Contentus menu

● Introductio ad Tungsten Carbide

● Proprietatibus Tungsten carbide

● Applications of Tungsten Carbide

● Factores contribuens ad crepuit in Tungsten carbide

>> Scelerisque accentus

>> Mechanica accentus

>> Material Defectiones

>> Corrosio

>> Labes

● Crack propagationem in Tungsten Carbide

● Menses ad imperium et ne fregisset

>> Material Electio

>> Design Optimization

>> Superficiem curatio

>> Processus imperium

>> Operating conditionibus

● Conclusio

● Faq

>> I. Est Tungsten carbide fragile?

>> II. Potest Tungsten carbide sit conflatis?

>> III. Quomodo temperatus afficiunt Tungsten carbide?

>> IV. Quid est typicam lifespan of Tungsten carbide components?

>> V. Potest findatur Tungsten carbide reparari?

● Citations:

Tungsten carbide celebratur ad eius eximia duritia, gerunt resistentia, et excelsum liquescens punctum, faciens illud anguli in materia in diverse industrias. Ex cutting instrumenta quae figura mundus circum nos ad induendum partes qui pati rancidum abrasione, Tungsten carbide stat quasi testamentum ad humana ingenii. Tamen, sicut aliqua materia subiecta ad rigor of realis-mundus applications, quod est susceptibilis ad crepuit in specifica conditionibus. Hic articuli DELING in intricacia in Tungsten carbide, explorat factores conferre ad suum eventum, scrutandis suis applications et outlining ad praeveni Crack propagationum, ex hoc quoddam magnificentiam et reliability components ex hoc mirabilem materia.

Introductio ad Tungsten Carbide

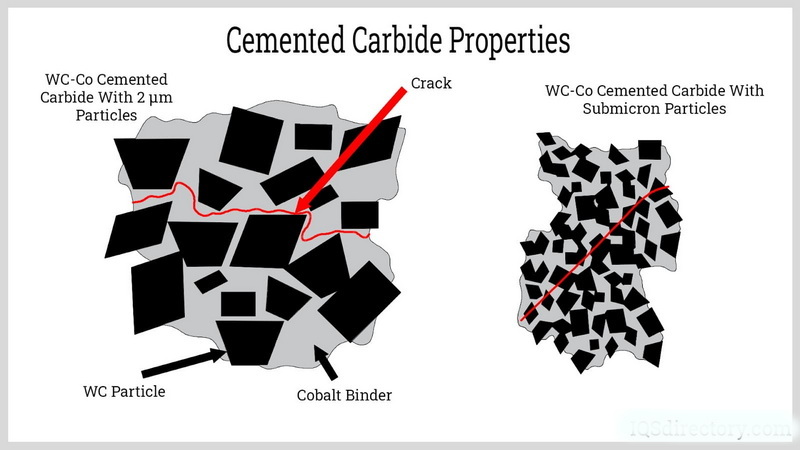

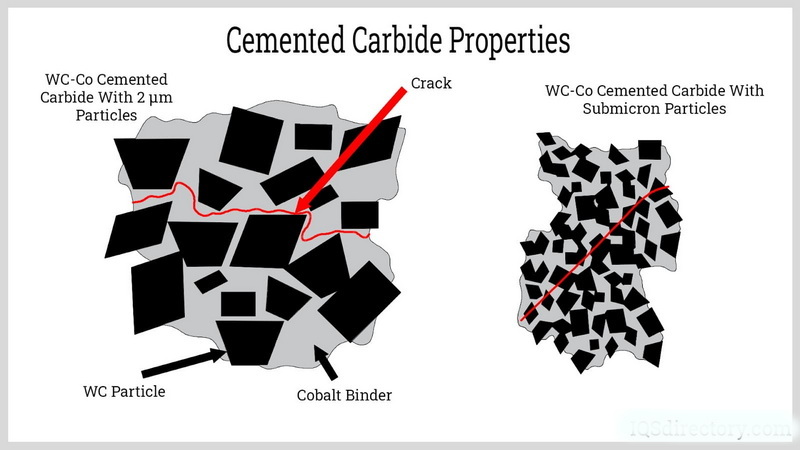

Tungsten Carbide (WC) est chemical compositis constans ex paribus Tungsten et ipsum. Est ut difficile, fragilis materia quaedam excelsum liquescens punctum (2,870 ° C) et eximia gerunt resistentia. Tungsten carbide est communiter usus est in forma cemented carbides, ubi wc grana sunt in unum per metallicis ligans, typice Cobalt. Hoc Synergistic combination cedit a materia cum princeps duritia, vires, et lenta, faciens eminenter idoneam postulantes applications per spectro de industrias.

