Content Menu

● Introduction to Tungsten Carbide

>> Chemical Composition and Structure

● Covalent Bonds in Tungsten Carbide

>> Characteristics of Covalent Bonds

● Physical Properties of Tungsten Carbide

>> Applications of Tungsten Carbide

● Industrial Applications

● Manufacturing Process

>> Challenges in Manufacturing

● Environmental Impact

>> Recycling and Sustainability

● Conclusion

● Frequently Asked Questions

>> 1. What is the chemical formula of tungsten carbide?

>> 2. What is the hardness of tungsten carbide?

>> 3. What are the primary applications of tungsten carbide?

>> 4. How is tungsten carbide synthesized?

>> 5. What is the melting point of tungsten carbide?

● Citations:

Tungsten carbide, with the chemical formula WC, is a compound that consists of equal parts of tungsten and carbon atoms. It is renowned for its exceptional hardness, high density, and resistance to corrosion, making it a crucial material in various industrial applications, including cutting tools, abrasives, and even jewelry. The question of whether tungsten carbide is covalent involves understanding its atomic structure and the nature of the bonds between its constituent atoms.

Introduction to Tungsten Carbide

Tungsten carbide is synthesized by combining tungsten and carbon in a precise ratio. The resulting material exhibits a hexagonal crystal structure, which contributes to its hardness and stability. The compound was first synthesized by Henri Moissan in 1893, and its industrial production began around 1913-1918.

Chemical Composition and Structure

Tungsten carbide's chemical composition primarily consists of tungsten and carbon, with a typical ratio of about 94% tungsten and 6% carbon by weight. The hexagonal structure of WC is characterized by layers of tungsten atoms with carbon atoms filling half of the interstices, resulting in a trigonal prismatic coordination for both tungsten and carbon.

Illustration of the hexagonal crystal structure of tungsten carbide, showing tungsten atoms (blue) and carbon atoms (black) in a trigonal prismatic arrangement.

Covalent Bonds in Tungsten Carbide

The hardness and stability of tungsten carbide are largely due to the strong covalent bonds between tungsten and carbon atoms. These bonds have a high bond strength, which gives the material its exceptional resistance to deformation and wear. The tungsten-carbon bond length is approximately 220 pm, comparable to the single bond in W(CH3)6.

Characteristics of Covalent Bonds

Covalent bonds are formed when atoms share electrons to achieve a stable electronic configuration. In the case of tungsten carbide, the covalent bonds are particularly strong due to the difference in electronegativity between tungsten and carbon, which enhances the bond strength.

Schematic representation of covalent bonding between tungsten and carbon atoms in tungsten carbide.

Physical Properties of Tungsten Carbide

Tungsten carbide is known for its high melting point (approximately 2870°C), high density (about 15.6 g/cm³), and exceptional hardness (Mohs hardness of about 9). It also exhibits a high Young's modulus (around 550 GPa), indicating its stiffness and resistance to deformation.

Applications of Tungsten Carbide

Due to its unique combination of hardness, wear resistance, and thermal stability, tungsten carbide is widely used in cutting tools, abrasives, and wear-resistant parts. It is also used in jewelry due to its durability and aesthetic appeal.

