Content Menu

● What is Tungsten Carbide?

● Properties of Tungsten Carbide

>> Hardness

>> Strength

>> Density

>> Thermal Properties

● Applications of Tungsten Carbide

>> Cutting Tools

>> Mining and Drilling

>> Aerospace and Defense

>> Jewelry

● Advantages of Tungsten Carbide

>> Durability

>> Precision

>> Chemical Resistance

>> Thermal Stability

● Limitations of Tungsten Carbide

>> Brittleness

>> Cost

>> Weight

>> Limited Workability

● Environmental and Health Considerations

>> Recycling

>> Occupational Safety

● Future Prospects

>> Additive Manufacturing

>> Nanostructured Tungsten Carbide

>> Sustainable Production

● Conclusion

● Frequently Asked Questions

>> 1. How does tungsten carbide compare to other hard materials?

>> 2. Can tungsten carbide rings be resized?

>> 3. Is tungsten carbide safe to wear as jewelry?

>> 4. How long does tungsten carbide maintain its polish?

>> 5. Can tungsten carbide be recycled?

● Citations:

Tungsten carbide is a remarkable material that has gained significant popularity in various industries due to its exceptional properties. This article will explore the characteristics, applications, and benefits of tungsten carbide to determine whether it truly lives up to its reputation.

What is Tungsten Carbide?

Tungsten carbide is a chemical compound consisting of equal parts tungsten and carbon atoms. It is typically produced as a fine gray powder and can be pressed and formed into various shapes for use in tools, jewelry, and industrial machinery[1].

Properties of Tungsten Carbide

Hardness

One of the most notable characteristics of tungsten carbide is its exceptional hardness. It ranks between 8.5 and 9 on the Mohs scale of hardness, making it one of the hardest materials known to man, second only to diamond[3]. This extreme hardness contributes to its excellent wear resistance and durability.

Strength

Tungsten carbide offers impressive strength, with a compressive strength higher than virtually all melted and cast or forged metals and alloys. It is approximately twice as rigid as steel and four to six times as rigid as cast iron and brass[13].

Density

With a density nearly twice that of steel, tungsten carbide provides a substantial weight to products made from it. This high density contributes to its stability and performance in various applications[1].

Thermal Properties

Tungsten carbide exhibits excellent thermal stability and conductivity. It can withstand high temperatures without significant deformation, making it suitable for use in high-temperature environments[15].

Applications of Tungsten Carbide

The unique properties of tungsten carbide make it an ideal material for a wide range of applications across various industries.

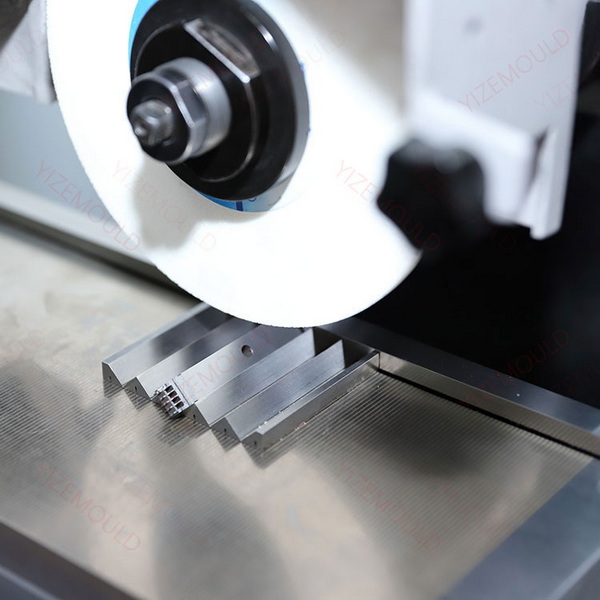

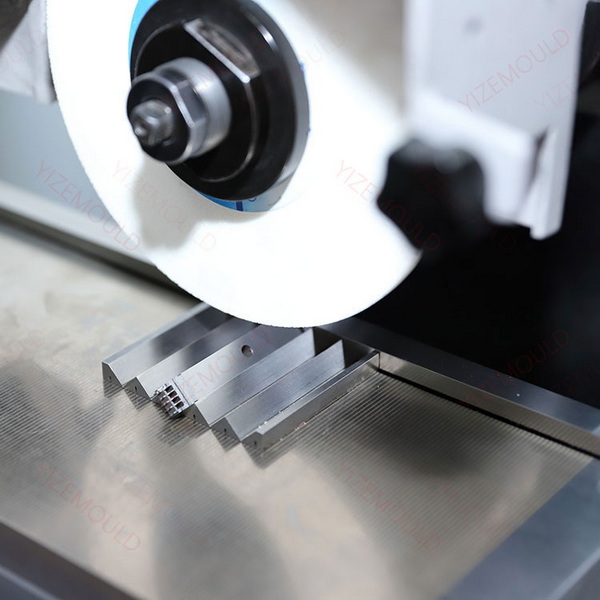

Cutting Tools

Tungsten carbide is extensively used in the manufacturing of cutting tools due to its hardness and wear resistance. These tools maintain their sharpness for extended periods, even when cutting through tough materials like steel or titanium[2].

