Content Menu

● Introduction to Tungsten Carbide and Steel

>> Tungsten Carbide

>> Steel

● Cost Comparison: Tungsten Carbide vs. Steel

>> Raw Material Costs

>> Production Processes

>> Applications and Cost-Effectiveness

● Differences in Properties and Applications

>> Hardness and Wear Resistance

>> Thermal Stability

>> Magnetism

>> Spark Test

● Applications of Tungsten Carbide and Steel

>> Tungsten Carbide Applications

>> Steel Applications

● Environmental and Health Considerations

>> Tungsten Carbide

>> Steel

● Recycling and Sustainability

>> Tungsten Carbide Recycling

>> Steel Recycling

● Conclusion

● FAQs

>> 1. What are the primary components of tungsten carbide?

>> 2. Why is tungsten carbide more expensive than steel?

>> 3. What are the advantages of using tungsten carbide over steel?

>> 4. What are common applications of steel?

>> 5. How does the scrap value of tungsten carbide compare to steel?

● Citations:

Tungsten carbide and steel are two vastly different materials used in various industrial applications due to their unique properties. Tungsten carbide is renowned for its exceptional hardness and wear resistance, making it ideal for cutting tools and wear parts. On the other hand, steel is a versatile metal widely used in construction, automotive, and consumer goods due to its strength, durability, and cost-effectiveness. This article will delve into the differences between tungsten carbide and steel, focusing on their cost, production processes, and applications.

Introduction to Tungsten Carbide and Steel

Tungsten Carbide

Tungsten carbide is a ceramic material composed primarily of tungsten and cobalt. It is known for its extreme hardness, which is approximately twice that of steel, and its ability to maintain a sharp cutting edge even at high temperatures. This makes tungsten carbide particularly useful in applications requiring high wear resistance and precision, such as cutting tools and industrial wear parts.

Tungsten carbide drill bits are designed for drilling through hard materials like concrete and metal. Their tips are typically made from tungsten carbide, which is brazed onto a steel shaft to combine the hardness of carbide with the flexibility of steel.

Steel

Steel is a metal alloy primarily composed of iron and carbon, with various other elements added to enhance its properties. It is widely used due to its balance of strength, durability, and cost-effectiveness. Steel can be further categorized into different types, such as high-speed steel (HSS), stainless steel, and structural steel, each suited for specific applications.

Steel is commonly used in construction due to its high strength-to-weight ratio and versatility. It is used in building frames, bridges, and other structural elements.

Cost Comparison: Tungsten Carbide vs. Steel

The cost of tungsten carbide is significantly higher than that of steel. This difference is primarily due to the raw materials used in their production. Tungsten carbide is made from tungsten and cobalt, both of which are expensive and rare compared to iron, the main component of steel. Additionally, the production process for tungsten carbide involves sintering, which requires sophisticated equipment and techniques, further increasing its cost.

Raw Material Costs

- Tungsten Carbide: The high cost of tungsten and cobalt contributes to the overall expense of tungsten carbide. These materials are not only expensive but also difficult to process, which adds to the final cost.

Tungsten ore is rare and requires complex extraction and refining processes, contributing to the high cost of tungsten carbide.

- Steel: Steel is made primarily from iron, which is abundant and less expensive than tungsten or cobalt. This makes steel significantly cheaper than tungsten carbide.

