Content Menu

● Introduction to Carbide Mining Strips

● Why Choose Chinese Manufacturers?

● Top 10 Carbide Mining Strips Manufacturers and Suppliers in China

>> 1. ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD.

>>> Company Overview

>>> Product Range

>>> Unique Advantages

>>> Factory and Production

>>> Product Example

>> 2. Zhuzhou Cemented Carbide Group Co., Ltd. (ZCC)

>> 3. Zigong Cemented Carbide Group Co., Ltd. (ZGCC)

>> 4. Xiamen Golden Egret Special Alloy Co., Ltd. (GESAC)

>> 5. OKE Precision Cutting Tools Co., Ltd.

>> 6. CY CARBIDE MFG. CO., LTD. (CYC)

>> 7. Penglai Ultra-rigid Composite Material Co., Ltd.

>> 8. Zhejiang Dewei Cemented Carbide Manufacturing Co., Ltd.

>> 9. Zhuzhou Jinggong Cemented Carbide Co., Ltd.

>> 10. Jinan Institute of Metallurgical Science Co., Ltd.

● Key Features of Quality Carbide Mining Strips

● Applications of Carbide Mining Strips

● Manufacturing Process: From Powder to Precision Tool

● How to Source Carbide Mining Strips from China

● Trends and Innovations in Carbide Mining Strips

● Quality Control and Certifications

● Conclusion

● FAQ: Carbide Mining Strips Manufacturers and Suppliers

>> 1. What are the main applications of carbide mining strips?

>> 2. How do I choose the right carbide mining strips manufacturer?

>> 3. What grades of tungsten carbide are commonly used for mining strips?

>> 4. How are carbide mining strips manufactured?

>> 5. Are Chinese carbide mining strips manufacturers reliable for OEM services?

Carbide mining strips are essential components in the mining and heavy industry sectors, prized for their exceptional hardness, wear resistance, and durability. These strips, typically made from tungsten carbide, are indispensable for cutting, drilling, and wear protection applications in mining, construction, and manufacturing. As demand for high-performance and long-lasting tools grows, sourcing from reliable Carbide Mining Strips Manufacturers and Suppliers in China has become a priority for global brands, wholesalers, and OEMs.

This article presents an in-depth look at the top 10 carbide mining strips manufacturers and suppliers in China, with a detailed focus on ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD., a recognized leader in the industry.

