Content Menu

● Introduction to Tungsten Carbide

>> Physical Properties

● Electrical Conductivity of Tungsten Carbide

>> Comparison with Other Materials

● Applications of Tungsten Carbide

>> Advanced Applications

● Manufacturing Process

>> Role of Binders

● Challenges and Future Developments

>> Environmental Impact

● Conclusion

● FAQs

>> 1. Is Tungsten Carbide Conductive?

>> 2. How Does Tungsten Carbide Compare to Copper in Conductivity?

>> 3. Why Is Tungsten Carbide Used in Cutting Tools?

>> 4. Is Tungsten Carbide Jewelry Conductive?

>> 5. What Affects the Conductivity of Tungsten Carbide?

● Citations:

Tungsten carbide is a compound made of tungsten and carbon, known for its exceptional hardness and wear resistance. It is widely used in industrial applications, including cutting tools, mining equipment, and wear parts. However, when it comes to electrical conductivity, tungsten carbide behaves differently from pure metals. This article will delve into the electrical properties of tungsten carbide, exploring whether it is non-conductive and its applications in various fields.

Introduction to Tungsten Carbide

Tungsten carbide, with the chemical formula WC, is a carbide compound that combines tungsten and carbon atoms. It is renowned for its high melting point, hardness, and resistance to corrosion and wear. These properties make it an ideal material for manufacturing tools and machinery components that require durability and precision.

Physical Properties

- Hardness: Tungsten carbide ranks between 9.0 and 9.5 on the Mohs scale, making it one of the hardest materials known, second only to diamond.

- Thermal Conductivity: It has a thermal conductivity of about 110 W/(m·K), which is higher than many metals but lower than copper.

- Density: The density of tungsten carbide is approximately 15.7 g/cm³, which is significantly higher than most metals.

Electrical Conductivity of Tungsten Carbide

Tungsten carbide is not a free-electron conductor like metals. Instead, its electrical conductivity is achieved through a "jump" mechanism, where electrons move from one location to another within its lattice structure. This mechanism allows tungsten carbide to conduct electricity, albeit not as efficiently as metals like copper or silver.

Comparison with Other Materials

- Copper: Copper is one of the best electrical conductors, with a conductivity much higher than tungsten carbide.

- Tool Steel and Carbon Steel: Tungsten carbide's electrical conductivity is comparable to these materials, making it suitable for applications where moderate conductivity is required.

Applications of Tungsten Carbide

Despite its limited electrical conductivity, tungsten carbide is used in various applications due to its other beneficial properties:

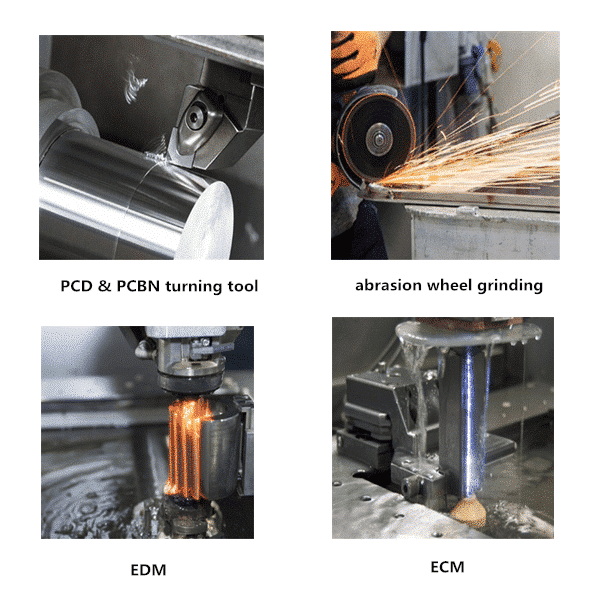

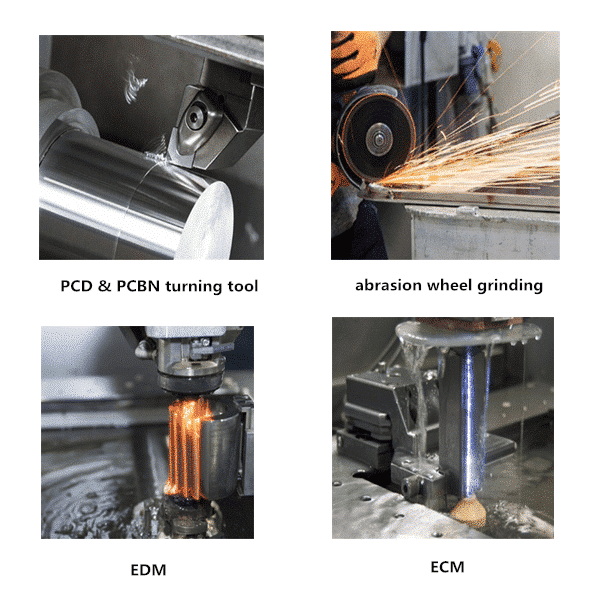

1. Cutting Tools: Its hardness and wear resistance make it ideal for manufacturing cutting tools used in machining metals and other hard materials.

