Content Menu

● Understanding Tungsten Carbide Chainsaw Chains

● Identifying When to Sharpen Your Chain

● Tools and Materials Needed

● Step-by-Step Guide to Sharpening

>> 1. Preparation

>> 2. Sharpening the Teeth

>> 3. Adjusting the Depth Gauges

>> 4. Final Steps

● Tips for Maintaining Your Tungsten Carbide Chainsaw Chain

● Common Mistakes to Avoid

● Conclusion

● FAQ

>> 1. How often should I sharpen my tungsten carbide chainsaw chain?

>> 2. Can I use a regular chainsaw file to sharpen a tungsten carbide chain?

>> 3. What is the best type of chainsaw sharpener for tungsten carbide chains?

>> 4. How do I know if my depth gauges are at the correct height?

>> 5. Can I repair a broken or chipped carbide tip?

● Citations:

Maintaining a sharp chainsaw chain is crucial for efficient and safe wood cutting. Among the various types of chainsaw chains, tungsten carbide chains stand out for their durability and ability to cut through abrasive materials. However, even the toughest carbide chains require sharpening over time. This article provides a comprehensive guide on how to sharpen a tungsten carbide chainsaw chain, ensuring it remains in optimal condition for years to come.

Understanding Tungsten Carbide Chainsaw Chains

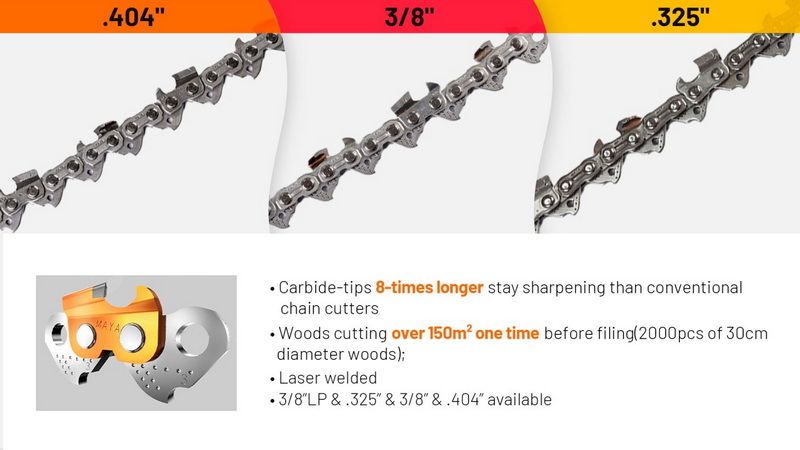

Tungsten carbide chainsaw chains are designed for demanding cutting tasks where standard steel chains would quickly dull or break. The "teeth" of these chains are tipped with tungsten carbide, an extremely hard and wear-resistant material[1]. This allows the chain to maintain its edge longer when cutting through hardwoods, dirty wood, or even materials containing small amounts of abrasive particles[5].

Advantages of Tungsten Carbide Chains:

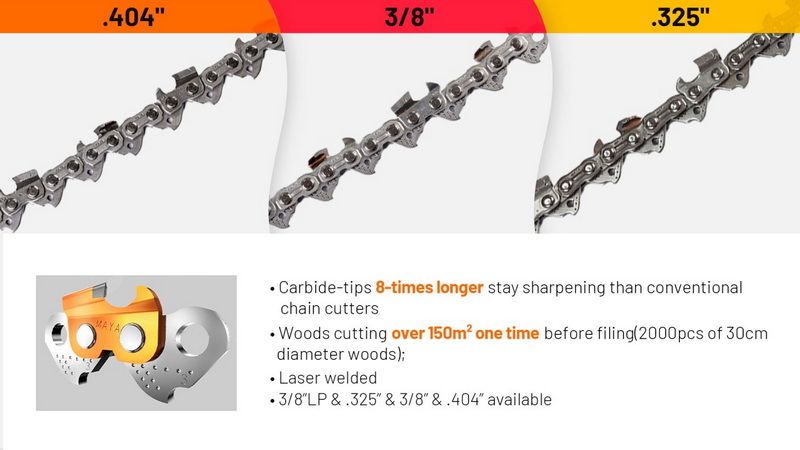

- Extended lifespan: Carbide chains stay sharp much longer than steel chains, reducing the frequency of sharpening[1].

- Durability: They are more resistant to wear and damage from abrasive materials[2].

- Versatility: Suitable for cutting a variety of materials, including hardwoods and contaminated wood[5].

Disadvantages of Tungsten Carbide Chains:

- Cost: Carbide chains are significantly more expensive than standard steel chains[1].

- Sharpening complexity: Sharpening requires specialized tools and techniques[2].

- Brittleness: Carbide is more prone to chipping or breaking upon impact with hard objects like rocks or metal[2].

Identifying When to Sharpen Your Chain

Recognizing when your tungsten carbide chainsaw chain needs sharpening is essential for maintaining cutting efficiency and preventing damage to your saw. Here are some key indicators:

1. Reduced Cutting Speed: If the saw takes longer to cut through wood, it's a sign that the chain is dulling.

2. Increased Effort: If you need to apply more pressure to the saw to maintain cutting speed, the chain likely needs sharpening.