Introduction to Carbide Mining Strips

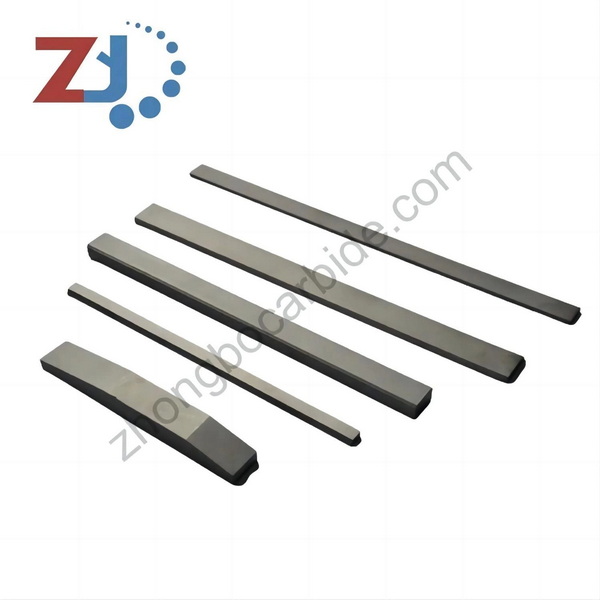

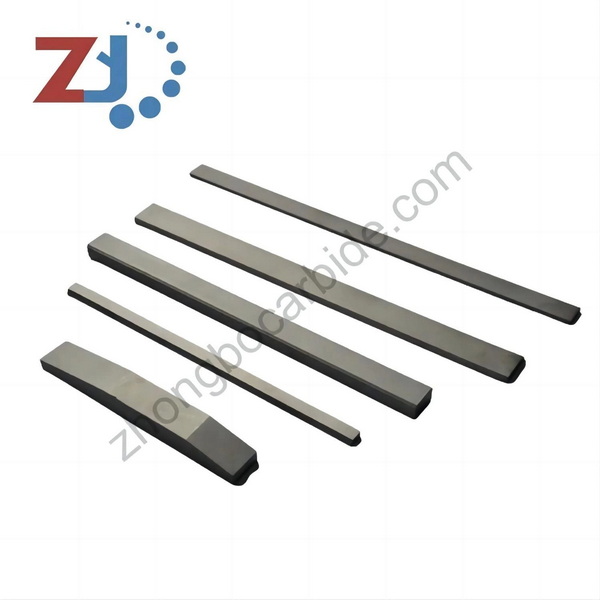

Carbide mining strips are rectangular or custom-shaped bars made from tungsten carbide, a material renowned for its superior hardness, toughness, and resistance to abrasion. These strips are widely used in mining, construction, and industrial machinery to extend the lifespan of tools and equipment subjected to harsh working environments.

Carbide strips are fabricated from tungsten carbide, a compound known for its exceptional durability and performance in demanding conditions. These strips are utilized in various industries, from manufacturing to mining, due to their ability to maintain sharpness and resist wear under high-stress environments. Their unique properties make them a preferred choice for applications where ordinary steel or alloy tools would quickly fail.

Why Choose Chinese Manufacturers?

China is a global powerhouse in the production of carbide mining strips due to:

- Advanced manufacturing technology: Chinese manufacturers have invested heavily in state-of-the-art equipment and automation, ensuring consistent quality and high production efficiency.

- Competitive pricing: Large-scale production and efficient supply chains allow Chinese suppliers to offer highly competitive prices without sacrificing quality.

- Large-scale production capacity: Many Chinese factories can fulfill large and urgent orders, making them ideal partners for international brands and wholesalers.

- Extensive R&D and customization options: Leading manufacturers offer tailored solutions to meet specific customer requirements, including custom grades, sizes, and shapes.

- Strong export experience: Decades of exporting to markets worldwide have equipped Chinese companies with the expertise to handle international logistics, documentation, and quality standards.

Leading Carbide Mining Strips Manufacturers and Suppliers in China provide OEM services, strict quality control, and fast delivery, making them the preferred choice for international buyers.

Top 10 Carbide Mining Strips Manufacturers and Suppliers in China

1. ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD.

Location: Zunyi, Guizhou, China

Established: 1998

Annual Output: 500–600 tons

Export Markets: Germany, Denmark, Japan, the USA, and more

Certifications: ISO, strategic partner of Guizhou Steel Rope (Group) Co., Ltd.

Company Overview

ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD. is a high-tech enterprise specializing in the R&D, production, and sales of carbide products, with a focus on carbide mining strips. The company operates a modern factory spanning over 16,000 square meters, equipped with advanced machinery and a skilled workforce. Zhongbo's annual sales exceed 200 million CNY, and its products are exported globally.

Product Range

- Carbide Mining Strips

- Carbide saw tips

- Cold heading dies

- Drawing dies

- Carbide buttons

- Hammer stone and impact drill pieces

- Custom-shaped carbide components

Unique Advantages

- Customization: Offers tailored solutions for various mining and industrial applications, including different grades, shapes, and dimensions.

- Quality Assurance: Implements strict quality control throughout the production process, from raw material selection to final inspection.

- Global Reach: Established branch offices, including Bee International Trade LLC in the USA, to facilitate international trade and provide local support.

- Innovation: Continuous investment in R&D to maintain technological leadership and develop new carbide grades for emerging applications.

Factory and Production

ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD. operates a cutting-edge facility with automated production lines, advanced sintering furnaces, and precision grinding equipment. The company employs experienced engineers and technicians who oversee every stage of production, ensuring that each batch of carbide mining strips meets stringent international standards.