Proprietatibus Tungsten carbide

Tungsten carbide habet unique confluentes proprietatibus, quae reddere eam indispensibile pro late ordinata applications:

- High Durness: Tungsten Carbide regnat in Mohs scale de duritia, typice perscriptum inter 9,0 et 9.5, ita cementing suo situ ut unus de durissima materiae nota est hominibus.

- Gerunt resistentia: Exhibits uniceed resistentia ad abrasion, exhibet, et alias formas gerunt, ensuring a diuturna muneris vitae usque in maxime puniendo ambitus.

- Altum liquescens Point: Cum a Point Soaring ad 2,870 ° C, Tungsten carbide potest sustinere extrema temperaturis sine succumbendo deformatio vel damnum virtutis, ita enabling usum in altum temperatus applications.

- compressive fortitudo: Tungsten Carbide gloriatus eximia compressive viribus, enabling eam ad pati substantial onerat sine deformatione vel structural defectum.

- Pubur conductivity: quod habet commendabilem scelerisque conductivity, facilius efficiens calor dissipatio in altum temperatus applications, ita prohibere overheating et scelerisque damnum.

- Chemical inertness: Tungsten Carbide exhibet insignis resistentia ad lata spectro ex eget profectae, reddendo idoneam ad deployment in mordendo environments in aliis materiae esset cito.

Applications of Tungsten Carbide

Tungsten carbide invenit extensive applicationem per millia de industries, propter eius eximia proprietatibus et versatility:

- Cutting Tools: Non est extensive in cutting instrumenta pro machining, EXERCITATIO, et milling operationes, ubi duritiam et gerunt resistentia ut efficiens materiam remotionem et reducendo downty.

- Gerunt partes: Tungsten carbide components sunt necessaria in applications postulantes princeps gerunt resistentia, ut nozzles, gestus et moritur, ubi sustinere constans abrasione et exesa, ensuring certa perficientur et extenditur et ensuring in vita et extenditur et ensuring ad resistent et extenditur servitium vitae.

- Drilling and Mining: It is utilized in drill bits and other tools for boring through formidable materials such as rock and concrete, enabling efficient excavation and resource extraction in the mining and construction industries.

- Automotive: Tungsten Carbide invenit Application in Engine partes, TurbocharGRers, et braking systems, ubi gerunt resistentia et summus temperatus vires contribuere ad auctum perficientur, diuturnitatem et cibus efficientiam.

- Medical: Non est usus in manu orgismate, radialis protulit et implantatorum, propter eius diuturnitatem, corrosio resistentia, et biocompatibility, cursus et salus et efficaciam medicinae ratio et cogitationes.

- Jewelry: Tungsten carbide scriptor duritiam et scalpere resistentia facere a popularibus materia pro annulos et alia jewelry items, offering permanens pulchritudinem et resistentia ad cotidiana gerunt et lacrimam.

- Aerospace, quod est in aerospace industria pro componentium requiring princeps vires et gerunt resistentia, cursus reliability et salus aircraft et spatii operating in extrema conditiones.

- constructione: Tungsten carbide est communiter in constructione materiae ut vidit et terebro bits quod est fere unbreakable, permittens operarios ad praestare difficile jobs absque damnosa instrumenta.

Factores contribuens ad crepuit in Tungsten carbide

Quamvis eius eximia proprietatibus, Tungsten carbide non immunes ad crepuit in certa circumstantiis. Complures factores potest conferre ad initiationem et propagationem rimas in hac materia:

Scelerisque accentus

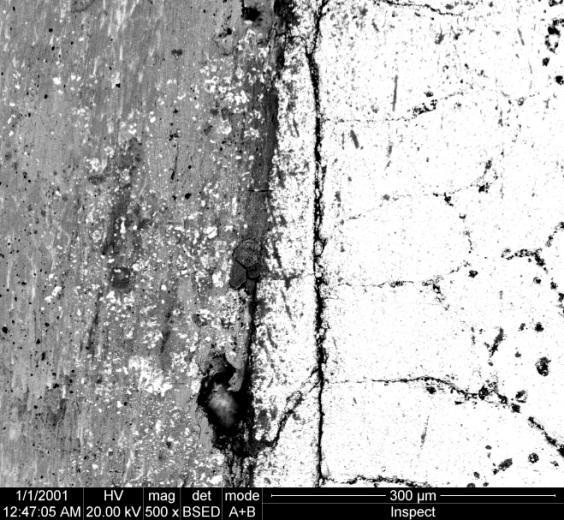

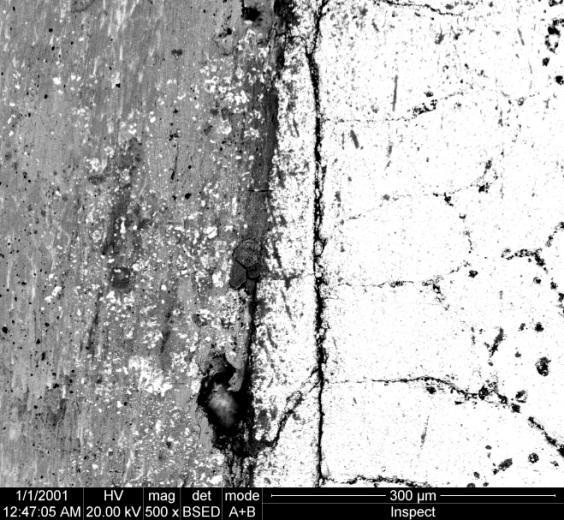

Tungsten Carbide Roll Annulorum sunt vulnerable ad calidum rimas per calidum volubilem processibus. Propagationem horum calidum rimas non solum in refrigerationem effectus sed etiam in proprietatibus advolvit materia. Per calidum volubilem, in superficiem temperatus de volumine anulus escalates propter contactus cum calidum-advolvit pars, causando superficiem metallum ad expand, dum metallum in altius stratis experitur a minor temperatus incremento. Hoc temperatus gradiente engenders compressive accentus super superficiem. Vice versa, cum superficies rotulo anulum exstinguere a refrigerationem aqua, superficies metallum contrahit, inducens distrahentes lacus. Et iterum alternation inter scelerisque accentus et refrigerationem potest causare calor lassitudine animos et micro-rimas ad imo in volumine circulum sulcus.

Mechanica accentus

High mechanica onerat et impulsum viribus potest initiatos rimas in Tungsten carbide components. Haec passes ut ex machinans operationes, servitium onerat, aut accidentales impingit. In conspectu accentus concentrationes, ut acuti angulos et notches, potest exacerbate crack initiation. Subito impingit vel nimia pressura potest creare accentus fracturae, ducens ad rimas, quae compromissis structural integritas materiae.

Material Defectiones

Inhomogeneities, Porosity, aut inclusions in Tungsten carbide materia potest agere ut crack initiation sites. Haec defectus ut oriri per vestibulum processus et infirmat materia scriptor resistentia ad crepuit. Vacuas, impudicitities, aut inaequalis distribution de ligans tempus potest creare infirma puncta in materia, faciens illud magis susceptibilis ad crack formation.

Corrosio

Crassus environments potest promote crack initiation et propagationem in Tungsten carbide. Chemical impetum in materia superficiem potest creare superficiem defectibus, quae agere ut accentus concentrators et facilitate resiliunt augmentum. Patefacio ut acida, alkalis, vel alias mordax substantiae potest ducere ad superficiem degradation, debilitam materiam et augendae eius suscipit ut elit.

Labes

Cyclic loading potest ducere lassitudinem fregisset in Tungsten carbide components. Repetita applicationem de accentus, etiam ad gradus infra materiam scriptor tensile viribus, potest facere microscopicis rimas ad formam et paulatim crescere in tempore. Per tempus, haec micro-rimas potest coalescere et propagare, eventually ducens ad calamitosas defectum de component.

Crack propagationem in Tungsten Carbide

Crack propagationem in Tungsten carbide entails extensio existentium rimas per materiam. In rate of resiliunt propagationem pendent pluribus factoribus, comprehendo applicantur accentus, materia microctructure et environmental conditionibus. Fere, Crack propagatione in Tungsten carbide est fragile, implicat, quae rimas tendunt ad crescere cursim et calamitosas sine significant plastic deformatio. Absentia significant plastic deformatio significat rimas propagare celeriter et unpredictably, ducens ad repentinum defectum ad component.

Menses ad imperium et ne fregisset

Plures mensuras potest implemented ad control et ne fregisset in Tungsten carbide components, ita enhancing eorum reliability et Vivacitas:

Material Electio

Discriptis convenientem gradu de Tungsten carbide in propria application est paramunt. Factors ad considerandum includit in ligans contentus, frumenti mole, et duritiam materiae. Nam applications involving altum accentus vel impulsum, opting ad gradus cum altius lenta et fractura resistentia est imperative. Electio autem ligans materiale, ut Cobalt, nickel, aut ferrum, potest etiam influere in materia scriptor resistentia ad crepuit.

Design Optimization

Designing components cum lenis transitionum, largitus radii et minimal accentus concentratione potest secundum substantiam reducere periculum crack initiation. Avoiding acuti angulos, notches et alia geometrica features quod potest agere ut accentus orts est. Rotundatis oras et gradual transitibus in Geometria potest auxilium distribute accentus magis aequaliter, obscuratis verisimilitudo ex Crack formation.