Mining and Drilling

The durability and strength of tungsten carbide make it an excellent choice for mining and drilling equipment. It is used in drill bits, mining picks, and other tools that require high wear resistance in abrasive environments[4].

Aerospace and Defense

Tungsten carbide finds applications in the aerospace and defense industries due to its high-temperature resistance and strength. It is used in turbine components, armor-piercing ammunition, and other critical parts[1].

Jewelry

In recent years, tungsten carbide has gained popularity in the jewelry industry, particularly for wedding bands. Its scratch resistance, durability, and unique appearance make it an attractive alternative to traditional precious metals[5].

Advantages of Tungsten Carbide

Durability

The exceptional hardness and wear resistance of tungsten carbide result in products that last significantly longer than those made from conventional materials. This durability translates to reduced maintenance and replacement costs in industrial applications[3].

Precision

Tungsten carbide's ability to maintain its shape and dimensions under stress makes it ideal for precision tools and components. This characteristic is particularly valuable in manufacturing processes that require high accuracy[15].

Chemical Resistance

Tungsten carbide exhibits excellent resistance to many chemicals and corrosive environments. This property makes it suitable for use in harsh industrial settings and chemical processing equipment[38].

Thermal Stability

The material's ability to withstand high temperatures without significant deformation or loss of properties makes it valuable in applications involving extreme heat, such as cutting tools used in high-speed machining[15].

Tungsten carbide thermal stability

Limitations of Tungsten Carbide

While tungsten carbide offers numerous advantages, it's essential to consider its limitations:

Brittleness

Despite its hardness, tungsten carbide can be brittle. Under extreme stress, it may crack or shatter rather than deform like softer metals[36].

Cost

The production of tungsten carbide can be more expensive than that of conventional materials, which may impact its adoption in some applications[15].

Weight

While the high density of tungsten carbide is advantageous in many applications, it can be a drawback in situations where weight is a critical factor[1].

Limited Workability

Due to its hardness, tungsten carbide can be challenging to machine or shape after sintering. This limitation can affect its versatility in certain manufacturing processes[24].

Environmental and Health Considerations

When working with tungsten carbide, it's important to consider potential environmental and health impacts:

Recycling

Tungsten carbide is recyclable, which helps mitigate environmental concerns associated with its production and disposal. Worn-out tools and scrap material can be reclaimed and reused[7].

Occupational Safety

Proper safety measures should be taken when handling tungsten carbide powder or dust, as inhalation can pose health risks. However, finished tungsten carbide products are generally considered safe for everyday use[35].

Future Prospects

As technology advances, new applications for tungsten carbide continue to emerge:

Additive Manufacturing

Research is ongoing to develop methods for 3D printing tungsten carbide components, which could revolutionize its use in complex geometries and custom applications[39].

Nanostructured Tungsten Carbide

Scientists are exploring nanostructured forms of tungsten carbide, which could enhance its properties and expand its potential applications in fields such as catalysis and energy storage[42].

Sustainable Production

Efforts are being made to develop more environmentally friendly production methods for tungsten carbide, including the use of recycled materials and alternative binders[37].

Conclusion

Tungsten carbide has proven itself to be an exceptional material with a wide range of valuable properties. Its unparalleled hardness, impressive strength, and excellent wear resistance make it an ideal choice for numerous applications across various industries. From cutting tools and mining equipment to aerospace components and jewelry, tungsten carbide continues to demonstrate its versatility and reliability.

While it does have some limitations, such as brittleness and higher production costs, the benefits of tungsten carbide often outweigh these drawbacks in many applications. Its ability to maintain sharpness, resist wear, and withstand high temperatures makes it a superior choice in situations where performance and longevity are crucial.

As research continues and new applications emerge, tungsten carbide is likely to play an increasingly important role in advancing technology and improving industrial processes. Its unique combination of properties positions it as a material of choice for engineers and designers seeking high-performance solutions.