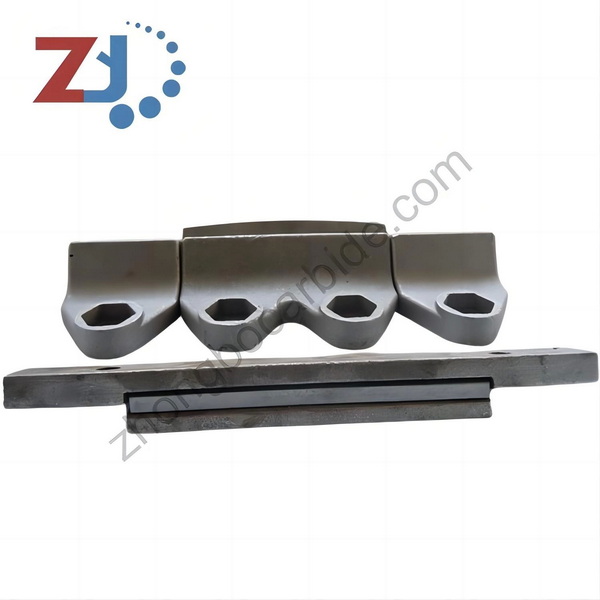

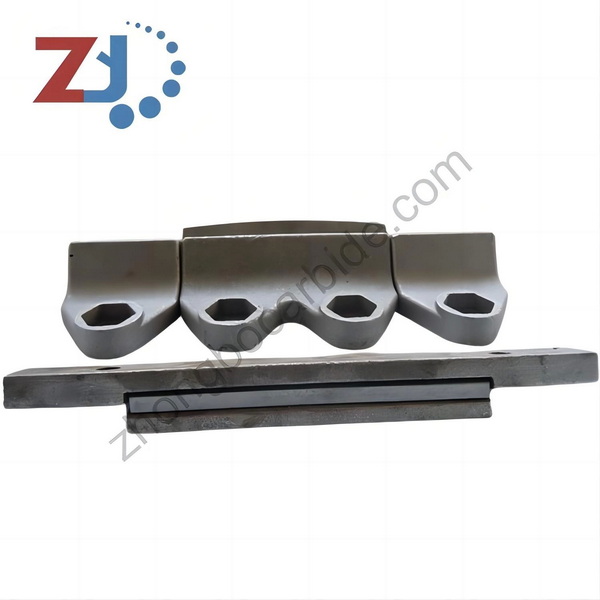

Product Example

Zhongbo's carbide mining strips are known for their high precision, consistent quality, and exceptional wear resistance. The company offers a wide range of standard and custom sizes to meet the diverse needs of its global clients.

2. Zhuzhou Cemented Carbide Group Co., Ltd. (ZCC)

Founded in 1954, ZCC is one of China's oldest and largest carbide manufacturers. With an annual output exceeding 8,000 tons, the company produces a comprehensive range of tungsten powder, cutting tools, mining tools, and rods. ZCC is renowned for its strong R&D capabilities, advanced production technology, and global distribution network.

3. Zigong Cemented Carbide Group Co., Ltd. (ZGCC)

Established in 1965, ZGCC specializes in tungsten powder, mining tools, wear parts, and rods. The company has a solid reputation for producing high-quality carbide mining strips and other carbide components for demanding applications. ZGCC's products are widely used in mining, construction, and manufacturing industries worldwide.

4. Xiamen Golden Egret Special Alloy Co., Ltd. (GESAC)

GESAC, founded in 1989, is a leader in the production of tungsten carbide rods, mining tools, and wear parts. The company is recognized for its high-quality alloys, innovative R&D, and commitment to environmental sustainability. GESAC supplies carbide mining strips to customers in over 50 countries.