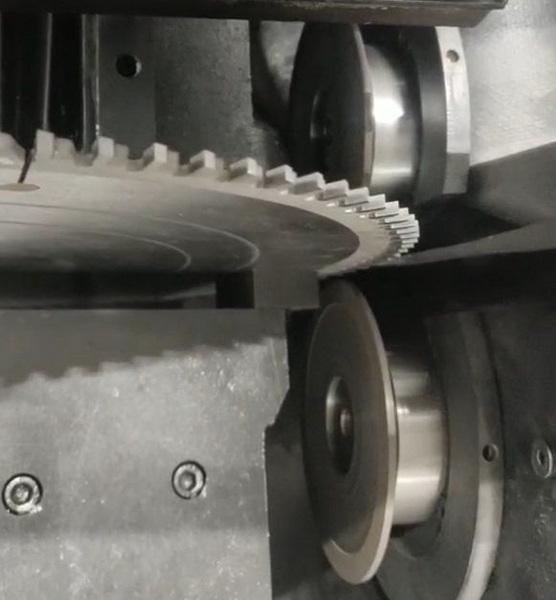

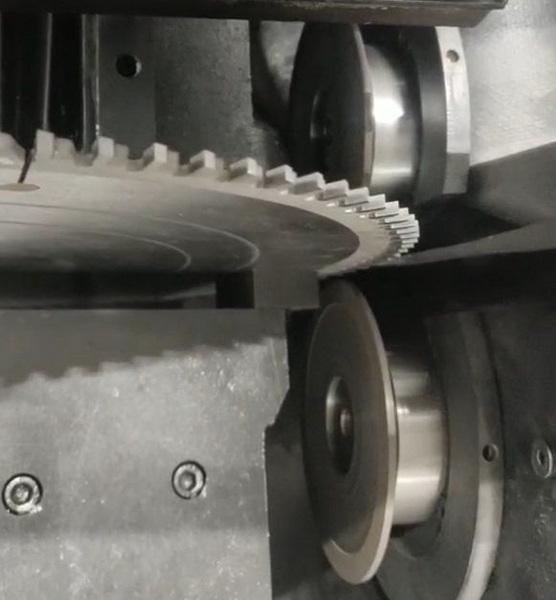

Industrial Applications

Tungsten carbide's properties make it an essential material in various industrial sectors:

- Cutting Tools: Tungsten carbide is used in cutting tools due to its ability to withstand high temperatures and maintain its hardness during machining operations.

- Aerospace: Its high strength-to-weight ratio and resistance to wear make it suitable for components in aerospace applications.

- Oil Drilling: Tungsten carbide coatings are used to protect drilling equipment from wear in harsh environments.

- Jewelry: Tungsten carbide rings and other jewelry items are popular due to their scratch resistance and durability.

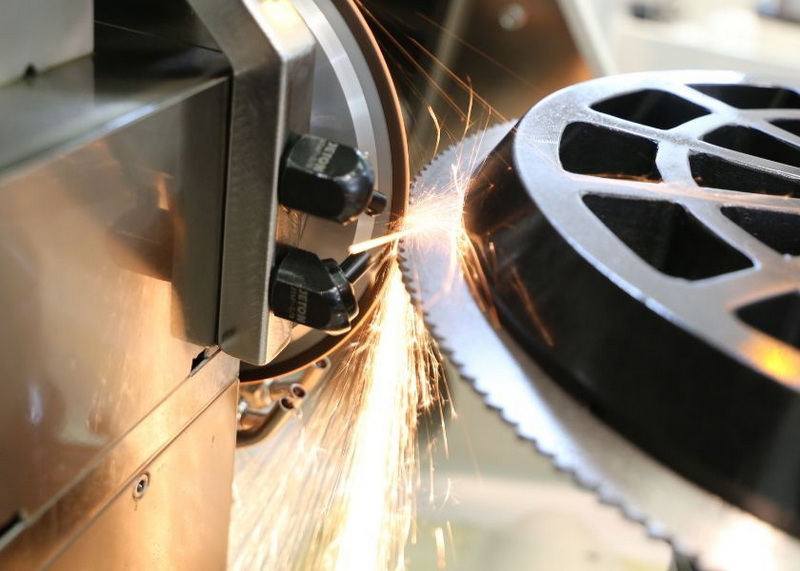

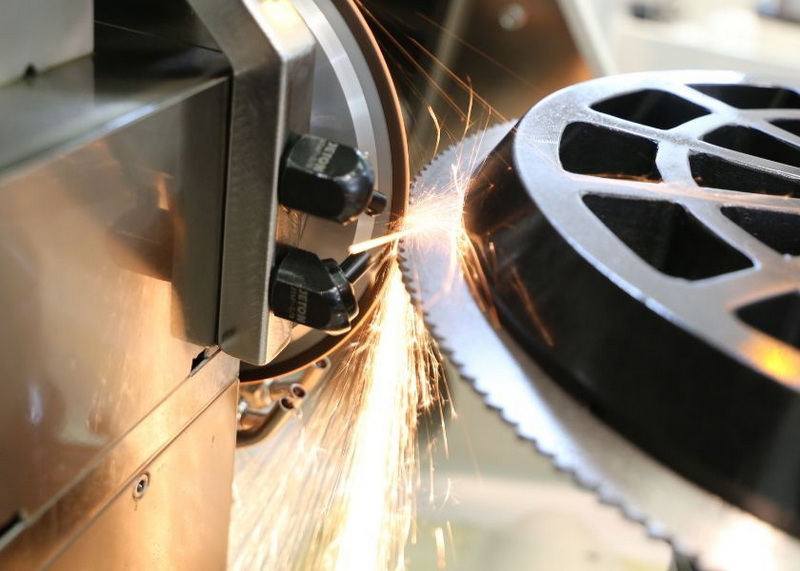

Manufacturing Process

The manufacturing process of tungsten carbide typically involves the following steps:

1. Powder Preparation: Tungsten and carbon powders are mixed in the appropriate ratio.

2. Sintering: The mixture is then sintered at high temperatures (around 1500°C) under pressure to form a solid compact.

3. Grinding and Shaping: The sintered material is ground and shaped into the desired form.

Challenges in Manufacturing

One of the challenges in manufacturing tungsten carbide is achieving uniform density and preventing defects during the sintering process. This requires precise control over temperature and pressure conditions.

