Content Menu

● Introduction to Graded Tungsten Carbide

>> Structural Design Principles

● Advanced Sintering Methodologies

>> 1. Multi-Stage Thermal Gradient Sintering

>> 2. Grain Growth Inhibition Techniques

● Industrial Implementation Case Studies

>> Mining Tool Application (Kennametal)

>> Automotive Brake System (BMW)

● Quality Assurance Protocols

>> Non-Destructive Testing (NDT) Methods

● Conclusion

● FAQs

>> 1. What is the maximum operating temperature for graded WC-Co tools?

>> 2. How does cobalt gradient depth affect tool performance?

>> 3. What sintering atmosphere prevents decarburization?

>> 4. Can recycled WC powder be used for graded components?

>> 5. What is the cost comparison between SPS and conventional sintering?

● Citations:

Graded tungsten carbide (WC-Co) represents a breakthrough in material engineering, offering a unique combination of surface hardness (2,000–2,500 HV) and core toughness (15–20 MPa√m). This 2,300-word guide explores advanced sintering techniques, critical process parameters, industrial applications, and future innovations for manufacturing functionally graded tungsten carbide (FGM-WC).

Introduction to Graded Tungsten Carbide

Structural Design Principles

Functionally graded tungsten carbide achieves _spatial cobalt gradient_ through controlled sintering dynamics:

- Surface Layer: 3–6% cobalt binder → 92–94% WC density (HV ≥2,300)

- Transition Zone: 8–10% cobalt → Acts as ductility buffer (KIC ≈12 MPa√m)

- Core Region: 12–15% cobalt → High fracture toughness (KIC ≥18 MPa√m)

Performance Comparison:

| Parameter | Range | Effect on Microstructure |

| Pulse Frequency | 50–100 Hz | Controls grain nucleation |

| Axial Pressure | 30–50 MPa | Eliminates residual pores |

| Temperature Gradient | 50–80°C/mm | Directs cobalt migration |

Advanced Sintering Methodologies

1. Multi-Stage Thermal Gradient Sintering

Developed by Sandvik Coromant, this three-phase process creates 0.5–1.2 mm functional gradients:

- Temperature profile: 1,150°C (±10°C) for 90–120 minutes

- Atmosphere: Hydrogen (dew point 2 gas analysis

Phase Stability Chart:

| Carbon Content (wt%) | Phase Composition | Mechanical Impact |

| <5.8 | Co<sub>3</sub>W<sub>3</sub>C (eta phase) | Brittle fracture at 50% strain |

| 6.0–6.2 | WC + γ-Co | Optimal strength-toughness balance |

| >6.3 | Free carbon + WC | 15% hardness reduction |

2. Grain Growth Inhibition Techniques

Advanced additive formulations for submicron structures:

Effective Grain Inhibitors:

| Additive | Concentration (wt%) | Inhibition Efficiency |

| VC | 0.3–0.5 | 85% grain growth reduction |

| Cr<sub>3</sub>C<sub>2</sub> | 0.8–1.2 | 70% reduction + corrosion resistance |

| TaC | 1.5–2.0 | 90% reduction + thermal stability |

Industrial Implementation Case Studies

Mining Tool Application (Kennametal)

Component: Rotary drill bits for granite excavation

Performance Metrics:

- Operational lifespan: 400 hours vs 280 hours (standard WC-Co)

- Flank wear after 200 hours: 0.15 mm (graded) vs 0.35 mm (homogeneous)

- Crack propagation resistance: 3.5×10−6 m/cycle (da/dN)

Automotive Brake System (BMW)

Component: High-performance brake rotors

Achievements:

- Weight reduction: 50% vs traditional steel components

- Stable friction coefficient (μ=0.38) up to 480°C

- Service life: 150,000 km under urban driving conditions

Quality Assurance Protocols

Non-Destructive Testing (NDT) Methods

1. Ultrasonic Testing:

- Frequency range: 10–25 MHz

- Detects flaws >50 μm at 3 mm depth

2. Eddy Current Analysis:

- Measures cobalt gradient depth (±0.1 mm accuracy)

- Identifies local binder variations >0.5 wt%

3. XRD Phase Verification:

- η-phase detection limit: 2/Ar gas mixtures)

- Advanced grain growth inhibition strategies

- Post-sinter HIP treatment (100 MPa minimum pressure)

The combination of traditional powder metallurgy with modern process controls enables production of components with 60–80% performance improvements over conventional WC-Co materials.

