Content Menu

● Introduction

● Components and Specifications

● Advanced Design Features

● Maintenance and Cleaning

● Installation and Setup

>> Video Tutorial on Die Installation

● Performance Benefits

● Compatibility and Applications

● Quality and Manufacturing

● Practical Usage Tips

● Common Applications

● Conclusion

● Frequently Asked Questions

>> Q1: Do Dillon 45 ACP Carbide Dies require case lubrication?

>> Q2: How often should the dies be cleaned?

>> Q3: Can these dies be used with other brands of reloading presses?

>> Q4: What is the expected lifespan of Dillon carbide dies?

>> Q5: How do I adjust the crimp die for optimal performance?

Introduction

Dillon 45 ACP Carbide Dies represent the pinnacle of ammunition reloading technology, offering precision, durability, and reliability for both novice and experienced reloaders. These American-made dies are crafted from premium-grade sintered carbide and undergo meticulous hand-finishing to meet exact standards.

Components and Specifications

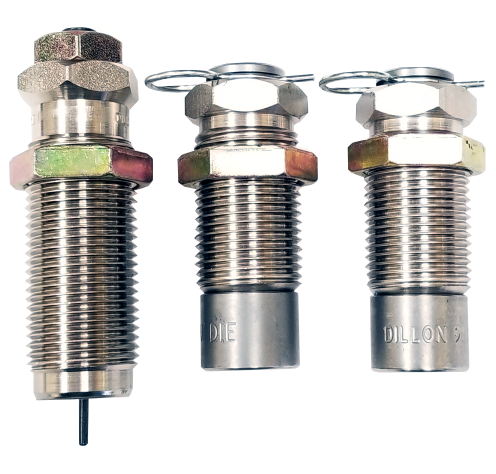

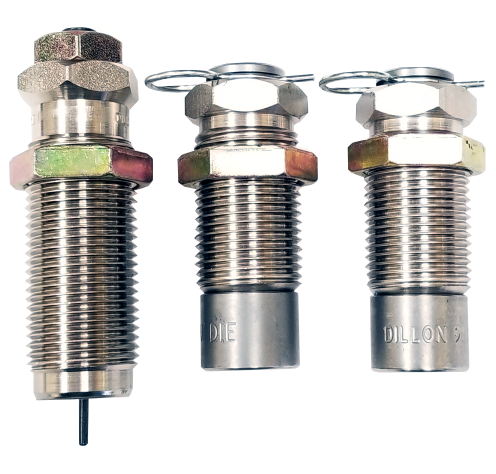

The Dillon 45 ACP Carbide Die Set includes three essential components:

- Sizer/Decapping Die

- Seating Die

- Separate Crimp Die (Taper Crimp for Auto Cartridges)

Advanced Design Features

The hallmark of Dillon's sizing die design is its long, tapered carbide ring featuring a radiused opening. This innovative design element particularly benefits progressive reloading operations. The enhanced lead-in radius represents a significant improvement over previous designs, facilitating smoother case insertion and reducing wear.

Maintenance and Cleaning

Dillon has engineered these dies with user-friendly maintenance in mind. The die insert can be removed for cleaning without disturbing the critical crimp adjustment settings. This feature eliminates the previous requirement of unscrewing the die from the toolhead and complete disassembly for routine maintenance.

Installation and Setup

Installing Dillon 45 ACP Carbide Dies requires attention to detail and proper alignment. The process involves:

1. Proper toolhead mounting

2. Die height adjustment

3. Crimp setting calibration

4. Case insertion depth setting

Video Tutorial on Die Installation

Performance Benefits

These carbide dies offer several advantages:

- Consistent sizing and crimping

- Reduced wear on cases

- Minimal maintenance requirements

- Enhanced reloading speed

- Superior precision in bullet seating

Compatibility and Applications

The Dillon 45 ACP Carbide Dies are designed for compatibility with various Dillon reloading presses, though it's important to note they are not compatible with the Square Deal B model. They excel in both single-stage and progressive reloading operations.

Quality and Manufacturing

Each die undergoes rigorous quality control measures during production. The manufacturing process involves:

- Premium grade carbide material selection

- Precision machining

- Hand-finishing for optimal performance

- Multiple quality inspection stages

Practical Usage Tips

For optimal results with Dillon 45 ACP Carbide Dies:

- Maintain proper lubrication

- Regular cleaning schedule

- Correct torque application

- Precise adjustment settings

- Proper case preparation

Common Applications

These dies are particularly well-suited for:

- High-volume reloading

- Competition ammunition preparation

- Practice ammunition loading

- Precision defensive round reloading

Conclusion

Dillon 45 ACP Carbide Dies represent a premium investment in reloading equipment, offering superior performance, longevity, and precision. Their thoughtful design features, coupled with robust construction, make them an excellent choice for both novice and experienced reloaders seeking consistent, high-quality ammunition production.

This comprehensive guide provides reloaders with the essential information needed to understand, operate, and maintain Dillon 45 ACP Carbide Dies effectively, ensuring optimal performance and longevity of their reloading equipment.

Frequently Asked Questions

Q1: Do Dillon 45 ACP Carbide Dies require case lubrication?

A: While carbide dies generally don't require case lubrication for straight-walled cases like the 45 ACP, a light application of lube can extend die life and improve operation smoothness.

Q2: How often should the dies be cleaned?

A: Regular cleaning is recommended every 1000 rounds, or sooner if you notice any resistance or inconsistency in operation. The frequency may vary based on usage patterns and environmental conditions.

Q3: Can these dies be used with other brands of reloading presses?

A: Yes, Dillon 45 ACP Carbide Dies feature standard 7/8-14 threads, making them compatible with most major brands of reloading presses.

Q4: What is the expected lifespan of Dillon carbide dies?

A: With proper maintenance and care, these dies can last for tens of thousands of rounds. Many users report successfully reloading hundreds of thousands of rounds with a single set.

Q5: How do I adjust the crimp die for optimal performance?

A: Start with minimal crimp and gradually increase while testing for proper headspacing and feeding. The ideal crimp should secure the bullet without causing case deformation.