Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Comparison with Other Hard Materials

>> Diamond

>> Cubic Boron Nitride (CBN)

>> Silicon Carbide (SiC)

● Applications of Tungsten Carbide

● History of Tungsten Carbide

● Advancements in Production Techniques

● Future Trends in Tungsten Carbide Applications

● Environmental and Health Considerations

● Economic Impact of Tungsten Carbide

● Conclusion

● FAQs

>> 1. What is the hardness of tungsten carbide compared to diamond?

>> 2. How is tungsten carbide produced?

>> 3. What are the primary applications of tungsten carbide?

>> 4. Is tungsten carbide more expensive than pure tungsten?

>> 5. Can tungsten carbide be recycled?

● Citations:

Tungsten carbide is renowned for its exceptional hardness and durability, making it one of the most sought-after materials in various industrial applications. However, the question remains: is tungsten carbide the hardest material? In this article, we will delve into the properties of tungsten carbide, compare it with other hard materials, explore its applications, discuss its history, advancements in production techniques, and future trends.

Introduction to Tungsten Carbide

Tungsten carbide is a compound made from tungsten and carbon, with a chemical formula of WC. It is produced through a process known as powder metallurgy, where tungsten carbide powder is mixed with a binder, typically cobalt, and then sintered at high temperatures to form a solid composite.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide has a Mohs hardness of approximately 9 to 9.5, which is second only to diamond. Its hardness on the Rockwell A scale ranges from 89 to 95 HRA, corresponding to about 69 to 81 HRC.

- Density and Elastic Modulus: It has a density of about 15.6 to 15.8 g/cm³ and an elastic modulus of approximately 530–700 GPa, making it three times stiffer than steel.

- Thermal Properties: Tungsten carbide has a high melting point of 2,870°C and good thermal conductivity, allowing it to maintain its structural integrity under extreme temperatures.

Comparison with Other Hard Materials

Diamond

Diamond is the hardest known material, with a Mohs hardness of 10. It is used in cutting tools and jewelry due to its exceptional hardness and brilliance.

Cubic Boron Nitride (CBN)

CBN is another extremely hard material, often used in cutting tools for machining hard metals. It has a Mohs hardness slightly lower than diamond but is more stable at high temperatures.

Silicon Carbide (SiC)

Silicon carbide, also known as carborundum, is used in abrasives and as a semiconductor material. It has a Mohs hardness of about 9 to 10 but is less dense than tungsten carbide.

Applications of Tungsten Carbide

Tungsten carbide is widely used in various industries due to its hardness and wear resistance:

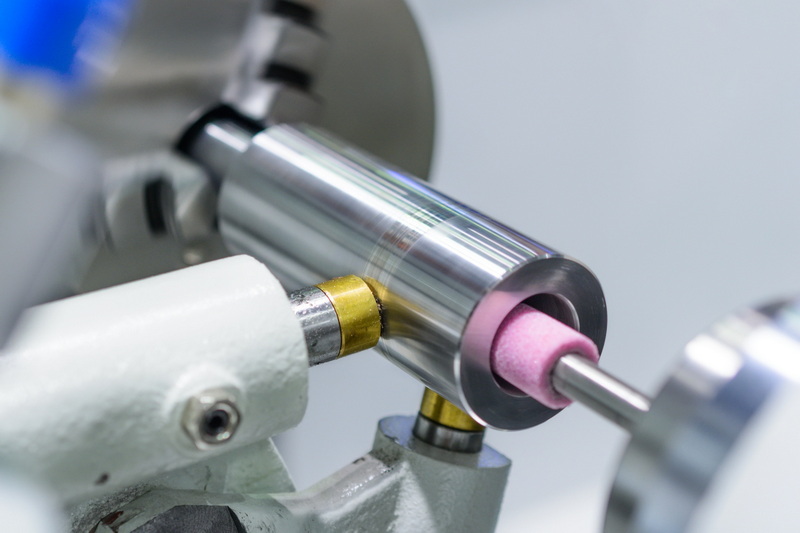

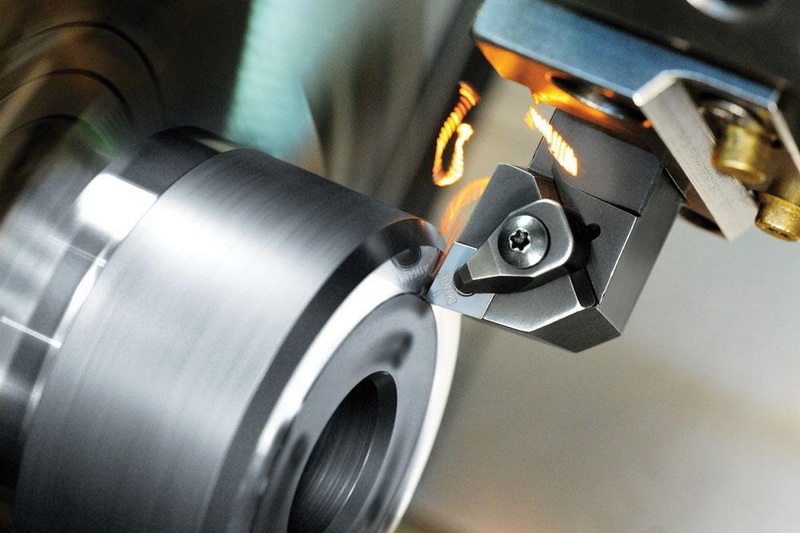

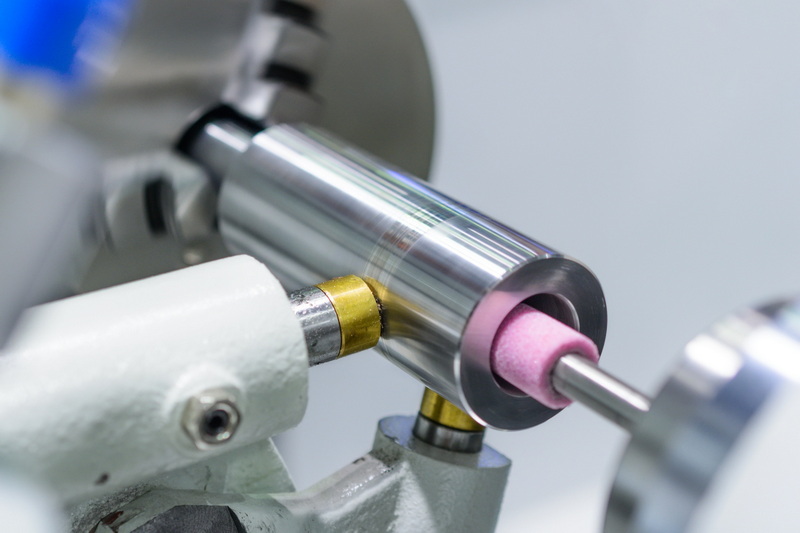

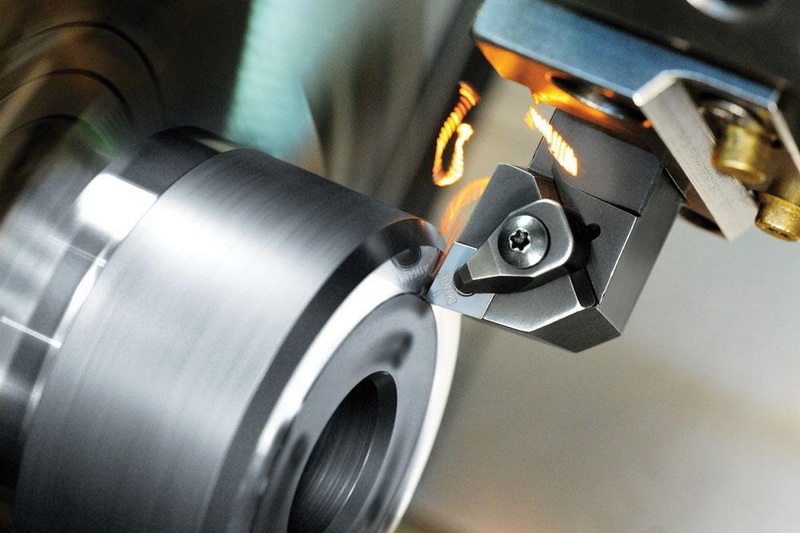

- Cutting Tools: It is used in carbide-tipped drill bits and saw blades for machining metals.

- Jewelry: Tungsten carbide rings are popular for their durability and scratch resistance.

- Aerospace and Defense: Used in armor-piercing ammunition and wear-resistant coatings for aircraft components.

- Oil and Gas: Protects drilling equipment from abrasive wear.

- Medical: Used in surgical instruments and implants due to its biocompatibility.

History of Tungsten Carbide

The development of tungsten carbide dates back to the early 20th century when it was first synthesized. Initially, it was used in cutting tools, but its applications expanded rapidly due to its superior properties. Over time, improvements in production techniques have made it more accessible and affordable for various industries.

Advancements in Production Techniques

Recent advancements in production techniques include the use of advanced sintering methods, such as hot isostatic pressing (HIP) and spark plasma sintering (SPS), which improve the density and uniformity of tungsten carbide products. Additionally, the development of new binders and additives has enhanced its mechanical properties.

Future Trends in Tungsten Carbide Applications

Future trends in tungsten carbide applications include its increased use in renewable energy technologies, such as wind turbines and solar panels, where its wear resistance can enhance component lifespan. Moreover, advancements in 3D printing technology may allow for more complex tungsten carbide structures to be produced, expanding its potential applications.

Environmental and Health Considerations

Tungsten carbide production involves the use of cobalt, which poses environmental and health risks. Efforts are being made to reduce cobalt content and develop more sustainable production methods. Additionally, tungsten carbide recycling is becoming increasingly important to conserve resources and minimize waste.

Economic Impact of Tungsten Carbide

The economic impact of tungsten carbide is significant, as it supports industries critical to global infrastructure and manufacturing. Its high cost is offset by its durability and performance, making it a valuable investment for many applications.

