Content Menu

● Introduction to Tungsten Carbide

>> Chemical Composition

● Acid Resistance of Tungsten Carbide

>> Corrosion Resistance Mechanism

● Applications of Tungsten Carbide

● Manufacturing Process

>> Powder Production

>> Mixing and Pressing

>> Sintering

● Challenges and Limitations

>> Environmental Impact

>> Recycling and Sustainability

● Conclusion

● FAQs

>> 1. What is the primary factor contributing to the acid resistance of tungsten carbide?

>> 2. Is tungsten carbide resistant to all types of acids?

>> 3. What role does cobalt play in the corrosion resistance of tungsten carbide?

>> 4. What are some common applications of tungsten carbide?

>> 5. How does temperature affect the corrosion resistance of tungsten carbide?

● Citations:

Tungsten carbide is renowned for its exceptional hardness and durability, making it a crucial material in various industrial applications, including cutting tools, wear-resistant parts, and even jewelry. One of its key properties is its resistance to corrosion, which is vital for its performance in harsh environments. This article delves into the acid resistance of tungsten carbide, exploring its chemical composition, properties, and applications.

Introduction to Tungsten Carbide

Tungsten carbide (WC) is a compound of tungsten and carbon, known for its high hardness, which ranks about 9.0–9.5 on the Mohs scale, and its high melting point of approximately 2,870°C. It is often combined with cobalt to form cemented carbide, which enhances its toughness and impact resistance.

Chemical Composition

The chemical composition of tungsten carbide plays a significant role in its corrosion resistance. It is primarily composed of tungsten and carbon, with cobalt often added as a binder to improve its mechanical properties. This composition provides a natural barrier against many corrosive substances.

Acid Resistance of Tungsten Carbide

Tungsten carbide is generally resistant to acids, but it can be attacked by certain mixtures. For instance, it is insoluble in water and most acids but is readily dissolved by a mixture of hydrofluoric acid and nitric acid. This property makes it suitable for use in environments where exposure to weak acids is expected.

Corrosion Resistance Mechanism

The corrosion resistance of tungsten carbide is primarily due to its dense crystal structure and the protective oxide layer formed by the binder metal, such as cobalt, when exposed to corrosive media. However, the cobalt binder can be susceptible to leaching in strong acidic conditions, which may compromise the structural integrity of the material.

Applications of Tungsten Carbide

Tungsten carbide is used in a wide range of applications due to its hardness and corrosion resistance:

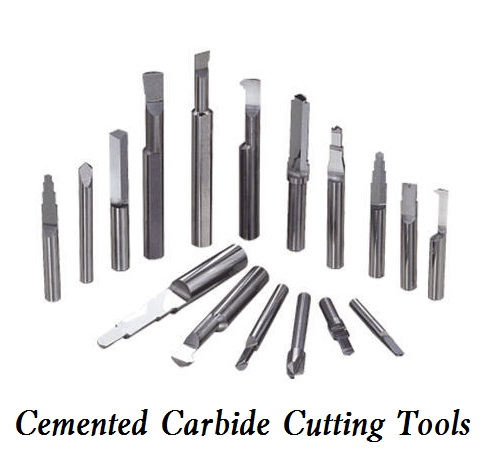

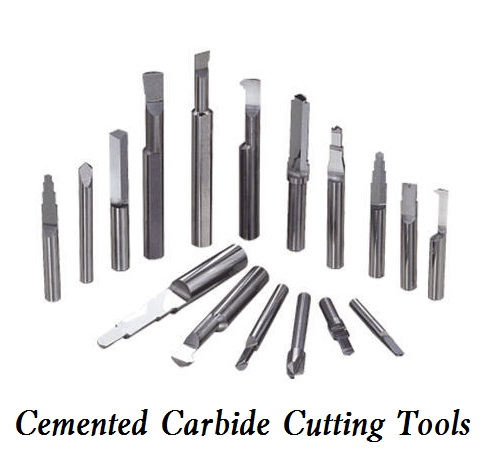

1. Cutting Tools: Tungsten carbide is used in cutting tools for its ability to withstand high temperatures and maintain sharpness over time. This is particularly beneficial in machining operations where the tool must endure high friction and heat without degrading.