2. Mining Equipment: Tungsten carbide is used in drill bits and other mining tools due to its durability under extreme conditions.

3. Jewelry: Tungsten carbide rings are popular for their scratch resistance and modern aesthetic. However, in jewelry form, tungsten carbide is often less conductive due to its ceramic-like structure.

4. Industrial Machinery: Components made from tungsten carbide are used in machinery that requires high precision and durability.

5. Aerospace Industry: Tungsten carbide is used in rocket nozzles and other components that require high thermal resistance and durability.

Advanced Applications

In recent years, tungsten carbide has been explored for use in advanced technologies, such as:

- Nuclear Applications: Due to its high density and neutron absorption properties, tungsten carbide is considered for use in nuclear reactors.

- Wear-Resistant Coatings: Tungsten carbide coatings are applied to surfaces to enhance wear resistance in high-friction environments.

Manufacturing Process

The manufacturing process of tungsten carbide involves several steps:

1. Powder Production: Tungsten and carbon powders are mixed and processed into a uniform compound.

2. Sintering: The powder mixture is then sintered at high temperatures to form a solid structure.

3. Binder Addition: A binder, often cobalt, is added to improve the mechanical properties and conductivity of the final product.

Role of Binders

Binders like cobalt play a crucial role in enhancing the conductivity of tungsten carbide. The amount of cobalt can significantly affect the final product's electrical properties, making it more conductive than pure tungsten carbide.

Challenges and Future Developments

Despite its advantages, tungsten carbide faces challenges in certain applications due to its limited conductivity. Researchers are exploring ways to enhance its conductivity while maintaining its hardness and wear resistance. This includes developing new binder materials and optimizing the sintering process.

Environmental Impact

The production of tungsten carbide can have environmental implications, particularly related to tungsten mining. Efforts are being made to improve sustainability in the supply chain and reduce waste during manufacturing.

Conclusion

Tungsten carbide is not entirely non-conductive; it exhibits electrical conductivity, though not as high as metals like copper. Its unique properties make it invaluable in various industrial applications where hardness and wear resistance are crucial. However, in forms like jewelry, its conductivity is significantly reduced.

FAQs

Here are some frequently asked questions about tungsten carbide's conductivity:

1. Is Tungsten Carbide Conductive?

Yes, tungsten carbide is conductive, but its conductivity is lower than that of metals like copper. It conducts electricity through a "jump" mechanism rather than free-electron conduction.

2. How Does Tungsten Carbide Compare to Copper in Conductivity?

Tungsten carbide's conductivity is significantly lower than copper's. While copper is one of the best conductors, tungsten carbide's conductivity is more comparable to tool steel and carbon steel.

3. Why Is Tungsten Carbide Used in Cutting Tools?

Tungsten carbide is used in cutting tools due to its exceptional hardness and wear resistance, which allow tools to last longer and maintain their cutting efficiency.

4. Is Tungsten Carbide Jewelry Conductive?

Tungsten carbide jewelry is generally non-conductive due to its ceramic-like structure. This property makes it safe for use in environments where electrical hazards are present.

5. What Affects the Conductivity of Tungsten Carbide?

The conductivity of tungsten carbide can be influenced by its composition, particularly the amount of cobalt in the binder phase. Higher cobalt content tends to increase its conductivity.

Citations:

[1] https://www.ls-carbide.com/news/Is-tungsten-carbide-electrically-conductive-.htm

[2] https://www.linkedin.com/pulse/properties-tungsten-carbide-shijin-lei-2c

[3] https://www.alamy.com/stock-photo/tungsten-carbide.html

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://create.vista.com/photos/tungsten-carbide/

[6] https://onlytungstenrings.com/is-tungsten-carbide-conductive/

[7] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[8] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide?page=2

[9] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[10] https://shop.machinemfg.com/does-tungsten-conduct-electricity-key-facts-and-insights/

[11] https://www.ipsceramics.com/technical-ceramics/tungsten-carbide/

[12] https://www.zhongbocarbide.com/is-tungsten-carbide-conductive.html

[13] https://www.sollex.se/en/blog/post/tungsten-carbide-and-technology-part-2

[14] https://pubs.acs.org/doi/10.1021/acsapm.4c01143

[15] https://www.imetra.com/tungsten-carbide-material-properties/

[16] https://wesltd.com/capabilities/materials/tungsten-carbide/

[17] https://www.freepik.com/free-photos-vectors/tungsten

[18] https://www.istockphoto.com/photos/tungsten-carbide

[19] https://stock.adobe.com/search?k=tungsten+carbide

[20] https://www.coorstek.com/en/materials/tungsten-carbide/

[21] https://www.hyperionmt.com/en/Resources/materials/cemented-carbide/thermal-properties/