Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide Powder

● Safety Concerns and Explosivity

>> Respiratory Hazards

>> Explosive Risks

>> Interaction with Oxidizers

● Handling and Safety Precautions

● Applications of Tungsten Carbide Powder

● Environmental Impact

>> Mitigation Strategies

● Conclusion

● Frequently Asked Questions

>> 1. What are the health risks associated with tungsten carbide powder exposure?

>> 2. Is tungsten carbide powder explosive?

>> 3. How should tungsten carbide powder be stored?

>> 4. What safety equipment is recommended when handling tungsten carbide powder?

>> 5. Can tungsten carbide powder react with other substances?

● Citations:

Tungsten carbide powder is a highly versatile material known for its exceptional hardness and durability, making it a crucial component in various industrial applications, including cutting tools, wear-resistant parts, and even jewelry. However, its safety profile, particularly regarding explosivity, is a topic of interest due to its potential risks in certain conditions. This article delves into the properties of tungsten carbide powder, its potential hazards, and whether it can be considered explosive under specific circumstances.

Introduction to Tungsten Carbide

Tungsten carbide is a compound of tungsten and carbon, with the chemical formula WC. It is renowned for its high melting point, hardness, and resistance to corrosion, which makes it ideal for applications requiring high wear resistance and strength. Tungsten carbide is often mixed with other metals like cobalt to form cemented carbide, which enhances its toughness and allows it to be used in tools and machinery.

Properties of Tungsten Carbide Powder

- Hardness: Tungsten carbide is one of the hardest substances known, with a Mohs hardness of about 9, making it suitable for cutting and drilling operations.

- Density: It has a high density, typically ranging from 13 to 15 g/cm³, which is even higher than lead.

- Thermal Conductivity: Tungsten carbide has good thermal conductivity, which helps in dissipating heat during machining processes.

Safety Concerns and Explosivity

While tungsten carbide itself is not typically considered explosive, its powder form can pose risks under certain conditions. The primary concerns are related to its potential to cause respiratory issues and its reactivity with strong oxidizers.

Respiratory Hazards

Inhalation of tungsten carbide dust can lead to respiratory irritation, including coughing, wheezing, and shortness of breath. Chronic exposure may result in more severe lung conditions such as pulmonary fibrosis or "hard metal lung disease," especially if the powder contains other metals like cobalt or nickel[2][7].

Explosive Risks

Tungsten carbide powder is generally not explosive under normal conditions. However, finely divided tungsten carbide dust can become a fire or explosion hazard if it is exposed to high temperatures or strong ignition sources. The risk is heightened when the powder is dispersed in the air in high concentrations[2].

Interaction with Oxidizers

Tungsten carbide reacts violently with strong oxidizers, which can lead to fires or explosions. This reactivity is a significant concern during handling and storage.

Handling and Safety Precautions

To minimize risks associated with tungsten carbide powder, it is crucial to follow strict safety protocols:

- Personal Protective Equipment (PPE): Use gloves, safety goggles, and respiratory protection to prevent skin contact and inhalation[7].

- Ventilation: Ensure good ventilation in work areas to reduce dust accumulation.

- Storage: Store the powder in a cool, dry place away from strong oxidizers.

Applications of Tungsten Carbide Powder

Tungsten carbide powder is widely used in various industries due to its unique properties:

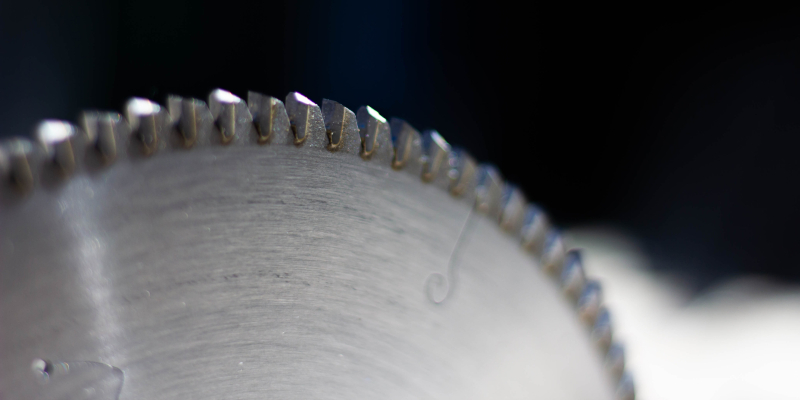

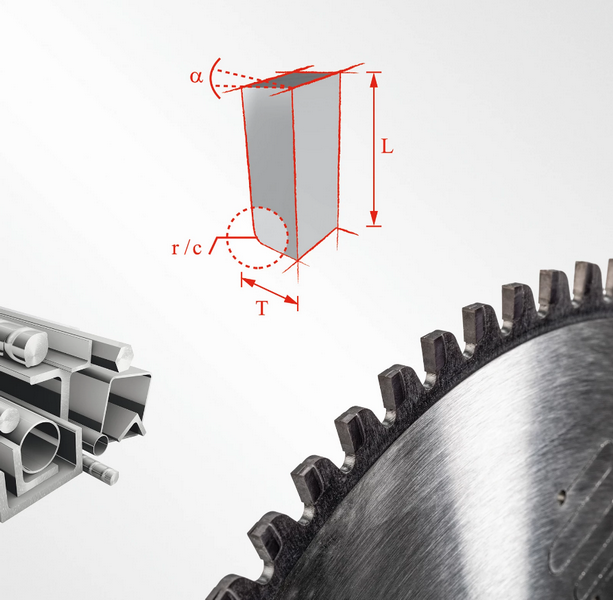

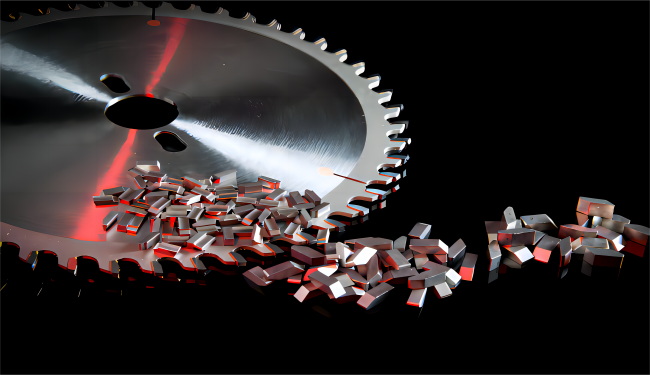

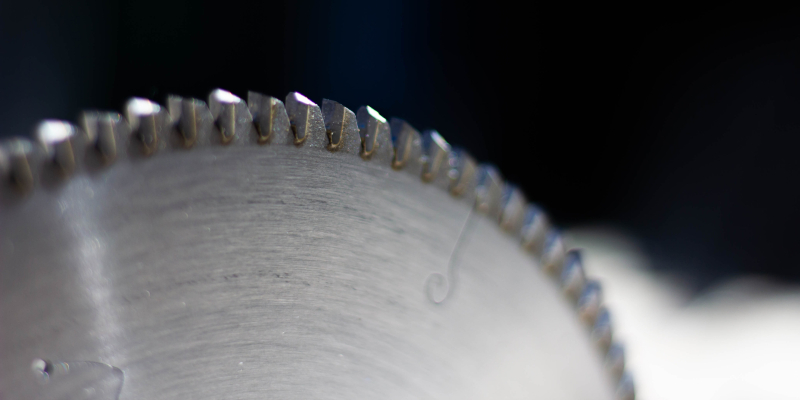

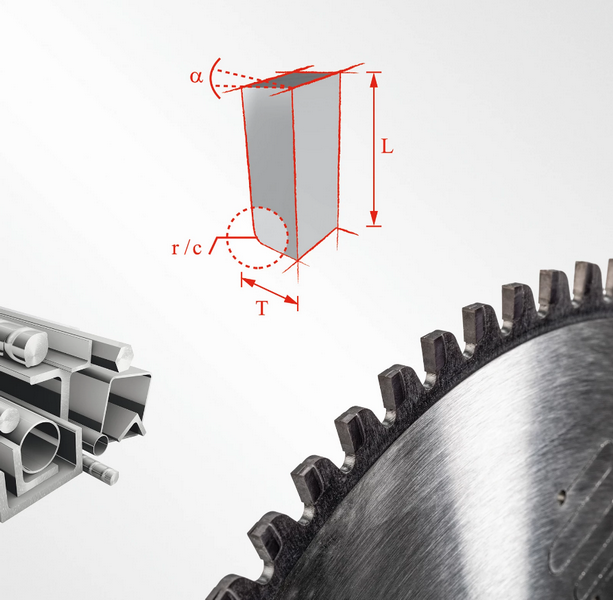

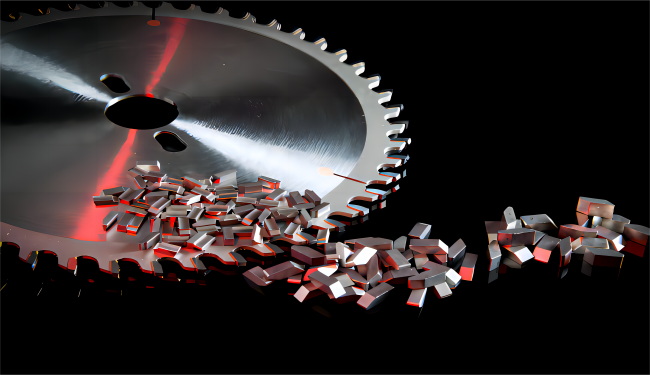

- Industrial and Manufacturing Sector: It is used in manufacturing cutting tools, wear-resistant components, and high-performance coatings. The material's hardness makes it ideal for creating cutting inserts used in metalworking, mining equipment, and oil drilling tools[1][6].