2. Wear-Resistant Parts: Its high wear resistance makes it ideal for parts that are subject to abrasion and erosion, such as in mining equipment and construction machinery.

3. Jewelry: Tungsten carbide jewelry is popular due to its durability and resistance to scratches. It is often used in wedding bands and other types of jewelry that require a high level of wear resistance.

4. Aerospace Industry: Tungsten carbide is used in the aerospace industry for its high strength-to-weight ratio and resistance to extreme temperatures.

5. Medical Equipment: It is also used in medical equipment, such as surgical instruments, due to its biocompatibility and resistance to corrosion.

Manufacturing Process

The manufacturing process of tungsten carbide involves several steps, including powder production, mixing with a binder, pressing, and sintering. The quality of the final product depends on the precision of these processes, particularly the sintering temperature and time, which affect the material's density and hardness.

Powder Production

Tungsten carbide powder is produced through a carburization process where tungsten metal is heated with carbon at high temperatures. This process ensures the formation of a uniform carbide phase.

Mixing and Pressing

The powder is then mixed with a binder, typically cobalt, and pressed into the desired shape using various techniques such as cold isostatic pressing or injection molding.

Sintering

The final step involves sintering the pressed parts at high temperatures, usually above 1,400°C, in a vacuum or inert atmosphere to achieve full densification and optimal mechanical properties.

Challenges and Limitations

Despite its excellent properties, tungsten carbide faces challenges in certain applications. For example, its high hardness can make it brittle, leading to cracking under impact. Additionally, the cobalt binder can leach out in acidic environments, reducing its corrosion resistance.

Environmental Impact

The production of tungsten carbide involves the use of tungsten, which is often mined in conflict zones. This raises ethical concerns and highlights the need for sustainable sourcing practices.

Recycling and Sustainability

Efforts are being made to recycle tungsten carbide to reduce waste and conserve resources. Recycling involves collecting used parts, crushing them into powder, and reusing the material in new products.

Conclusion

Tungsten carbide exhibits strong acid resistance, making it suitable for various industrial applications. However, its performance can be compromised in strong acidic conditions, particularly when the cobalt binder is involved. Understanding its properties and limitations is crucial for optimizing its use in corrosive environments.

FAQs

1. What is the primary factor contributing to the acid resistance of tungsten carbide?

The primary factor contributing to the acid resistance of tungsten carbide is its dense crystal structure and the protective oxide layer formed by the binder metal, such as cobalt.

2. Is tungsten carbide resistant to all types of acids?

No, tungsten carbide is not resistant to all types of acids. It can be dissolved by a mixture of hydrofluoric acid and nitric acid.

3. What role does cobalt play in the corrosion resistance of tungsten carbide?

Cobalt acts as a binder that enhances the toughness and impact resistance of tungsten carbide. It also forms a protective oxide layer when exposed to corrosive media, but it can leach in strong acidic conditions.

4. What are some common applications of tungsten carbide?

Tungsten carbide is commonly used in cutting tools, wear-resistant parts, and jewelry due to its hardness and corrosion resistance.

5. How does temperature affect the corrosion resistance of tungsten carbide?

Temperature can affect the corrosion resistance of tungsten carbide by influencing the rate of chemical reactions. Higher temperatures can accelerate corrosion processes, especially in the presence of strong acids.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.carbide-part.com/pt/blog/an-in-depth-analysis-of-tungsten-carbides-corrosion-resistance/

[3] https://www.chemicalbook.com/ChemicalProductProperty_EN_CB5174366.htm

[4] https://www.istockphoto.com/photos/tungsten-carbide

[5] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[6] https://www.freepik.com/free-photos-vectors/tungsten

[7] https://dergipark.org.tr/tr/download/article-file/3225323

[8] https://www.vedantu.com/chemistry/tungsten-carbide

[9] https://www.jlsmoldparts.com/talking-corrosion-resistance-tungsten-carbide-grades/

[10] https://www.linkedin.com/pulse/corrosion-resistance-tungsten-carbide-shijin-lei

[11] https://www.reddit.com/r/explainlikeimfive/comments/161dg58/eli5_why_is_tungsten_resistant_to_acids_what/

[12] https://periodictable.com/Elements/074/pictures.html