Content Menu

● Introduction to Tungsten Carbide

>> Key Properties of Tungsten Carbide:

● Steps to Add Tungsten Carbide Tips

>> 1. Acquiring Tungsten Carbide Blanks

>> 2. Cutting and Shaping

>> 3. Sharpening

>> 4. Attaching the Handle

● Safety Precautions

● Challenges and Considerations

● Applications of Tungsten Carbide Tools

● Tips for Working with Tungsten Carbide

● Cost Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What are the benefits of using tungsten carbide over steel?

>> 2. How do I sharpen tungsten carbide tools?

>> 3. Can tungsten carbide be bent or shaped like steel?

>> 4. What safety precautions should I take when working with tungsten carbide?

>> 5. Where can I purchase tungsten carbide blanks?

● Citations:

Tungsten carbide is renowned for its exceptional hardness and durability, making it an ideal material for tool tips in various applications, including woodworking, metalworking, and pottery. Adding tungsten carbide tips to homemade tools can significantly enhance their performance and longevity. However, working with tungsten carbide requires careful consideration due to its brittleness and the need for specialized tools for shaping and sharpening. This article will guide you through the process of incorporating tungsten carbide tips into your homemade tools, highlighting the necessary steps, materials, and safety precautions.

Introduction to Tungsten Carbide

Tungsten carbide is a composite material made from tungsten carbide particles bonded together by a metal matrix, typically cobalt. This composition provides tungsten carbide with its remarkable hardness and resistance to wear, making it superior to steel in many tooling applications. However, its brittleness means it cannot be bent or shaped like steel, limiting its use to straight or simple curved forms.

Key Properties of Tungsten Carbide:

- Hardness: Tungsten carbide is significantly harder than steel, which makes it ideal for cutting and wear-resistant applications.

- Brittleness: It is very brittle and cannot be bent or pounded into shape without breaking.

- Durability: Tungsten carbide tools retain their sharpness much longer than steel tools.

Steps to Add Tungsten Carbide Tips

1. Acquiring Tungsten Carbide Blanks

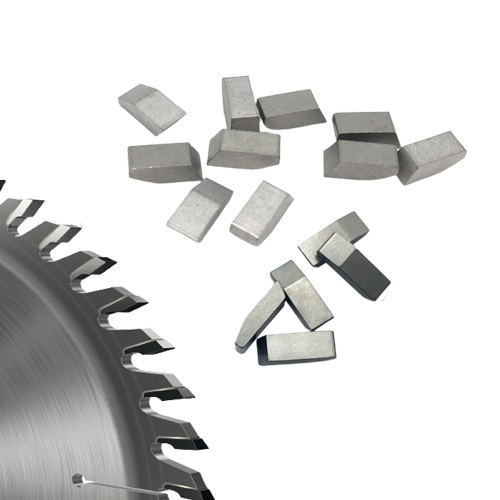

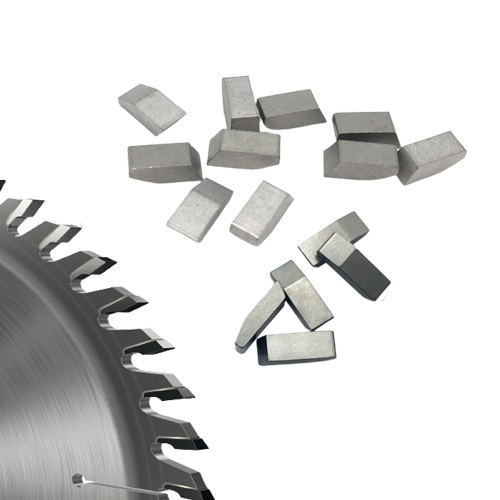

You can purchase tungsten carbide blanks in various shapes and sizes online. These blanks are often available in round or flat forms and can be pre-cut to specific lengths. For detailed work, smaller blanks are preferable.

2. Cutting and Shaping

To cut or shape tungsten carbide, you will need diamond-coated tools. Diamond blades or grinding wheels are essential for cutting and sharpening tungsten carbide due to its extreme hardness.