- Technology Industry: The semiconductor industry uses tungsten carbide for high-precision tools in circuit board drilling and electronic component manufacturing. Its electrical conductivity and wear performance make it valuable for producing specialized electrical contacts and switches[1].

- Aerospace and Automotive Sectors: Tungsten carbide is utilized in specialized coating applications for engine components and landing gear systems in aerospace, and in abrasion-resistant components and high-performance engine parts in automotive manufacturing[1].

- Energy Sector: It is used in components for power generation equipment and renewable energy systems, particularly in areas exposed to harsh environmental conditions or high mechanical stress[1].

Environmental Impact

The manufacturing process of tungsten carbide products, including seals and other components, contributes to environmental degradation through energy consumption and waste generation. Improper disposal can lead to water and soil pollution due to the presence of tungsten and other heavy metals[8].

Mitigation Strategies

To minimize the environmental impact, strategies such as investing in renewable energy sources, optimizing manufacturing processes, and implementing effective waste management practices are crucial. Additionally, exploring alternative materials and recycling tungsten carbide waste can help reduce the environmental footprint[8].

Conclusion

Tungsten carbide powder is not inherently explosive but can pose fire or explosion risks under specific conditions, such as high temperatures or strong ignition sources. It is essential to handle the powder with caution, adhering to safety guidelines to prevent accidents and health issues. By understanding the properties and potential hazards of tungsten carbide, industries can ensure safe and effective use of this valuable material.

Frequently Asked Questions

1. What are the health risks associated with tungsten carbide powder exposure?

Tungsten carbide powder exposure can cause respiratory irritation, skin allergies, and eye irritation. Chronic exposure may lead to severe lung conditions like pulmonary fibrosis[2][7].

2. Is tungsten carbide powder explosive?

Tungsten carbide powder is generally not explosive under normal conditions. However, finely divided dust can become a fire or explosion hazard under rare conditions with high temperatures or strong ignition sources[2].

3. How should tungsten carbide powder be stored?

Tungsten carbide powder should be stored in a cool, dry place away from strong oxidizers to prevent chemical reactions that could lead to fires or explosions.

4. What safety equipment is recommended when handling tungsten carbide powder?

Recommended safety equipment includes gloves, safety goggles, and respiratory protection to prevent skin contact and inhalation of dust[7].

5. Can tungsten carbide powder react with other substances?

Yes, tungsten carbide reacts violently with strong oxidizers, which can lead to fires or explosions. It is crucial to avoid contact with such substances during handling and storage[2].

Citations:

[1] https://www.linde-amt.com/resource-library/articles/tungsten-carbide-powder

[2] https://powder.samaterials.com/tds/sc/1733388175-DP1931.pdf

[3] https://pubmed.ncbi.nlm.nih.gov/16168748/

[4] https://cpcb.nic.in/displaypdf.php?id=aHdtZC9UdW5zZ3Rlbl9TY3JhcF9NZXRhbF9DdXR0aW5nXzEzLjA0LjE3LnBkZg%3D%3D

[5] http://www.tungsten-powder.com/National-Standard-of-Tungsten-Carbide-Powder.html

[6] http://tungsten-powder.com/what-are-applications-of-tungsten-carbide-powder.html

[7] https://www.safetyandhealthmagazine.com/articles/work-safely-with-tungsten-carbide-2

[8] https://www.lepuseal.com/a-news-the-environmental-impact-of-tungsten-carbide-seals-in-industrial-processes

[9] https://www.rocktechnology.sandvik/siteassets/general-documents/download-center/sis/sis-english-composition-203us-r2.pdf

[10] https://www.hyperionmt.com/en/products/Ready-to-Press-Powders/standard-carbide-powder-grades/

[11] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/use.html

[12] https://int-enviroguard.com/blog/tungsten-carbide-exposure-are-your-workers-at-risk/

[13] https://www.itia.info/health-environment/

[14] https://bionium.miami.edu/_assets/pdf/msds/tungsten.pdf

[15] https://www.stanfordmaterials.com/Tungsten-Carbide-Powder.html

[16] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[17] https://nj.gov/health/eoh/rtkweb/documents/fs/1960.pdf

[18] https://19january2017snapshot.epa.gov/sites/production/files/2014-03/documents/ffrrofactsheet_contaminant_tungsten_january2014_final.pdf

[19] https://dtsc.ca.gov/wp-content/uploads/sites/31/DORY/TUNGSTEN-CARBIDE-TULON-COMPANY.pdf

[20] https://www.lgcstandards.com/GB/en/Tungsten-carbide-powder/p/ECRM-B%20783-1