critical component of precision manufacturing, offering exceptional hardness, durability, and accuracy. In Canada, a rich ecosystem of Carbide Round Moulds Manufacturers and Suppliers has emerged, supplying OEM partners, brand owners, and international wholesalers with products that meet the highest standards. This guide reviews the leaders in Canadian carbide round mould production, explores their technological prowess, and reveals how they support OEM and custom engineering projects for global clients.

The Role of Carbide Round Moulds in Modern Industry

Carbide round moulds, often manufactured from tungsten carbide or cemented carbide, offer superior performance compared to traditional steel. Their unique combination of wear resistance, thermal stability, and ability to maintain exact tolerances makes them invaluable in automotive, aerospace, electronics, and medical device production. These industries demand consistent tool longevity and precise part reproduction, which carbide moulds deliver over extended production runs.

Manufacturers who invest in carbide moulds see lower operating costs over time, as longer mould lifespan means fewer changeovers and less downtime. Additionally, improved surface finish and minimal deformation during stamping or extrusion result in higher-grade products, boosting competitiveness in international markets.

Top Carbide Round Moulds Manufacturers and Suppliers in Canada

Canada Carbide

Founded in Ontario in 1969, Canada Carbide remains a benchmark for quality in cemented carbide blanks and precision tooling. Their round moulds are tailored for OEM applications and prized for durability and consistent dimensional stability. With robust domestic support and international shipping capabilities, Canada Carbide is recognized as a trusted partner for global tool-and-die operations.

Flair Precision Inc.

Located in Ontario, Flair Precision serves major OEM clients like Space X, General Motors, Magna, Honda, and Linamar. They offer turnkey design-to-delivery solutions for round moulds and tool blanks, featuring advanced abrasive technology, multi-axis CNC machines, and state-of-the-art coating facilities. This ensures their carbide products meet the most demanding requirements of modern production.

Hard Metals Canada Inc.

Hard Metals Canada specializes in shaped and rectangular carbide blanks, carbide round moulds, and polycrystalline diamond components. Their expertise in material consulting and rapid prototyping enables them to deliver tailored solutions to international customers, from concept validation to completed tooling.

De Boer Tool Ltd.

Mississauga's De Boer Tool is renowned for its integrated approach to solid carbide drilling and custom round mould manufacturing. Backed by ISO-certified quality systems and advanced product inspection, their edge preparation and unique coatings ensure defect-free, high-performance products for OEM and private label projects.

General Carbide Canada

Established in 1968, General Carbide Canada combines metallurgical insight and HIP sintering processes to deliver carbide tools, round dies, and wear parts for brands across North America. Their distribution and partner network supports cost-efficient, high-volume OEM programs and advanced technical support through every stage of product development.

Castelar Tool & Grinding Inc.

With deep experience since 1972, Castelar Tool offers personalized solutions for drills, end mills, round moulds, threading, and chamfering—delivering custom development on tight timelines for applications ranging from industrial stamping to electronics.

Sharpex Inc.

Founded in Québec in 1997, Sharpex supplies custom and standard carbide cutting tools and round moulds to the automotive, medical device, and advanced electronics sectors. Their expedited logistics and ability to scale production support high-volume exports to international partners.

The Manufacturing Process of Carbide Round Moulds

Carbide round mould production begins with the careful selection of tungsten carbide powder, typically derived from the chemical and thermal reduction of tungsten ore. This powder is then blended with metallic binders—commonly cobalt or nickel—to create a material with the ideal combination of hardness, toughness, and resistance to fracture.

The mixture undergoes powder metallurgy, a process involving high-pressure compaction into the desired mould shape, followed by sintering at extremely high temperatures to bond the compounds and binders. Advanced facilities may utilize hot isostatic pressing (HIP) to eliminate micro-voids, improving density and prolonging tool life.

Precision CNC machining and CAD/CAM design are used for finishing and shaping the moulds, ensuring exactness. Quality control processes such as ultrasonic and CMM inspection guarantee that moulds meet the demanding tolerances required for intricate forming operations.

The technical strength of Canadian manufacturers is their ability to rapidly prototype new mould designs using additive manufacturing and 3D printing, permitting the cost-efficient development of custom geometries. This agility is essential for serving the ever-changing needs of international OEM clients.

Key Technologies Driving Canadian Carbide Round Moulds Excellence

- High-Speed CNC Machining: Enables accurate finishing of round moulds with intricate details, supporting mass customization.

- Advanced Powder Metallurgy: Facilitates the creation of carbide materials with tailored properties for diverse production environments.

- Laser and Ultrasonic Metrology: Guarantees dimensional accuracy within microns, supporting zero-defect standards.