1. Cutting the Bevel: Use a diamond blade to cut the bevel of the chisel. A common bevel angle is 25°.

2. Flattening the Back: Use a diamond stone to flatten the back of the blade. This can be done at a slight angle or parallel to the blade's edge.

3. Sharpening

Sharpening tungsten carbide requires patience and the right tools. Silicon carbide sandpaper can be used, but it works slowly. Start with 600 grit and progress to finer grits for a sharper edge.

4. Attaching the Handle

Once the tungsten carbide tip is prepared, you can attach a handle. This can be done using epoxy or another strong adhesive. Ensure the handle is securely attached to withstand the forces applied during use.

Safety Precautions

When working with tungsten carbide and diamond tools, safety is paramount:

- Protective Gear: Wear safety glasses and a face shield to protect against flying particles.

- Ventilation: Ensure good ventilation to avoid inhaling dust particles.

Challenges and Considerations

Working with tungsten carbide presents several challenges:

- Brittleness: Tungsten carbide cannot be bent or shaped like steel, limiting its use to straight forms.

- Specialized Tools: Diamond-coated tools are necessary for cutting and sharpening, which can be expensive.

Applications of Tungsten Carbide Tools

Tungsten carbide tools are versatile and can be used in a variety of applications:

- Woodworking: Tungsten carbide tipped saw blades and chisels are excellent for cutting hardwoods and maintaining sharpness over time.

- Metalworking: Tungsten carbide tools are used in milling and drilling operations due to their ability to withstand high temperatures and wear.

- Pottery and Ceramics: Tungsten carbide tools are used for trimming and shaping ceramics due to their hardness and precision.

Tips for Working with Tungsten Carbide

- Use the Right Tools: Always use diamond-coated tools for cutting and sharpening.

- Handle with Care: Due to its brittleness, handle tungsten carbide with care to avoid breakage.

- Regular Maintenance: Regularly inspect and maintain your tools to ensure they remain effective.

Cost Considerations

While tungsten carbide tools are more expensive than steel tools upfront, their longevity often offsets the cost over time. Additionally, the cost of diamond-coated tools for shaping and sharpening should be factored into your budget.

Conclusion

Adding tungsten carbide tips to homemade tools can significantly enhance their performance and longevity. While working with tungsten carbide requires specialized tools and techniques, the benefits of increased durability and sharpness retention make it a worthwhile investment for serious craftsmen and hobbyists.

Frequently Asked Questions

1. What are the benefits of using tungsten carbide over steel?

Tungsten carbide tools stay sharp much longer than steel tools, often up to 100 times longer, making them ideal for applications where tool longevity is crucial.

2. How do I sharpen tungsten carbide tools?

Sharpening tungsten carbide requires diamond-coated tools or silicon carbide sandpaper. Start with coarse grits and progress to finer grits for a sharper edge.

3. Can tungsten carbide be bent or shaped like steel?

No, tungsten carbide is very brittle and cannot be bent or shaped like steel. It must be cut or ground into the desired shape using diamond-coated tools.

4. What safety precautions should I take when working with tungsten carbide?

Wear protective gear such as safety glasses and a face shield to protect against flying particles. Ensure good ventilation to avoid inhaling dust.

5. Where can I purchase tungsten carbide blanks?

Tungsten carbide blanks can be purchased online from various suppliers. They come in different shapes and sizes, and some suppliers sell them individually.

Citations:

[1] https://www.youtube.com/watch?v=dWUoKy8rCcQ

[2] https://www.reddit.com/r/Pottery/comments/18t3wap/tungsten_carbide_trimming_tools_anyone_know_how/

[3] https://www.ukworkshop.co.uk/threads/how-would-i-make-these-tungsten-carbide-tools.146503/

[4] https://www.model-engineer.co.uk/forums/topic/tungsten-carbide-tipped-lathe-tools/

[5] https://www.youtube.com/watch?v=cLJuiT7Mj90

[6] https://www.homemadetools.net/homemade-tungsten-carbide-tip-scriber

[7] https://turnedwoodenbowls.co.uk/2012/09/23/tungsten-carbide-woodturning-tools/

[8] https://www.facebook.com/BlackBeardProjects/videos/i-like-a-tungsten-carbide-tip-on-my-ball-peen-hammer-/1679061779654939/