3. Rough Cuts: A dull chain produces rough, uneven cuts instead of smooth, clean ones.

4. Excessive Vibration: A dull chain can cause the saw to vibrate more than usual, leading to operator fatigue and potential damage to the saw.

5. Production of Sawdust Instead of Woodchips: A sharp chain produces large, uniform woodchips, while a dull chain creates fine sawdust[1].

6. Chain Pulls to One Side: If the chain tends to veer to one side during cutting, it may be unevenly sharpened or damaged.

Tools and Materials Needed

Sharpening a tungsten carbide chainsaw chain requires specialized tools and materials due to the hardness of the carbide[2]. Here's a list of essential items:

1. Diamond Sharpening Wheel: A diamond-coated grinding wheel is necessary to effectively sharpen the carbide tips. The wheel should be specifically designed for chainsaw chains and compatible with your sharpening equipment.

- Grit: A medium-grit diamond wheel (e.g., 200-400 grit) is suitable for general sharpening. Finer grits (e.g., 600 grit or higher) can be used for polishing the cutting edges.

- Shape: Choose a wheel shape that matches the profile of your chain's teeth. Common shapes include flat wheels for the top plate and rounded wheels for the side plate.

2. Chainsaw Sharpener: A chainsaw sharpener provides a stable and precise platform for grinding the chain's teeth.

- Electric Chainsaw Sharpener: These sharpeners use an electric motor to rotate the grinding wheel at a consistent speed. They offer greater precision and speed compared to manual methods[1].

- Manual Chainsaw Sharpener: These sharpeners rely on hand power to move the grinding wheel. While they require more effort, they can be more portable and affordable.

3. Magnifying Glass: A magnifying glass helps you inspect the cutting edges of the teeth for sharpness and any signs of damage.

4. Depth Gauge Tool: This tool is used to adjust the depth gauges (also known as rakers) on the chain. The depth gauges control how much wood each tooth takes with each pass.

5. Flat File: A flat file is used to lower the depth gauges to the correct height after sharpening the teeth[1].

6. Vise: A vise is used to hold the chainsaw bar securely during sharpening, especially when using a manual sharpener or flat file[1].

7. Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and hearing protection when sharpening a chainsaw chain[2].

- Safety Glasses: Protect your eyes from flying debris.

- Gloves: Protect your hands from sharp edges and potential cuts.

- Hearing Protection: Reduce the risk of hearing damage from the noise of the sharpening equipment.

8. Coolant: Use a coolant, such as water or cutting oil, to keep the chain and grinding wheel cool during sharpening. This prevents overheating and potential damage to the carbide tips.

9. Marker Pen: Use a marker pen to mark the starting tooth on the chain to ensure you sharpen all teeth evenly[1].

Step-by-Step Guide to Sharpening

Follow these steps to sharpen your tungsten carbide chainsaw chain effectively:

1. Preparation

1. Clean the Chain: Before sharpening, thoroughly clean the chainsaw chain to remove any dirt, debris, or oil. Use a brush and solvent if necessary.

2. Inspect the Chain: Examine the chain for any signs of damage, such as broken or chipped teeth. Replace the chain if the damage is severe.

3. Mount the Chain: If using an electric sharpener, mount the chain on the sharpener according to the manufacturer's instructions. If using a manual sharpener, secure the chainsaw bar in a vise.

4. Mark the Starting Tooth: Use a marker pen to mark the first tooth you will sharpen. This helps you keep track of your progress and ensure that you sharpen all teeth evenly[1].

2. Sharpening the Teeth

1. Set the Grinding Angle: Adjust the angle of the grinding wheel to match the manufacturer's recommended angle for your chain. This angle is typically between 25 and 35 degrees.

2. Grind the Top Plate:

- Electric Sharpener: Gently lower the grinding wheel onto the top plate of the tooth. Use light, even pressure and avoid applying too much force, which can damage the carbide tip.

- Manual Sharpener: Hold the grinding wheel at the correct angle and carefully grind the top plate of the tooth. Use smooth, controlled movements and avoid jerking or sudden stops.

3. Grind the Side Plate:

- Electric Sharpener: Adjust the angle of the grinding wheel to match the side plate angle. Gently grind the side plate, using light, even pressure.

- Manual Sharpener: Hold the grinding wheel at the correct angle and carefully grind the side plate. Use smooth, controlled movements.

4. Cooling: Apply coolant frequently during grinding to prevent overheating. Dip the chain in water or apply cutting oil with a brush.

5. Repeat: Repeat the grinding process for each tooth on the chain, working your way around until you return to the marked starting tooth[1]. Ensure that you sharpen each tooth to the same length and angle for consistent cutting performance[7].

3. Adjusting the Depth Gauges

1. Check Depth Gauge Height: After sharpening the teeth, use a depth gauge tool to check the height of the depth gauges (rakers). The depth gauges should be slightly lower than the cutting edges of the teeth.