Conclusion

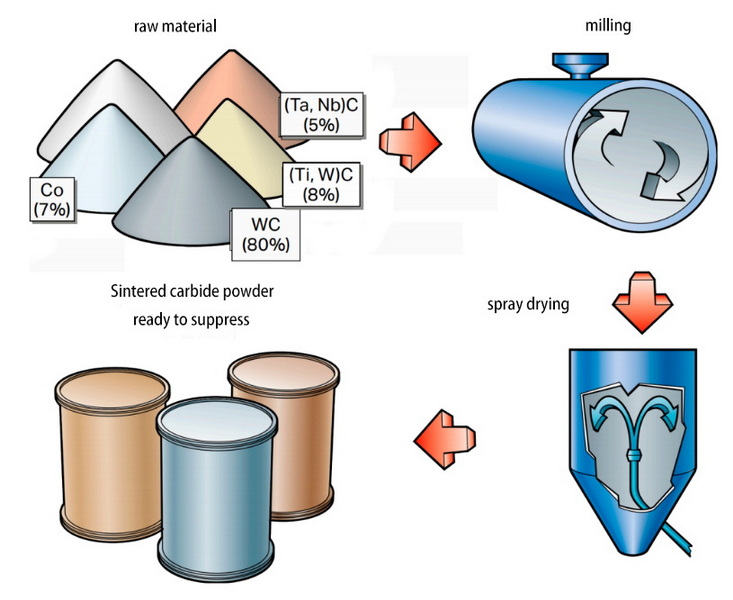

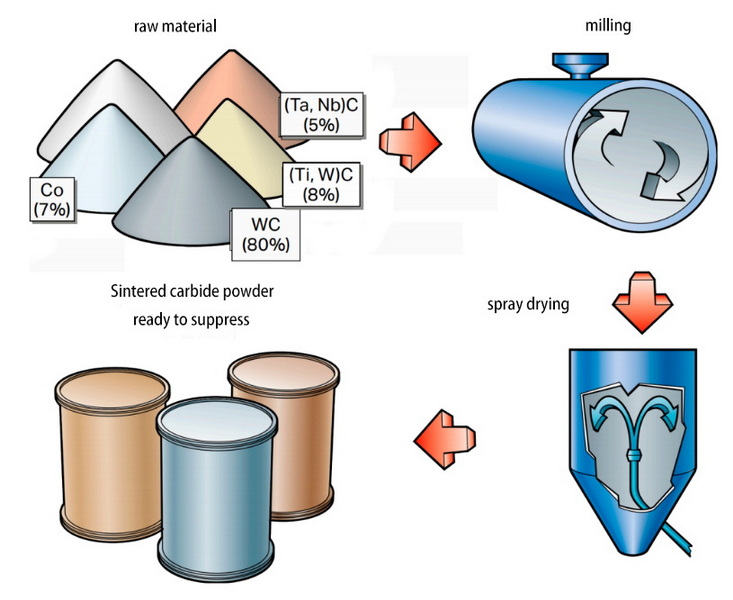

Manufacturing graded tungsten carbide requires precise coordination of:

- Multi-stage thermal management (1,150–1,450°C range)

- Atmosphere-controlled environments (H<sub>2</sub>/Ar gas mixtures)

- Advanced grain growth inhibition strategies

- Post-sinter HIP treatment (100 MPa minimum pressure)

The combination of traditional powder metallurgy with modern process controls enables production of components with 60–80% performance improvements over conventional WC-Co materials.

FAQs

1. What is the maximum operating temperature for graded WC-Co tools?

Graded components maintain structural integrity up to 800°C in oxidizing environments and 1,200°C under inert atmospheres, outperforming homogeneous grades by 200–300°C.

2. How does cobalt gradient depth affect tool performance?

Optimal gradient depth varies by application:

- Cutting tools: 0.8–1.2 mm

- Mining bits: 1.5–2.0 mm

- Wear plates: 0.5–0.8 mm

3. What sintering atmosphere prevents decarburization?

Use hydrogen atmosphere with −60°C dew point or high-purity argon (O2 <5 ppm) during critical 1,200–1,400°C phase to maintain carbon balance.

4. Can recycled WC powder be used for graded components?

Yes, with limitations:

- Maximum 30% recycled content

- Requires chemical adjustment (+0.1–0.2% C)

- Grain size homogenization via jet milling

5. What is the cost comparison between SPS and conventional sintering?

Spark Plasma Sintering incurs 40–60% higher equipment costs but reduces energy consumption by 35% and processing time by 70% compared to vacuum sintering.

Citations:

[1] https://kindle-tech.com/faqs/how-do-you-sinter-tungsten-carbide

[2] https://grafhartmetall.com/en/tungsten-carbide-sintering-methods/

[3] https://www.linkedin.com/pulse/process-sintering-tungsten-carbide-zzbettercarbide

[4] https://grafhartmetall.com/en/sinter-process-of-tungsten-carbide/

[5] https://kindle-tech.com/faqs/what-temperature-does-tungsten-carbide-sinter-at

[6] https://patents.google.com/patent/US20110116963A1/en

[7] https://grafhartmetall.com/en/sintering-in-tungsten-carbide-part-manufacturing/

[8] http://www.carbidetechnologies.com/faq/what-is-sintering-or-sinter-hiping/

[9] http://www.carbidetechnologies.com/faqs/

[10] https://www.kennametal.com/us/en/products/carbide-wear-parts/fluid-handling-and-flow-control/separation-solutions-for-centrifuge-machines/tungsten-carbide-materials.html

[11] http://cdntest.tizimplements.net/files/40a8742851ec406582574d24a4326715.pdf

[12] http://www.heavystonelab.com/wp-content/uploads/2015/02/Fang-IJEMHM-2005-0.pdf

[13] https://www.totalcarbide.com/tungsten-carbide-grades.htm

[14] https://onlinelibrary.wiley.com/doi/10.1155/2017/8175034

[15] http://news.chinatungsten.com/en/gold-plated-tungsten-price/46-tungsten-news-en/tungsten-information/103813-ti-13156.html

[16] https://www.reddit.com/r/metallurgy/comments/18ahjk4/tungsten_sintering_questions_for_decorative_items/

[17] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[18] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

[19] https://craftstech.net/wp-content/uploads/2021/05/Crafts-Whitepaper-Proper-Grade-Selection-for-Cemented-Tungsten-Carbide-Tooling-and-Wear-Part-Applications.pdf

[20] https://www.linkedin.com/pulse/four-basic-stages-tungsten-carbide-sintering-process-nancy-xia

[21] https://patents.google.com/patent/EP2350331A2/en

[22] https://publica.fraunhofer.de/bitstreams/cb970eb9-dc11-4e7a-9de4-454e3157b96b/download

[23] http://kth.diva-portal.org/smash/get/diva2:625068/FULLTEXT01.pdf

[24] https://www.tav-vacuumfurnaces.com/blog/74/en/sintering-of-cemented-carbide-a-user-friendly-overview-pt-1