Superficiem curatio

Applicando compressive RELICTUM Summa ad superficiem Tungsten Carbide components potest bolster eorum resistentia ad crepuit. Superficiem treatments ut exortum Peening et laser Peening potest inducere compressive passiones, quod contra tensile passiones et inhibere crack incrementum. Haec treatments creare superficiem accumsan quod est magis resistens ad crack initiation et propagationem.

Processus imperium

Meticulose imperium vestibulum processus, ut peccare et machining, potest minimize introductio materialis defectus. Cucumque uniformis density, minimizing porosity, et avertens superficies damnum durante machining sunt essentialis pro prohibitione crack initiation. Diligenter diligenter ad processum parametri ut temperatus, pressura et refrigerationem rates potest auxilium minimize formationem defectus et ensure consistent material qualitas.

Operating conditionibus

Devitantes nimia onera, impingit et scelerisque passiones in ministerium potest longum lifespan of Tungsten carbide components. Exsequendum proprietatem refrigerationem artes, lubricatae et sustentacionem exercitia potest etiam in periculo inpendio. Ordinarius inspectionem et sustentationem potest auxilium identify et oratio potential proventus ante se escalate in discrimine defectis.

Conclusio

Tungsten carbide, cum insigni proprietatibus et versatility, manet in angulatum materia in variis industries. Dum gloriantur eximia duritia et gerunt resistentia, non immune ad crepuit in quibusdam conditionibus. By understanding the factors that contribute to cracking, such as thermal stress, mechanical stress, material defects, corrosion, and fatigue, and implementing measures to control and prevent crack propagation, engineers and manufacturers can ensure the longevity and reliability of tungsten carbide components. Selectionem diligenter, consilio optimization, superficiem curatio, processus imperium, et adhaesionem ad propriis operating conditionibus sunt crucial pro mitigating periculo fregisset et maximizing in perficientur of Tungsten carbide in postulantes applications. Sicut technology progreditur et novum applications emerge, continua investigationis et progressionem nisus erit porro augendae intellectus et utendo Tungsten carbide, solidifeling in situ ut a materia electionis in discrimine components per a wide spectro de industria.

Faq

I. Est Tungsten carbide fragile?

Etiam, Tungsten carbide est plerumque considerari in fragilis materia, quae significat quod habet tendentia ad fractura vel crack magis quam deforme plastically sub accentus. Hoc fragtileness est unum de factoribus, qui potest contribuere ad eius susceptibilitatem ad crepuit.

II. Potest Tungsten carbide sit conflatis?

Welding Tungsten carbide est complex processus ex eius princeps liquescens punctum et fragtissime. Special Welding ars, ut laser welding aut brazing, potest ad iungere Tungsten carbide ad alias materiae, sed ex iuncturam potest esse susceptibilis ad crepuit.

III. Quomodo temperatus afficiunt Tungsten carbide?

Tungsten carbide retinet duritiam et vires ad altum temperaturis, faciens idoneam summus temperatus applications. Tamen, celeri temperatus mutat vel scelerisque cycling potest inducere scelerisque passiones, quae potest ducere ad crepuit, praesertim si materia non recte disposito vel fabricari.

IV. Quid est typicam lifespan of Tungsten carbide components?

Et lifespan of Tungsten carbide components variat fretus applicationem, operating conditionibus et materiales. Cum propriis cura et sustentacionem, Tungsten carbide components potest novissimo per multos annos, etiam in postulantes ambitum. Tamen, factors ut nimia accentus, corrosio, aut lassitudine potest breviare eorum lifespan.

V. Potest findatur Tungsten carbide reparari?

Rescindens ramked Tungsten carbide est saepe provocantes debitum ad eius fragtilitatem et altum liquescens punctum. In quibusdam casibus, rimas potest reparari a Brazing vel usura specialized adhesives, sed reparari pars non habet idem vires et perficientur sicut originali. In multis casibus, repositoque in rumpitur pars est maxime reliable solution.

Citations:

[I] https://www.maxcarbide.com/info-detail/what-are-the-reages-for-the-cracks-of-the-tungsten-carbide-roll-roll-roll-roll

[II] https://en.wikipedia.org/wiki/tungsten_carbide

[III] https://www.samaterials.com/content/application-of-tungsten-in-modern-industry.html

[IV] https://carbideprocessors.com/pages/carbide-parts/crack-propogation.html

[V] https://www.itia.info/properties-intermetur

[VI] https://eurobalt.net/blog/2022/03/28/ALL-The-Application-Of-TungSten-carbide/

[VII] https://ggencarbide.com/pdf/general-carbide-designers-guide-tungsten-carbide.pdf

[VIII] http://www.tungsten-carbide.com.cn

[IX] https://www.tungco.com/insights/blog/5-tungsten-carbide-apply/

[X] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/