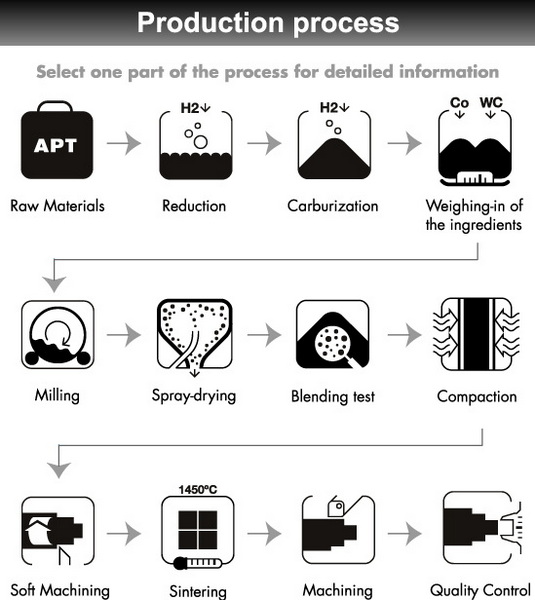

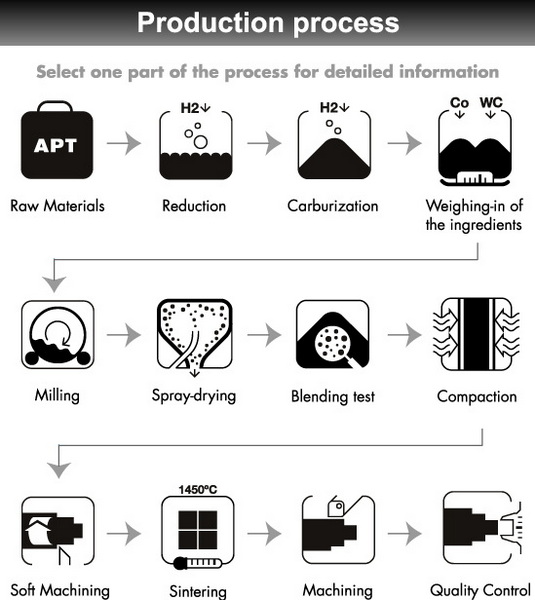

Production Processes

- Tungsten Carbide: The production of tungsten carbide involves a sintering process that requires precise control over temperature and pressure. This process is complex and labor-intensive, contributing to the higher cost of tungsten carbide.

The sintering process involves heating the tungsten carbide powder to a high temperature under pressure, causing the particles to fuse together.

- Steel: Steel production involves melting iron and other alloying elements together, a process that is more straightforward and less expensive than sintering.

Applications and Cost-Effectiveness

Despite being more expensive upfront, tungsten carbide can be more cost-effective in the long run due to its durability and ability to withstand high temperatures and wear. Steel, on the other hand, is generally less expensive and offers good performance for a wide range of applications, making it a cost-effective choice for many industries.

Tungsten carbide tools are used in high-wear applications where their durability is crucial, while steel tools are suitable for general cutting tasks.

Differences in Properties and Applications

Hardness and Wear Resistance

- Tungsten Carbide: Known for its exceptional hardness, tungsten carbide is ideal for cutting tools and wear parts that require high resistance to abrasion and impact.

These tools maintain their cutting edge longer and can handle harder materials than steel tools.

- Steel: While steel is less hard than tungsten carbide, it offers good wear resistance and is suitable for a wide range of applications where extreme hardness is not necessary.

Thermal Stability

- Tungsten Carbide: Maintains its hardness and mechanical properties at high temperatures, making it suitable for applications requiring thermal stability.

Tungsten carbide tools are used in environments where high-speed steel would lose its effectiveness.

- Steel: Loses hardness at high temperatures, limiting its use in extreme thermal conditions.

Magnetism

- Tungsten Carbide: Non-magnetic, which can be used to distinguish it from steel.

A magnet will not be attracted to tungsten carbide, unlike steel.

- Steel: Magnetic, making it easy to identify with a magnet.

Spark Test

- Tungsten Carbide: Produces orange sparks when ground, which are closer together than those from steel.

This test can help differentiate tungsten carbide from steel.

- Steel: Produces sparks that are more spread out and typically yellow or white.

Applications of Tungsten Carbide and Steel

Tungsten Carbide Applications

- Cutting Tools: Tungsten carbide is used in drill bits, saw blades, and milling tools due to its hardness and wear resistance.

These blades are designed for cutting through hard materials like wood and metal.

- Wear Parts: Used in wear-resistant components such as nozzles and liners due to its ability to withstand abrasion.

Tungsten carbide wear parts are used in environments where high wear resistance is critical.

Steel Applications

- Construction: Steel is widely used in building frames, bridges, and other structural elements due to its strength and cost-effectiveness.

Steel frames provide the structural support for many modern buildings.

- Automotive: Used in vehicle bodies and parts due to its strength-to-weight ratio and durability.

Steel is essential for the structural integrity and safety of vehicles.

Environmental and Health Considerations

Tungsten Carbide

- Environmental Impact: The extraction and processing of tungsten can have environmental impacts, such as pollution from mining activities.

Efforts are being made to reduce the environmental footprint of tungsten mining.

- Health Concerns: Exposure to tungsten dust can pose health risks, including respiratory issues.

Proper safety equipment and ventilation are crucial when handling tungsten carbide.

Steel

- Environmental Impact: Steel production is energy-intensive and contributes to greenhouse gas emissions, though recycling helps reduce this impact.

Recycling steel reduces the need for raw materials and lowers emissions.

- Health Concerns: Steel production involves handling hot metals and can pose risks if proper safety measures are not taken.

Ensuring worker safety is critical in steel manufacturing environments.