Conclusion

While tungsten carbide is not the hardest material, it is one of the most versatile and widely used due to its exceptional hardness, wear resistance, and durability. Its applications span from industrial cutting tools to consumer products like jewelry. As production techniques continue to advance and new applications emerge, tungsten carbide will remain a critical material in various industries.

FAQs

1. What is the hardness of tungsten carbide compared to diamond?

Tungsten carbide has a Mohs hardness of 9 to 9.5, which is second only to diamond's Mohs hardness of 10.

2. How is tungsten carbide produced?

Tungsten carbide is produced through a powder metallurgy process involving the sintering of tungsten carbide powder with a binder like cobalt.

3. What are the primary applications of tungsten carbide?

Tungsten carbide is used in cutting tools, jewelry, aerospace, and oil & gas industries due to its hardness and wear resistance.

4. Is tungsten carbide more expensive than pure tungsten?

Yes, tungsten carbide is more expensive due to its complex manufacturing process and enhanced properties.

5. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled, reducing waste and conserving resources.

Citations:

[1] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[2] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[3] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://www.alamy.com/stock-photo/tungsten-carbide.html

[6] https://www.refractorymetal.org/tungsten-carbide-uses-properties.html

[7] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[8] https://www.vedantu.com/chemistry/tungsten-carbide

[9] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[10] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[11] https://www.yatechmaterials.com/en/technology/hardness-of-tungsten-carbide/

[12] https://www.carbide-products.com/blog/hardness-of-tungsten-carbide/

[13] https://www.meadmetals.com/blog/what-are-the-strongest-metals

[14] https://www.imetra.com/tungsten-carbide-material-properties/

[15] https://testbook.com/question-answer/identify-the-hardest-metal--5c2505b3f78a043402418c88

[16] https://www.azom.com/properties.aspx?ArticleID=1203

[17] https://ewsllp.in/why-to-choose-tungsten-carbide-over-other-metals/

[18] https://www.ohiocarbonblank.com/metallic-materials/tungsten-carbide

[19] https://industrialmetalservice.com/metal-university/differentiating-tungsten-carbide-vs-steel-and-other-tooling/

[20] https://www.reddit.com/r/askscience/comments/f02z1/materials_science_question_why_does_an_extremely/

[21] https://www.azom.com/article.aspx?ArticleID=1203

[22] https://www.syalons.com/2024/07/08/silicon-carbide-vs-tungsten-carbide-wear-applications/

[23] https://www.azom.com/article.aspx?ArticleID=4827

[24] https://stock.adobe.com/search?k=tungsten+carbide

[25] https://www.istockphoto.com/photos/tungsten-carbide

[26] https://www.basiccarbide.com/tungsten-carbide-grade-chart/

[27] https://www.shutterstock.com/search/tungsten-metal

[28] https://www.shutterstock.com/search/tungsten

[29] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[30] https://supraindustries.com/uses-of-tungsten-carbide-burrs/

[31] https://stock.adobe.com/search?k=carbide

[32] http://www.chinatungsten.com/cutting-tools/grades-and-performance/hardness-comparison-table.html

[33] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[34] https://periodictable.com/Elements/074/pictures.html

[35] http://www.tungsten-carbide.com.cn/tungsten-carbide-hardness-conversion-table.html

[36] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[37] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/tungsten-carbide-grades-applications

[38] https://www.shutterstock.com/search/tungsten-carbide

[39] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[40] https://www.britannica.com/science/tungsten-carbide

[41] https://www.totalmateria.com/en-us/articles/tungsten-carbide-metals-1/

[42] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[43] https://www.zhongbocarbide.com/how-hard-is-tungsten-carbide-hrc.html

[44] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[45] https://grafhartmetall.com/en/the-advantages-of-tungsten-carbide-over-traditional-tools/

[46] https://www.linkedin.com/pulse/7-questions-tungsten-carbide-burrs-shijin-lei

[47] https://www.linkedin.com/pulse/3-questions-tungsten-carbide-buttons-shijin-lei

[48] https://testbook.com/question-answer/the-correct-sequence-in-increasing-hardness-of-too--5f7b06e358308f3eaca24ba0

[49] https://www.yatechmaterials.com/en/cemented-carbide-industry/answers-to-questions-about-the-use-of-tungsten-carbide-edm-blocks/

[50] http://www.carbidetechnologies.com/faqs/

[51] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[52] https://consolidatedresources.com/blog/10-facts-about-tungsten-carbide/

[53] https://tuncomfg.com/about/faq/

[54] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[55] https://www.ukowiretools.com/faq/

[56] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[57] https://www.linkedin.com/pulse/tungsten-vs-carbide-whats-difference-haijun-liu

[58] https://create.vista.com/photos/tungsten-carbide/

[59] https://www.linkedin.com/pulse/properties-tungsten-carbide-shijin-lei-1c

[60] https://rselectro.in/blog-description/5-tungsten-carbide-applications/9135

[61] https://www.tungstenman.com/tungsten-carbide-hardness.html

[62] https://www.thermalspray.com/questions-tungsten-carbide/

[63] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/