2. File Depth Gauges: If the depth gauges are too high, use a flat file to lower them to the correct height. File each depth gauge evenly, using smooth, controlled strokes.

3. Round the Front Edge: Use the flat file to slightly round the front edge of each depth gauge. This helps prevent the chain from grabbing or chattering during cutting[4].

4. Final Steps

1. Inspect the Chain: Carefully inspect the sharpened chain for any remaining damage or irregularities.

2. Clean the Chain: Clean the chain again to remove any grinding debris.

3. Lubricate the Chain: Apply chainsaw bar oil to the chain before reinstalling it on the saw[2].

4. Test the Chain: Reinstall the chain on the chainsaw and test it by cutting a piece of wood. The chain should cut smoothly and efficiently.

Tips for Maintaining Your Tungsten Carbide Chainsaw Chain

- Regular Cleaning: Clean your chainsaw chain after each use to remove dirt, debris, and oil. This helps prevent wear and tear and extends the life of the chain.

- Proper Lubrication: Always use a high-quality chainsaw bar oil to lubricate the chain. Proper lubrication reduces friction and heat, which can damage the chain.

- Correct Tension: Maintain the correct chain tension according to the manufacturer's recommendations[2]. A chain that is too loose can derail, while a chain that is too tight can overheat and break.

- Avoid Contact with Hard Objects: Be careful to avoid hitting rocks, metal, or other hard objects while cutting[2]. Contact with these objects can damage the carbide tips and reduce the chain's cutting performance.

- Store Properly: Store your chainsaw and chain in a dry, protected location to prevent rust and corrosion.

- Professional Sharpening: If you are not comfortable sharpening your tungsten carbide chainsaw chain yourself, consider taking it to a professional sharpening service[1]. They have the specialized tools and expertise to sharpen your chain correctly.

Common Mistakes to Avoid

- Overheating: Avoid overheating the chain during sharpening. Overheating can damage the carbide tips and reduce their hardness.

- Applying Too Much Pressure: Use light, even pressure when grinding the teeth. Applying too much pressure can cause the grinding wheel to wear out quickly or damage the chain.

- Incorrect Grinding Angle: Use the correct grinding angle for your chain. An incorrect angle can reduce the chain's cutting performance and cause it to dull quickly.

- Neglecting Depth Gauges: Always adjust the depth gauges after sharpening the teeth. Neglecting the depth gauges can cause the chain to grab or chatter during cutting.

- Using the Wrong Grinding Wheel: Use a diamond grinding wheel specifically designed for chainsaw chains. Using the wrong type of wheel can damage the carbide tips.

Conclusion

Sharpening a tungsten carbide chainsaw chain requires specialized tools and techniques, but it is a worthwhile investment for maintaining the performance and longevity of your chain. By following the steps outlined in this guide and avoiding common mistakes, you can keep your carbide chain in optimal condition for years of reliable cutting.

FAQ

1. How often should I sharpen my tungsten carbide chainsaw chain?

The frequency of sharpening depends on the type of wood you are cutting and the conditions in which you are working[1]. If you are cutting clean, soft wood, you may only need to sharpen your chain every few months. However, if you are cutting dirty, abrasive wood, you may need to sharpen it more frequently[5].

2. Can I use a regular chainsaw file to sharpen a tungsten carbide chain?

No, you cannot use a regular chainsaw file to sharpen a tungsten carbide chain[2]. Carbide is much harder than steel, so you need a diamond-coated grinding wheel to effectively sharpen the teeth.

3. What is the best type of chainsaw sharpener for tungsten carbide chains?

The best type of chainsaw sharpener for tungsten carbide chains is an electric sharpener with a diamond grinding wheel[1]. Electric sharpeners provide greater precision and speed compared to manual methods.

4. How do I know if my depth gauges are at the correct height?

The depth gauges should be slightly lower than the cutting edges of the teeth. Use a depth gauge tool to check the height and a flat file to adjust them as needed[1].

5. Can I repair a broken or chipped carbide tip?

Repairing a broken or chipped carbide tip is difficult and may not be cost-effective[2]. In most cases, it is best to replace the entire chain if the damage is severe.

Citations:

[1] https://forums.whirlpool.net.au/archive/2649892

[2] https://rapcoindustries.com/carbide-chainsaw-chain-care-maintenance/

[3] https://thetreetrove.com/how-to-sharpen-a-carbide-chainsaw-chain/

[4] https://www.youtube.com/watch?v=a1XUBdvwjnE

[5] https://www.reddit.com/r/Chainsaw/comments/pmpx7m/getting_a_tungsten_carbide_tipped_chain_for/

[6] https://chainsawnerds.com/can-carbide-chainsaw-chains-be-sharpened/

[7] https://static.stihl.com/security_data_sheet/downloads/Sharpening-STIHL-Saw-Chains.pdf

[8] https://www.youtube.com/watch?v=AirVAQS3Cy8

[9] https://arbtalk.co.uk/forums/topic/91698-sharpening-a-tungsten-carbide-chain/

[10] https://www.reddit.com/r/Chainsaw/comments/11prlys/are_carbide_chainsaw_chains_worth_the_money_whats/