Recycling and Sustainability

Tungsten Carbide Recycling

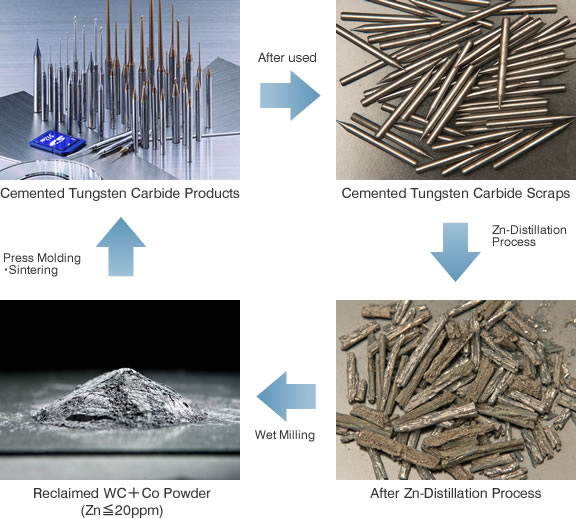

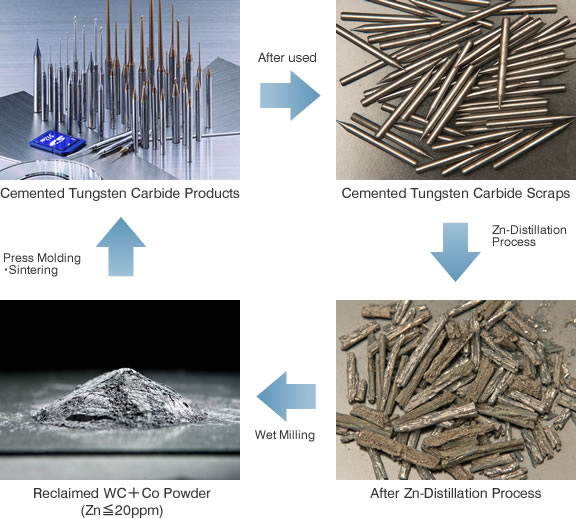

Tungsten carbide can be recycled, which helps reduce waste and conserve resources. The recycling process involves collecting used carbide parts, crushing them, and then refining the tungsten content for reuse.

Recycling tungsten carbide is economically and environmentally beneficial.

Steel Recycling

Steel is one of the most recycled materials globally. Recycling steel reduces energy consumption and greenhouse gas emissions associated with primary steel production.

Steel recycling involves collecting scrap steel, melting it, and reforming it into new products.

Conclusion

In conclusion, tungsten carbide is significantly more expensive than steel due to its raw materials and production process. However, its superior hardness and durability make it a cost-effective choice for applications requiring high wear resistance and thermal stability. Steel, on the other hand, offers versatility and cost-effectiveness for a wide range of applications where extreme hardness is not necessary. Understanding the differences between these materials is crucial for selecting the most appropriate option for specific industrial needs.

FAQs

1. What are the primary components of tungsten carbide?

Tungsten carbide is primarily composed of tungsten and cobalt, with tungsten being the main component that provides hardness and wear resistance.

2. Why is tungsten carbide more expensive than steel?

Tungsten carbide is more expensive due to the high cost of its raw materials (tungsten and cobalt), its complex production process involving sintering, and the lower volume of production compared to steel.

3. What are the advantages of using tungsten carbide over steel?

Tungsten carbide offers superior hardness, wear resistance, and thermal stability, making it ideal for high-wear applications and environments requiring precision and durability.

4. What are common applications of steel?

Steel is widely used in construction, automotive, consumer goods, and various industrial applications due to its strength, durability, and cost-effectiveness.

5. How does the scrap value of tungsten carbide compare to steel?

Tungsten carbide is worth significantly more than steel in scrap form due to its high tungsten content, which can be easily refined and reused.

Citations:

[1] https://blog.carbideprocessors.com/tungsten-carbide/price-difference-between-carbide-and-steel-wear-parts/

[2] https://iscrapapp.com/blog/difference-between-carbide-high-speed-steel/

[3] https://www.istockphoto.com/photos/tungsten-carbide

[4] https://www.freepik.com/free-photos-vectors/steel

[5] https://industrialmetalservice.com/metal-university/differentiating-tungsten-carbide-vs-steel-and-other-tooling/

[6] https://www.carbide-products.com/blog/tungsten-carbide-and-hss/

[7] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[8] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[9] https://unsplash.com/s/photos/steel

[10] https://www.reekecarbide.com/tungsten-carbide/tungsten-carbide-and-stainless-steel-a-comparison-of-strengths-and-suitability.html

[11] https://www.istockphoto.com/photos/structural-steel

[12] https://shop.machinemfg.com/high-speed-steel-vs-tungsten-steel-whats-the-difference/

[13] https://shop.machinemfg.com/tungsten-vs-steel-a-comprehensive-analysis/

[14] https://www.reddit.com/r/weddingplanning/comments/2s15h1/what_difference_does_it_make_if_i_buy_a_600/

[15] https://www.larsonjewelers.com/pages/tungsten-rings-pros-cons-facts-myths

[16] https://brite.co/blog/tungsten-vs-stainless-steel/

[17] https://rrcarbide.com/the-difference-between-tungsten-carbide-vs-high-speed-steel/

[18] https://cowseal.com/carbide-vs-steel/

[19] https://www.flickr.com/photos/phillycarbide/4505474309/

[20] http://picture.chinatungsten.com/list-18.html

[21] https://www.pexels.com/search/steel/

[22] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[23] https://periodictable.com/Elements/074/pictures.html