5. OKE Precision Cutting Tools Co., Ltd.

OKE specializes in cemented carbide and CNC cutting tool products. Since its establishment in 1996, the company has focused on precision tools for mining and metalworking. OKE's carbide mining strips are valued for their dimensional accuracy, strength, and adaptability to various mining and construction environments.

6. CY CARBIDE MFG. CO., LTD. (CYC)

Founded in 2003, CYC produces tungsten carbide products for mining, construction, oil & gas, and other industries. The company is known for its RTP powders and custom carbide solutions, offering a wide range of grades and shapes to suit specific customer requirements.

7. Penglai Ultra-rigid Composite Material Co., Ltd.

Penglai Ultra-rigid specializes in carbide roller rings, nano-carbide tools, and shield tools. Established in 2002, the company focuses on high-performance and large-grain carbide products for mining and heavy industry. Penglai's products are designed to deliver superior wear resistance and longevity.

8. Zhejiang Dewei Cemented Carbide Manufacturing Co., Ltd.

Dewei, founded in 2001, offers carbide rods, blanks, inserts, and customized solutions for mining and industrial applications. The company emphasizes premium raw material sourcing and advanced manufacturing techniques to ensure consistent quality and performance.

9. Zhuzhou Jinggong Cemented Carbide Co., Ltd.

Zhuzhou Jinggong, established in 2003, specializes in non-standard carbide products for mining, including rods, mining tools, cutting tips, and saw tips. The company is known for its flexibility, rapid prototyping, and ability to fulfill complex custom orders.

10. Jinan Institute of Metallurgical Science Co., Ltd.

Founded in 1991, this institute is a leader in the development and production of solid cemented carbide rods, TBM carbide, and mining inserts. With a strong focus on R&D and innovation, Jinan Institute supplies advanced carbide solutions to mining and coal-cutting tool manufacturers worldwide.

Key Features of Quality Carbide Mining Strips

| Feature | Description |

| Hardness | HV 1600+ for maximum wear resistance |

| Toughness | Withstands impact and heavy loads |

| Customization | Available in various grades (YG6, YG8, YG15, etc.) and dimensions |

| Corrosion Resistance | Nickel alloy binders for harsh environments |

| Precision | Manufactured to tight tolerances for industrial applications |

Quality carbide mining strips are distinguished by their ability to maintain sharpness and structural integrity under continuous stress. The choice of binder, grain size, and sintering process all play critical roles in determining the final properties of the strip. Leading manufacturers use advanced powder metallurgy techniques and strict quality control to ensure every strip meets the highest standards.

Applications of Carbide Mining Strips

Carbide mining strips are used in:

- Mining tools: Drilling, cutting, crushing, and excavation

- Construction equipment: Chisels, hammers, and wear plates

- Metalworking: Cutting and machining tools

- Oil and gas drilling: Wear-resistant components

- Woodworking: Cutting, shaping, and smoothing tools

- Industrial machinery: High-wear parts and protective surfaces

Their exceptional hardness and resistance to deformation make carbide mining strips ideal for high-impact, high-abrasion environments. In mining, they are often used as inserts in drill bits and cutting heads, where they significantly extend tool life and reduce downtime. In construction and metalworking, carbide strips are used to manufacture blades, knives, and wear parts that must operate reliably under tough conditions.

Manufacturing Process: From Powder to Precision Tool

The production of carbide mining strips involves several precise steps:

1. Powder Preparation: High-purity tungsten powder is mixed with a cobalt binder.

2. Spray Drying: The mixture is dried into uniform granules.

3. Pressing: The powder is pressed into strip shapes using molds or extrusion.

4. Sintering: Strips are heated at over 1,400°C to fuse tungsten particles and form a dense, hard structure.

5. Grinding and Polishing: Achieves exact dimensions and smooth surfaces, ensuring compatibility with end-use applications.

6. Inspection: Each strip undergoes rigorous quality checks for hardness, dimensions, and surface finish.

Advanced sintering techniques and precision grinding ensure that every strip meets the demanding requirements of modern mining and industrial operations. Manufacturers often offer additional services such as surface coating and custom packaging to meet specific customer needs.