Environmental Impact

The production of tungsten carbide can have environmental implications, primarily due to the mining of tungsten and the energy-intensive sintering process. Efforts are being made to improve sustainability by reducing waste and using more efficient manufacturing techniques.

Recycling and Sustainability

Recycling tungsten carbide is becoming increasingly important to reduce waste and conserve resources. This involves collecting used tungsten carbide tools and reprocessing them into new products.

Schematic of the recycling process for tungsten carbide, showing collection, sorting, and reprocessing stages.

Conclusion

Tungsten carbide is indeed a covalent compound, with its hardness and stability stemming from the strong covalent bonds between tungsten and carbon atoms. Its unique properties make it a versatile material for a wide range of industrial applications. As technology advances, efforts to improve manufacturing efficiency and sustainability will continue to enhance its role in modern industries.

Frequently Asked Questions

1. What is the chemical formula of tungsten carbide?

Tungsten carbide has the chemical formula WC, consisting of equal parts of tungsten and carbon atoms.

2. What is the hardness of tungsten carbide?

Tungsten carbide has a Mohs hardness of about 9, making it one of the hardest substances known, second only to diamond.

3. What are the primary applications of tungsten carbide?

Tungsten carbide is primarily used in cutting tools, abrasives, wear-resistant parts, and jewelry due to its hardness and durability.

4. How is tungsten carbide synthesized?

Tungsten carbide is synthesized by combining tungsten and carbon in a precise ratio, often through sintering processes.

5. What is the melting point of tungsten carbide?

The melting point of tungsten carbide is approximately 2870°C, making it suitable for high-temperature applications.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[3] https://www.istockphoto.com/photos/tungsten-carbide

[4] https://www.retopz.com/understanding-the-chemical-properties-of-tungsten-carbide-an-explanatory-overview/

[5] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[6] https://www.reekecarbide.com/blog/the-mystery-of-hardness-unlocking-the-secrets-of-tungsten-carbide.html

[7] https://www.carbideprobes.com/wp-content/uploads/2019/07/TungstenCarbideDataSheet.pdf

[8] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[9] http://www.carbidetechnologies.com/faqs/

[10] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[11] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[12] https://tuncomfg.com/about/faq/

[13] https://www.nature.com/articles/s41467-018-03429-z

[14] https://www.nature.com/articles/srep01646

[15] https://www.imetra.com/tungsten-carbide-material-properties/

[16] https://www.nature.com/articles/nature08730

[17] http://www.tungsten-carbide.com.cn/tungsten-carbide-properties.html

[18] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide

[19] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[20] https://www.vedantu.com/chemistry/carbide

[21] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[22] https://nocmetals.com/conclusion-mastery-of-tungsten-carbide-processing/

[23] https://www.linkedin.com/pulse/7-questions-tungsten-carbide-burrs-shijin-lei

[24] https://eternaltungsten.com/Frequently-Asked-Questions-FAQs

[25] https://www.tungstenworld.com/pages/tungsten-news-common-questions-about-tungsten

[26] https://www.tungstenringsco.com/faq

[27] https://www.yatechmaterials.com/en/cemented-carbide-industry/answers-to-questions-about-the-use-of-tungsten-carbide-edm-blocks/

[28] https://www.linkedin.com/pulse/3-questions-tungsten-carbide-buttons-shijin-lei

[29] https://www.carbide-part.com/blog/carbide-vs-tungsten-carbide/

[30] https://www.alamy.com/stock-photo/tungsten-carbide.html

[31] https://periodictable.com/Elements/074/pictures.html

[32] https://create.vista.com/photos/tungsten-carbide/

[33] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[34] http://picture.chinatungsten.com/list-18.html

[35] https://www.refractorymetal.org/tungsten-carbide-uses-properties.html

[36] https://cowseal.com/tungsten-vs-tungsten-carbide/

[37] https://www.mdpi.com/2079-4991/15/3/170

[38] http://machinetoolrecyclers.com/rita_hayworth.html