- Additive Manufacturing: Offers fast prototyping and low-volume production of custom parts, shrinking lead times for complex geometries.

- HIP Sintering: Provides exceptional density and homogeneous microstructure for extended tool life.

These technologies allow Canadian Carbide Round Moulds Manufacturers and Suppliers to exceed industry standards for performance, reliability, and fast delivery.

OEM Services and Custom Solutions

Canadian carbide suppliers excel in providing robust OEM programs to foreign brand owners, wholesalers, and producers. Services include:

- Private branding and labelling for global markets

- Custom design support from initial CAD concept through prototype iteration

- Comprehensive technical documentation, certification, and compliance support

- Full-cycle logistics solutions for international shipments

- After-sales consultation and warranty support for long-term clients

This end-to-end support allows buyers to focus on market growth while Canadian partners manage all aspects of manufacture, quality, and logistics.

Application Scenarios for Carbide Round Moulds

Carbide round moulds are vital in numerous sectors:

- Automotive and aerospace: Used for precision metal forming, cold extrusion, and high-speed stamping operations.

- Electronics: Enable the production of intricate components with minimal deformation and maximum surface integrity.

- Medical devices: Ensure sterile manufacturing environments and superior wear resistance for surgical equipment and tools.

- Food processing: Support robust tooling for packaging, stamping, and assembly lines.

- General manufacturing: Employed in everything from wire drawing to mechanical assembly, where accuracy and longevity are paramount.

Canadian suppliers cater to these diverse needs through continuous R&D and the ability to scale custom projects rapidly.

Sustainability and Ethical Manufacturing

Most Canadian Carbide Round Moulds Manufacturers and Suppliers are deeply committed to sustainable operations. Recycling initiatives are standard, with scrap carbide reclaimed and reprocessed, reducing environmental impact and material costs. Energy-efficient machinery further lowers the carbon footprint, while responsible sourcing of tungsten and cobalt fulfills ever-stricter ethical standards.

Some suppliers are partnering with academic and research institutions to develop new eco-friendly binder formulations and manufacturing methods that minimize waste and optimize energy use.

Market Trends and Global Positioning

Canada's carbide round mould industry is marked by several trends:

- Rapid adoption of automation and robotics for improved throughput and quality control

- Integration of AI-driven monitoring and predictive maintenance in high-output facilities

- Rising export volume to the US, Europe, and Asia

- Increased focus on sustainable, closed-loop manufacturing systems

- Expansion of advanced certification and international compliance capabilities

These trends underline the capability of Canadian suppliers to deliver not only world-class products but also progressive service models that support OEM clients worldwide.

How to Select a Carbide Round Mould Manufacturer in Canada

Whether for OEM projects or ongoing supply partnerships, selecting the right manufacturer is critical:

- Prioritize those with comprehensive technical certifications, like ISO 9001, and proven documentation of QA processes.

- Evaluate their flexibility in prototyping and willingness to accommodate custom requirements.

- Request case studies or references showcasing successful similar projects, especially with international buyers.

- Discuss post-sale support, warranty policies, and logistics capabilities for reliable global shipping.

- Examine their commitment to sustainable practices, including recycling and ethical sourcing.

A well-chosen supplier will ensure risk mitigation, rapid problem resolution, and long-term reliability.

Conclusion

Canadian Carbide Round Moulds Manufacturers and Suppliers serve as pillars of the international precision tooling market. By capitalizing on advanced manufacturing processes, innovative technologies, and a culture of continuous improvement, they deliver unmatched value to OEMs, wholesalers, and brand owners across the globe. Their expertise, commitment to certification, and sustainable operations distinguish Canadian firms as preferred partners for those seeking reliability, flexibility, and the ability to meet evolving manufacturing challenges.

Frequently Asked Questions (FAQ)

1. What makes Canadian carbide round moulds superior to steel alternatives?

Canadian carbide round moulds offer significantly better wear resistance, longer tool life, and improved dimensional consistency, thanks to advanced powder metallurgy and precision machining.

2. Can Canadian suppliers deliver private-label and OEM solutions?

Yes, leading manufacturers provide comprehensive OEM services including custom design, private branding, technical documentation, and global shipping support.

3. What industries most benefit from Canadian carbide moulds?

Automotive, aerospace, medical devices, electronics, and food processing industries all benefit due to the durability and precision of carbide moulds.

4. How do sustainability practices influence the Canadian carbide tooling sector?

Most suppliers are dedicated to recycling, energy efficiency, and ethically sourced materials, making the industry one of the leaders in responsible manufacturing.

5. What should buyers consider when choosing a Canadian carbide round mould supplier?

Review technical qualifications, project experience, capacity for custom design, after-sale technical support, and the supplier's operational sustainability.