How to Source Carbide Mining Strips from China

Sourcing carbide mining strips from China can be highly advantageous if approached strategically. Here are some practical tips:

- Identify reputable manufacturers: Focus on companies with proven track records, international certifications, and positive customer feedback.

- Request samples: Evaluate the quality, consistency, and performance of the strips before placing large orders.

- Clarify customization options: Communicate your specific requirements regarding grades, sizes, and tolerances.

- Negotiate terms: Discuss pricing, lead times, minimum order quantities, and after-sales support.

- Visit factories (if possible): On-site visits can help verify production capabilities and quality control processes.

- Leverage OEM services: Many Chinese manufacturers offer private labeling, custom packaging, and design assistance for international brands.

By following these steps, buyers can establish reliable partnerships with leading carbide mining strips manufacturers and suppliers in China, ensuring a steady supply of high-quality products.

Trends and Innovations in Carbide Mining Strips

The carbide mining strips industry is constantly evolving, with manufacturers investing in R&D to develop new materials and production techniques. Some notable trends include:

- Nano-grain carbide: Improved wear resistance and toughness through finer grain structures.

- Enhanced binders: New binder formulations for increased corrosion resistance and strength.

- Recycling and sustainability: Greater use of recycled tungsten and eco-friendly production methods.

- Digital manufacturing: Adoption of automation, robotics, and data analytics for higher efficiency and consistency.

- Surface coatings: Application of advanced coatings (such as TiN or diamond-like carbon) to further enhance strip performance in extreme environments.

These innovations are driving the industry forward, enabling carbide mining strips manufacturers and suppliers to deliver products that meet the ever-increasing demands of global mining and industrial sectors.

Quality Control and Certifications

Quality assurance is a top priority for leading Chinese carbide mining strips manufacturers and suppliers. Key aspects include:

- Raw material inspection: Only high-purity tungsten and cobalt are used.

- In-process monitoring: Automated systems track critical parameters during pressing, sintering, and grinding.

- Final inspection: Each strip is tested for hardness, density, dimensions, and surface finish.

- Certifications: Most top manufacturers hold ISO 9001 and other relevant certifications, demonstrating their commitment to consistent quality and continuous improvement.

Buyers should always request documentation and, if possible, third-party inspection reports to verify product quality before shipment.

Conclusion

China's carbide mining strips manufacturers and suppliers are at the forefront of the global market, offering high-quality, durable, and customizable solutions for demanding industrial applications. ZUNYI ZHONGBO CEMENTED CARBIDE CO., LTD. stands out for its innovation, quality control, and global reach, making it the top choice for international buyers seeking reliable OEM partners. By understanding the capabilities and strengths of each leading manufacturer, buyers can make informed decisions to enhance their operations with superior carbide mining strips. As the industry continues to innovate, sourcing from China will remain a strategic advantage for brands, wholesalers, and manufacturers worldwide.

FAQ: Carbide Mining Strips Manufacturers and Suppliers

1. What are the main applications of carbide mining strips?

Carbide mining strips are primarily used in mining, construction, metalworking, oil and gas drilling, woodworking, and industrial machinery due to their hardness and wear resistance.

2. How do I choose the right carbide mining strips manufacturer?

Consider factors such as production capacity, quality certifications, customization options, export experience, and customer reviews when selecting a manufacturer.

3. What grades of tungsten carbide are commonly used for mining strips?

Common grades include YG6, YG8, YG15, and YG20, each offering different balances of hardness, toughness, and wear resistance for specific applications.

4. How are carbide mining strips manufactured?

The process involves powder preparation, pressing, sintering, and precision grinding to achieve the desired hardness and dimensions. Advanced techniques ensure consistent quality.

5. Are Chinese carbide mining strips manufacturers reliable for OEM services?

Yes, leading Chinese manufacturers offer robust OEM services, strict quality control, and global support, making them reliable partners for international brands and wholesalers.