In conclusion, the answer to the question "Is tungsten carbide good?" is a resounding yes. Its exceptional characteristics and wide-ranging applications demonstrate that tungsten carbide is not just good – it's an outstanding material that continues to shape the future of various industries.

Frequently Asked Questions

1. How does tungsten carbide compare to other hard materials?

Tungsten carbide is one of the hardest materials available, second only to diamond. It is significantly harder than materials like steel, titanium, and even some ceramics. This exceptional hardness contributes to its superior wear resistance and durability in various applications[3].

2. Can tungsten carbide rings be resized?

No, tungsten carbide rings cannot be resized due to their extreme hardness and brittleness. Unlike softer metals like gold or silver, tungsten carbide cannot be cut or stretched to adjust the size. If a different size is needed, the ring would need to be replaced[34].

3. Is tungsten carbide safe to wear as jewelry?

Yes, tungsten carbide is generally safe to wear as jewelry. It is hypoallergenic for most people, especially when it's cobalt-free. However, some individuals may be sensitive to nickel, which is sometimes used as a binder in tungsten carbide jewelry. It's always best to check the specific composition of the jewelry if you have known metal allergies[36].

4. How long does tungsten carbide maintain its polish?

Tungsten carbide is known for its ability to maintain its polish and shine for an exceptionally long time. Due to its extreme hardness and scratch resistance, a well-made tungsten carbide item can retain its luster for many years, even with daily wear. This makes it particularly popular for wedding bands and other jewelry that is worn regularly[34].

5. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled. In fact, recycling tungsten carbide is an important practice in the industry. Worn-out tools, scrap material, and other tungsten carbide products can be reclaimed and processed to recover the tungsten for reuse. This recycling process helps conserve resources and reduce the environmental impact of tungsten carbide production[7].

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[3] https://grafhartmetall.com/en/the-advantages-of-tungsten-carbide-over-traditional-tools/

[4] https://www.itia.info/applications-markets/

[5] https://www.larsonjewelers.com/pages/tungsten-rings-pros-cons-facts-myths

[6] https://www.alamy.com/stock-photo/tungsten-carbide.html

[7] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[8] https://www.tungstenworld.com/pages/faq

[9] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[10] http://hardmetal-engineering.blogspot.com/2011/

[11] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[12] https://www.tungstenrepublic.com/Tungsten-Carbide-Rings-FAQ.html

[13] https://www.carbideprobes.com/wp-content/uploads/2019/07/TungstenCarbideDataSheet.pdf

[14] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[15] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[16] https://patrickadairdesigns.com/blogs/blog/the-pros-and-cons-of-tungsten-rings

[17] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[18] https://www.thermalspray.com/why-is-tungsten-carbide-becoming-increasingly-popular/

[19] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[20] https://www.larsonjewelers.com/pages/the-pros-cons-of-tungsten-carbide-rings

[21] https://stock.adobe.com/search?k=tungsten

[22] https://www.wedgewoodrings.com/purchase/p/tungsten-carbide-ring

[23] https://create.vista.com/photos/tungsten-carbide/

[24] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[25] https://www.shutterstock.com/search/solid-tungsten-carbide

[26] https://www.titanjewellery.co.uk/Mens/Tungsten-Carbide-Rings.html

[27] https://www.happylaulea.com/collections/tungsten-carbide

[28] https://www.reeds.com/bridal/shop-by-metal-type/mens-tungsten-carbide-wedding-bands.html?rfk=1

[29] https://www.timelesstungsten.com/tungsten-carbide-rings/

[30] https://goldrefiningforum.com/threads/tungsten-question.6239/

[31] https://www.thermalspray.com/questions-tungsten-carbide/

[32] https://web.ung.edu/media/chemistry/Chapter4/Chapter4-StoichiometryOfChemicalReactions.pdf

[33] https://www.researchgate.net/topic/Tungsten/2

[34] https://eternaltungsten.com/Frequently-Asked-Questions-FAQs

[35] https://www.reddit.com/r/metallurgy/comments/ub4dg9/question_about_tungsten_carbide_toxicity/

[36] https://tungstentitans.com/pages/faqs

[37] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[38] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[39] https://www.azom.com/article.aspx?ArticleID=1203

[40] https://www.millercarbide.com/6-facts-about-tungsten-carbide-balls-and-how-to-use-them/

[41] http://www.machinetoolrecyclers.com/rita_hayworth.html

[42] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[43] http://hardmetal-engineering.blogspot.com/2011/